|

|

Ремонт сервопривода Baumuller

Также для восстановления подобного промышленного оборудования понадобится хорошая материально-техническая база. При выполнении всех выше перечисленных условий, шансы на успешный ремонт сервопривода Baumuller возрастают в геометрической прогрессии.

Именно поэтому за ремонтом сервоприводов, независимо от производителя лучше всего обращаться в специализированный сервисный центр, который отвечает всем техническим требованиям, такой как Кернел. Наш цент имеет отличную материально-техническую базу, а за время существования с 2002 года специалисты компании накопили бесценный опыт в том числе опыт в ремонте сервоприводов BAUMULLER.

Особенности ремонта сервопривода Baumuller

- Аппаратная часть;

- Программная часть.

В первую очередь ремонтируется аппаратная часть промышленного сервопривода. После глубокой диагностики неисправного блока выявляются все неисправные компоненты, которые в последствии заменяются на оригинальные запасные части (по возможности), в случае если сервопривод уже давно снят с производства и найти оригинальные запчасти просто невозможно они заменяются на аналоги.

Данный вид ремонта называется компонентным. От других видов его отличает две немаловажные детали.

- Значительное удешевление ремонта;

- Существенное сокращение времени ремонта.

По завершении ремонта аппаратной части сервопривода наступает очередь программной. В зависимости от серии выбирается программный продукт и зашивается в блок.

Заключительный этап ремонта сервопривода BAUMULLER это проверка на специализированном стенде. Все блоки проверяются без нагрузки и с нагрузкой не менее двух часов.

Коды ошибок сервопривода Baumuller

При обнаружении неисправности при работе сервопривода будет активирована соответствующая защита и выведено предупреждающее сообщение на дисплей сервоуслилителя или цифрового пульта. Коды неисправностей приведены в таблице ниже.

Все коды ошибок сервоприводов Baumuller BM4400, BM4600 и BM4700 представлены в руководстве пользователя (manual) в файле ниже.

Смотреть все выводимые ошибки сервопривода Baumuller BM4400, BM4600 и BM4700.

Схемы

Схемы типовых подключений сервоприводов Baumuller

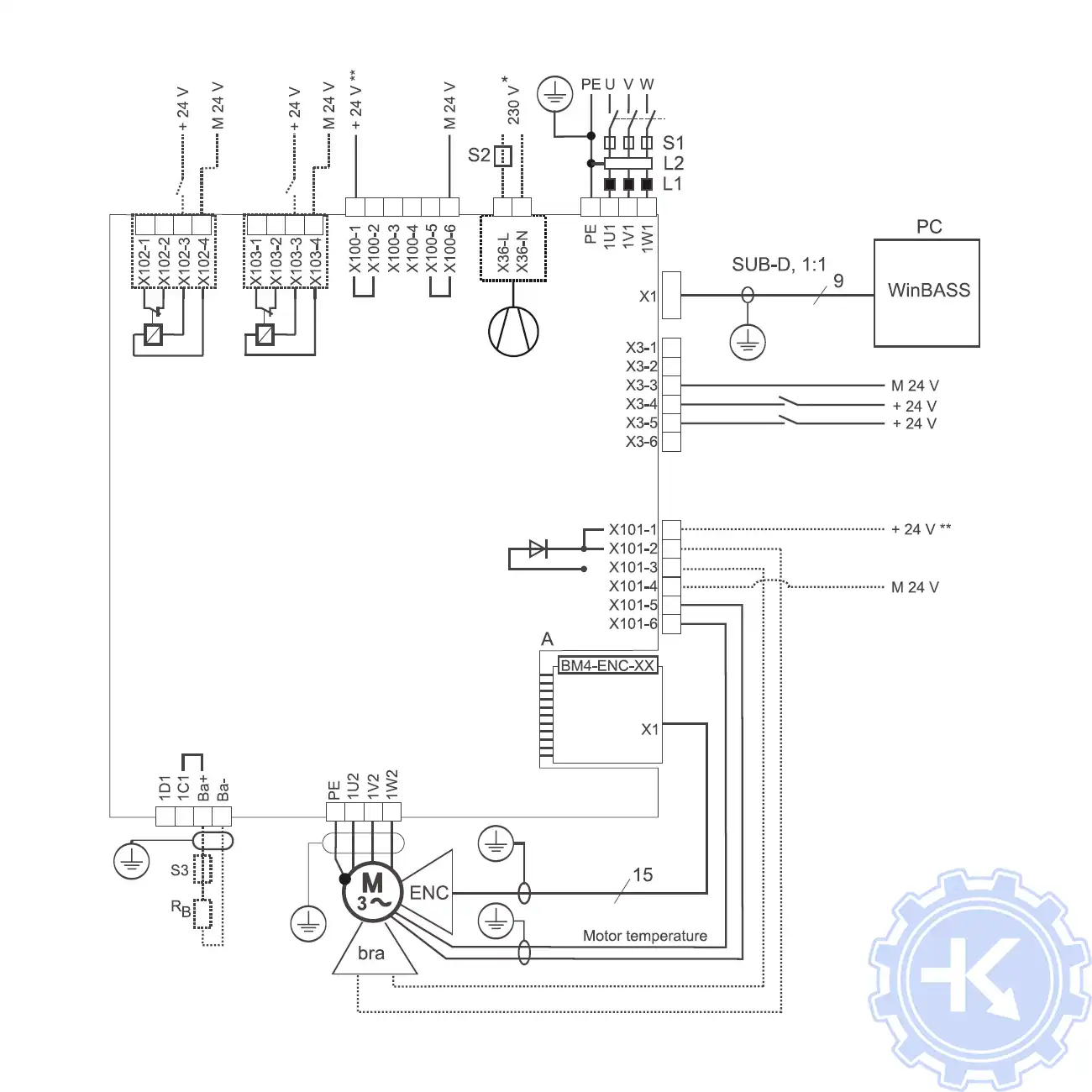

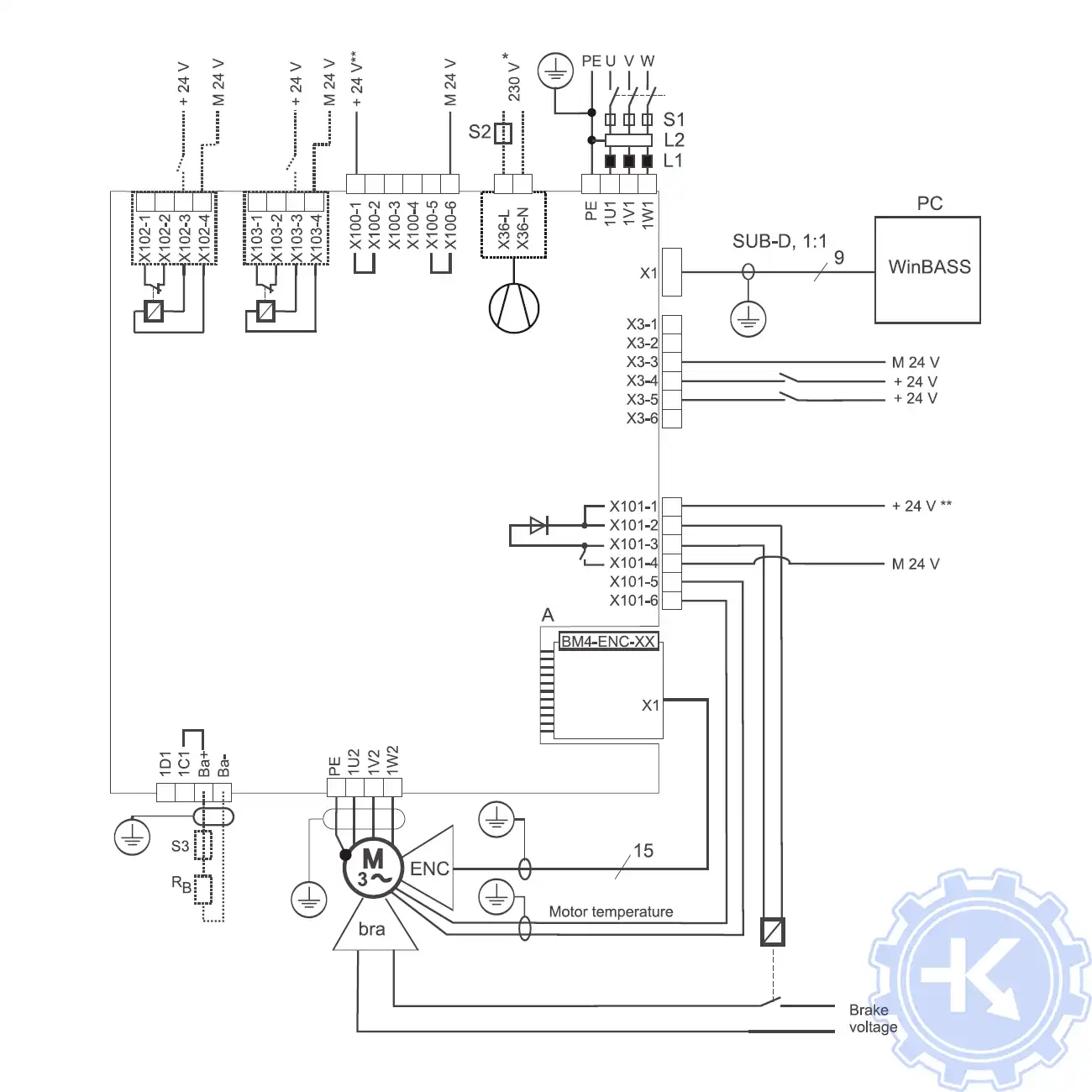

В некоторых случает может понадобится схема подключения сервоприводов, ниже мы показаны схемы сервопривода BAUMULLER b maxx.

|

Схема подключения с напрямую управляемым моторным тормозом BAUMULLER BM4400, BM4600 и BM4700 |

Схема подключения с непосредственным управлением через дополнительное реле BAUMULLER BM4400, BM4600 и BM4700 |

|

|

|

Преимущество ремонта сервоприводов Baumuller в нашем сервисном центре

Во время эксплуатации электроприводов BAUMULLER может возникнуть проблема, далеко не всегда возникшую проблему можно исправить на месте своими силами, наш сервисный центр готов вам в этом помочь, выполнив качественный ремонт сервоприводов BAUMULLER в сжатые сроки с полугодовой гарантией.

Мы не только восстановим неисправный блок, но и подскажем как действовать в той или иной ситуации для максимально долгой и безаварийной работы сервопривода.

Работы, проводимые при ремонте сервопривода Baumuller в Истиклоле:

- Предварительный осмотр на возможность восстановления бесплатный;

- Мы производим ремонт сервопривода BAUMULLER на компонентном уровне (экономия бюджета и времени)

- При ремонте сервоприводов ни каких конструктивных изменений не вносим;

- Ремонт блоков с применением оригинальных запасных частей (по возможности).

- Вы платите исключительно за результат — работающий сервопривод;

- Гарантия на ремонт сервопривода Baumuller и на запасные части замененные в процессе ремонта 6 месяцев;

- Сроки ремонта варьируются от 5 до 15 рабочих дней;

За два десятилетия существования сервисного центра нашими специалистами были успешно проведены тысячи подобных ремонтов с каждым разом поднимая квалификацию наших инженеров. Ниже представлен далеко не полный список сервоприводов BAUMULLER серии b maXX ремонтируемые в нашем сервисном центре.

|

Ремонт сервопривода Baumuller |

BM4412-ST1-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4413-ST1-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4422-ST1-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4423-ST1-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4424-ST0-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4426-ST1-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4432-Z16-01215-0309 |

|

Ремонт сервопривода Baumuller |

BM4433-SI0-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4434-SI1-01200-03-E80 |

|

Ремонт сервопривода Baumuller |

BM4435-SI0-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4443-SI-01200-03 |

В таблице представлены исключительно сервопривода BAUMULLER серии b maXX ремонт которых мы вам предлагаем, также специалисты нашей компании ремонтируют сервопривода не зависимо от серии и под каким брендом они были выпущены.

Оставить заявку на ремонт сервопривода Baumuller

У вас остались вопросы, связанные с ремонтом или сбросом ошибок, а также программированием и настройкой сервоприводов BAUMULLER? Оставьте заявку на ремонт сервопривода Baumuller в Истиклоле нашим менеджерам. Связаться с ними можно несколькими способами:

- Заказав обратный звонок (кнопка в правом нижнем углу сайта)

- Посредством чата (кнопка расположена с левой стороны сайта)

- Позвонив по номеру телефона:

- +7(8482) 79-78-54;

- +7(8482) 55-96-39;

- +7(917) 121-53-01

- Написав на электронную почту: 89171215301@mail.ru

За время существования сервисного центра нашими специалистами были отремонтированы тысячи единиц промышленной электроники. Вот далеко не полный список производителей промышленной электроники и оборудования, ремонтируемой в нашей компании.

1. Р086 включен (контроль блокировки якоря)

2. Превышено время Р087 работы привода при ограничении тока (Р014 и Р015)

3. Продолжительная работа со скоростью меньше в Р078

Maintenance

8.2

In the event of an error, parameter M error code (P124) indicates the appropriate error code. This error

is acknowledged when bit Reset disturbance in M control word (P120) is set from 0 to 1. If there is more

than one error, the system shows the next one immediately after acknowledgement.

!

Drive Manager Function Module (Error ID 00xx)

Error ID

Error Text

0001

BASS protocol timeout

hex

0003

Dual-Port RAM time-

hex

out (cyclical data)

0004

Dual-Port RAM time-

hex

out (working data)

0005

System boot procedure

hex

0010

Error switch (program

hex

error)

92

Meaning

The communications source set in

P124 has not responded for longer

than the timeout set in P128.

An error was determined while

reading the boot data set from the

EEPROM. You can get more infor-

mation about the type of error by

referring to parameter DSM Mes-

sage (P192).

This disturbance usually occurs if

you replaced the controller firm-

ware with firmware that is incom-

patible.

Only for software development

5.03047.01

Error reaction

Error reaction can be

set in P189

Inhibit pulses imme-

diately

Inhibit pulses imme-

diately

Baumüller Nürnberg Electronic GmbH & Co. KG

Remedy

Check communications

(cables, daughterboard,

etc.)

You should carefully

check the data set in the

controller’s RAM and then

program it in the EE-

PROM as the boot data

set.

V-Controller (BUS 6 VC)

Всем привет!

Начало темы вот здесь https://www.chipmaker.ru/topic/212693/

Но там в основном про станок и ЧПУ. И немного про привод.

Есть станок Gildemeister Max Muller MD3S.

Имеется шпиндельный ДПТ мощностью 25 кВт и прямой привод на шпиндель при помощи клиновидных ремней.

Управляет этим двигателем аналоговый тиристорный привод Baumuller, 400В, 100А

Со станком происходят дивные вещи.

Стабильно работал только на оборотах до 400 об/мин для вращения в обе стороны.

При попытке увеличить обороты для вращения против часовой стрелки уходил в перегрузку по току.

Для вращения по часовой стрелке работал до 600 об/мин, при больших оборотах уходил в ошибку при старте либо при остановке.

На станке есть амперметр, который показывает ток шпиндельного двигателя. Он имеет зеленую зону до 100А.

Пусковой ток:

до 300 об/мин — 10-15А

при 400 об/мин — 35-40 А

и так далее почти пропорционально оборотам

выше 1100 об/мин — стрелка подпрыгивает при пуске до 120А(красная зона). Это нормально?

Скажу сразу что с завода привод настроен так, что обороты набирает очень быстро, где-то 0,5 сек до 1800 об/мин.

Что обнаружили. Видно, что привод ведет себя по разному при вращении по часовой и против часовой стрелки.

Привод имеет две ступени тиристоров. Поменяли их местами. Проблема тоже поменялась местами.

Поменяли все тиристорные модули на новые.

Привод стабильно работает до 950 об/мин на обоих направлениях вращения одинаково.

При больших оборотах амперметр уходит в красную зону и вырубается стойка, хотя мотор можно остановить с пульта, а запустить уже нет. При оборотах более 1800 об/мин сразу уходит в защиту по току, выключается весь станок.

3-х фазная сеть у меня не шибко мощная, напряжение проседает с 380В до 355В при старте 1100 об/мин

Сегодня решили замерять ток обмотки возбуждения до 1000 об/мин. По шильдику номинальный ток 3,6А.

В реальности он больше 5А.

Привод имеет плату «регулировки поля», она регулирует напряжение и ток обмотки возбуждения.

Есть большие подозрения что она неисправна.

Может такое превышение тока обмотки возбуждения быть причиной таких сбоев?

Постараюсь выложить фото схемы и описания данной платы. Забегая вперед скажу, что все контрольные точки имеют напряжения в пределах допустимых, это те которые удалось измерить мультиметром.

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Instruction handbook

English

Language

Translation

Document No. 5.01046.06

Part No.

354844

Stand

11-Nov-2014

E

5.01046.06

Read the Manual before starting any work!

b maXX

(BM4-F-)DIO-XX

(BM4-F-)FIO-XX

Digital IO module

BM4400, BM4400 ES

BM4600, BM4600 ES

BM4700, BM4700 ES

Related Manuals for Baumuller B MaXX 4000 Series

Summary of Contents for Baumuller B MaXX 4000 Series

-

Page 1

Instruction handbook English Language Translation Document No. 5.01046.06 Part No. 354844 Stand 11-Nov-2014 b maXX (BM4-F-)DIO-XX (BM4-F-)FIO-XX Digital IO module BM4400, BM4400 ES BM4600, BM4600 ES BM4700, BM4700 ES Read the Manual before starting any work! 5.01046.06… -

Page 2

Copyright This Instruction handbook may be copied by the owner in any quantity, but only for internal use. This Instruction handbook may not be copied or reproduced, in whole or in part, for any other purposes. The use and disclosure of information contained in this Instruction handbook are not permit- ted. -

Page 3: Table Of Contents

Table of Contents General …………..Information on this Instruction handbook .

-

Page 4

Table of Contents Mounting …………..33 Preparation of mounting . -

Page 5: General

ENERAL Information on this Instruction handbook The DIO/FIO-XX or BM4-F-DIO/FIO-XX can be operated in combination with a b maXX 4000, only. Therefore this Instruction handbook is an addition to the Instruction handbook of b maXX BM4400, BM4400 ES, BM4600, BM4600 ES, BM4700, BM4700 ES (short b maXX 4000) 5.12008.

-

Page 6: Key To Symbols

Key to symbols Key to symbols Warning notes Warning notes are identified by symbols in this Instruction handbook. The notes are in- troduced by signal words that express the extent of the danger. It is imperative that these notes be complied with and are conscientiously regarded in or- der to prevent accidents, personal injury and material damage.

-

Page 7: Limitation Of Liability

General Limitation of liability All specifications and notes in these instruction handbook were compiled taking into ac- count the applicable standards and regulations, the state of the art and our knowledge and experience of many years. The manufacturer assumes no liability for damages due to: m noncompliance with the instruction handbook m usage for other than the intended purpose m usage by untrained personnel…

-

Page 8: Other Applicable Documents

Other applicable documents Other applicable documents Components of other manufacturers are integrated into the device. For these purchased parts, hazard assessments have been performed by the respective manufacturers. The compliance of the design construction with the applicable European and national regula- tions has been declared for the components by the respective manufacturers.

-

Page 9: 1.10 Used Terms

General 1.10 Used terms The term function module or the designation DIO/FIO-XX (ES controlller) or BM4-F-DIO/ FIO-XX (standard controller) is also used in this documentation for the Baumüller product „b maXX Digital IO module“. A list of the abbreviations used can be found in b maXX 4000 5.12008, Appendix A: Abbreviations.

-

Page 10

1.11 List of associated documentations Doc No. Part No. Part No. German English SERCOS slave module BM4-O-SER-01 5.04012 380910 381069 SERCOS slave module BM4-O-SER-01 parameter handbook 5.04013 381652 381653 EtherCAT slave module BM4-O-ECT-01/ECT-01 5.06003 394953 394954 Ethernet with EtherCAT master for b maXX drive PLC 5.07001 407996 407997… -

Page 11: Safety

AFETY This section provides an overview of all of the important safety aspects for optimum pro- tection of personnel as well as for the safe and problem-free operation. Contents of the Instruction Handbook Each person who is tasked with performing work on or with the device must have read and understood this Instruction Handbook and the Instruction Handbook of b maXX 4000 5.12008 before working with the device.

-

Page 12: Use, Compliant With Intended Purpose

Use, compliant with intended purpose Use, compliant with intended purpose The BM4-F-DIO/FIO-XX is used compliant with its intended purpose, if it is built-in/oper- ated within b maXX 4000 controller, only. The Digital IO module is considered as being used compliant with its intended purpose if all notes and information of this Instruction handbook and the Instruction handbook b maXX 4000 5.12008 are adhered to.

-

Page 13: Training Of The Personnel

Safety Training of the personnel WARNING! Risk of injury due to insufficient qualifications! Improper handling can lead to significant personal injury and material damage. Therefore: m Certain activities can only be performed by the persons stated in the respective chapters of this Instruction handbook. In this Instruction handbook, the following qualifications are stipulated for various areas of activity: m Operating personnel…

-

Page 14: Special Hazards

Special hazards Special hazards In the following section, the remaining marginal risks will be stated that have been iden- tified as a result of the hazard analysis. Observe the safety notes listed here and the warning notes in the further chapters of this manual to reduce health risks and dangerous situations.

-

Page 15: Fire Fighting

Safety Moving components WARNING! Risk of injury from moving components! Rotating components and/or components moving linearly can result in severe injury. Therefore: m Do not touch moving components during operation. m Do not open any covering during operation. m The amount of residual mechanical energy depends on the application. Powered components still turn/move for a certain length of time even after the power supply has been switched off.

-

Page 16: Safety Equipment

Safety equipment Safety equipment WARNING! Risk of fatal injury due to non-functional safety equipment! Safety equipment provides for the highest level of safety in a facility. Even if safety equipment makes work processes more awkward, under no circumstances may they be circumvented.

-

Page 17: 2.10 Signs And Labels

Safety 2.10 Signs and labels The following symbols and information signs are located in the working area. They refer to the immediate vicinity in which they are affixed. WARNING! Risk of injury due to illegible symbols! Over the course of time, stickers and symbols on the device can become dirty or oth- erwise unrecognizable.

-

Page 18

2.10 Signs and labels Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 Baumüller Nürnberg GmbH of 74… -

Page 19: Technical Data

ECHNICAL Electrical data DIO-01 / DIO-11 FIO-01 / FIO-11 Supply voltage 24 V (19 to 28 V) Current consumption (24 V) max. 2.0 A Current consumption (internal) max. 50 mA Number of inputs Evaluation of inputs edges (2 inputs can be used for writing on one parameter) Number of IO-linking groups input Max.

-

Page 20: Operation Conditions

Operation conditions Operation conditions The operation conditions of the BM4000, see b maXX 4000 5.12008 are valid. Transportation temperature range — 25 °C bis + 70 °C Transportation climate classification 2 K 3 EN 60721-3-2 Storage temperature range — 25 °C bis + 55 °C Storage climate classification 1 K 4 EN 60721-3-1…

-

Page 21: Design And Operation

ESIGN AND PERATION A b maXX BM4000 device consists of power unit and controller part Power unit Controller part standard controller Design cover (standard controller only) Standard controller BM4XXX-XXX-XX1XX BM4XXX-XXX-XX2XX BM4XXX-XXX-XX3XX Controller part ES controller ES controller BM4XXX-XXX-XX4XX BM4XXX-XXX-XX5XX Figure 1: b maXX BM4000) The BM4-F-DIO/FIO-XX is designed as plug-in module within the standard controller and can be replaced or upgraded.

-

Page 22: Function

Function Function The Digital IO module has inputs and outputs for digital signals in 24 V industry logic. Digital output can be obtained from the internally processed signals (e.g. for relay con- trols). Digital signals can be passed on by the inputs to the controller (e.g. switching con- tacts, etc.).

-

Page 23: Bm-F-Dio/Fio-Xx For Standard Controller

Design and Operation BM-F-DIO/FIO-XX for standard controller The BM4-F-DIO/FIO-XX is a plug-in module for the controller of b maXX 4000-series. The BM4-F-DIO/FIO-XX plug-in module is connected to the controller with a plug on its back. On the front is a 10-pole connector. Plug (back side) Module identification DIO-01…

-

Page 24

BM-F-DIO/FIO-XX for standard controller Possible combinations function modules/option modules Function modules Option modules Controller unit preferred slot Baumüller Nürnberg GmbH recommends, in order to reach the highest functional range, to insert the plug-in modules into these slots. possible slot only if the preferred slot is occupied, we recommend in order to reach the highest functional range, to insert the plug-in modules into this slot. -

Page 25: Type Plate Bm4-F-Dio/Fio-Xx For Standard Controller

Design and Operation NOTE! EtherCAT option modules must not be plugged in slot J of a 3-rowed controller unit, because the module can be damaged. In case another BM4X-X-XXX plug-in module is plugged in an unsuitable slot, it will not operate. We have made sure, that neither the module nor the device are dam- aged.

-

Page 26: Type Code Bm4-F-Dio/Fio-Xx For Standard Controller

BM-F-DIO/FIO-XX for standard controller 4.2.3 Type code BM4-F-DIO/FIO-XX for standard controller NOTE! This type code is valid for the BM4-F-DIO/FIO-XX of series b maXX 4000 exclusive- ly. For other plug-in modules are different type codes available. Type code: -F — DIO — XX Device family, in which the plug-in module can be built in — DIO — XX…

-

Page 27: Dio/Fio-Xx In Es Controller

Design and Operation DIO/FIO-XX in ES controller The DIO-XX/FIO is mounted stationary in the ES controller. e.g. DIO-01 connector position D Figure 4: DIO/FIO-XX in ES controller The controller is ordered with the desired function/option modules, these are mounted stationary (exception slot H) and cannot be changed. Only the option module in slot H can be changed/added.

-

Page 28: Position Dio/Fio-Xx In Es Controller

DIO/FIO-XX in ES controller 4.3.1 Position DIO/FIO-XX in ES controller Each position is clearly identified by a character. The DIO/FIO-XX can be used at the following position. DIO-01, DIO-11, FIO-01, FIO-11 DIO-01, DIO-11, FIO-01, FIO-11 DIO-01, DIO-11, FIO-01, FIO-11 DIO-01, DIO-11, FIO-01, FIO-11 Controller Combinations function modules/option modules Function modules…

-

Page 29: Type Plate Dio/Fio-Xx In Es Controller

Design and Operation NOTE! Only 2 analog outputs can be parametrized or linked even more than one AIO module is available. 4.3.2 Type plate DIO/FIO-XX in ES controller The type code of the DIO/FIO-XX is included in the type plate of the basic unit. 4.3.3 Type code DIO/FIO-XX in ES controller The type code has the form:…

-

Page 30

Display and operation elements Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 Baumüller Nürnberg GmbH of 74… -

Page 31: Transport And Packaging

RANSPORT AND ACKAGING What to observe when transporting For initial transport the BM4-F-DIO/FIO-XX for standard controller is packed at the man- ufacturer. If the device is to be further transported, ensure that the following conditions are met throughout the entire transport: m Climate class 2 K 3 as per EN 60721-3-2 m Temperature range — 25 °C up to + 70 °C m Vibration, shock, continuous shock class 2 M 1 as in EN 60721-3-2…

-

Page 32: Unpacking

Unpacking Unpacking After having received the still packaged device: h Avoid transport shocks and hard jolts, e.g. when putting an item down. If no transport damage is visible: h Open the packaging of the device. h Verify the delivery scope based on the delivery note. File a claim with the responsible Baumüller representative if the delivery is incomplete.

-

Page 33: Mounting

OUNTING In this chapter we describe the mechanical mounting of the plug-in module BM4-F-DIO/FIO-XX for BM4400, BM4600, BM4700 with standard controller. NOTE! The Digital IO module are mounted stationary in the BM4400, BM4600, BM4700 with ES controller and cannot be changed, therefore no mounting is necessary! Preparation of mounting h Check the marking DIO/FIO-XX, wether the right plug-in module is available.

-

Page 34: Assembly

Assembly Assembly WARNING! Danger as a result of faulty mounting! The mounting requires qualified personnel with adequate experience. Faulty mount- ing can lead to life-threatening situations or substantial material damage. Therefore: m Only allow mounting to be performed by employees of the manufacturer or by oth- er qualified personnel.

-

Page 35

Mounting 4 Turn the twist lock beyond and beneath by 90°. The twist locks now are standing horizontally. 5 Take the front panel cover towards the front off. Keep this cover. NOTICE! Note electrostatic discharge! The BM4-F-DIO/FIO-XX contains ESD sensible parts. Therefore: m Regard the described ESD procedures when handling the plug-in module. -

Page 36

Assembly Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 Baumüller Nürnberg GmbH of 74… -

Page 37: Installation

NSTALLATION In this chapter we describe the electrical installation of the DIO/FIO-XX or BM4-F-DIO/ ZMounting– FIO-XX. The mechanical mounting is described in from page 33 and not necessary with BM4400 ES, BM4600 ES and BM4700 ES. Safety notes DANGER! Risk of fatal injury from electrical current! There is an immediate risk of fatal injury if live electrical parts are contacted.

-

Page 38: Requirements On The Electrical Connection

Requirements on the electrical connection Requirements on the electrical connection NOTICE! The danger is: Electricity. In case you do not ensure the requirements to the electrical connection of the Digital IO module, the DIO/FIO-XX or BM4-F-DIO/FIO-XX can be damaged/de- stroyed. m Ensure that the electrical power connection parameters as specified in the techni- cal data are adhered to and that the connections are made in accordance with the instructions.

-

Page 39: Connection Diagrams

Installation Connection diagrams Standard controller ES controller Figure 8: Connection diagram Digital IO module Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 of 74…

-

Page 40

Connection diagrams Pin assignment Pin No. Assignment IN 1 IN 2 IN 3 IN 4 OUT 1 OUT 2 OUT 3 OUT 4 +24 V *) plug connector 10-pole M 24 V NOTE! *) limit the current to 2.5 A. (due to this also UL 508 C with a maximum current of 4 A will be considered.) Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. -

Page 41: Installation Procedure

Installation Installation procedure 1 Switch off the b maXX 4400 device and assure it against unintentional switching on during mounting. DANGER! Risk of fatal injury from electrical current! There is an immediate risk of fatal injury if live electrical parts are contacted. Therefore: m Switch off the current when any kind of work is being performed on the electrical system and ensure safety before switching on again.

-

Page 42: Internal Circuit Diagram Digital Io Module

Internal circuit diagram Digital IO module Internal circuit diagram Digital IO module Figure 9: Internal circuit of Digital IO module Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 Baumüller Nürnberg GmbH of 74…

-

Page 43: Commissioning/Operation

OMMISSIONING PERATION This commissioning assures, that the DIO/FIO-XX or BM4-F-DIO/FIO-XX has been cor- rectly recognized. Further information relating to commissioning and parameter settings of the encoder module can be found in parameter manual b maXX 4000 5.03039. Assure, that before commissioning the following preconditions are fulfilled: 1 The BM4-F-DIO/FIO-XX is correctly mounted (standard controller only).

-

Page 44: Procedure Of The Commissioning

Procedure of the commissioning NOTICE! Environmental conditions that do not meet the requirements. Environmental conditions that are non-compliant can lead to property damage. Therefore: m Ensure that the environmental conditions are kept compliant during operation (see instruction handbook b maXX 4000, operation conditions). WARNING! Risk of injury due to insufficient qualifications! Inevitably, when operating this electrical device, certain parts of this device are ener-…

-

Page 45: Prodrive Navigation

Commissioning/Operation 3 Open with ProDrive the window „Diagnosis“. Figure 10: ProDrive navigation Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 of 74…

-

Page 46: Prodrive Service

Procedure of the commissioning 4 Choose submenu „Service“ This window shows the position/slot of the recognized Digital IO module. If the Digital IO module is available in position/slot D, then the following is displayed: „Slot D Digital IO 4 Input, 4 Output Version X“. „X“…

-

Page 47: Prodrive Navigation, Submenu „Io Digital Inputs

Commissioning/Operation 7 Configuration / submenu „IO digital inputs“ Figure 12: ProDrive navigation, submenu „IO digital inputs“ 8 The submenu contains „Digital input link 1 — 4“ e.g. choose „Digital input link 2“. The window „Digital input link 2“ is opened. The inputs can be selected in the center of the window.

-

Page 48: Module Not Existent

Procedure of the commissioning 10 Check whether the text: „module not existent“ is displayed. In this case, the module was not recognized. Figure 14: Module not existent m Only if there is no message under the scale, the Digital IO module is recognized properly and can be used.

-

Page 49: Testing Of The Digital Io Module

Commissioning/Operation 8.2.2 Testing of the Digital IO module Once the plug-in module has been recognized properly, then it can be checked whether the input and outputs are working correctly using ProDrive. Pre-conditions Basic unit b maXX 4000 has been commissioned, BM4-F-DIO/FIO-XX has been plugged in or DIO/FIO-XX is available (ES controller).

-

Page 50

Procedure of the commissioning 8 Below, next to „bit-pattern at low“ click on the “…“ symbol and enter with the value „&hFFFD“ and Ok in the window which appears. The window closes again and the field under „bit pattern at low“ in the window „Digital in- put link 2“… -

Page 51: Menu „Digital Output Link

Commissioning/Operation Testing the out- We try for instance to execute the function at the digital output 1 (= Digital output link 1). puts 1 ProDrive navigation „IO digital outputs“. 2 In the project tree: „Device/configuration/IO digital outputs/digital output link 2“. 3 In the window „Digital output link 2“, by the side of „Selection output“, select „output D.2“…

-

Page 52

Procedure of the commissioning Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 Baumüller Nürnberg GmbH of 74… -

Page 53: Maintenance

AINTENANCE Safety notes Basic information WARNING! Risk of injury due to improperly performed maintenance work! Improper maintenance can lead to severe personal injury and material damage. Therefore: m Before beginning work, make sure that there is enough space for mounting. m Make sure that the mounting area is kept clean and orderly.

-

Page 54: Inspection Intervals — Maintenance Notes

Inspection intervals — maintenance notes Inspection intervals — maintenance notes Refer to Instruction handbook b maXX 4000, 5.12008. Repairs In case of device damage, please inform your sales office or: Baumüller Nürnberg GmbH Ostendstr. 80 — 90 90482 Nuremberg Germany Tel.

-

Page 55: Troubleshooting And Fault Correction

ROUBLESHOOTING AND AULT CORRECTION 10.1 Behavior in case of malfunctions Basic information DANGER! Risk of fatal injury from electrical current! Inevitably, when operating this electrical device, certain parts of it are energized with hazardous voltage. Therefore: m Pay heed to areas on the device that could be dangerous. WARNING! Risk of injury due to improper fault correction! Therefore:…

-

Page 56: Fault Detection

10.2 Fault detection 10.2 Fault detection The fault can be caused by mechanical or electrical malfunctions. LED H4 The occurrence of an error state of a device b maXX 4000 is signalled by the lighting up of the red LED H4 on the front side of the housing. NOTE! If warnings or errors occur without error reaction the LED H4 „error“…

-

Page 57

Troubleshooting and Fault correction Operating Furthermore the error message is shown in the operating software: software ProDrive h Start the operating program ProDrive (from FW 3.07), if it isn’t running yet. NOTE! The controller software version and the operating software version must be compat- ible to use ProDrive with all functions. -

Page 58: Drive Manager Prodrive

10.2 Fault detection h Select „Drive management“ The window „Drive manager“ opens, see below with an exemplary (error) message. Before the communication between controller and PC/laptop is started, the messages in in this list have been arranged in numerical order. The newly occurring messages are added to the end of the list, when communication is active.

-

Page 59: 10.3 Error Handling

Troubleshooting and Fault correction 10.3 Error handling The error messages in the system are built up hierarchically. An error message can result from a beneath in the hierarchic arranged error message. This is why the message „Error“ (level 1) can base on an error, which e. g. has appeared in „ModuleError“…

-

Page 60: 10.3.1 Error Reset

10.3 Error handling 10.3.1 Error reset If the red error LED is lighting up, there is at least one error. There are several methods to reset errors: m Via ProDrive (from FW 3.07): Button “Quit errors” (either in the dialog box “Device manager” or on the page “Device manager“.

-

Page 61: 10.3.2 Error Messages

Troubleshooting and Fault correction 10.3.2 Error messages Figure 21: Survey error list The (error) messages are displayed in ProDrive window „Drive manager“. Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 of 74…

-

Page 62

10.3 Error handling 1st level 1st level errors are only interesting for the access to errors via parameters, to be used without ProDrive, e. g. at Field bus communication. This errors are not shown in ProDrive/ 7-segment display. Bit mapping see description of the parameter P0200 in the parameter manual. 2nd level Order of the error messages see survey (ZAbbildung 21–… -

Page 63

Troubleshooting and Fault correction 3rd level error messages NOTE! 3rd level errors are only displayed in ProDrive separated by a decimal point from the ZAbbildung 21– corresponding 2nd level error (refer to auf Seite 61). e.g.: Motor error 102: Group error find notch position (2nd level) Find notch position error 102.64: Drive moved more than 4 times delta angle. -

Page 64

10.3 Error handling Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 Baumüller Nürnberg GmbH of 74… -

Page 65: Disposal

ISPOSAL NOTE! Baumüller products are not subject to the scope of application of the EU’s Waste Electrical and Electronic Equipment Directive (WEEE, 2002/96/EC). Hence, Baumüller is not obligated to bear any costs for taking back and disposing of old de- vices.

-

Page 66: Disposal Facilities/Authorities

11.2 Disposal facilities/authorities NOTICE! Avoid polluting the environment as a result of improper disposal. Therefore: m Only dispose in compliance with the health and safety regulations. m Take heed of any special local regulations. If you are unable to directly ensure safe disposal yourself, commission a suitable disposal contractor.

-

Page 67: Appendixa — Declaration Of Conformity

A — D PPENDIX ECLARATION OF ONFORMITY Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 of 74…

-

Page 68

EG — Declaration of Conformity Doc.-No: 5.14002.00 Date: 12-Mar-2014 according to EMC Directive 2004/108/EC and Low Voltage Directive 2006/95/EC The Manufacturer: Baumüller Nürnberg GmbH Ostendstraße 80-90 90482 Nuremberg, Deutschland declares that the product: Name: b maXX Type: Digital IO module b maXX BM4000 standard controller BM4-F-DIO-01, BM4-F-DIO-11, BM4-F-FIO-01, BM4-F-FIO-11 From manufacturing date: 01-May-2005 as developed, designed and manufactured in accordance with the EMC Directive 2004/108/EC and the Low Voltage Di-… -

Page 69: Table Of Figures

Table of Figures Table of Figures b maXX BM4000) ……………………Digital IO module for standard controller………………Type plate BM4-F-DIO/FIO-XX for standard controller………….. DIO/FIO-XX in ES controller …………………. BM4-F-DIO/FIO-XX for standard controller…………….Mounting ………………………. Remove insulation……………………Connection diagram Digital IO module ………………Internal circuit of Digital IO module ………………..

-

Page 70

Table of Figures Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 Baumüller Nürnberg GmbH of 74… -

Page 71: Index

Index Accidents Key to symbols Assembly LED H2 Caution LED H4 Connecting cables, requirements Limitation of liability Current consumption Customer service Maintenance Malfunctions, behavior Danger Modifications Danger areas DC link discharge time 14, 65 Design cover Note Diagnosis Discharge, electrostatic Disposal 8, 65 Operating instructions, contents…

-

Page 72

Index Technical data Temperature range Testing the inputs Testing the outputs Transport inspection Troubleshooting Twist lock Type code ES controller Type of plug-in module Type plate ES controller Standard controller Unpacking Use, compliant with indented purpose Warning Warning notes Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. -

Page 73: Overview Of Revisions

Overview of Revisions Overview of Revisions Version Status Changes 5.01046.06 11-Nov-2014 Revision because of ES controller Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 of 74…

-

Page 74

Notes: Instruction handbook b maXX (BM4-F-)DIO/FIO-XX (Digital IO module) Document No. 5.01046.06 Baumüller Nürnberg GmbH of 74… -

Page 76

Baumüller Nürnberg GmbH Ostendstraße 80-90 90482 Nürnberg T: +49(0)911-5432-0 F: +49(0)911-5432-130 www.baumueller.de All information given in this manual is customer information, subject to change without notice. We reserve the right to futher develop and actualize our products continuously using our permanent revision service. Please notice, that specifications/data/information are current values according to the printing date. These statements are not legally binding according to the measurement, computation and calculations.