Температурные контроллеры серии TC давно присутствуют в нашем ассортименте. Приборы применяются нами для собственного производства и широко реализуются торговым подразделением. По итогам анализа наиболее часто встречающихся вопросов возникающих в ходе эксплуатации была написана эта небольшая статья.

Не будем пока рассматривать аварийные ситуации. Разберем три, наиболее часто встречающиеся ошибки, которые пользователь может устранить самостоятельно.

Первая, самая простая и частая из возникающих проблем.

Контроллер переведен в режим «STOP»

Выглядит это вот так.

Ошибкой такая надпись не является. Появляется при одновременном нажатии кнопок «Вверх» и «Вниз». Надпись означает что регулирование остановлено. Продолжение регулирования включается повторным одновременным нажатием кнопок «Вверх» и «Вниз»

Вторая по числу обращений проблема.

На контроллере появляется надпись “OPEN”.

Появление надписи означает обрыв термопары. Очень частая проблема при эксплуатации термического оборудования. Термопары при неправильном выборе или использовании в некоторых видах техпроцессов выгорают достаточно быстро.

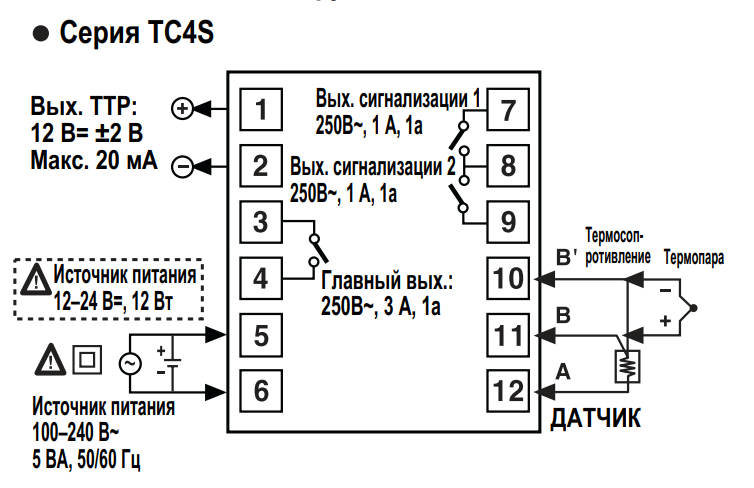

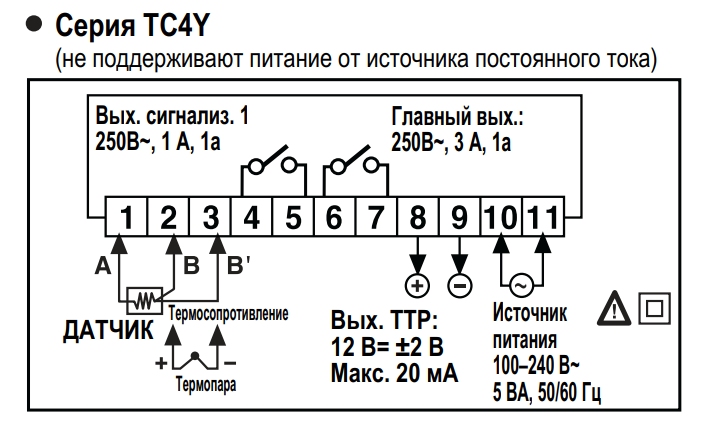

Наиболее быстрый способ диагностики – получаем доступ к колодке прибора, отключаем термопару и устанавливаем перемычку между входом 10 и 11 для серии TC4S и 2 и 3 для серии TC4Y.

Внимание! При манипуляциях – прибор должен быть отключен от сети. Соблюдайте правила техники безопасности.

Если перемычка установлена, прибор должен показывать температуру окружающей среды.

Третья ошибка. Встречается редко, но решение проблемы не описано ни в одной документации – производитель не смог догадаться что пользователь может так сделать.

Появление

ошибки вызвано нажатием кнопок управления в момент включения (очень

часто) или наличие внутренней ошибки контроллера (крайне редко).

Контроллер перешел в тестовый режим.

Решение проблемы – сбросить ошибку.

Инструкция для выхода из тестового режима температурного контроллера TC4:

1. Сначала необходимо войти в тестовый режим. Для этого надо нажать стрелку «Вверх» одновременно с включением питания. Если вы видите на экране такую же надпись как выше – вы уже находитесь в тестовом режиме.

2. Если вы нажмете «Mode» два раза – начнется тест дисплея «1111»

3. При появлении надписи «1111», последовательно нажимайте кнопку «Вверх». На экране вы увидите значения: «22.22», «444.4», «88.8.8» до появления значения «Key»

4. Когда дисплей устройства отобразит «Key», надо нажать стрелку «Вверх» и кнопку «Mode» одновременно.

5. Контроллер вышел из тестового режима.

Внимание! Все манипуляции необходимо проводить с подключенной термопарой!

Инструкции по эксплуатации на русском языке доступны в нашем файловом архиве.

Обращайтесь!

Появились вопросы? Пишите на почту support@ttpribor.ru

DRW170775AA

TEMPERATURE CONTROLLER

TC4 Series

I N S T R U C T I O N M A N U A L

Thank you for choosing our Autonics product.

Please read the following safety considerations before use.

Safety Considerations

※Please observe all safety considerations for safe and proper product operation to avoid hazards.

※Safety considerations are categorized as follows.

Warning Failure to follow these instructions may result in serious injury or death.

Caution Failure to follow these instructions may result in personal injury or product damage.

※The symbols used on the product and instruction manual represent the following

symbol represents caution due to special circumstances in which hazards may occur.

Warning

1. Fail-safe device must be installed when using the unit with machinery that may cause serious injury

or substantial economic loss. (e.g. nuclear power control, medical equipment, ships, vehicles,

railways, aircraft, combustion apparatus, safety equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in fire, personal injury, or economic loss.

2. Install on a device panel to use.

Failure to follow this instruction may result in electric shock or fire.

3. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock or fire.

4. Check ‘Connections’ before wiring.

Failure to follow this instruction may result in fire.

5. Do not disassemble or modify the unit.

Failure to follow this instruction may result in electric shock or fire.

Caution

2

1. When connecting the power input and relay output, use AWG 20(0.50mm

) cable or over and tighten

the terminal screw with a tightening torque of 0.74~0.90N . m.

When connecting the sensor input and communication cable without dedicated cable, use AWG

28~16 cable and tighten the terminal screw with a tightening torque of 0.74~0.90N . m.

Failure to follow this instruction may result in fire or malfunction due to contact failure.

2. Use the unit within the rated specifications.

Failure to follow this instruction may result in fire or product damage.

3. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in electric shock or fire.

4. Do not use the unit in the place where flammable/explosive/corrosive gas, humidity, direct sunlight,

radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in fire or explosion.

5. Keep metal chip, dust, and wire residue from flowing into the unit.

Failure to follow this instruction may result in fire or product damage.

Ordering Information

T C 4 S

1 4 R

N

Indicator — Without control output

Control output

R

Relay output+SSR drive output

2

24VAC 50/60Hz, 24-48VDC

Power supply

4

100-240VAC 50/60Hz

N

No alarm output

Sub output

1

Alarm1 output

2

Alarm1 + Alarm2 output

※2

S

DIN W48

H48mm (terminal block type)

SP

DIN W48

H48mm (11pin plug type)

Y

DIN W72

H36mm

Size

M

DIN W72

H72mm

H

DIN W48

H96mm

W

DIN W96

H48mm

L

DIN W96

H96mm

Digit

4

9999 (4 Digit)

Setting type

C

Set by touch switch

Item

T

Temperature controller

※1: In case of the AC voltage model, SSR drive output method (standard ON/OFF control, cycle control,

phase control) is available to select.

※2: It is unavailable for TC4SP, TC4Y.

※3: Sockets for TC4SP (PG-11, PS-11(N)) are sold separately.

※ The above specifications are subject to change and some models may be discontinued

without notice.

※ Be sure to follow cautions written in the instruction manual and the technical descriptions

(catalog, homepage).

Specifications

TC4 Series

Series

TC4S

TC4SP

TC4Y

TC4M

Power

AC power

100-240VACᜠ 50/60Hz

supply

AC/DC Power 24VACᜠ 50/60Hz, 24-48VDCᜡ

Allowable voltage range 90 to 110% of rated voltage

Power

AC power

Max. 5VA (100-240VAC 50/60Hz)

consumption

AC/DC Power Max. 5VA (24VAC 50/60Hz), Max. 3W (24-48VDC)

Display method

7Segment (Red), Other display (Green, Yellow, Red LED)

Character size (W×H)

7.0×15.0mm

7.4×15.0mm 9.5×20.0mm 9.5×20.0mm 7.0×14.6mm 11.0×22.0mm

Input

RTD

DPt100Ω, Cu50Ω (Allowable line resistance max.5Ω per a wire)

type

TC

K (CA), J (IC), L (IC)

At room temperature (23℃±5℃): (PV ±0.5% or ±1℃, select the higher one) ±1digit

RTD

Display

Out of room temperature range: (PV ±0.5% or ±2℃, select the higher one) ±1digit

accuracy

※1

※ For TC4SP, add ±1℃ by accuracy standard.

TC

Relay

250VACᜠ 3A 1a

Control

output

SSR

12VDCᜡ ± 2V 20mA Max.

Alarm output

AL1, AL2 Relay: 250VACᜠ 1A 1a (※TC4SP, TC4Y have AL1 only.)

Control method

ON/OFF and P, PI, PD, PID control

Hysteresis

1 to100℃/℉ (0.1 to 50.0℃/℉) variable

Proportional band (P)

0.1 to 999.9℃/℉

Integral time (I)

0 to 9999 sec.

Derivative time (D)

0 to 9999 sec.

Control period (T)

0.5 to 120.0 sec.

Manual reset

0.0 to 100.0%

Sampling period

100ms

Dielectric

AC power

2,000VAC 50/60Hz for 1min. (between input terminal and power terminal)

strength

AC/DC Power 1,000VAC 50/60Hz for 1min. (between input terminal and power terminal)

Vibration

0.75mm amplitude at frequency of 5 to 55Hz in each X, Y, Z direction for 2 hours

Mechanical

OUT: Min. 5,000,000 operations, AL1/2: Min. 5,000,000 operations

Relay

OUT: Min. 200,000 operations (250VAC 3A resistive load),

life cycle

Electrical

AL1/2: Min. 300,000 operations (250VAC 1A resistive load)

Insulation resistance

Min. 100MΩ (at 500VDC megger)

Noise immunity

Square-wave noise by noise simulator (pulse width 1㎲) ± 2KV R-phase and S-phase

Memory retention

Approx. 10 years (When using non-volatile semiconductor memory type)

Environ

Ambient temp. -10 to 50℃, Storage: -20 to 60℃

-ment

Ambient humi. 35 to 85%RH, Storage: 35 to 85%RH

Double insulation or reinforced insulation (mark:

Insulation type

measuring input part and the power part: AC power 2kV, AC/DC Power 1kV)

Approval

Approx. 141g

Approx. 123g

Approx. 174g

Approx. 204g

※2

Weight

(approx. 94g)

(approx. 76g)

(approx. 85g)

(approx. 133g)

※1: Thermocouple L (IC) type, RTD Cu50Ω

At room temperature (23℃ ±5℃): (PV ±0.5% or ±2℃, select the higher one) ±1digit

Out of room temperature range: (PV ±0.5% or ±3℃, select the higher one) ±1digit

In case of TC4SP Series, ±1℃ will be added.

※2: The weight includes packaging. The weight in parentheses is for unit only.

※Environment resistance is rated at no freezing or condensation.

Unit Description

1

1

2

3

4

2

5

8

6

7

3

5

1. Present temperature (PV) display

5. Control/alarm output indicator

RUN mode: Present temperature (PV) display.

OUT: It will turn ON when control output (Main Control

Parameter setting mode: Parameter or

Output) is ON.

parameter setting valuedisplay.

※ In case of CYCLE/PHASE control of SSR drive

output, it will turn ON when MV is over 3.0%.

2. Deviation indicator, Auto-tuning indicator

(only for AC power type)

It shows current temperature (PV) deviation

AL1/AL2: It will light up when alarm output Alarm1/

based on set temperature (SV) by LED.

Alarm2 are on.

No. PV deviation temp. Deviation display

6.

key

1

Over 2℃

indicator ON

Used when entering into parameter group, returning

2

Below ±2℃

indicator ON

to RUN mode, moving parameter, and saving setting

3

Under -2℃

indicator ON

values.

The deviation indicators (

,

,

) flash by

7. Adjustment

every 1 sec. when operating auto tuning.

Used when entering into set value change mode, digit

moving and digit up/down.

3. Set temperature (SV) indicator

Press any front key once to check or change

8. FUNCTION key

current set temperature (SV), the set

Press

+

※1

temperature (SV) indicator is ON and preset set

STOP, alarm output cancel, auto-tunning) set in inner

value is flashed.

parameter [DI-K].

※ Press

+

4. Temperature unit (℃/℉) indicator

It shows current temperature unit.

operation to move digit.

Input Sensor and Temperature Range [IN-T]

Input sensor

Display

Temperature range (℃) Temperature range (℉)

K (CA)

-50 to 1200

KCA

Thermocouple

J (IC)

-30 to 500

JIC

※3

L (IC)

LIC

-40 to 800

DPtH

-100 to 400

DPt100Ω

-100.0 to 400.0

DPtL

RTD

-50 to 200

CUsH

Cu50Ω

-50.0 to 200.0

CUsL

Installation

TC4S/SP (48

48mm) Series

TC4Y (72

36mm) Series

※ Mount the product on the panel, fasten bracket by pushing with tools as shown above.

(In case of TC4Y, fasten bolts for bracket.)

Dimensions

TC4S Series

TC4W

TC4H

TC4L

48

6

64.5

TC4Y Series

72

7

TC4M Series

72

6

64.5

Bracket

TC4S/TC4SP Series

31

48.6

20

5

45

, Dielectric strength between the

Approx. 194g

Approx. 194g

Approx. 254g

(approx. 122g)

(approx. 122g)

(approx. 155g)

15

21

55

56

6

7, 8

4

Connections

※ TC4 Series has selectable control output; Relay output, and SSR drive output.

AC/DC power type does not have SSRP function.

TC4S Series

SSR OUT:

1

7

AL1 OUT:

12VDC ±2V

250VAC 1A 1a

20mA Max

2

8

AL2 OUT:

250VAC 1A 1a

3

9

Relay OUT:

B’

RTD

250VAC 3A 1a

4

10

B

5

11

—

+

A

※1

6

12

SOURCE

SENSOR

100-240VAC 5VA 50/60Hz

24VAC 5VA 50/60Hz

24-48VDC 3W

TC4Y Series

Relay OUT:

keys for 3 sec. to operate function (RUN/

AL1 OUT:

250VAC 3A 1a

250VAC 1A 1a

1 2 3 4 5 6 7 8 9 10 11

keys at the same time in set value

A

B

B’

— +

SSR OUT:

RTD

SENSOR

12VDC ±2V

※1

SOURCE

20mA Max

100-240VAC 5VA 50/60Hz

TC

24VAC 5VA 50/60Hz

24-48VDC 3W

-58 to 2192

TC4M Series

-22 to 932

1

10

-40 to 1472

-148 to 752

2

11

-148.0 to 752.0

3

12

-58 to 392

-58.0 to 392.0

4

13

SSR OUT:

AL1 OUT:

12VDC ±2V

250VAC 1A 1a

20mA Max

5

14

AL2 OUT:

250VAC 1A 1a

6

15

Other Series

Relay OUT:

250VAC 3A 1a

B’

RTD

7

16

8

17

B

A

9

18

SOURCE

SENSOR

100-240VAC 5VA 50/60Hz

24VAC 5VA 50/60Hz

24-48VDC 3W

※Use crimp terminals or teminals of size specified below.

a b

<Round>

<Forked>

a

Min. 3.0mm

Min. 3.0mm

b

Max.5.8mm

Max.5.8mm

TC4SP Series

6

72.2

48

58.5

45

84

77

TC4H Series

48

6

64.5

Panel cut-out

TC4Y Series

30

A

60

C

TC4M, TC4W, TC4H, TC4L Series

Size

A

B

C

Model

TC4S

Min. 65

Min. 65

45

+0.6

0

TC4SP

Min. 65

Min. 65

45

+0.6

46

0

TC4Y

Min. 91

Min. 40

68

+0.7

0

TC4M

Min. 90

Min. 90

68

+0.7

0

TC4H

Min. 65

Min. 115

45

+0.6

0

TC4W

Min. 115

Min. 65

92

+0.8

0

12

TC4L

Min. 115

Min. 115

92

+0.8

0

23.9

SSR Drive Output Selection Function (SSRP Function)[SSrM]

● SSRP function is selectable one of standard ON/OFF control, cycle control, phase control by utilizing

standard SSR drive output.

TC4SP Series

● Realizing high accuracy and cost effective temperature control as linear output(cycle control and

phase control).

6

—

5

7

AL1 OUT:

● Select one of standard ON/OFF control [STND], cycle control [CYCL] , phase control [PHAS] at [SSrM]

Relay OUT

250VAC 1A 1a

parameter of Parameter group 2. For cycle control, connect zero cross turn-on SSR or random

250VAC 3A 1a

+

4

8

turn-on SSR. For phase control, connect random turn-on SSR.

SSR OUT:

12VDC ±2V

TC

RTD

B’

3

9

TC

20mA Max

—

—

Temperature controller

+

B

2

10

+

—

A

+

1

11

※1

SENSOR

SOURCE

100-240VAC 5VA 50/60Hz

24VAC 5VA 50/60Hz

24-48VDC 3W

TC4H, TC4W, TC4L Series

1

13

Power

100-240VAC

2

14

50/60Hz

3

15

※ When selecting cycle or phase control mode, the power supply for a load and a temperature

4

16

controller must be the same.

5

17

※ In case of selecting cycle [CYCL] or phase [PHAS] control mode for PID control, control cycle [T] is

not allowed to set.

6

18

※ For AC/DC power model (TC4 — 2R), this parameter [SSrM] is not displayed and it is available only

7

19

standard control by relay or SSR.

SSR OUT:

AL1 OUT:

12VDC ±2V

250VAC 1A 1a

20mA Max

8

20

1)Standard ON/OFF control [STND]

AL2 OUT:

250VAC 1A 1a

A mode to control the load in the

9

21

same way as Relay output type.

Relay OUT:

250VAC 3A 1a

B’

RTD

TC

10

22

(ON: output level 100%,

—

OFF: output level 0%)

+

B

11

23

—

+

A

2)Cycle control [CYCL]

12

24

※1

SENSOR

SOURCE

A mode to control the load by

100-240VAC 5VA 50/60Hz

24VAC 5VA 50/60Hz

repeating output ON / OFF

24-48VDC 3W

according to the rate of output

TC

※1: AC power: 100-240VAC 5VA 50/60Hz

—

within setting cycle.

AC/DC power: 24VAC 5VA 50/60Hz

+

Having improved ON / OFF noise

24-48VDC 3W

feature by Zero Cross type.

3)Phase control [PHAS]

A mode to control the load by

a

controlling the phase within

AC half cycle. Serial control is

a b

c

b

available.

<Crimp terminal>

(unit: mm)

Random turn-on SSR must be

Terminal number

a

b

c

used for this mode.

1 to N

6

Max. 1.9

Max. 4.0

(unit: mm)

TC4W Series

96

6

64.5

TC4L Series

96

6

64.5

Terminal cover (sold separately)

RSA-COVER (48×48mm)

RMA-COVER (72×72mm)

70

3

48.4

9.8

22.5

D

RHA-COVER

RLA-COVER (96×96mm )

(48×96mm, 96×48mm )

45

47.2

4

94

3

+0.6

0

45

+0.6

0

31.5

+0.5

0

68

+0.7

0

92

+0.8

0

45

+0.6

0

92

+0.8

0

SSR voltage output

SSR module

(TC4Series)

(12VDC)

Load

AC

OUT

ON

OFF

ON

OFF

AC

OUT

50Cycle

50Cycle

50%

80%

AC

OUT

10%

50%

TC Series

Output connections

See H-139 page for output.

Application of relay output type

A

TC Series

Condenser

0.1㎌

630V

Relay contact terminal

Keep A length as long as possible when wiring the

temperature controller and the load. If wire length of A is

short, counter electromotive force which occurs from a coil

of magnet switch & power relay may flow in power line of

the unit, and it may cause malfunction.

If wire length of A is short, please connect mylar

condensers 104(630V) on the both ends of «

coil) to protect electromotive force.

Simple «error» diagnosis

● When the load (Heater etc) is not operated

Please check operation of the OUT lamp located in front

panel of the unit.

If the OUT lamp does not operate, please check the

parameter of all programmed mode.

If lamp is operating, please check the output(Relay, SSR

drive voltage) after separating output line from the unit.

● When it displays OPEN during operation

This is a warning that external sensor is open.

Please turn off the power and check the wire state of the

sensor. If sensor is not open disconnect sensor line from

the unit and short the input +, — terminal. Turn on the

power of the unit and check the controller displays room

temperature.

If this unit cannot display room temperature, this unit is

broken. Please remove this unit and contact our service

center. (When the input mode is thermocouple, it is

available to display room temperature.)

H-66

Heater

Power

Magnet or

Relay contact

» (magnet

Application of SSR drive output method

TC Series

+

Voltage

output

terminal

—

※ SSR should be selected by the capacity of load,

otherwise, it may short-circuit and result in a fire. Indirect

heated should be used with SSR for efficient working.

※ Please use a cooling plate or it may cause the capability

deterioration, breakdown of SSR for a long usage.

※ Refer to the H-63 page for phase/cycle control connections.

Caution for using

● The connection wire of this unit should be separated from

the power line and high voltage line in order to prevent

from inductive noise.

● For crimp terminal, select following shaped terminal (M3)

Max. 5.8mm

● Please install power switch or circuit-breaker in order to

cut power supply off.

● The switch or circuit-breaker should be installed near by

users.

● This unit is designed for temperature controlling only. Do

not apply this unit as a voltage meter or a current meter.

● In case of using RTD sensor, 3-wire type must be used.

If you need to extend the line, 3-wires must be used

with the same thickness as the line. It might cause

temperature difference if the resistance of line is different.

● In case of making power line and input signal line close,

line filter for noise protection should be installed at power

line and input signal line should be shielded.

● Keep away from the high frequency instruments.(High

frequency welding machine & sewing machine, big

capacitive SCR controller)

● When supplying measured input, if HHHH or LLLL is

displayed, measured input may have problem. Turn off

the power and check the line.

● Installation environment

It shall be used indoor.

Altitude Max. 2000m.

Pollution Degree 2

Installation Category Ⅱ .

SSR

I

L

Power

N

O

P

A

U

D

Load power

T

Max. 5.8mm