- Печать

Страницы: 1 … 6 7 [8] Вниз

Тема: ARL-200/300/500 (Прочитано 43649 раз)

0 Пользователей и 1 Гость просматривают эту тему.

Есть специальная программка Shafferbox setup en V13

Записан

Игрушка не предназначена для детей школьного возраста. Может содержать мелкие части которые ребенок может проглотить. Перед покупкой убедитесь, что ваш ребенок уже умеет читать.

всем спасибо. В личку прислали английскую версию

Записан

Здравствуйте. Привод ADrive (станция на ARL-300) при включении выдаёт error 2 (low dc bus). Напряжения на клеммах частотника в норме, 380 и 24. Режим эвакуации не включается.

Лифт с монтажа, ездил на ревизии, после месячного простоя такая история случилась. Прошу помощи

Записан

low dc bus

— низкое напряжение на шине постоянного тока. Чаще всего это свидетельствует о большом отборе мощности с шины постоянного тока: например механически заблокирован ротор электродвигателя, либо пробой силового модуля IGBT в частотном преобразователе. Мультиметром в положении «проверка диодов» прозвонить клеммы U,V,W относительно DC+, DC- в прямой и обратной полярности. Коротких замыканий быть не должно, только значение падения напряжения диодов.

Записан

спасибо

Неисправность трёхфазного выпрямительного модуля. В А-Драйвах он выполнен отдельно, замена вполне адекватна по цене.Выходит из строя при неисправности вентиляторов охлаждения и при перекосе фаз (резкие броски по одной из фаз).На моделях В (7.5 и 11 кВт) придется менять термопасту на мосте и IGBT, на моделях С (15 и 22 кВт) мост стоит отдельно и отличается формфактором, обязательно проверяйте по посадочным местам и маркировке -были случаи несовпадения.

Записан

спасибо

Неисправность трёхфазного выпрямительного модуля.

Мост целый dc+ dc- 580v. частотник, как я понял, при первом включении в ошибку впал. Забрал в лабораторию для детального анализа.

Записан

Добрый день. Не могу подобрать PUK код для контроллера arl 300 sn 30-4426 v.3.13. не могли бы мне помочь в данной ситуации, лифт встал не могу зайти в меню, кто то заблокировал лифт до меня. Надеюсь на вашу поддержку, спасибо.

Записан

А зачем подбирать? Пишите письмо по адресу support@arkel.com.tr на английском приблизительно такого текста:

Can you please send me the PUK for Arkel 300, sn 30-4426. Thank you in advance. Regards, Имя, Фамилия

и получаете ответ в течении одного рабочего дня.

Записан

Никогда не сдавайся.

Добрый день. Не могу подобрать PUK код для контроллера arl 300 sn 30-4426 v.3.13. не могли бы мне помочь в данной ситуации, лифт встал не могу зайти в меню, кто то заблокировал лифт до меня. Надеюсь на вашу поддержку, спасибо.

Все большое спасибо за поддержку. Все получилось. Особенная благодарность Ивану vakhter.

Записан

Подскажите пожалуйста, за что отвечают провода S1A, S1B идущие с крыши кабины (плата FX-SERI V3.61) в станцию. Плата ARL-300. Не CAN шина случаем по которой приказы отправляются?

« Последнее редактирование: Август 15, 2020, 17:07:52 от Виталий. »

Записан

Добрый день, пожалуйста помогите советом. Турецкий лифт YUKSELIS ARL-300+Adrive 7,5kw (безмашинка), при торможении на вызванном этаже, например 6, за несколько секунд до открытия дверей внезапно отображает 7,8 и показание остается таким пока не вернется на первый этаж. При вызове с других этажей например с 5го, лифт открывается на 3 этаже соответственно. Замена модуля Encabit plus не помогла. ARL-300 при этом ошибок не выдает. При поездки от первого до последнего этажей все этажи читаются нормально. Проблема возникает при торможении на некоторых этажах. Буду рад если посоветуете где искать неисправность…

Записан

спасибо

Была похожая проблема именно при торможении. Решилось подключением заземления

Записан

спасибо

Спаисбо, Виталий. Сегодня буду проверять подключив заземление и отпишусь. Есть еще подозрение на тормозной резистор, до начала проблемы в резистор попал мусор из-за чего он сильно нагрелся и сработало отключение автомата электричества. Резистор почистили, контакты перепроверили, работает нормально. Может ли он создавать помехи/короткие замыкания и вызвать мою проблему?

Удалено цитирование предыдущего сообщения.

« Последнее редактирование: Ноябрь 14, 2020, 09:31:51 от Мишаня »

Записан

Была похожая проблема именно при торможении. Решилось подключением заземления

Добрый день, заземление не помогло… Где еще искать проблему?

Записан

- Печать

Страницы: 1 … 6 7 [8] Вверх

-

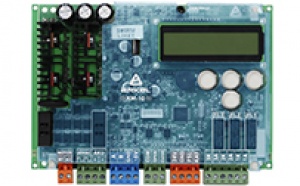

ARL-300 LIFT CONTROLLER

USER MANUAL

-

www.arkel.com.tr

ARKEL 2011 ARL-300 2

Publisher ARKEL Elektrik Elektronik Ticaret Ltd. ti.

erifali Mah. Bayraktar Bulvar Sehit Sk. No:32 Umraniye Istanbul

TURKIYETEL: (+90 216) 540 03 10 11 — 12

Fax: (+90 216) 540 03 09

E-mail : [email protected]

www.arkel.com.tr

Date of issue 2011

Document version V1.9 Hardware version V2.1 Software version

V2.14 -

www.arkel.com.tr

ARKEL 2011 ARL-300 3

CONTENTS INTRODUCTION

………………………………………………………………………………………………………………………………………..

51. LCD SCREEN AND KEYPAD USAGE

………………………………………………………………………………………………………

6STARTUP SCREEN

……………………………………………………………………………………………………………………………………

6MAIN SCREEN

………………………………………………………………………………………………………………………………………….

6ENTERING MENU

…………………………………………………………………………………………………………………………………….

6EXIT FROM MENU

……………………………………………………………………………………………………………………………………

6LCD CONTRAST SETTING SCREEN

…………………………………………………………………………………………………………

7GROUP STATUS SCREEN

…………………………………………………………………………………………………………………………

7MANUAL MOVEMENT SCREEN

………………………………………………………………………………………………………………

7CALL SETTTING SCREEN

………………………………………………………………………………………………………………………..

7RANDOM CALL SCREEN

…………………………………………………………………………………………………………………………

72. LIST OF PARAMETERS

…………………………………………………………………………………………………………………………..

8LISAN/LANGUAGE

………………………………………………………………………………………………………………………………….

9LIFT TYPE

………………………………………………………………………………………………………………………………………………..

9NUMBER OF FLOORS

………………………………………………………………………………………………………………………………

9COMMAND TYPE

…………………………………………………………………………………………………………………………………….

9CAR CALLS FROM

………………………………………………………………………………………………………………………………….

10DOOR TYPE

……………………………………………………………………………………………………………………………………………

10DOOR COMMANDS

………………………………………………………………………………………………………………………………..

10A.DOOR AT FLOOR

………………………………………………………………………………………………………………………………..

10WAITS AT FLOOR

…………………………………………………………………………………………………………………………………..

11DOOR LOCK WAIT

…………………………………………………………………………………………………………………………………

11DOOR OPEN ERROR

……………………………………………………………………………………………………………………………….

11PHOTOCELL TIME

………………………………………………………………………………………………………………………………….

11CAR LIGHT DELAY

………………………………………………………………………………………………………………………………..

11PARK FLOOR

………………………………………………………………………………………………………………………………………….

12PARKING TIME

………………………………………………………………………………………………………………………………………

12FIRE PARK FLOOR

…………………………………………………………………………………………………………………………………

12MOTOR STAR TIME

……………………………………………………………………………………………………………………………….

12STAR/DELTA DELAY

……………………………………………………………………………………………………………………………..

12MOTOR STOP DELAY

…………………………………………………………………………………………………………………………….

13VALVE DROP DELAY

…………………………………………………………………………………………………………………………….

13CONTACTOR DELAY

……………………………………………………………………………………………………………………………..

13MAX FLOOR TO FLR

………………………………………………………………………………………………………………………………

13MAX LOW SPEED T

………………………………………………………………………………………………………………………………..

13DOOR PRE OPENING

………………………………………………………………………………………………………………………………

13RELEVELING

………………………………………………………………………………………………………………………………………….

13BATTERY RESCUE

…………………………………………………………………………………………………………………………………

14DISPLAY SETUP

……………………………………………………………………………………………………………………………………..

14FX_SERI A,B,C,..

……………………………………………………………………………………………………………………………………..

15PT0-PT3 OUTPUT

……………………………………………………………………………………………………………………………………

15BINARY/GRAY CODE

…………………………………………………………………………………………………………………………….

15PR RELAY FUNC.

……………………………………………………………………………………………………………………………………

15GONG OUTPUT

………………………………………………………………………………………………………………………………………

16RST PHASE CHECK

………………………………………………………………………………………………………………………………..

16FAULT LIST

……………………………………………………………………………………………………………………………………………

16ERASE FAULT LIST

………………………………………………………………………………………………………………………………..

16LIMITS AT INSP.

……………………………………………………………………………………………………………………………………..

16FUNCTION OF 120

…………………………………………………………………………………………………………………………………..

16POSITION RESET

……………………………………………………………………………………………………………………………………

17EXT.SAFETY RELAY

………………………………………………………………………………………………………………………………

17GROUP ID

……………………………………………………………………………………………………………………………………………….

17SERVICE TIME

……………………………………………………………………………………………………………………………………….

17END OF SERV TIME

………………………………………………………………………………………………………………………………..

17FIRST STOP

…………………………………………………………………………………………………………………………………………….

17LAST STOP

……………………………………………………………………………………………………………………………………………..

18VATMAN CALLS

……………………………………………………………………………………………………………………………………

18EVACUATION FLOOR

……………………………………………………………………………………………………………………………

18DIRECTION ARROWS

…………………………………………………………………………………………………………………………….

18 -

www.arkel.com.tr

ARKEL 2011 ARL-300 4

PASSWORD

…………………………………………………………………………………………………………………………………………….

19EXIT FROM MENU

………………………………………………………………………………………………………………………………….

193. ARL-300 ERROR CODES

……………………………………………………………………………………………………………………….

204. LEDS AND JUMPERS ON ARL-300 BOARD

………………………………………………………………………………………….

215. FX_SERI SERAL CAR COMMUNCATON BOARD

……………………………………………………………………………

226. FX_SERI_32 SERAL CAR COMMUNCATON AND CALL INPUT BOARD

………………………………………. 227. ARL-SARJ CHARGE

CONTROLLER

…………………………………………………………………………………………………….

238. LEVELED INDICATOR BOARD

…………………………………………………………………………………………………………….

249. INSTALLATION OF MAGNETIC SWITCHES AND MAGNETS

……………………………………………………………

259.1 INSTALLATION AND CONNECTION FOR M1 COUNTER

………………………………………………………………….

269.2. INSTALLATION AND CONNECTION FOR ML1-ML2 COUNTER

……………………………………………………….

2610. CONNECTION OF TOP & BOTTOM LIMIT SWITCHES

…………………………………………………………………….

3010.1. USING SPOOL SWITCHES

………………………………………………………………………………………………………………

3010.2. USING BI-STABLE MAGNETIC SWITCHES

…………………………………………………………………………………….

3111. DOOR BRIDGING SAFETY CIRCUIT

………………………………………………………………………………………………….

3211.1. DOOR BRIDGING PRINCIPLE

…………………………………………………………………………………………………………

3312. GROUP OPERATION

……………………………………………………………………………………………………………………………

3413. DIMENSIONS OF ARL-300 CONTROLLER

…………………………………………………………………………………………

3514. ARL-300 TERMINALS & PLUGS

………………………………………………………………………………………………………….

3614.1. COMMON TERMINALS ON ARL-300 CONTROLLER

………………………………………………………………………………….

3614.2. RELAY OUTPUT TERMINALS ACCORDING TO DRIVE

TYPE………………………………………………………………………..

3714.3. TERMINALS & PLUGS ON KBK4 CONNECTION BOARD

……………………………………………………………………………

3814.4. TERMINALS & PLUGS ON KBK2 CONNECTION BOARD

……………………………………………………………………………

3915. GENERAL SAFETY REGULATIONS

…………………………………………………………………………………………………..

39 -

www.arkel.com.tr

ARKEL 2011 ARL-300 5

INTRODUCTION ARL-300 fulfills the requirements of Europian

electric and hydraulic lifts directive EN81-1/2. ARL-300 is

universal. With just a few parameter changes; it can be used for

hydraulic elevators or rope traction with two-speed or VVVF (geared

and gearless drive), up to 24 stops, and for groups of up to 4

elevators up to 2m/s speed. Most of the functions needed for any

elevator system are integrated into the ARL-300 lift

controller:— Door-bridging safety relays in case of door pre-opening and

re-leveling, — Single automatic door support, — Mains phase

protection, — Motor temperature monitoring, — Binary, inverted

Binary, Gray and inverted Gray code outputs for LCD and Dot-matrix

indicatorsARL-300 is compitable with the serial car communication board

FX-SERI (up to 16 stops) and FX-SERI-32 (up to 24 stops) which

reduces labour and cable costs. KBK connection boards are used with

ARL-300 which are used instead of panel rail terminals and supplied

with ribbon cables. ARL-300 provides emergency rescue operations

for electric (geared and gearless drive) and hydraulic elevators.

Technical Data Description ValueDimensions Length width height

260 200 35

Working temperature 0 — +60 C Degree of protection IP20 Supply

voltage 24 VDC 5 Vdc Control inputs 24 VDC(High active) Control outputs 24 VDC

Short-circuit protected Safety circuit voltage Maksimum voltage

230VAC(24VDC for emergency lowering with Hydraulic systems !!!)

-

www.arkel.com.tr

ARKEL 2011 ARL-300 6

1. LCD SCREEN AND KEYPAD USAGE ARL-300 has an LCD screen with

2-row and 16-character and 4-key keypad.STARTUP SCREEN

When system is energized for the first time or restarted the

SPLASH SCREEN appears. After being displayed this screen for about

3 seconds, MAIN SCREEN is displayed.MAIN SCREEN

The main screen shows the important lift parameters, 100 (Supply

Voltage) and FLOOR (floor number).ENTERING MENU

In order to enter MENU SCREEN, push and hold the LEFT button for

3 seconds. If there is no password has been entered before (0000:

factory default) the first parameter LISAN/LANGUAGE is displayed on

LCD.If a password has been assigned before, you must enter the four

digit password by pressing the UP and DOWN buttons. Then press the

RIGHT button. The first parameter is displayed. If the password is

enteredincorrectly an error massage INVALID PASSWORD will appear on the

LCD. If the password is entered incorrectly for three times, the

system gets blocked and it is required to enter the PUK CODE. You

can pass through the parameters by pressing LEFT and RIGHT buttons

and change the parameters by pressing UP and DOWN buttons. When you

change a parameter by pressing UP and DOWN buttons, the new value

for that parameter is recorded in the temporary memory. It is not

necessary to press any key to record any changed parameter. All

parameters are recorded to the memory after leaving the program

menu. If the power off the controller is turned off and on again

before leaving the program menu, the parameters keep the older

values.EXIT FROM MENU

In order to exit from the MENU SCREEN, first push the RIGHT

button until the EXIT SCREEN is displayed. When this screen is

displayed push UP button to exit from the menu.2-row 16-character LCD screen

ARL-300 V1.4x SERI NO : 36-0298

WAITS FOR CALL 100: 24V FLOOR: 1

LISAN/LANGUAGE ENGLISH

ENTER PASSWORD 0000

EXIT FROM MENU

-

www.arkel.com.tr

ARKEL 2011 ARL-300 7

LCD CONTRAST SETTING SCREEN

LCD display contrast can be adjusted by this screen. In order to

enter this screen, press UP or DOWN keys while on main screen. UP

key is used to increase and DOWN key is used to decrease the LCD

contrastvalue. x signs are used to show the contrast value. After

adjusting contrast value, entering menu is required for once in

order to save this setting. Otherwise when the power turns off,

controller will lose the changes.GROUP STATUS SCREEN

In order to enter this screen press LEFT button while on main

screen. The working status of 4 lifts in a group operation are

displayed on in this screenA, B, C, D : The GROUP ID is defined for controllers in a group

operation +, — : Indicates the controllers status in a group

operation while controller is in group communication [ ] : The own

GROUP ID of the controller — : Indicates the controllers which are

not in a group operation or not definedMANUAL MOVEMENT SCREEN

In order to enter this screen, push and hold the RIGHT button

for 3 seconds. UP and DOWN buttons are used for running UP and DOWN

while in this screen. Press also the RIGHT button together for

runningwith fast speed. Press LEFT button to exit this screen. CALL

SETTTING SCREENIn order to enter this screen, move with LEFT button while on

main screen. Press UP and DOWN buttons to designate the call and

press RIGHT button to activate the call.RANDOM CALL SCREEN

It is possible to give random calls by using this screen. In

order to enter this screen, move with LEFT button while on main

screen. Controller generates a random call by pressing the UP

button while on this screen.This call is displayed in the first line. After giving the first

random call, press UP / DOWN buttons to designate the number of

random calls. The number of random calls is displayed in the second

line. The number of random calls is automatically decreased as the

calls are acknowledged. Press LEFT button to exit this screen.KONTRAST xxxxxxx

GROUP STATUS [A+] B- — —

MANUAL MOVMENT 100:24V FLOOR: 1

CALL SET : 1 ACTIVE CALL : —

RANDOM CALL : — REMAINING :

-

www.arkel.com.tr

ARKEL 2011 ARL-300 8

2. LIST OF PARAMETERS The list of parameters in ARL-300 menu are

listed below: LISAN/LANGUAGE LIFT TYPE NUMBER OF FLOORS COMMAND

TYPE CAR CALLS FROM DOOR TYPE DOOR COMMANDS A.DOOR AT FLOOR WAITS

AT FLOOR DOOR LOCK WAIT DOOR OPEN ERROR PHOTOCELL TIME CAR LIGHT

DELAY PARK FLOOR PARKING TIME FIRE PARK FLOOR FIREMAN MODE MOTOR

STAR TIME (for Hydraulic lifts) STAR/DELTA DELAY (for Hydraulic

lifts) MOTOR STOP DELAY (for Hydraulic lifts) VALVE DROP DELAY (for

Hydraulic lifts) CONTACTOR DELAY (for VVVF rope lifts) MAX FLOOR TO

FLR MAX LOW SPEED T. DOOR PRE OPENING (for Hydraulic and VVVF rope

lifts) RELEVELING (for Hydraulic lifts) BATTERY RESCUE (for

Hydraulic lifts) RESCUE TYPE (for VVVF rope lifts) DISPLAY SETUP

FX_SERI A,B,C,.. PT0-PT3 OUTPUT BINARY/GRAY CODE PR RELAY FUNC.

GONG OUTPUT RST PHASE CHECK FAULT LIST ERASE FAULT LIST LIMITS AT

INSP. FUNCTION OF 120 POSITION RESET EXT.SAFETY RELAY (for

Hydraulic lifts) GROUP ID SERVICE TIME END OF SERV. TIME FIRST STOP

LAST STOP VATMAN CALLS EVACUATION FLOOR MAX.CAR CALLS DIRECTION

ARROWS PASSWORD EXIT FROM MENU -

www.arkel.com.tr

ARKEL 2011 ARL-300 9

This parameter stores the language of the menu.

TRKE: Turkish ENGLISH: English NEDERLANDS: Dutch ROMANA: Romany

P: Russian DUITS: Germany ITALIANO: Italian5 language options can be selected in the menu at the same time.

ARL-300 menu languages are divided into 2 language groups. These

language options are:1st group: Turkish, English, Duits, Dutch and Russian 2nd group:

Turkish, English, Duits, Romany and ItalianThis parameter stores the drive type of lift.

HYDRAULIC 2 SPEED ROPED L. VVVF ROPED LIFT

For VVVF roped lifts (geared and gearless drive) also the

parameter RESCUE TYPE must be set according to the system.This parameter stores the number of stops in lift system from 2

to 24.2-24 stops

This parameter stores the lift command type.

SIMPLE COLLECTVE : Car and landing call buttons are tied

together. There is no difference between car and landing calls. 1

BUTTON UP&DOWN : Car and landing call buttons are connected

separately. Car calls and landing calls are collective in both

directions. 1 BUTTON DOWN : Car and landing call buttons are

connected separately. Car calls are collective in both directions

where landing calls are collective when the lift moves downwards. 1

BUTTON UP : Car and landing call buttons are connected separately.

Car calls are collective in both directions where landing calls are

collective when the lift moves upwards. 2 BUTTON SEL.COL : Car,

landing up and landing down buttons all are connected separately.

Car and landing call are all serviced in full collective manner.

UNIVERSAL : Non-collective system. Car and landing call buttons are

tied together.LISAN/LANGUAGE

LIFT TYPE

NUMBER OF FLOORS

COMMAND TYPE

-

www.arkel.com.tr

ARKEL 2011 ARL-300 10

This parameter determines the communication between controller

and car.MAINBOARD : Parallel connection is used between controller and

car. There is no serial communication board (FX_SERI) used in

inspection box.SERIAL E.CARD 16 : The serial communication board FX-SERI-16 is

used in inspection box for connection between lift controller and

car for up to 16 stops. Landing panels are connected as in parallel

mode.SERIAL E.CARD 32 : The serial communication board FX-SERI-32 is

used in inspection box for connection between lift controller and

car for more than 16 stops. Landing panels are connected as in

parallel mode.For systems with more than 16 stops, it is required to use

serial car installation in ARL-300 control system. FX_SERI_32 board

must be used both in inspection box and in control panel.This parameter stores the type of automatic door.

ONLY CAR DOOR : Semi-automatic landing door and automatic car

door FULL AUTOMATIC : Full-automatic car and landing door.Automatic door open-close signal type.

CLOSE SIGNAL: When only a door close signal is used. Door is

closed when the door close signal is ON and door is open when the

door close signal is removed. When 120 signal (stop circuit) is

OFF, door remains close. OPEN/CLOSE SGNL: Door open signal and door

close signals are used. Door is closed when the door close signal

is ON. Door is open when the door open signal is ON. Door remains

its position when there is no door signal ON. When 120 signal (stop

circuit) is OFF, none of the door signals are activated.According to the EN81-1/2, door movement must be prevented when

emergency stop, inspection or recall modes engaged.Automatic door position when lift waits at floor level.

WAITS CLOSED : Waits with closed door. WAITS OPEN : Waits with

open door. (Not in conformity with EN81-1/2)Waits open is not allowed according to the standard EN 81-1/2.

So this parameter must be set to Waits closed to fully fit

EN81-1/2. The lifts at the countries which has own standard other

then EN81-2/2 or at the lifts that modernized and taken measures

against risk of doors waiting open can be set as Waits open.CAR CALLS FROM

DOOR TYPE

DOOR COMMANDS

A.DOOR AT FLOOR

-

www.arkel.com.tr

ARKEL 2011 ARL-300 11

This parameter stores the time period for car to wait at floor

before moving for the next call in collective systems.0 to 60 seconds

If a serial communication board (FX-SERI) is used in inspection

box and the OPEN/CLOSE button signals are connected to serial

communication board, this parameter should be increased.According to the EN81-1/2for semi-automatic doors, car must wait

at least 2 seconds at floor before moving again.For non-collective systems, the parameters WAITS AT FLOOR and

CAR LIGHT DELAY should be set to same value and must be set to at

least 2 seconds.This parameter stores the maximum time period to wait for door

lock signal (140) after door close signal comes to controller.10 to 99 seconds Set this parameter to 35 s for semi-automatic

doors and 95 s for full automatic doors.At the end of this time period if doors still cannot be closed,

controller gives an error and goes out of service.10 to 240 seconds DISABLED: Door open error function is

disabled.Set this parameter to 240 s for full automatic doors.

This parameter stores the photocell time.

0 to 60 seconds

This parameter determines the car light delay time.

DISABLED : Car light delay is disabled (Not in conformity with

EN 81-1/2 for semi-automatic doors) 1 to 240 secondsAccording to the EN 81-1/2 turning off car light delay is not

allowed for semi-automatic doors.For non-collective systems, the parameters WAITS AT FLOOR and

CAR LIGHT DELAY should be set to same value and must be set to at

least 2 seconds.WAITS AT FLOOR

DOOR LOCK WAIT

DOOR OPEN ERROR

PHOTOCELL TIME

CAR LIGHT DELAY

-

www.arkel.com.tr

ARKEL 2011 ARL-300 12

This parameter defines the parking floor.

DISABLED : Parking floor is disabled. 1 to 24 : The parking

floor of the elevator.When parking floor is not disabled and lift has no calls within

this time, it moves to parking floor and stays there until a call

comes.0 to 250 seconds

Fire parking floor number. When the fire input of the lift

(terminal YAN) is activated then the car immediately moves to this

floor and waits there with open doors. The elevator returns to

normal operationafter the fire signal is deactivated. DISABLED : Fire parking

floor is disabled. 1 to 24: The fire parking floor of the

elevator.If the elevator serves as a fire-fighters lift then this

parameter should be enabled.DISABLED : Fire-fighters mode is disabled. ENABLED :

Fire-fighters mode is enabled.In ARL-300 system, the fire-fighters mode is only available with

serial car installation. Theinput terminals 804, K20 ve DTS are used for connection of the

signals required in fire-fighters mode. 804: Fire-fighters key

switch input K20: Door is fully open contact input DTS: Door is

fully closed contact input The contacts used for door open and

closed limits must be normally closed contacts. When door is fully

open/closed these signals must be turned off.This parameter determines the switching time of the motor from

star connection to delta connection in startup. (For hydraulic

systems)0.0 to 9.9 seconds

This parameter determines the time to wait after finished the

star connection and will start the delta connection. (For hydraulic

systems)0.0 to 9.9 seconds

PARK FLOOR

PARKING TIME

FIRE PARK FLOOR

FIREMAN MODE

MOTOR STAR TIME

STAR/DELTA DELAY

-

www.arkel.com.tr

ARKEL 2011 ARL-300 13

This parameter determines the delay time for main contactor to

drop after a stop command. (For hydraulic systems)0.0 to 9.9 seconds

This parameter determines the delay time for valves to drop

after a stop command. (For hydraulic systems)0.0 to 9.9 seconds

The time to keep the main contactor switch on after the movement

ends can be adjusted by this parameter. (For VVVF roped lifts)0.0 to 9.9 seconds

This parameter stores the maximum time allowed to pass without

changing the current floor number.5 to 120 seconds

According to the EN81-1/2, the motor run time limiter shall

function in a time which does not exceed the smaller of the

following two values:a) 45 s b) time for travelling the full travel with rated load,

plus 10 s, with a minimum of 20 s if the full travel time is less

than 10 s.This parameter stores the maximum time allowed to reach the

floor level after passing to low speed.5 to 60 seconds

This parameter determines the activation of door pre-opening

(for Hydraulic and VVVF rope lifts).DISABLED : Door pre-opening is disabled. ENABLED : Door

pre-opening is enabled.This parameter determines the activation of releveling for

hydraulic systems (for Hydraulic and VVVF rope lifts).DISABLED : Releveling is disabled. ENABLED : Releveling is

enabled.MOTOR STOP DELAY

VALVE DROP DELAY

CONTACTOR DELAY

MAX FLOOR TO FLR

MAX LOW SPEED T

DOOR PRE OPENING

RELEVELING

-

www.arkel.com.tr

ARKEL 2011 ARL-300 14

This parameter determines the activation of the emergency

battery lowering for hydraulic systems. (for Hydraulic lifts).DISABLED : Emergency battery lowering is disabled. ENABLED :

Emergency battery lowering is enabled.The rescue type of the system for VVVF rope lifts (geared and

gearless drive).EXTERNAL OR NONE : This option should be selected for geared

asynchronous machines. BRAKE RELEASE: This option should be

selected for gearless synchronous machines when the evacuation

process is done by ARL-300 with releasing the brakes. DRIVE WITH

VVVF : This option should be selected for gearless synchronous

machines when the evacuation process is done by inverter with

driving the motor (for evacuation with battery or UPS).The floor settings for 7-segment displays or simple floor

indicators are adjusted with the help of this screen. Press UP

button during in this parameter to enter display setup screen. Then

you can change theblinking parameter by pushing UP/DOWN buttons. Use LETF/RIGHT

buttons for selecting floor number and its display setup. The

display setup can be entered for each floor separately. The floor

texts can be selected for 7-segment displays and the output signals

can be selected for simple floor indicators in ARL-300 menu are

listed below: Display type Options7-segment -9, -8, -7, -6, -5, -4, -3, -2, -1, 0, 1, 2, 3, 4, 5,

6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23,

24, 25, 26, 27, 28, 29, A, b, C, d, E, F, H, J, L, n, o, P, u, y,

space, -, =, 1A, 1b, 2A, 2bSimple floor indicator

K1, K2, K3, K4, K5, K6, K7, K8, K9, KX K1: Only A terminal gives

output K2: Only B terminal gives output K8: Only G2 terminal gives

output K9: Only BC terminal gives output KX: All A, B, … , BC

terminals give outputThe outputs A, B, C, D, E, F, G, BC and G2 on KBK-2 connection

board are used for 7-segment displays at landings. In addition to

this, the output 20 on FX_SERI_32 board is used for systems more

than 16 stops. These outputs are also used for 7-segment display in

car when car installation is paralel. The simple floor indicator

signals K1, K2, , K8, K9 are respectively given from A, B, , G2 and

BC outputs (on KBK-2 and FX_SERI boards). For example, when K1

option is assigned for 1st stop, the simple floor indicator signal

for 1st stop will be given from output A.BATTERY RESCUE

RESCUE TYPE

DISPLAY SETUP

-

www.arkel.com.tr

ARKEL 2011 ARL-300 15

When FX_SERI serial communication boards are used, the code type

of display outputs given from A, B, C, terminals on FX_SERI boards

is programmed by this parameter.7 SEGMENT OUTPUT : 7 segment code outputs GRAY CODE OUT : Gray

code outputs BINARY CODE OUT : Binary code outputs INVERTED BINARY

: Inverted binary code outputs INVERTED GRAY C. : Inverted gray

code outputs When display outputs are programmed to binary/gray

code, A, B, C, D and E outputs give gray/binary code signals (M0,

M1, M2, M3 and M4) respectively. Output A is the least significant

bit and B is the most significant bit. Output E is only activated

on FX_SERI_32 board for more than 16 stops. For activating simple

floor indicator outputs this parameter must be se to 7 segment

output. A, B, , G2 and BC outputs give K1, K2, , K8 and K9 signals

respectively.This parameter determines the code type of programmable outputs

(floor position for LCD and Dot Matrix Display).GRAY CODE : Gray code output for position indicators BINARY CODE

: Binary code output for position indicators Programmable outputs

PT0, PT1, PT2 and PT3 on ARL-300 board give gray/binary code

signals (M0, M1, M2 and M3) respectively. PT1output is the least

significant bit and the PT4 is the most significant bit. The

programmable outputs M0-M4 on FX_SERI_32 board are also programmed

with this parameter. These outputs are used for systems more than

16 stops instead of PT1-PT3 outputs on ARL-300 mainboard.This parameter is used to determine the beginning code of

outputs which are programmed to gray/binary code on ARL-300

controller or FX_SERI board.0, 1, 2, 3 : Gray/Binary code outputs start counting from 0 (0

code output for 1st floor ) 15,16,17,18 : Gray/Binary code outputs

start counting from 15 (15 code output for 1st floor )This parameter is used to determine the function of PR

programmable relay output on ARL-300 controller.GONG OUTPUT : Gong output. When serial car connection is used,

terminal DD at FX_SERI board is used as gong output. 2nd MOTOR

CNTRL. : The second motor control output used for releveling of

high power hydraulic systems.FX_SERI A,B,C,..

PT0-PT3 OUTPUT

BINARY/GRAY CODE

PR RELAY FUNC.

-

www.arkel.com.tr

ARKEL 2011 ARL-300 16

This parameter is used to determine the ding-dong timing.

ON DOOR OPENING : Gong signal is activated when the door is

opening. WHEN SLOWING : Gong signal is activated when the car slows

down. WHEN STOPED : Gong signal is activated when the car

stops.This parameter determines the activation of phase order and

phase failure protection.DISABLED : RST phase check is disabled. ENABLED : RST phase

check is enabled.Controller saves the last 60 errors in its memory. By this,

facility for maintenance and reparing is provided. Use UP button to

display the fault list.The list of the faults is displayed on the secreen. Last error

is number 1 and the oldest error is number 60.All faults in the memory are erased. Press UP button and then

press DOWN button to approve erasing fault list.On inspection mode this parameter defines if car stops

immediately after reaching Bottom & Top limit switches or

continue until to the floor level.DIRECT STOP GO FLOOR LEVEL

Set this parameter to GO FLOOR LEVEL for systems with AKUS-SD

evacuation unit.This parameter determines the manner of the controller when 120

signal cut off.STOP ONLY : When 120 signal is cut off, the system is stopped.

After the signal comes back, controller returns to operation. STOP

& BLOCK : When 120 signal is cut off, the system is stopped and

blocked. In order to run the system, controller must be reset.

BLOCK LANDINGS : When 120 signal is cut off, landing calls are

blocked. Elevator returns to normal operation when a car command is

given or when the landing door is opened.GONG OUTPUT

RST PHASE CHECK

FAULT LIST

FAULT NO: 1 H1 H1:FAIL TO LOCK

ERASE FAULT LIST

LIMITS AT INSP.

FUNCTION OF 120

-

www.arkel.com.tr

ARKEL 2011 ARL-300 17

Although the ARL-300 controller remembers the last position at

any mains power failure, controller can reset its position after a

mains failure. This parameter can be set to ENABLED for hydraulic

liftsand rope lifts with AKUS-SD emergency battery leveling device.

So the controller resets its position when mains power is live.DISABLED ENABLED

This parameter determines if there is external safety

relay/contactor used with valves block connection. (for hydraulic

systems)INSTALLED NOT INSTALLED

This parameter determines the GROUP ID of the controller in a

group operation. It can be set as A,B,C and D. Each GROUP ID must

be diffrent in a group operation.CONTROLLER A to D

This parameter is decreased for each day as long as the

controller runs. When this value becomes 0 the elevator behaves as

set in the parameter END OF SERV TIME.0-255 days

The controllers behaviour after the maintenance date is

exceeded.CONTINUE WORKING : No action, even a warning message. Elevator

runs as normal. STOP : Lift is blocked and stop operating waits for

maintenance.This parameter is only used for group operation. When each

elevator has different number of stops in group operation, this

parameter is used to adjust the first stop for the elevator which

has difference. It is required toadjust the NUMBER OF FLOOR parameter to the same value for each

elevator in group. For example, there is a dublex system with 10

stops, but elevator A does not serve to the bottom floor. The

NUMBER OF FLOOR parameter must be set to 10 at each elevator and

FIRST STOP parameter must be set to AT BOTTOM + 1 at only elevator

B. AT BOTTOM FLOOR: This elevator serves to the bottom floor in

group operation. AT BOTTOM + 1: The first stop of this elevator is

1 floor above the bottom floor in group. AT BOTTOM + 2: The first

stop of this elevator is 2 floor above the bottom floor in group.

AT BOTTOM + 3: The first stop of this elevator is 3 floor above the

bottom floor in group.POSITION RESET

EXT.SAFETY RELAY

GROUP ID CONTROLLER A

SERVICE TIME

END OF SERV TIME

FIRST STOP

-

www.arkel.com.tr

ARKEL 2011 ARL-300 18

This parameter is only used for group operation. When each

elevator has different number of stops in group operation, this

parameter is used to adjust the last stop for the elevator which

has difference. It is required toadjust the NUMBER OF FLOOR parameter to the same value for each

elevator in group. For example, there is a dublex system with 10

stops, but elevator A does not serve to the top floor. The NUMBER

OF FLOOR parameter must be set to 10 at each elevator and LAST STOP

parameter must be set to AT TOP FLOOR — 1 at only elevator B. AT

TOP FLOOR: This elevator serves to the top floor in group

operation. AT TOP FLOOR — 1: The last stop of this elevator is 1

floor below the top floor in group. AT TOP FLOOR — 2: The last stop

of this elevator is 2 floors below the top floor in group. AT TOP

FLOOR — 3: The last stop of this elevator is 3 floors below the top

floor in group.This parameter determines the response type of the elevator

during the VATman operation.Single car call: Only one call is active in VATman operation

(Other calls will be canceled). Last car call: The last call will

be active in VATman operation (Other calls will be canceled). Multi

car call: All car calls will be active in VATman operation.The evacuation floor number. When the evacuation function is

enabled, elevator cancels all calls. Stops at nearest floor if it

moves and goes to the evacuation floor. After it comes to the

evacuation floor, itopens door and waits at this floor with open doors. After

waiting 30 seconds, elevator closes the doors and returns to normal

operation. The evacuation function is available only with serial

car installation and it is enabled by using a panic button at car

panel which is connected to the terminal 805 on ARL-300 controller

that is not used when the car communication is serial. DISABLED: If

there is no panic button on car operating panel this function must

be disabled. 1-24: Evacuation floor.This parameter determines the maximum number of car commands.

After reaching this number the car commands will not be

accepted.NO LIMIT: There is no limit for number of car commands. 1-15 :

Maximum number of car commands.The operating type of up and down direction arrows (31 and 32

signals ).RUN DIR+NEXT DIR : When the elevator is running, direction

arrows indicate the running direction. When the elevator waits at

floor, direction arrows indicate the direction of next travel.NEXT DIRECTION : Direction arrows indicate the direction of next

travel when the elevator waits at floor. No indication is given

when the elevator is running.LAST STOP

VATMAN CALLS

EVACUATION FLOOR

MAX.CAR CALLS

DIRECTION ARROWS

-

www.arkel.com.tr

ARKEL 2011 ARL-300 19

The password to enter program parameters menu. Use UP/DOWN

buttons to set the password. Dont forget your password. It will be

asked to enter into the menu next time.In order to exit from the menu, push UP button.

PASSWORD 0000

EXIT FROM MENU

-

www.arkel.com.tr

ARKEL 2011 ARL-300 20

3. ARL-300 ERROR CODES CODE ERROR H1 FAIL TO LOCK DOOR. 140

SIGNAL IS MISSED H2 FLOOR TO FLOOR MAX TRAVEL TIME ELAPSED H3 DOOR

IS NOT CLOSED FOR A LONG TIME H4 MAX SLOW SPEED TRAVEL TIME ELAPSED

H5 BOTH LIMIT SWITCHS UP&DOWN IS OPEN H6 TOP LIMIT SWITCH IS

CUTS OFF WHILE RUNNIG DOWN H7 BOTTOM LIMIT SWITCH IS CUTS OFF WHILE

RUNNIG UP H8 MOTOR PTC CIRCUIT IS OPEN. MOTOR OVER HEAT H9 SYSTEM

ERROR H10 CONTACTOR CHECK BACK ERROR H11 ML1 & ML2 SIGNALS

SHORT CIRCUIT TO EACH OTHER H12 DOOR BRIDGING RELAYS SR2 & SR3

DONT PICK UP H13 DOOR BRIDGING RELAYS SR2 or SR3 DONT DROP H14 DOOR

BRIDGING RELAY SR1 CHECK BACK ERROR H15 RST MAINS POWER SUPPLY

FAILURE H16 24V (100) SUPPLY IS UNDER LIMIT H17 PTC SIGNAL OPEN.

MOTOR OVER HEATED H18 FAULT SIGNAL FROM VVVF DRIVER H19 SAME GROUP

ID NAME USED ON CONTROLLERS H20 120 (STOP) SIGNAL IS MISSING.

ELEVATOR BLOCKED H21 EXTERNAL SAFETY RELAY CHECK BACK ERROR H22

SERVICE TIME OVERFLOW -

www.arkel.com.tr

ARKEL 2011 ARL-300 21

4. LEDs and JUMPERs ON ARL-300 BOARD

-

www.arkel.com.tr

ARKEL 2011 ARL-300 22

5. FX_SERI Serial Car Communication Board FX_SERI is used in

inspection box with systems less than 16 floors for serial car

communication with ARL-300 controllers. Two wires will be enough

and no other installation is needed betwen car and control panel

for car buttons, indicators, over load, full load, gong, direction

arrows, car lamp, automatic door open / close buttons and

inspection operation buttons. The code type of display outputs A,

B, C, on FX_SERI board can be programmed to 7 segment code, gray

code, binary code, inverted gray code or inverted binary code by

the ARL-300 menu.6. FX_SERI_32 Serial Car Communication and Call Input Board

FX_SERI_32 is used with systems more than 16 floors with ARL-300

controllers. It is used in inspection box for serial car connection

and in control panel for call input-output connections with ARL-300

controllers. When it is used in inspection box, two wires will be

enough and no other installation is needed betwen car and control

panel for car buttons, indicators, over load, full load, gong,

direction arrows, car lamp, automatic door open / close buttons and

inspection operation buttons. There are also gray/binary code

outputs M0-M4 at FX_SERI_32 board which can be used for LCD and

Dot-matrix indicators. The code type of outputs can be set by

ARL-300 menu.Output setting of 32 signal

+-

2 jumpers are used for output settings of 31 (Down Arrow

Indicator) and 32 (Up Arrow Indicator) outputs:Plug jumpers to + and middle pins for signal output 100 (+24V)

Plug jumpers to — and middle pins for signal output 1000 (0V)Output setting of 31 signal

Reserved

Setting of the FX_SERI_32 usage

Jumper is used for selecting the usage of FX_SERI_32 board

either for car calls or landing calls:Plug jumper to upper 2 pins in case of using in inspection box

for car calls Plug jumper to lower 2 pins in case of using in

control panel for landing calls -

www.arkel.com.tr

ARKEL 2011 ARL-300 23

7. ARL-SARJ CHARGE CONTROLLER

ARL-SARJ board is used only with Hydraulic lifs. It charges the

batteries (2 x 12V/1.2Ah) used for hydraulic emergeny lowering.

(When mains power is off 24Vdc supply is required for ARL-300

controller and 12Vdc supply is required for safety circuits and for

emergency lowering valve) ARL-SARJ board checks the mains power in

normal operation mode. It charges the batteries and gives the PTC

signal to ARL-300 board according to state of terminals T1-T2 .The processor is working correctly

Mains power is ON Relay is activated Battery charging is

activated -

www.arkel.com.tr

ARKEL 2011 ARL-300 24

8. LEVELED INDICATOR BOARD LEVELED indicator is normally used

with hydraulic systems (Optional with rope lifts). It indicates the

floor level with LEDs on it even the power is off. The board must

also be supplied with a battery when there is no voltage at

terminals 100-1000. After the car is levelled it also sounds an

alert by buzzer. There is also a lamp output (12V/1W) which can be

used to display levelled signal in a different place. The magnetic

switches which will be connected to LEVELED board (SML1-SML2 or

SJF) must also be supplied with the battery (12V) in order to give

signals to LEVELED board even the 24V is off.Levelled indicator

Buzzer for sound alert when car is levelled after evacuation

L+ ve L- output for connection external lamp (12V/1W)

Counter type selection jumper:

For ML1-ML2 counter: ML For M1 or JF counter: 142

Magnetic switch inputs:

For ML1-ML2 counter: SML1 ve SML2 For M1 or JF counter: SJF

Battery connection (BAT+) must be done from inspection box

(12V) -

www.arkel.com.tr

ARKEL 2011 ARL-300 25

9. INSTALLATION OF MAGNETIC SWITCHES AND MAGNETS ARL-300

controller uses two different car positioning system listed below:

Standart M1 counter: Used with two-speed systems ML1-ML2 counter:

Used with VVVF and hydraulic systems The following table shows the

type of magnetic switches required for car positioning:Car position sensing Drive type Door

pre-opening and releveling

Required magnetic switches

Standart M1 counter Two speed NO SM1 (Bi-stable) SJF

(Bi-stable)ML1-ML2 counter VVVF/ Hydraulic YES/NO SML1, SML2

(Mono-stable)SJF1, SJF2 (Mono-stable)

-

www.arkel.com.tr

ARKEL 2011 ARL-300 26

9.1 INSTALLATION AND CONNECTION FOR M1 COUNTER Installation of

magnetic switches and magnets M1 counter positioning requires 2

additional magnetic switches on the car top: 1. Floor counting ve

deceleration magnetic switch (SM1, Bi-stable) 2. Level stopping

magnetic switch (SJF, Bi-stable) Bi-stable magnetic switches and

round magnets are used for this positioning system. SM1 (ML1)

magnetic switch is used for floor counting at the same time for

deceleration of the car. SJF (142) magnetic switch is used for

stopping at floor level.Install the round magnets carefuly according to wiring diagrams

with taking care of the distance between magnets and the pole of

magnets (see sheet 13). Connection of magnetic switches SM1

magnetic switch is connected to terminals ML1-100. SJF magnetic

switch is connected to terminals 142-100. 9.2. INSTALLATION AND

CONNECTION FOR ML1-ML2 COUNTERML1-ML2 counter positioning requires 4 additional magnetic

switches on the car top: 1. Door zone magnetic switches (SML1,

SML2) 2. Travelling magnetic switches (SJF1, SJF2) -

www.arkel.com.tr

ARKEL 2011 ARL-300 27

9.2.1. DOOR ZONE MAGNETIC SWITCHES (SML1, SML2)

1. Door Zone Magnetic Switch-1 (SML1, Monostable, NO-normally

open) 2. Door Zone Magnetic Switch-2 (SML2, Monostable, NO-normally

open)SML1-SML2 magnetic switches inform control panel that the car is

in door opening zone.Installation of magnetic switches Install the SML1-SML2 magnetic

switches on the cage beam in a pre-assembled bracket. SML2magnetic switch must be on top of SML1 and two of them must

observe the same side of guide rail.Connection of magnetic switches SML1-SML2 magnetic switches are

connected to plugs ML1-100 and ML2-100 respectively.Ribbon magnets are used for this positioning system. The length

of the zone magnets are approx. 40cm. The number of zone magnets

are determined by number of floor:Number of ribbon magnets length 40 cm = Number of floor

Installation of zone magnetsMove the car to the end of floors Car threshold must be exactly

at the floor level Install the ribbon magnet opposite to the zone

magnetic switches. The middle of the ribbon magnet must be on a

level with the middle of the magnetic switches. The distance

between magnetic switches and magnet must be 1-2 cm. 40 cm ribbon

magnets must be fixed with screw or glue Repeat this installing

operation at all floors.CAR

FLOOR LEVEL

20cm

20cm

-

www.arkel.com.tr

ARKEL 2011 ARL-300 28

9.2.2. TRAVELLING MAGNETIC SWITCHES (SJF1, SJF2) 1. Downward

travelling magnetic switch (SJF1, Monostable, NO-normally open) 2.

Upward travelling magnetic switch (SJF2, Monostable, NO-normally

open) SJF1 and SJF2 magnetic switches are used to deceleration and

stopping the car depending on the direction of travel. Moreover

they are used to relevelling for hydraulic systems.Installation of magnetic switches Install the SJF1 and SJF2

magnetic switches on the cage beam in a pre-assembled brackets

separately. They must be installed side by side and must observe

the different side of guide rail. Connection of magnetic switches

SJF1 magnetic switch is connected to plugs 141-100. SJF2 magnetic

switch is connected to plugs 142-100.The length of the zone magnets are approx. 10cm. The number of

zone magnets are determined by number of floor and can be

calculated by the following formula:Number of ribbon magnets length 10 cm = (Number of floor x 4)

-2 -

www.arkel.com.tr

ARKEL 2011 ARL-300 29

Installation of travelling magnets There are two types of

travelling ribbon magnets:— Level stopping/relevelling magnetic switches — Deceleration

magnetic switches Level stopping/relevelling ribbon magnetsNote

The 3 cm distance of magnet above/below the magnetic switches is

determined by the need of deceleration distance. It can be

different in any system. It is required that both magnetic switches

observe their magnets at floor level.Deceleration magnets

Note

The deceleration distance is determined by speed of the car. It

can be different in any system and can be accepted 180 cm for VVVF

systems and 60 cm for hydraulic systems.Move the car to the end of floors Car threshold must be exactly

at the floor level Install one of the ribbon magnets length 10cm

opposite to theSJF1 magnetic switch. The middle of the magnetic switch must

observe the ribbon magnet 3 cm above and 7 cm below. The distance

between magnetic switches and magnet must be 1-2 cm.Install the other ribbon magnet length 10cm opposite to the SJF2

magnetic switch. The middle of the magnetic switch must observe the

ribbon magnet 7 cm above and 3 cm below. The distance between

magnetic switches and magnet must be 1-2 cm.Repeat this installing operation at all floors.

Install the ribbon magnet as deceleration distance above the

SJF1 magnetic switch (Excluding the top floor).Install the ribbon magnet as deceleration distance below the

SJF2 magnetic switch (Excluding the bottom floor).Repeat this installing operation at all floors

Down direction stop distance

Up direction stop distance

Up direction deceleration distance

Down direction deceleration distance

-

www.arkel.com.tr

ARKEL 2011 ARL-300 30

10. CONNECTION OF TOP & BOTTOM LIMIT SWITCHES

ARL-300 controller is available with two different top &

bottom limit switch options.Spool switches Bi-stable magnetic switches

10.1. USING SPOOL SWITCHES

Installation and connection of SKSR1 bottom limit switch and

metal plate Move the car to the bottom floor. The bottom limit

switch must be switched off when car is below the bottom floor

level as deceleration distance. It means it must be switched when

down deceleration signal for bottom floor is activated. Install the

spool switch and metal plate according to this need. If the spool

switch is mounted to car, it is connected to terminals 817-100 at

car top. If it is mounted to shaft, it is connected to terminal

817-100 at control panel. Installation and connection of SKSR2 top

limit switch and metal plateMove the car to the top floor. The top limit switch must be

switched off when the car is above thebottom floor level as deceleration distance. It means it must be

switched when up deceleration signal for top floor is activated.

Install the spool switch and metal plate according to this

need.If the spool switch is mounted to car, it is connected to plugs

818-100 at car top. If it is mounted toshaft, it is connected to plugs 818-100 at control panel.

Note

Make the connection of up & down limit switches according to

the wiring diagram (see sheet 8 and 13) -

www.arkel.com.tr

ARKEL 2011 ARL-300 31

10.2. USING BI-STABLE MAGNETIC SWITCHES Installation and

connection of SKSR1 bottom limit switchInstall the SKSR1 bi-stable magnetic switches on the cage beam

in a pre-assembled bracket. SKSR1 magnetic switch is connected to

plugs 817-100. Installation of round magnets for bottom limit

switchInstallation and connection of SKSR1 top limit switch

Install the SKSR2 bi-stable magnetic switches on the cage beam

in a pre-assembled bracket. SKSR2 magnetic switch is connected to

plugs 818-100. Installation of round magnets for top limit

switchMove the car to the bottom floor. Car must be exactly at the

floor levelInstall the round magnet with red color side above the SKSR1

magnetic switch as deceleration distance. It means it must be

switched on when down deceleration signal for bottom floor is

activated.Install the round magnet with black color side a little above

the red color magnet. It means it must be switched off when the car

is out of the bottom limit zone. The distance between magnetic

switch and magnets must be 1-2 cm.Move the car to the bottom floor. Car must be exactly at the

floor levelInstall the round magnet with red color side below the SKSR2

magnetic switch as deceleration distance. It means it must be

switched on when up deceleration signal for bottom floor is

activated.Install the round magnet with black color side a little below

the red color magnet. It means it must be switched off when the car

is out of the top limit zone. The distance between magnetic switch

and magnets must be 1-2 cm.FLOOR LEVEL

Down direction deceleration distance

Red side

Black side

FLOOR LEVEL

Up direction deceleration distance

-

www.arkel.com.tr

ARKEL 2011 ARL-300 32

11. DOOR BRIDGING SAFETY CIRCUIT The door bridging safety

circuit is integrated in the ARL-300 controller board (SR1, SR2,

SR3 safety relays and RBE relay) and enables car movements in the

door zone with open car and landing doors. This makes approaching

and relevelling with open doors possible. The door bridging circiut

requires two magnetic switches on car roof SML1 ( door zone-1) and

SML2 (door zone-2). SML1-SML2 magnetic switches must be installed

in the same pre-assembled bracket and SML2 (door zone-2) magnetic

switch must be on top of SML1 (door zone-1). 40cm ribbon magnets

are used with door zone magnetic switches. The door bridging

operation can only be activated and commissioned if these two

magnetic switches including magnets are installed and connected

(see installation and connection of door zone magnetic

switches).Note

If the two functions Door pre-opening and Hydaulic relevelling

are not required, the door bridging operation is not activated. But

the magnetic switches zone-1 & zone-2 including magnets are

required for ML1-ML2 counter positioning.Warning

According to EN81, the maximum size of the door zone is 400mm

(200mm in each direction). The actual dimensions of the door zone

are forced by the length of the door cam. The distance to the door

zone magnets must not be larger than the length of thedoor cam. Maximum length 40cm. The door zone magnets must be

placed so both magnetic switches are closed in thedoor zone and open outside the door zone.

-

www.arkel.com.tr

ARKEL 2011 ARL-300 33

11.1. DOOR BRIDGING PRINCIPLE The door bridging principle can be

described with the following steps below : The relays SR1, SR2, SR3

and RBE are released in the beginning. If the car approaches the

target floor with a slow speed, safety relay SR1 (starting doorbridging) is activated by the controller. By the way SR2 and SR3

safety relays get ready to be triggered and activated by SR1

safetyrelay when car reaches the door zone. The safety relays SR2 and

SR3 issue the zone message to the controller (car is in door zone).

If the car reaches the door zone, first the magnetic switches of

door zone-1 ( SML1) trigger andactivate the safety relay SR2 (when running downward). After

then the magnetic switches of door zone-2 ( SML2) trigger and

activate the SR3. The safety relay SR1 (starting door bridging) is

released after the SR2 and SR3 relays areactivated. After the control software received the bridging

available message, the enable relay RBE isactivated. These relays state (RBE activated, SR1 released, SR2

activated, SR3 activated) bridges the doorcontacts in the safety circuit and allows drive movement with

the doors open as showed in the following diagram.Door safety contacts of ARL-300 controller

Terminal 120 (Begining of door

safety circuits)

Terminal 140 (End of safety circuits)

Landingdoor locks (for manual

landing doors)

Landing door contacts

Car doorcontacts

Door safety circuit is bridged with the door bridging

contacts -

www.arkel.com.tr

ARKEL 2011 ARL-300 34

12. GROUP OPERATION

ARL-300 controller is available with group operation up to 4

elevators via RS-485 serial communication. 2 terminals S2A and S2B

are used for group communication on ARL-300 controller.12.1. CONNECTION OF CONTROL PANELS IN GROUP OPERATION There is

no need any extra group controller in group operation. Only to do

is connecting each control panels. 4-wire cables are used for

connecting all control panels in elevator group operation.

Connection of 4 control panel is showed below:12.2. CONNECTIONS OF LANDING BUTTONS IN DUBLEX OPERATION Landing

call buttons should be connected paralel to each control panel for

dublex operation. So when one of controller goes out of group

operation by any reason the other controller can carry out landing

calls. It is recommended to connect each landing call buttons to

one one control panel for an elevator group of 3 and 4 elevators.

By this way landing calls will not be connected to one of the

controller in elevator group. But even some controllers goes out of

group operation by any reason the other controllers can carry out

landing calls and you can save on cables and connections. Operating

of any landing buttons on any landing panel results in sending this

information to all the lifts. All the landing buttons are

illuminated when the call is registered and the group control

program takes care the call. 12.3. GROUP OPERATION SETTINGSAfter connection of control panels in the elevator group only to

do is setting each controller as A, B, C or D on ARL-300 menu. Each

controller must have a different group ID. Group operation can be

monitored on each ARL-300 controllers group status screen.PANEL A PANEL B PANEL C PANEL D

-

www.arkel.com.tr

ARKEL 2011 ARL-300 35

35m

m

13. DIMENSIONS OF ARL-300 CONTROLLER Front View

Panel fitting hole

LCD

Keypad Cover fitting screw

Sideway View

Cover fitting screw Cover Cover screw Pcboard Pcboard fitting

screw260mm

190m

m

200m

m

27m

m

250mm

260mm

-

www.arkel.com.tr

ARKEL 2011 ARL-300 36

14. ARL-300 TERMINALS & PLUGS 14.1. Common Terminals On

ARL-300 Controller L1,L2,L3 Main Phase N Neutral 1 Car Supply

Output (220Vac) 2 Car Lamp Output (220Vac) LO Relay Output of

Retiring Cam (Common Contact) LA Relay Output of Retiring Cam

(Normaly Open Contact ) K3 Door Close Signal Output K5 Door Open

Signal Output K15 Door Open/Close Signal Common 10A Safety Circuit

Supply Ground Input 120 Stop Circuit Monitoring InputMax. 230Vac 130 Landing Door Contacts Monitoring Input 140A

Landing Door Lock Contacts Monitoring Input 140B Landing Door Lock

Contacts Monitoring Input(During evacuation operation for rope lifts with AKUS-SD or

hydraulic systems)Max. 28Vdc

10B Common of Main Contactors Output SF1 Door Bridging Relay

Contact Common (120 circuit) Only for VVVF and Hydraulicsystems for door pre-opening and relevelling. SF2 Door Bridging

Relay Contact Output (140 circuit)ML1 (M1) Door Zone Magnetic Switch-1 Input These connections

depend on the drive type of the elevator.ML2 Door Zone Magnetic Switch-2 Input 141 Down Stop &

Deceleration Magnetic Switch Input 142 Up Stop & Deceleration

Magnetic Switch Input PT0 Programmable Output (M0: Gray/Binary Code

Output) The functions ofprogrammable outputs are assigned from the menu.

PT1 Programmable Output (M1: Gray/Binary Code Output) PT2

Programmable Output (M2: Gray/Binary Code Output) PT3 Programmable

Output (M3: Gray/Binary Code Output) KRC Contactors Feed-back Input

S2A-S2B Group Operation Communication Terminals S1A-S1B Car

Communication Terminals (for comm. with FX-SERI boards) 1000 Signal

Circuit Ground 100 Signal Circuit Supply (+24Vdc) PTC Motor

Thermistor & Panel ThermostatOil Thermostat Input (Hydraulic) & Brake Resistor Thermostat

(VVVF)K19 Door Close Limit Switch Input These inputs must be bridged

to terminal 100 when door limit switches are not checked by ARL-300

controller (excluding 1-phase and 3-phase automatic lift doors) K16

Door Open Limit Switch InputPR Programmable Relay Common Input The function of this output

is assigned from the menu. PRA Programmable Relay OutputXK1 To XK1 plug on KBK4 Connection Board with 14-wire flat cable

XK2 To XK2 plug on KBK2 Connection Board with 20-wire flat cable

XK3 To XK3 plug on KBK2 Connection Board with 20-wire flat

cable -

www.arkel.com.tr

ARKEL 2011 ARL-300 37

14.2. Relay Output Terminals According to Drive Type

Relay Outputs for Two Speed Systems: V11 KU1, KU2, KH Contactors

Supply Common VA Up Direction Contactor (KU2) Output VB, VC High

Speed Contactor (KH) Output VD Down Direction Contactor (KU1)

Output RU Low Speed Contactor (KF) Output 11 Low Speed Contactor

(KF) Supply CommonRelay Outputs for VVVF Systems (*): Geared drive

(Asynchronous machine) Gearless drive (Asynchronous machine)

Evacuation with Brake ReleasingEvacuation with Active Motor Driving

V11 VVVF Signals Supply Common

VVVF Signals Supply Common

VVVF Signals Supply Common

VA Up Direction Signal Output Up Direction Signal Output Up

Direction Signal Output VB, VC High Speed Signal Output High Speed

Signal Output High Speed Signal Output VD Down Direction Signal

Output Down Direction Signal Output Down Direction SignalOutput AV1 Low Speed Signal Common Automatic Evacuation

SignalCommon Evacuation Active Contactor Supply Common

AV2 Low Speed Signal Output (**) Automatic Evacuation Signal

OutputEvacuation Active Contactor Output

RE1 Inspection Speed Signal Common

Inspection Speed Signal Common

Mains Active Contactor Supply Common

RE2 Inspection Speed Signal Output (***)

Inspection Speed Signal Output

Mains Active Contactor Output

RU Main Contactors Output Main Contactors Output Main Contactors

Output 11 Main Contactors SupplyCommon Main Contactors Supply Common

Main Contactors Supply Common

*: The type of VVVF system (geared or gearless) is determined by

the paramater RESCUE TYPE. **: For gearless drive with ADrive

Inverter, the low-speed signal should be given from up and down

signals in parallel with diodes. ***: For gearless drive uses

active motor driving as evacuation method, the inspection speed

signal should be given from a normally closed contact of an

additional relay which should be activated from the terminal 869EK

on KBK-4 board.Relay Outputs for Hydraulic Systems: V11 Valve Group Supply

Common VA Slow-Up Valve Output VB Fast-Up Valve Output VC Slow-Down

Valve Output VD Fast-Down Valve Output AV1 Emergency Valve Supply

Common AV2 Emergency Valve Output RE1 Operation Mode Selection

Contactor Supply Common RE2 Operation Mode Selection Contactor

Output RU Up Contactor Output RD Delta Contactor Output RS Star

Contactor Output 11 Contactor Supply Common -

www.arkel.com.tr

ARKEL 2011 ARL-300 38

14.3. Terminals & Plugs On KBK4 Connection Board 869

Inspection Switch Input (From Inspection Box)500 Parallel car installation Inspection Down Button Input

Serial car installation Call Cancel Button Input (The common of

signal must betaken from inspection signal 869) 501 Inspection Up Button Input

YAN Fire Alarm Switch Input DEP Earthquake Sensor Contact InputDTS Parallel car installation Door Close Button Input Serial car

installation Door Fully Closed Limit Switch Input (for

fire-fighters lift)K20 Parallel car installation Door Open Button & Door

Pressure Contact & PhotocellContact Input Serial car installation Door Fully Open Limit

Switch Input (for fire-fighters lift)804 Parallel car installation Over-load Contact Input Serial car

installation Fireman Switch (in car operation panel) Input (for

fire-fighters lift)

805 Parallel car installation Full-load Contact Input Serial car

installation Panic (Evacuation) Button Input (for panic function)

VAT Car Priority Switch Input 817 Down Limit Mechanical Switch

Input 818 Up Limit Mechanical Switch InputPI Programmable Input

For VVVF systems Inverter Error Signal Input For Hydaulic

systems External Contactor ChecbackSignal (when external contactors are used for hydraulic valve

blocks like Beringer, GMV, etc.)869EK The End of Inspection Singal Input (Inspection operation +

Recall operation >To Control Card)XK1 To XK1 plug on ARL-300 Controller Board with 14-wire flat

cable If Recall Hand Terminal is not connected to panel If Recall

Hand Terminal is connected to panelUse jumper

Do not use jumper

Figure-1 : KBK4 board jumper selection (two pins)

-

www.arkel.com.tr

ARKEL 2011 ARL-300 39

14.4. Terminals & Plugs On KBK2 Connection Board 190 Not

used.There is no default output signal for common of landing calls

(190) for non-collective systems in ARL-300 controller. For this purpose, it

is recommended to use an additional relay which will be activated

from the busy signal 12 and 1000 (0V). The normally closed contact

of the relay is used. The common of NC contact is connected to

terminal 1000 (0V) and the contact output is used as 190 signal.

Moreover, the parameters «WAITS AT FLOOR» and «CAR LIGHT DELAY»

parameter must be set correctly for non-collective systems.A-G2 7-Segment Display Output X1-X16 Car Call / Landing Call

Inputs 02 Out of Service Indicator Output 12 Busy Indicator Output

31 Down Arrow Indicator Output 32 Up Arrow Indicator Output S1A-S1B

Car Communication (FX-SERI) Terminals S2A-S2B Group Operation

Communication Terminals XK2 To XK2 plug on ARL-300 Controller Board

with 20-wire flat cable XK3 To XK2 plug on ARL-300 Controller Board

with 20-wire flat cableIf outputs of 31,32,02 and 12 signals are connected to terminal

100If outputs of 31,32,02 and 12 signals are connected to terminal

1000Figure-2 : KBK2 board jumper selection (three pins) 15. GENERAL

SAFETY REGULATIONSAll persons performing installation and commissioning work on

the ARL-300 Controller must read these chapters and follow the

regulations.In a lift control system, for a full electrical conformity with

EN 81-1/2 standards it is required that controller (control

boards), control panel and electrical connections must be proper.

ARKEL guaranties that controller and control panel are in

conformity with the standards. However external connections of

control panel and other electrical connections are under installers

responsibility. -

www.arkel.com.tr

ARKEL 2011 ARL-300 40

There are small points to take care while connecting your

flexible cable. Arrange your cable order according to their

electrical signal level. Although the cables have enough

insulation, long parallel cables have transformer effect. The

signals can joint between each neighbors. If there is two or more

flexible cables it is better to separate low an high voltage

signals. Here is an example of faulty connection. Cable No: Signal

Signal level ———— —————————————

————— 1 100 (24 Source) 24Vdc 2 A (Digital segment) 24Vdc

3 B (Digital segment) 24Vdc … 10 817 (UP limit Switch) 24Vdc 11

818 (Down limit switch) 24Vdc 12 810 (Magnetic Cam Power-) 180Vdc

13 2001 (Magnetic Cam Power+) 180Vdc 14 804 (Over load) 24Vdc 15

401 (Car Call 1) 24Vdc 16 402 (Car Call 2) 24Vdc … 20 406 (Car

Call 6) 24Vdc 21 2 (Car Lamp) 220Vac 22 1 (Car Power source) 220Vac

In this example ever car lamp on/off operation makes high voltage

peaks on line and it can leak to 406 (car call signal). In long

term this cause a fault on 406 output transistor. Also there is

risk because of Magnetic cam power lines. 818 and 804 signal may

have faulty operation in long term. Here is an example of correct

connection order. 100, A, B, C, D, E, F, G, 804, 805, 401, 402,

403, .. , All 24V signals, 1000, Signal ground 0V, PE, N, Earth

Line, Neutral , 810, 2001, 1, 2, . All high voltage signalsATTENTION! Take care while connecting

your flexible cable

-

www.arkel.com.tr

ARKEL 2011 ARL-300 41

This page intentionally left blank

-

www.arkel.com.tr

ARKEL 2011 ARL-300 42

ARKEL Elektrik Elektronik Ticaret Ltd. ti. erifali Mah.

Bayraktar Bulvar ehit Sok. No:32 Umraniye Istanbul TURKIYETEL: (+90 216) 540 03 10 — 11 -12 Fax: (+90 216) 540 03 09

E-mail : [email protected] www.arkel.com.tr

-

Системы управления лифта ARKEL

-

Контроллер для системы управления лифтом ARL 300

Назад в каталог

Контроллер для системы управления лифтом ARL 300

Артикул: ARL 300

Под заказ

Задать вопрос продавцу

- Описание товара

- Характеристики

- Отзывы0

| Подходит для всех видов систем управления в гидравлических и канатных лифтах до 24 остановок |

| Групповая работа до 4 групп |

| Открывание с открытыми дверями и открывание дверей с помощью внутренних реле для мостов |

| Схема защиты двигателя внутренней последовательности |

| Встроенные входы и выходы управления дверью |

| Программируемое 7-сегментное меню для индикаторов, Серый, инвертированный Серый, Двоичный, инвертированный Выходы двоичного кода и сигналы выхода на выход |

| Отдельные буквенно-цифровые названия этажей для каждой остановки |

| Сохранение последних 60 ошибок в памяти позволяет отслеживать обратное отслеживание ошибок |

| Цифровые и сигнальные выходы с защитой от короткого замыкания |

| FX_SERI до 16 остановок, экономия на кабельных и трудовых расходах с использованием карт последовательного интерфейса FX_SERI_32 на 16 остановок |

| Зарядка в гидравлических лифтах Аварийная загрузка с 2 батареями 12 В, производимыми карточкой ARL-SARJ |

| Функция аварийного автовосстановления для безредукторных лифтов |

| Соединительные платы, которые упрощают соединения с помощью плоских кабелей, экономят терминалы платы |

ПОЛЬЗОВАТЕЛЬСКИЙ ИНТЕРФЕЙС

| Регулируемые параметры системы с помощью ЖК-дисплея и кнопок на карте пользователем |

| Экран, показывающий состояние лифта в нормальной работе, с кодом ошибки в случае ошибки |

| Регулировка контрастности (яркости) экрана Lcd с помощью клавиш на карте |

| Меню PUK-кода защиты от защиты паролем и несанкционированного использования |

| Турецкий, английский, русский, голландский, румынский, немецкий, итальянский варианты меню |

ОБЩИЕ СВОЙСТВА

| Количество остановок | : | 24 остановки |

| Тип управления | : | Любая система трафика |

| Тип привода | : | Быстрый пар гидравлических бесступенчатая скорость Редукторной тяговой машина Gearless машина (машина жилая и МД) |

| Командир группы | : | имеются |

| Последовательная связь | : | С кабиной |

| Дополнительные функции | : | Внутренняя схема моста для двери Встроенная автоматическая регулировка двери Внутренняя фазовая последовательная защита двигателя Программируемый выход серого / двоичного кода для индикации |

Вам может понравиться

Быстрый просмотр

Под заказ

ARL-300

Станция управления лифтом

Быстрый просмотр

Под заказ

ARL-200

Станция управления лифтом

Быстрый просмотр

Под заказ

ARL 100

Станция управления лифта

Быстрый просмотр

в наличии

Плата управления для телескопических подъемных дверей с двигателем 24 В постоянного тока

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

ARL-500

LIFT CONTROL SYSTEM

Programming Manual

Related Manuals for Arkel ARL-500

Summary of Contents for Arkel ARL-500

-

Page 1

ARL-500 LIFT CONTROL SYSTEM Programming Manual… -

Page 2

Keep the manual in a safe place and available to engineering and installation personnel during the control panel functioning period. ARKEL is not responsible for those mistakes that may be found in this manual and for the damages that they may cause. -

Page 3: Table Of Contents

5.3.3. REVKON PROGRAMMABLE INPUTS SCREENS …………… 18 5.3.4. KABKON PROGRAMMABLE INPUTS SCREENS …………… 19 5.4. OUTPUT STATUS SCREENS ……………………… 20 5.4.1. ARL-500 FIXED RELAY OUTPUTS SCREEN …………….20 5.4.2. ARL-500 PROGRAMMABLE RELAYS SCREENS …………….. 20 5.4.3. ARL-500 PROGRAMMABLE TRANSISTORS SCREENS …………21 5.4.4.

-

Page 4

7.1.4. JUMPERs on ARL-500 main controller ………………..92 7.1.4.1. Assigning the supply voltage of encoder in incremental positioning …………92 7.1.4.2. Activating the battery source of real time clock ………………..92 7.1.5. LCD CONTRAST trimpot on ARL-500 controller …………….92 7.2. REVKON C ……………………93 ONTROLLER 7.2.1. -

Page 5

7.4.5. KKBT Non-indicator Call Module ………………….. 121 7.4.5.1. KKBT Technical Data ……………………….122 7.4.5.2. KKBT Pin Assignments ………………………. 123 7.4.5.3 Floor Setting With Dipswitches On KKBT ………………124 8. ARL-500 DISPLAY MESSAGES ………………..125 8.1. STATUS MESSAGES ……………………….125 8.2. ERROR MESSAGES ……………………….132 ARL-500… -

Page 6: General

The ARL-500 Lift Controller complies with: Lift Directive 95/16/EC — European standards EN 81-1, EN 81-2 1.2. ELECTROMAGNETIC COMPATIBILITY (EMC) The ARL-500 Lift Controller and its components comply with the standards according to Directives of electro magnetic compatibility 2004/108/EC — EN 55011 Issue 2007…

-

Page 7: Manual Description

1.3. MANUAL DESCRIPTION Please read this manual carefully before installing the ARL-500 Lift Controller System. This manual will help you during installation of the ARL-500 controller and its components. In case of any problems, users are advised to contact manufacturer without any delay giving details of the problem.

-

Page 8: Introduction

ARL-500 is universal. With just a few parameter changes; it can be used for rope traction or hydraulic elevators, with two-speed or VVVF, up to 48 stops, and for groups of up to 8 elevators.

-

Page 9: Programming Interface

3. PROGRAMMING INTERFACE The user interface of ARL-500 lift controller system consists of 128×64 pixel resolution graphic LCD, keypads, LEDs, jumpers and trimpots. GRAPHIC LCD ARL-500 Controller has 128×64 pixel resolution illuminated blue graphic LC-Display. KEYPAD The ARL-500 controller is operated by using 6-key keypad. These keys have different functions in different displays.

-

Page 10: Keypad Functions According To Screen

4. KEYPAD FUNCTIONS ACCORDING TO SCREEN The ARL-500 controller is operated by using 6-key keypad. The functions of keys according to screen are described in the tables below: Key functions in the main screen To previous/next monitoring screens Open service options screen…

-

Page 11

Increase / decrease value Select menu item / set Exit submenu / menu item Key functions in the change password submenu Move cursor left / right Increase / decrease value Select menu item / change Exit submenu / menu item ARL-500 ARKEL 2010… -

Page 12

Exit submenu / menu item Key functions in the parking settings submenu Move cursor left / right To next / previous menu item Increase / decrease value Select menu item / set Exit submenu / menu item ARL-500 ARKEL 2010… -

Page 13: Display Screen