Hello,

<UPDATES IN RED TEXT BELOW>

The purpose of this post is to inform the community of one of the causes of and suggestions on how to resolve the 59.F0 error issue for the CP4025, CP4525 and CM4540.

<ITB Primary Transfer Roller Alienation- Sensor Flag Sticking in Up Position>

The ITB (Intermediate Transfer Belt, aka. Transfer Kit) has a feature that removes the contact of primary transfer rollers (one for each color under the belt surface) when the printer is not running to prevent sets, etc. The printer knows the location of the transfer rollers by cycling the system and getting a response from the sensor: (K on Manual Sensor Test for 4025/4525 and SR9 on CM4540). The ITB has a white plastic pusher (in image #3 below) that moves the sensor flag lever on the printer (can be seen on left side with ITB removed hanging down from sheet metal cutout- Image #3). The flag passes through the photo interrupter of the sensor. The sensor flag/lever is returned to the home postion (down-image #2) by gravity. In some cases, the sensor flag/lever can become stuck in the up position (see image #1 and #3 below). When the flag/lever sticks or returns slowly the result can be a 59.F0 error.

Below is a recommended suggestion to resolve this problem:

- Upgrade the FW

- Remove the ITB

- Remove the fuser and on the left side (front of printer side) you can see the sensor flag holder (image #1 and #2 below)

- If the sensor flag/lever is stuck in the up position then reach in and carefully release the part with your fingers. The images below show the sensor flag/lever stuck in the up position. Actuate the flag/lever a few times to make sure it is loosened up.

- Re-install the ITB

- Re-install the fuser

- Reboot to see if the error clears

If the issue returns in a short period of time, then the flag/lever is likely dragging and returning slowly or getting stuck again. If this occurs, then it is recommended to:

- Remove the top cover

- Inspect the POSITION DETECT ASSY RM1-5604 to ensure the photo interupter is seated correctly

- Check the sensor flag for proper movement

- Replace the POSITION DETECT ASSY RM1-5604

NOTE: The ITB is typically not the cause of this issue.

I hope this helps.

Regards,

DaveK.

I work for HP

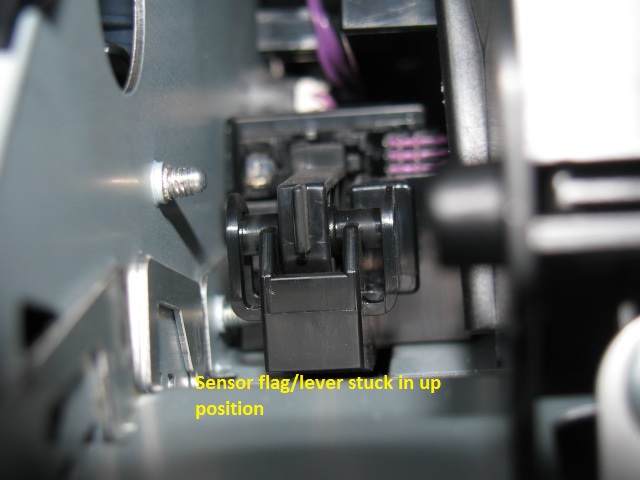

<Image #1>

Just below is an image looking in with the fuser removed at the sensor flag/lever in the holder with the photo interrupter located on the left side (front of printer). The sensor flag/lever is stuck in the up position which causes the 59.F0 error:

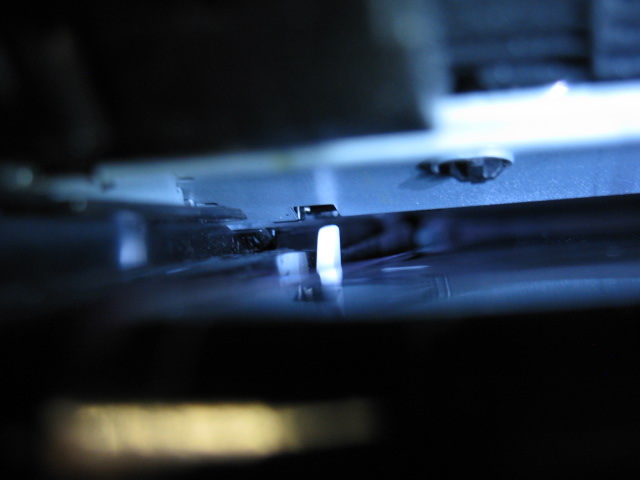

<Image #2>

Just below is an image looking in with the fuser removed at the sensor flag/lever in the holder with the photo interrupter located on the left side (front of printer). The sensor flag/lever is in the down position

<Image #3>

Just below is an image of the ITB Primary Transfer Roller Alienation Pusher (white plastic part) and Sensor Flag/Lever (black plastic part stuck in the up position in the sheet metal cutout) as seen looking at the left side (front of printer) from the right side of the printer with the right door open and ITB still installed.

Hello,

<UPDATES IN RED TEXT BELOW>

The purpose of this post is to inform the community of one of the causes of and suggestions on how to resolve the 59.F0 error issue for the CP4025, CP4525 and CM4540.

<ITB Primary Transfer Roller Alienation- Sensor Flag Sticking in Up Position>

The ITB (Intermediate Transfer Belt, aka. Transfer Kit) has a feature that removes the contact of primary transfer rollers (one for each color under the belt surface) when the printer is not running to prevent sets, etc. The printer knows the location of the transfer rollers by cycling the system and getting a response from the sensor: (K on Manual Sensor Test for 4025/4525 and SR9 on CM4540). The ITB has a white plastic pusher (in image #3 below) that moves the sensor flag lever (POSITION DETECT ASSY) on the printer (can be seen on left side with ITB removed hanging down from sheet metal cutout- Image #3). The flag passes through the photo interrupter of the sensor. The sensor flag/lever is returned to the home postion (down-image #2) by gravity. In some cases, the sensor flag/lever can become stuck in the up position (see image #1 and #3 below). When the flag/lever sticks or returns slowly the result can be a 59.F0 error.

Below is a recommended suggestion to resolve this problem:

- Upgrade the FW (http://h20564.www2.hp.com/hpsc/swd/public/readIndex?sp4ts.oid=3965807&swLangOid=8&swEnvOid=4062)

- If the error persisits, remove the ITB

- Remove the fuser and on the left side (front of printer side) you can see the sensor flag holder (image #1 and #2 below)

- If the sensor flag/lever is stuck in the up position then reach in and carefully release the part with your fingers. The images below show the sensor flag/lever stuck in the up position. Actuate the flag/lever a few times to make sure it is loosened up.

- Re-install the ITB

- Re-install the fuser

- Reboot to see if the error clears

If the issue returns in a short period of time, then the flag/lever is likely dragging and returning slowly or getting stuck again. If this occurs, then it is recommended to:

- Use the attached document «59.F0_Error_Position Detect Assy Cleaning(CP4025_CP4525) to clean the POSITION DETECT ASSY to resolve the sticking flag.

NOTE: The ITB is typically not the cause of this issue.

I hope this helps.

Regards,

DaveK.

I work for HP

<Image #1>

Just below is an image looking in with the fuser removed at the sensor flag/lever in the holder with the photo interrupter located on the left side (front of printer). The sensor flag/lever is stuck in the up position which causes the 59.F0 error:

<Image #2>

Just below is an image looking in with the fuser removed at the sensor flag/lever in the holder with the photo interrupter located on the left side (front of printer). The sensor flag/lever is in the down position

<Image #3>

Just below is an image of the ITB Primary Transfer Roller Alienation Pusher (white plastic part) and Sensor Flag/Lever (black plastic part stuck in the up position in the sheet metal cutout) as seen looking at the left side (front of printer) from the right side of the printer with the right door open and ITB still installed.

How to fix the 59.F0 Error

59.F0 Error Description:

This 59.F0 (that is F-zero, not F-oh) error is primarily caused by a transfer alienation failure in which the ITB is stuck and unable to rotate, the SR9 sensor (the primary transfer roller disengagement sensor) has gone bad or the fuser drive assembly has failed.

The 59.F0 error is a common error on the CP and CM, and M version HP Color LaserJet products. Printers such as the HP Color LaserJet CP3525, CP4025, CP4525, M651, M680 and CM4540 encounter the dreaded 59.F0 error often.

59.F0 Error Code

Even the newer LaserJets M477 and M452 encounter the 59.F0 error. However, in the case of these models, the cause is a timing issue which can be resolved by updating the DC Controller firmware (contact Metrofuser for further information regarding this fix). Either way, diagnosing the 59.F0 error issue could be time consuming and costly.

59.F0 error, the usual culprit is a failing Fuser Drive Assembly

For a 59.F0 error, the usual culprit is a failing Fuser Drive Assembly; this assembly drives the fuser and also turns a flag on your transfer belt assembly.

HP 59.F0 Error Found on The HP Color laserJet CP3525 CM3530 CP4525 & CM4540

Solution to the 59.F0 Error

When troubleshooting the 59.f0 error, we recommend starting with the transfer belt itself. Remove the belt from the printer. On the right-hand side there is a white round protrusion that engages the belt with the drive assembly. You can rotate this clockwise (2) to rotate the belt and if all goes well, unlock the sensor flag into position (1).

-

How To Replace The HP CP4025 CP4525 CM4540 CP3525 CM3530 Transfer Kit Belt

-

How to Clean and Maintain The HP Color LaserJet Transfer Belt ITB ETB Assemblies

-

CP3525 CM3530 and CP4025 Fuser Drive Duplex Simplex Conversion RM1-5001 RM1-4974 Service Note

If the flag fails to engage downwards or spin, then replace the belt. This is a common issue on the CP3525, CP4025, CP4525 and CM4540 series products.

If replacement of the transfer belt does not resolve the 59.F0 error, then it could either be the Fuser Drive Gear assembly or the solenoid located on the assembly. Gaining access to this assembly is time consuming and could take up to four hours. Due to the amount of assemblies required just to gain access to the Drive Assembly, plan on at least two hours to obtain access to the solenoid itself.

59.F0 error repair and the HP Color laserJet CP3525 CM3530 CP4525 & CM4540 motor

59.F0 error repair and the HP Color laserJet CP3525 CM3530 CP4525 & CM4540 59.F0 solenoid

Much like the solenoids that release to engage the Tray 2 pickup drive, the Fuser Drive Assembly solenoid may also be sticking due to the wear of the noise dampening sponge, which can expose the glue causing the timing of the Fuser Drive Gear to slip.

The picture above shows the Fuser Drive Assembly removed from the machine. The highlighted screws are required to be removed in order to access the solenoid.

The next picture shows the access point of the screws on the assembly still located inside the printer. These screws are accessible by removing the back cover, DC Controller, Low Voltage Power Supply and High Voltage Power Supply (both upper and lower).

The Main Drive Assembly (MDA) is not required to be removed to gain access to

the solenoid. After removal of the solenoid, denatured or 99% alcohol can be used to remove the glue from it. Remove the spring and armature from the solenoid. Thoroughly clean any residual adhesive left by the old solenoid pad. Be sure to also clean the underside of the armature before reassembling the solenoid.

Three or four layers of electrical tape can be applied in order to act as a replacement noise dampener. It is also recommended as to eliminate the magnetic charge that could build up when the solenoid arm strikes the base.

The solenoid is not always the issue. If the sponge is intact, and it does not stick, the Fuser Drive Assembly may very well be the issue. The part number for the Fuser Drive Assembly solenoid is RK2-0950.

If the transfer belt and Fuser Drive Assembly solenoid are good, the gears on Fuser Drive Assembly may be out of alignment. The three gears at the backside of the solenoid are keyed to keep them properly synchronized. Often, these gears will skip a tooth and then be out of sync, causing a 59.F0 error. Once the Fuser Drive Assembly is removed from the printer, you can easily remove two of these three gears and realign them so that the keyed gaps and teeth are in the right spots.

The Fuser Drive Assembly part numbers are as follows:

-

HP Color LaserJet CP3525 Simplex RM1-5001

-

HP Color LaserJet CM3530 CP3525 Duplex RM1-4974

-

HP Color LaserJet CM4540 Duplex RM1-5656

-

HP Color LaserJet CP4520 CP4525 Duplex RM1-5656

-

HP Color LaserJet CP4520 CP4525 Simplex RM1-6702

59.F0 Error Repair Difficulty Level

The 59.F0 level of repair is a 9 out of 10. Depending on the level of technical expertise, this procedure should take approximately four to five hours from start to finish if replacing the Fuser Drive Assembly.

For technical assistance or to schedule a training module please contact us at 908-245-2100.

Other Helpful Resources

-

Paper Jam Solutions For Laserjet Printers

-

Printer Service And Parts Glossary

-

Printer Service Error Codes

-

Developing a Critical HP Printer Parts Stocking Strategy

Metrofuser is a leading global innovator, manufacturer of printer parts, equipment, diagnostics, repair information and systems solutions for professional users performing critical tasks. Products and services include hp printer parts, printers and printer repair training. Parts include hp printer parts such as printer fusers, printer maintenance kits and other hp printer replacement parts.

The company’s, customers include office equipment dealerships, online retailers, repair centers and MPS service providers nationwide. Metrofuser has been named to Inc. Magazine’s fastest growing companies five consecutive years. Contact us at 908-245-2100, Dial 0 for sales.

Hello,

<UPDATES IN RED TEXT BELOW>

The purpose of this post is to inform the community of one of the causes of and suggestions on how to resolve the 59.F0 error issue for the CP4025, CP4525 and CM4540.

<ITB Primary Transfer Roller Alienation- Sensor Flag Sticking in Up Position>

The ITB (Intermediate Transfer Belt, aka. Transfer Kit) has a feature that removes the contact of primary transfer rollers (one for each color under the belt surface) when the printer is not running to prevent sets, etc. The printer knows the location of the transfer rollers by cycling the system and getting a response from the sensor: (K on Manual Sensor Test for 4025/4525 and SR9 on CM4540). The ITB has a white plastic pusher (in image #3 below) that moves the sensor flag lever on the printer (can be seen on left side with ITB removed hanging down from sheet metal cutout- Image #3). The flag passes through the photo interrupter of the sensor. The sensor flag/lever is returned to the home postion (down-image #2) by gravity. In some cases, the sensor flag/lever can become stuck in the up position (see image #1 and #3 below). When the flag/lever sticks or returns slowly the result can be a 59.F0 error.

Below is a recommended suggestion to resolve this problem:

- Upgrade the FW

- Remove the ITB

- Remove the fuser and on the left side (front of printer side) you can see the sensor flag holder (image #1 and #2 below)

- If the sensor flag/lever is stuck in the up position then reach in and carefully release the part with your fingers. The images below show the sensor flag/lever stuck in the up position. Actuate the flag/lever a few times to make sure it is loosened up.

- Re-install the ITB

- Re-install the fuser

- Reboot to see if the error clears

If the issue returns in a short period of time, then the flag/lever is likely dragging and returning slowly or getting stuck again. If this occurs, then it is recommended to:

- Remove the top cover

- Inspect the POSITION DETECT ASSY RM1-5604 to ensure the photo interupter is seated correctly

- Check the sensor flag for proper movement

- Replace the POSITION DETECT ASSY RM1-5604

NOTE: The ITB is typically not the cause of this issue.

I hope this helps.

Regards,

DaveK.

I work for HP

<Image #1>

Just below is an image looking in with the fuser removed at the sensor flag/lever in the holder with the photo interrupter located on the left side (front of printer). The sensor flag/lever is stuck in the up position which causes the 59.F0 error:

<Image #2>

Just below is an image looking in with the fuser removed at the sensor flag/lever in the holder with the photo interrupter located on the left side (front of printer). The sensor flag/lever is in the down position

<Image #3>

Just below is an image of the ITB Primary Transfer Roller Alienation Pusher (white plastic part) and Sensor Flag/Lever (black plastic part stuck in the up position in the sheet metal cutout) as seen looking at the left side (front of printer) from the right side of the printer with the right door open and ITB still installed.

Hello,

<UPDATES IN RED TEXT BELOW>

The purpose of this post is to inform the community of one of the causes of and suggestions on how to resolve the 59.F0 error issue for the CP4025, CP4525 and CM4540.

<ITB Primary Transfer Roller Alienation- Sensor Flag Sticking in Up Position>

The ITB (Intermediate Transfer Belt, aka. Transfer Kit) has a feature that removes the contact of primary transfer rollers (one for each color under the belt surface) when the printer is not running to prevent sets, etc. The printer knows the location of the transfer rollers by cycling the system and getting a response from the sensor: (K on Manual Sensor Test for 4025/4525 and SR9 on CM4540). The ITB has a white plastic pusher (in image #3 below) that moves the sensor flag lever on the printer (can be seen on left side with ITB removed hanging down from sheet metal cutout- Image #3). The flag passes through the photo interrupter of the sensor. The sensor flag/lever is returned to the home postion (down-image #2) by gravity. In some cases, the sensor flag/lever can become stuck in the up position (see image #1 and #3 below). When the flag/lever sticks or returns slowly the result can be a 59.F0 error.

Below is a recommended suggestion to resolve this problem:

- Upgrade the FW

- Remove the ITB

- Remove the fuser and on the left side (front of printer side) you can see the sensor flag holder (image #1 and #2 below)

- If the sensor flag/lever is stuck in the up position then reach in and carefully release the part with your fingers. The images below show the sensor flag/lever stuck in the up position. Actuate the flag/lever a few times to make sure it is loosened up.

- Re-install the ITB

- Re-install the fuser

- Reboot to see if the error clears

If the issue returns in a short period of time, then the flag/lever is likely dragging and returning slowly or getting stuck again. If this occurs, then it is recommended to:

- Remove the top cover

- Inspect the POSITION DETECT ASSY RM1-5604 to ensure the photo interupter is seated correctly

- Check the sensor flag for proper movement

- Replace the POSITION DETECT ASSY RM1-5604

NOTE: The ITB is typically not the cause of this issue.

I hope this helps.

Regards,

DaveK.

I work for HP

<Image #1>

Just below is an image looking in with the fuser removed at the sensor flag/lever in the holder with the photo interrupter located on the left side (front of printer). The sensor flag/lever is stuck in the up position which causes the 59.F0 error:

<Image #2>

Just below is an image looking in with the fuser removed at the sensor flag/lever in the holder with the photo interrupter located on the left side (front of printer). The sensor flag/lever is in the down position

<Image #3>

Just below is an image of the ITB Primary Transfer Roller Alienation Pusher (white plastic part) and Sensor Flag/Lever (black plastic part stuck in the up position in the sheet metal cutout) as seen looking at the left side (front of printer) from the right side of the printer with the right door open and ITB still installed.

How to fix the 59.F0 Error

59.F0 Error Description:

This 59.F0 (that is F-zero, not F-oh) error is primarily caused by a transfer alienation failure in which the ITB is stuck and unable to rotate, the SR9 sensor (the primary transfer roller disengagement sensor) has gone bad or the fuser drive assembly has failed.

The 59.F0 error is a common error on the CP and CM, and M version HP Color LaserJet products. Printers such as the HP Color LaserJet CP3525, CP4025, CP4525, M651, M680 and CM4540 encounter the dreaded 59.F0 error often.

59.F0 Error Code

Even the newer LaserJets M477 and M452 encounter the 59.F0 error. However, in the case of these models, the cause is a timing issue which can be resolved by updating the DC Controller firmware (contact Metrofuser for further information regarding this fix). Either way, diagnosing the 59.F0 error issue could be time consuming and costly.

59.F0 error, the usual culprit is a failing Fuser Drive Assembly

For a 59.F0 error, the usual culprit is a failing Fuser Drive Assembly; this assembly drives the fuser and also turns a flag on your transfer belt assembly.

HP 59.F0 Error Found on The HP Color laserJet CP3525 CM3530 CP4525 & CM4540

Solution to the 59.F0 Error

When troubleshooting the 59.f0 error, we recommend starting with the transfer belt itself. Remove the belt from the printer. On the right-hand side there is a white round protrusion that engages the belt with the drive assembly. You can rotate this clockwise (2) to rotate the belt and if all goes well, unlock the sensor flag into position (1).

-

How To Replace The HP CP4025 CP4525 CM4540 CP3525 CM3530 Transfer Kit Belt

-

How to Clean and Maintain The HP Color LaserJet Transfer Belt ITB ETB Assemblies

-

CP3525 CM3530 and CP4025 Fuser Drive Duplex Simplex Conversion RM1-5001 RM1-4974 Service Note

If the flag fails to engage downwards or spin, then replace the belt. This is a common issue on the CP3525, CP4025, CP4525 and CM4540 series products.

If replacement of the transfer belt does not resolve the 59.F0 error, then it could either be the Fuser Drive Gear assembly or the solenoid located on the assembly. Gaining access to this assembly is time consuming and could take up to four hours. Due to the amount of assemblies required just to gain access to the Drive Assembly, plan on at least two hours to obtain access to the solenoid itself.

59.F0 error repair and the HP Color laserJet CP3525 CM3530 CP4525 & CM4540 motor

59.F0 error repair and the HP Color laserJet CP3525 CM3530 CP4525 & CM4540 59.F0 solenoid

Much like the solenoids that release to engage the Tray 2 pickup drive, the Fuser Drive Assembly solenoid may also be sticking due to the wear of the noise dampening sponge, which can expose the glue causing the timing of the Fuser Drive Gear to slip.

The picture above shows the Fuser Drive Assembly removed from the machine. The highlighted screws are required to be removed in order to access the solenoid.

The next picture shows the access point of the screws on the assembly still located inside the printer. These screws are accessible by removing the back cover, DC Controller, Low Voltage Power Supply and High Voltage Power Supply (both upper and lower).

The Main Drive Assembly (MDA) is not required to be removed to gain access to

the solenoid. After removal of the solenoid, denatured or 99% alcohol can be used to remove the glue from it. Remove the spring and armature from the solenoid. Thoroughly clean any residual adhesive left by the old solenoid pad. Be sure to also clean the underside of the armature before reassembling the solenoid.

Three or four layers of electrical tape can be applied in order to act as a replacement noise dampener. It is also recommended as to eliminate the magnetic charge that could build up when the solenoid arm strikes the base.

The solenoid is not always the issue. If the sponge is intact, and it does not stick, the Fuser Drive Assembly may very well be the issue. The part number for the Fuser Drive Assembly solenoid is RK2-0950.

If the transfer belt and Fuser Drive Assembly solenoid are good, the gears on Fuser Drive Assembly may be out of alignment. The three gears at the backside of the solenoid are keyed to keep them properly synchronized. Often, these gears will skip a tooth and then be out of sync, causing a 59.F0 error. Once the Fuser Drive Assembly is removed from the printer, you can easily remove two of these three gears and realign them so that the keyed gaps and teeth are in the right spots.

The Fuser Drive Assembly part numbers are as follows:

-

HP Color LaserJet CP3525 Simplex RM1-5001

-

HP Color LaserJet CM3530 CP3525 Duplex RM1-4974

-

HP Color LaserJet CM4540 Duplex RM1-5656

-

HP Color LaserJet CP4520 CP4525 Duplex RM1-5656

-

HP Color LaserJet CP4520 CP4525 Simplex RM1-6702

59.F0 Error Repair Difficulty Level

The 59.F0 level of repair is a 9 out of 10. Depending on the level of technical expertise, this procedure should take approximately four to five hours from start to finish if replacing the Fuser Drive Assembly.

For technical assistance or to schedule a training module please contact us at 908-245-2100.

Other Helpful Resources

-

Paper Jam Solutions For Laserjet Printers

-

Printer Service And Parts Glossary

-

Printer Service Error Codes

-

Developing a Critical HP Printer Parts Stocking Strategy

Metrofuser is a leading global innovator, manufacturer of printer parts, equipment, diagnostics, repair information and systems solutions for professional users performing critical tasks. Products and services include hp printer parts, printers and printer repair training. Parts include hp printer parts such as printer fusers, printer maintenance kits and other hp printer replacement parts.

The company’s, customers include office equipment dealerships, online retailers, repair centers and MPS service providers nationwide. Metrofuser has been named to Inc. Magazine’s fastest growing companies five consecutive years. Contact us at 908-245-2100, Dial 0 for sales.

Принтер или МФУ HP CLJ Pro M377 / M452 / M477 и другие модели выдают ошибку 59.F0 или 59.C0 выкл. и вкл. Устройство. Давайте разберемся в проблеме. Данная ошибка возникает после определенного пробега устройства. Ошибки в датчиках или по другому в концевиках. Ошибка 59.F0 означает что неисправна лента переноса, но если лента не прошла свой ресурс заявленным производителем, то какой смысл ее менять, да и к тому же это не дешевое удовольствие.

Разберем в чем неисправность ошибки, в ленте переноса изображения есть микрик, в котором со временем окисляется контакт и мозги устройства сигнализируют ошибку, не дающую дальнейшей работы на оборудовании.

Что можно сделать в данной ситуации, самое простое заменить ленту, второе очистка микрика от окислов. Чтобы до него добраться сначала надо разобрать принтер и извлечь ленту переноса. Далее становится труднее, так как повредив перенос изображения, вы автоматически попадаете на замену ее. Сам датчик не разбирается легко, концевик можно извлечь с помощью иголок не повредив его крепление. Контакты нужно очистить и привезти в порядок. Мультиметр должен показывать сопротивление не больше одного ома. Чтоб сэкономить время и деньги вы всегда можете обратиться к нам по ремонту принтеров.

Замена ленты переноса или профилактика аппарата

При разборке узла переноса нужно быть очень внимательным, так как повредив узел уже нельзя будет добиться идеальной печати документов. По работе мастер извлекает ленту переноса, разбирает ее полностью, проводит профилактику, затем добирается до виновника ошибки. Так как к нам очень много заходит аппаратов с этими ошибками, у нас есть инструмент который легко извлекает ножку микрика из датчика.

Провести ремонт в нашем сервисе довольно просто, создав заявку или обратившись по другим контактам. Занимает по времени от одного до двух дней в зависимости от загруженности инженеров. Насколько долго это прослужит, прослужит до конца ресурса ленты переноса.

HP laser colour jet printer is showing 59 F0 Error, and not printing papers properly? Are you too facing the same issue? So the solution to this scenario is provided in a detailed manner and step to step solution to the HP 59 F0 Error.

There are many errors faced by the HP printer like 59.30- motor startup error, 59.40-motor rotation error, 59.90- ITB motor error, 59.F0, etc.

Methods to Solve Error 59.F0 on HP m452nw

The answer to this will be, it is a primarily caused by transfer alienation failure in which ITB is stuck and unable to rotate and the roller disarrangement sensor has gone bad or failed. Usually, for 59.F0, it is recommended to try resetting the toner and the fuser assembly. It is basically the solution to improve HP M452Nw 59 F0 Error:

Solution 1:

- Reset the printer using the power switch, turn off the printer for a few minutes.

- Turn on the printer and wait for the HP colour jet printer to revitalise.

- If there’s any surge protector remove it.

- If the problem continues then replaces the motor.

Solution 2:

- Verify the ITB installed adequately or not.

- Reconnect the primary transfer disengagement sensor.

- Run the sensor test in the sensor monitor mode to verify that the primary transfer disengagement is functioning correctly, if not replace it.

- Perform the alienation drive.

Examine the fuser motor, if not working properly, replace it

Solution 3:

- Reset the printer; turn off the power by using power switch and wait for some time.

- Remove the surge protector (if the user is using).

- If the problem is still there, then the PCA Assembly needs to be replaced.

- If still it’s troubling after replacing the PCA Assembly, then you might have to replace the product.

Steps To Perform ITB Alienation Test:

- Remove the transfer belt assembly.

- Open the toner access door and remove the cyan cartridge.

- Insert a flat blade screwdriver in the slot; let it stay there until the test is performed. The inserted screwdriver stimulates the toner access.

- Once done take it out, assemble it and switch it on.

- During the test, the gear needs to spin if it doesn’t spin or it tends to miss the spin then the fuser assembly is damaged. The only solution will be to repair it or replace it.

Steps to Solve 59.F0 Error on HP Printer:

- Check the ITB alienation sensor by doing manual sensor test in the troubleshooting menu.

- Reconnect the connectors of ITB.

- Perform ITB alienation test in the troubleshooting menu.

- Reconnect the connectors of primary roller disengagement motor. If it works then its recovered if not then it must be replaced.

- Hence this will hopefully solve the issue of 59.F0 Error M452Nw.

Thus, these are the few ways to check on the issues faced by the HP colour jet printer m452nw. Hopefully, these will fetch a solution to the users facing such issues.

venmartin Changed status to publish July 16, 2020

Принтер или МФУ HP CLJ Pro M377 / M452 / M477 и другие модели выдают ошибку 59.F0 или 59.C0 выкл. и вкл. Устройство. Давайте разберемся в проблеме. Данная ошибка возникает после определенного пробега устройства. Ошибки в датчиках или по другому в концевиках. Ошибка 59.F0 означает что неисправна лента переноса, но если лента не прошла свой ресурс заявленным производителем, то какой смысл ее менять, да и к тому же это не дешевое удовольствие.

Что делать с ошибкой 59.C0 и 59.F0

Разберем в чем неисправность ошибки, в ленте переноса изображения есть микрик, в котором со временем окисляется контакт и мозги устройства сигнализируют ошибку, не дающую дальнейшей работы на оборудовании.

Что можно сделать в данной ситуации, самое простое заменить ленту, второе очистка микрика от окислов. Чтобы до него добраться сначала надо разобрать принтер и извлечь ленту переноса. Далее становится труднее, так как повредив перенос изображения, вы автоматически попадаете на замену ее. Сам датчик не разбирается легко, концевик можно извлечь с помощью иголок не повредив его крепление. Контакты нужно очистить и привезти в порядок. Мультиметр должен показывать сопротивление не больше одного ома. Чтоб сэкономить время и деньги вы всегда можете обратиться к нам по ремонту принтеров.

Замена ленты переноса или профилактика аппарата

При разборке узла переноса нужно быть очень внимательным, так как повредив узел уже нельзя будет добиться идеальной печати документов. По работе мастер извлекает ленту переноса, разбирает ее полностью, проводит профилактику, затем добирается до виновника ошибки. Так как к нам очень много заходит аппаратов с этими ошибками, у нас есть инструмент который легко извлекает ножку микрика из датчика.

Провести ремонт в нашем сервисе довольно просто, создав заявку или обратившись по другим контактам. Занимает по времени от одного до двух дней в зависимости от загруженности инженеров. Насколько долго это прослужит, прослужит до конца ресурса ленты переноса.