Коды ошибок, актуальные для Canon imagePROGRAF iPF670, iPF605, iPF770, iPF750, iPF710, iPF650, iPF700, iPF785, iPF610, iPF765, iPF680, iPF760, iPF510, iPF780, iPF600, iPF500, iPF685, iPF720, iPF670e, iPF671, iPF671e (для картриджей PFI-102, PFI-104, PFI-107).

Check printing results

Call for service.

Call for service.

После проверки датчика деталей в сервисном меню, замените деталь, указанную в ошибке.

Проверьте загруженные данные перед повтором печати.

Проверьте количество бумаги.

Exchange for the compatible paper to HP-GL/2.

The memory is full.

Check if there is the non-image area of the print. Verify the transmitted data before reprinting.

The memory is full.

The memory is full.

The parameter is out of range.

Verify the transmitted data before reprinting.

This command is not supported.

Delete unwanted data

Delete unneeded jobs stored in Personal Boxes.

Now printing without saving data.

Delete unneeded jobs stored in Personal Boxs.

Prepare to replace the ink.

Renew the C ink tank

Prepare to replace the ink.

Renew the M ink tank.

Prepare to replace the ink.

Renew the Y ink tank.

Prepare to replace the ink.

Renew the MBK ink tank.

Prepare to replace the ink.

Renew the BK ink tank.

Replace the ink tank.

Renew the C ink tank.

Replace the ink tank.

Renew the M ink tank.

Replace the ink tank.

Renew the Y ink tank.

Replace the ink tank.

Renew the MBK ink tank.

Replace the ink tank.

Renew the BK ink tank.

Check ink tank.

Attach the C ink tank.

Check ink tank.

Attach the M ink tank.

Check ink tank.

Attach the Y ink tank.

Check ink tank.

Attach the MBK ink tank.

Check ink tank.

Attach the BK ink tank.

Check the media size check. Change the media size.

Delete unwanted data.

Press the stop button to cancel the print job. Delete print jobs from the queue.

Delete unneeded jobs stored on the hard disk.

Press Online to clear error.

Clean the printhead. Identify the nozzles in a nozzle check pattern. Replace the printhead.

Lift the release lever and reload the paper.

Check the leading end of paper. Reload the paper.

Lift the release lever and align leading edge with orange line.

Check the sheet length. Check to see if paper has not jammed.

Lift the release lever and reload the paper.

Check the right edge of paper. Check the paper type.

Lift the release lever and reload the paper.

Check the left edge of paper.

Check the paper type.

Press Online to clear the error and readjust printhead.

Check the paper on which a pattern is printed for smears. Check the environment for interferences from outside light.

Clean the printhead.

Press Online to clear the error and readjust printhead.

Check the paper on which a pattern is printed for smears. Check the environment for interferences from outside light.

Clean the printhead.

Lift the release lever and replace paper with A4/ LTR (vertical) or larger.

Replace with A4/Letter or any larger-sized paper.

Lift the release lever and replace paper with A3/ Ledger (vertical) or larger.

Replace with A3/11″x17″ or any larger-sized paper.

Lift the release lever and replace roll with 10 in. wide or larger roll.

Replace with roll media at least 10 inches in width.

Remove paper and press Load/Eject.

Remove the paper jam and reload the paper.

Lift the release lever and reload paper.

Reload the paper.

Check supported paper sizes.

Replace with larger-sized paper.

Check supported paper sizes.

Replace with smaller-sized paper.

Press Online to clear the error.

Replace with adjustable media.

Lift the release lever.

Correct the skew in the paper and reload it.

Reload paper.

Reload the paper

Press Load/Eject and reload the paper.

Reload the paper

Lift the release lever and reload the paper.

Reload the roll media.

Press Online to clear the error.

Check to see if paper has not jammed.

Press Load/Eject and load sheets.

Load cut sheets at the paper tray port.

Press OK, remove the sheets, and load a roll.

Replace with roll media.

Press Load/Eject and load a roll.

Load roll media.

Turn printer off and install roll feed unit.

Install the roll media unit.

Lift the release lever and replace the roll.

Renew the supply of roll media.

Press Load/Eject and reload the paper.

Check the type of paper that can be fed and reload the paper.

Press Load/Eject and remove the roll.

Load cut sheets at the paper tray port.

03130031-2E23

Turn off printer, wait, then turn on again.

Check the cutter unit.

03130031-2E14

Turn off printer, wait, then turn on again.

Replace the main controller PCB

03130031-2E16

Turn off printer, wait, then turn on again.

Check the mist fan.

03130031-2E17

Turn off printer, wait, then turn on again.

Check the suction fan.

03130031-2E20

Turn off printer, wait, then turn on again.

Check the purge unit.

03130031-2E22

Turn off printer, wait, then turn on again.

Check the purge unit.

03130031-2E23

Turn off printer, wait, then turn on again.

Check the purge unit.

03130031-2E25

Turn off printer, wait, then turn on again.

Check the carriage unit. Check the linear encoder for smears.

03130031-2E26

Turn off printer, wait, then turn on again.

Check the carriage unit and surrounding parts.

03130031-2E27

Turn off printer, wait, then turn on again.

Check the carriage unit and surrounding parts.

03130031-2E1F

Turn off printer, wait, then turn on again.

Check the purge unit.

03130031-2E2A

Turn off printer, wait, then turn on again.

Check the feed roller encoder and surrounding part. Check to see if paper has not jammed.

03130031-2E29

Turn off printer, wait, then turn on again.

Check the roll feed unit. Check roll media. Check to see if paper has not jammed in the printer.

03130031-2E2E

Turn off printer, wait, then turn on again.

Check the roll feed unit.

03130031-4027

Turn off printer, wait, then turn on again.

Check the carriage unit and surrounding parts.

03130031-2E13

Turn off printer, wait, then turn on again.

03130031-2F32

Turn off printer, wait, then turn on again.

Replace the multi sensor unit.

03130031-2F3A

Turn off printer, wait, then turn on again.

Check the ink supply unit.

03130031-2F3B

Turn off printer, wait, then turn on again.

Remove the ink tanks and then reload them. Check the main controller PCB.

03130031-2F70

Turn off printer, wait, then turn on again.

03130031-2F71

Turn off printer, wait, then turn on again.

03130031-2F72

Turn off printer, wait, then turn on again.

03130031-260E

Turn off printer, wait, then turn on again.

Check the carriage unit and surrounding parts. Replace the main controller PCB.

03130031-2618

Turn off printer, wait, then turn on again.

Check the power supply unit.

03130031-260F

Turn off printer, wait, then turn on again.

Turn off printer and check roll feed unit

Replace the roll feed unit.

Turn off printer, wait a while, then turn it on again.

Transmit valid ROM data.

Turn off printer, wait a while, then turn it on again.

Verify the validity of MID data before transferring it.

03130031-2F2B

Turn off printer, wait, then turn on again.

Open top cover and replace the printhead.

Replace printhead

Open top cover and replace the right printhead.

Replace printhead

Open top cover and replace the right printhead.

Replace printhead

03800500-2F40

Turn off printer, wait, then turn on again.

Проверьте блок очистки печатающей головки и окружающие детали.

Проверьте датчик управления головкой и окружающие детали.

Убедитесь, что печатающая головка установлена правильно.

Если визуально все чисто и корректно подключено, нужно пробовать:

Заменить датчик управления головкой.

Заменить главную плату контроллера.

Замените печатающую головку.

Замените каретку.

03800500-2F2F

Turn off printer, wait, then turn on again.

Замените датчик управления печатающей головкой.

Замените печатающую головку.

Identify the head management sensor unit

Replace the head management sensor unit

Replace the printhead

03800500-2F30

Turn off printer, wait, then turn on again.

Замените датчик управления печатающей головкой.

Замените печатающую головку.

Identify the head management sensor unit

Replace the head management sensor unit

Replace the printhead

Press OK and replace ink tank.

Renew the Bk ink tank

Press OK and replace ink tank.

Renew the Y ink tank

Press OK and replace ink tank.

Renew the M ink tank

Press OK and replace ink tank.

Renew the C ink tank

Press OK and replace ink tank.

Renew the MBk ink tank

Press OK and replace ink tank.

Renew the MBk ink tank

Press OK and replace ink tank.

Replace with a fully replenished Bk ink tank

Press OK and replace ink tank.

Replace with a fully replenished Y ink tank

Press OK and replace ink tank.

Replace with a fully replenished M ink tank

Press OK and replace ink tank.

Replace with a fully replenished C ink tank

Press OK and replace ink tank.

Replace with a fully replenished MBk ink tank

Press OK and replace ink tank.

Replace with a fully replenished Bk ink tank

Press OK and replace ink tank.

Replace with a fully replenished Y ink tank

Press OK and replace ink tank.

Replace with a fully replenished M ink tank

Press OK and replace ink tank.

Replace with a fully replenished C ink tank

Press OK and replace ink tank.

Replace with a fully replenished MBk ink tank

Press OK and replace ink tank.

Replace with a valid Bk ink tank

Press OK and replace ink tank.

Replace with a valid Y ink tank

Press OK and replace ink tank.

Replace with a valid M ink tank

Press OK and replace ink tank.

Replace with a valid C ink tank

Press OK and replace ink tank.

Replace with a valid MBk ink tank

Press OK and replace ink tank.

Replace with a valid MBk ink tank

Press OK and check ink tank.

Install a Bk ink tank

Press OK and check ink tank.

Install a Y ink tank

Press OK and check ink tank.

Install a M ink tank

Press OK and check ink tank.

Install a C ink tank

Press OK and check ink tank.

Install a MBk ink tank

Press OK and check ink tank.

Install a MBk ink tank

Turn off printer, wait a while, and turn it on again.

Close the top cover and turn on the printer again.

Turn off printer, wait a while, and turn it on again.

Close the ink tank cover and turn on the printer again.

Replace the maintenance cartridge.

Renew the maintenance cartridge.

Cartridge capacity.

Replace the maintenance cartridge.

Replace the maintenance cartridge.

Replace the maintenance cartridge.

Renew the maintenance cartridge.

Replace the maintenance cartridge.

Renew the maintenance cartridge.

Check roll position.

Online: Print Load/Eject:

Change Paper

Check to see if a borderless printing spacer is installed. Reload the paper.

Check paper size setting.

Online: Print

Load/Eject: Change Paper

Check the paper size. Change the paper size.

Online: Print

Stop: Stop Printing

Load/Eject: Change Paper

Renew the supply of roll media.

Lift the release lever and reload the paper.

Cut paper manually. Check the cutter.

Press Online to clear the error.

Check the multi sensor.

Check the head management sensor.

Online: Print

Stop: Stop Printing

Load/Eject: Change Paper

Exchange for the compatible paper to HP-GL/2 before reprinting.

Delete unwanted data on your computer to resume printing.

Press Stop to cancel printing.

Delete unneeded jobs stored in Personal Boxes.

Cannot save. Delete unwanted data on your computer to resume printing.

Press Stop to cancel printing.

Press OK to reformat

Press the [OK] button to start reformatting the hard disk. When formatting is finished, the printer automatically restarts.

Turn off printer, wait a while, and turn it on again.

Invalid files will be deleted.

Restart the printer. Only the corrupted files will be deleted, and the printer will restart.

Turn off printer, wait, then turn on again.

Check the head management sensor. Replace the head management sensor. Replace the printhead.

Turn off printer, wait, then turn on again.

Check the pinch roller and surrounding part. Replace the pinch roller pressure drive unit.

Install printhead.

Install the printhead.

Replace the printhead.

Check the maintenance cartridge.

Install the maintenance cartridge.

Lift the release lever and reload the paper.

Check the cutter unit and surrounding part. Replace the cutter.

Renew the supply of roll media.

Manually rewind roll all the way and press OK.

Check the pick-up unit and roll media. Check to see if paper has not jammed.

Load cut sheets at the paper tray port.

Check the media size. Change the media size.

Confirm usage cond. of the paper.

Reload the paper.

Reload the roll media.

Hardware error 03130031-2F26 is a carriage motion error. In this blog, you will learn how to troubleshoot this error. Please be sure to carefully follow the instructions, as any deviation may cause further (potentially expensive) damage.

What The Code Means

Error 2F26 displays a message on the printer that says «Power On Again Carriage Motion Error».

The longer explanation is «Carriage operation disabled. A PWM duty of 100% has lasted for 200 msec in a carriage operation. A collision has been detected in a carriage operation (with the speed predicted from the PWM output valve having a deviation of 25 ips or more from the actual speed».

Yea, that one confuses us too, and we are certified technicians.

Here are the actual causes:

- If the motor could not be run at all or has resulted in an error after moving by a slight distance.

- A mechanical load error may be suspected

- The motor or drive circuit may be at fault

- If the carriage has run more or less out of control and resulted in an error, the encoder sensor may be at fault

How To Fix It

Before trying anything, we always recommend lifting the top cover to be sure there are no paper jams, and the carriage is securely in place on the right side of the printer.

Once you have verified the above information, power cycle the printer.

If the error has cleared, you are finished with this troubleshoot.

Error Has Not Cleared

The possible causes can vary. Here are 4 scenarios:

- Heavy load to the carriage drive function — this is caused by dirt on the carriage shaft, not enough tension of the carriage belt, or a foreign object.

- Electrical trouble on the carriage drive function — caused by abnormal electrical signals or voltage, not connected properly between cable and connector, or trouble on the carriage motor.

- Trouble on the linear encoder strip — caused by dirt or a scratch on the linear encoder strip, the carriage belt does not sit properly or keep enough tension, or a crack on the flexible cable/not connected properly

- Trouble on the purge unit — can not unlock the carriage unit, capping sequence can not be done properly, or cannot detect the current condition of the purge unit.

Search Error Code Here

Easily Search For Individual Error Codes Using The Search Field Above. Contact Us If you are Having Difficulty Finding Your Code.

Check the following:

- Where the carriage unit is. There may be a defective purge unit if it is at the extreme left position.

- Check if the carriage unit moves smoothly

- Check if there is an unexpected vertical uneven line around the leading edge

- Check how the carriage unit works initializing (need the latest version of the firmware)

- Check if the linear encoder strip sits properly

- Check if there is damage to the linear encoder strip

- The carriage unit does not sit on proper position even though the locking pin is in position

If The Error Does Not Clear

A technician can verify the specific type of error in service mode. It is not recommended for «end users» to enter service mode, however, on printer models that have become unsupported by the manufacturer, it may be necessary.

We discourage anyone from making any repairs without proper training and knowledge. Ignoring our recommendation could result in severe injury or death. However, if your model is no longer supported, the following information may be helpful.

Old Printers vs. New Computers

Depending on its age, your printer may simply not be worth repairing. Older models may not have compatible drivers for new computers and operating systems.

For information on Canon’s current line of new large format printers, please see the link to the right.

2F26 isn’t my error code!

If 2F26 is not the error code displayed on your screen, please see our blog post that lists all the possible 03133310 error codes so you can learn more about your specific error.

Ron Rodgers is an Imaging Ace & Print Industry Hotshot with a passion for helping people turn print into profit! Aside from being the founder of ProPrinting Systems, he is a marketing machine, funtrepreneur (like entrepreneur but more fun), blogger, YouTuber, podcaster, musician, husband, father, sales expert, and all-around nice guy.

Related Posts

About Ron Rodgers

Ron Rodgers is an Imaging Ace & Print Industry Hotshot with a passion for helping people turn print into profit! Aside from being the founder of ProPrinting Systems, he is a marketing machine, funtrepreneur (like entrepreneur but more fun), blogger, YouTuber, podcaster, musician, husband, father, sales expert, and all-around nice guy.

This post is simply more about adding some useful info in the archives since I’m not asking for help, but sharing my issue and fix.

The history of my printer is that from an early age, it had to have its main board and carriage replaced twice, yes, twice. It developed a problem in a channel that a new head didn’t fix. So a new carriage was installed, and although it brought some nozzles back in the channel, it was still clearly bad. So then a new main board was installed, but this too didn’t solve the problem. As it so happens, the original problem was more than likely the main board, and so when the new carriage was installed, the bad main board fried it. When the new board was installed, the new carriage was unfortunately already fried, so it was no good now as well, even though it was new. After a new main board, the second one, and a new carriage, also a second one, and two new heads, everything was back to normal.

Fast forward over a year, and the printer started to get this error code. «03130031-2F26» Reading the manual, it states that the carriage is inoperable and to check the surrounding parts, etc. Along with this, it also says to check the encoder strip and linear scale. There are hardly any posts anywhere with this error code, and the fix usually was the linear scale, but mine looked good.

The other error code I would get was 03130031-2F13 , which states «A/D converter external trigger output stop detection hardware error 1», and once again «Check the carriage unit and surrounding parts.»

One thing I noted was that this happened less when the printer was warm. So sure enough, I kept making sure the printer was very warm before using it. If the printer stops suddenly and displays this, I would have to go into service mode, do a nozzle check, go to regular mode, have it do this test where it runs the carriage back and forth for 5 minutes or more, and hope and pray it worked. For the most part, after it got going it was fine, but it was a struggle sometimes.

Fast forward to a month ago. I read all the printer posts here and am amazed by the guys fixing their HP 3100’s with the excellent help that Mark Lindquist is providing. It just so happened that I watched the video on replacing the belt, and noticed that they were oiling the carriage rod. I remember when the 2 techs were replacing my carriage unit and I asked about oiling and they said its not necessary. They were very careful to not damage it when they removed it, but all they did was install the new carriage unit after putting it back carefully. I also noticed that it had these felt pads, so I figured maybe the felt pads are pre-oiled, so each new carriage unit would also lubricate the rod.

So as I had this in my head, and looking at my error codes, I also came across some stuff that said these error codes have something to do with a timeout, or too much current draw on the motor that is moving the carriage. It always stops in the exact same place with a loud thump, but not because its hitting something, but just because the motor stops suddenly. It usually wouldn’t do it during loading paper, but it would do it just before printing, and it would never do it in service mode, although all you can do is print out nozzle checks and stuff. But still, it was some kind of software thing where unless its printing, it wasn’t monitoring some values. Also, given that it works much better when warm, although even this wasn’t as successful after many months as it used to be, it occurred to me that maybe what is going on is that too much friction is causing the motor to work a little harder, which spikes the voltage, and bam, error code and shut down. When its warm, either the little bit of lubricant that is there is more viscous, or the parts slightly expand from the heat, just enough to make it slide smoother.

So after lots of research, I decided that sewing machine oil should be good enough. I applied it just like in the video on my carriage rod, and for a few weeks now, I have not seen the error code again. Before, it would come up almost every time before doing a print until it warmed up enough to get it going.

I figure its very rare for a carriage to be replaced twice, and so whatever lubricant is put on the rod from the factory is enough for the life of the printer, but in my case, those felt pads probably soaked up whatever was there, as opposed to lubricating it some more, and it clearly needed more. I would have liked to get the special oil, since mine is only a $6 bottle that is sewing machine oil and I’m not even sure if its 100% syntethic, but I just didn’t want to initially spend $50 on a bottle, just in case it didn’t help it any more. Now I’m not sure if I should get better stuff, but this is certainly doing the trick.

I hope if someone ever has this error code come up, this posts helps them out!

Правила форума

Картинки и фотографии (если они нужны в сообщении) надо загружать только как вложения к своему сообщению (через кнопку Добавить файлы). Тогда картинки будут автоматически отображаться в сообщении.

-

Носки деда

- Сообщения: 5

- Стаж: 6 месяцев

- Благодарил (а): 1 раз

Ошибка canon ipf815 03130031-2618

Сообщение

Носки деда » 16 ноя 2022, 06:41

Добрый день! Помогите с плоттером, до этой ошибки жаловался что нужно заменить печатающую головку, путём сервисного меню ошибка сбрасывалась, до момента этой ошибки 03130031-2618, головку новую купили, но ничего не изменилось. в сервисное меню не заходит, выдаёт эту ошибку

-

Носки деда

- Сообщения: 5

- Стаж: 6 месяцев

- Благодарил (а): 1 раз

Ошибка canon ipf815 03130031-2618

Сообщение

Носки деда » 16 ноя 2022, 08:46

Goldwater писал(а): ↑16 ноя 2022, 08:14

Чем помочь? Приехаь починить? Почитать на ночь сервис-мануал?

есть ли он? есть только на ipf710, технически они совершенно разные. Просто может ктото сталкивался, или есть сервис мануал на ipf815

Отправлено спустя 51 минуту 47 секунд:

нашел на ipf810 0313xxxx-xxxx Sensors, fans, motors error

-

nicksun

- Сообщения: 160

- Стаж: 1 год 4 месяца

- Откуда: Ставрополь

- Благодарил (а): 7 раз

- Поблагодарили: 29 раз

-

Репутация:

Ошибка canon ipf815 03130031-2618

Сообщение

nicksun » 16 ноя 2022, 09:42

03130031-2618-VH voltage error

Короткое замыкание в ПГ. Следом за ПГ могла полететь главная плата. Перед установкой новой ПГ, надо было проверить на главной плате сборку R3501 (по крайней мере на 710 так было, тут думаю не сильно много изменений), транзистор Q3601. если элементы пробиты, то менять плату вместе с ПГ. Можно попробовать оживить.

Возможно сгоревший пред на 7А на Carriage relay PCB

-

Носки деда

- Сообщения: 5

- Стаж: 6 месяцев

- Благодарил (а): 1 раз

Ошибка canon ipf815 03130031-2618

Сообщение

Носки деда » 16 ноя 2022, 10:23

nicksun писал(а): ↑16 ноя 2022, 09:42

03130031-2618-VH voltage error

Короткое замыкание в ПГ. Следом за ПГ могла полететь главная плата. Перед установкой новой ПГ, надо было проверить на главной плате сборку R3501 (по крайней мере на 710 так было, тут думаю не сильно много изменений), транзистор Q3601. если элементы пробиты, то менять плату вместе с ПГ. Можно попробовать оживить.

Возможно сгоревший пред на 7А на Carriage relay PCB

сегодня разберу, погляжу. нашел вроде где она стоит

- Скриншот 16-11-2022 12.23.25.png (57.85 КБ) 317 просмотров

-

- 12 Ответы

- 1242 Просмотры

-

Последнее сообщение

09 фев 2022, 10:10

-

- 3 Ответы

- 436 Просмотры

-

Последнее сообщение

12 сен 2022, 10:28

-

- 6 Ответы

- 1160 Просмотры

-

Последнее сообщение

13 янв 2022, 22:27

-

- 10 Ответы

- 404 Просмотры

-

Последнее сообщение

04 апр 2022, 18:20

-

- 0 Ответы

- 119 Просмотры

-

Последнее сообщение

11 май 2022, 21:49

Canon imagePROGRAF Hardware Error 03130031 Introduction

When your Canon imagePROGRAF Plotter is stuck with an on-screen hardware error 0313003, you need to call the service center to get assistance to get your Canon large format printer back into working state. In this printer service guide, we will give you some ideas to decode Hardware Error 03130031 and its subcodes of the 4 digits in the end. You can Buy Printer Spare Parts from here

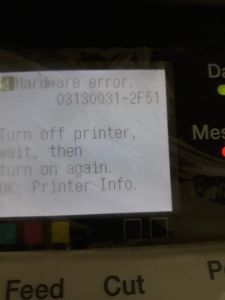

Decoding the Error 03130031

Since we have detailed documentation about this error, it will be easier for you to diagnose the error. The hard part is, this error is closely related to the ‘print head’ and in most cases, you need to replace it to fix the plotter. To diagnose the error in the right way, we need subcode, which is the last four characters of the error code followed by 03130031, for example, ‘2F51’. The whole error code will look like this, 03130031-2F51. Ca’t find the subcode? Contact us for plotter repair in Dubai

Now you know how to find the sub error code, But how to understand the meaning of the 4-digit code followed by 03130031?

Fixing HP Designjet plotter error codes

Hardware Error 03130031 Codes and their Meaning

The 03130031-[Sub Code] error codes are about 45 variants. They all have different meanings and here is how to clear/fix them.

Below are the list of Hardware Error 03130031 Codes

03130031-260E – Gap detection failure

03130031-2618 – VH voltage error

03130031-290A – HDD not connected/not detected

03130031-291B – Lift shift timeout

03130031-291D – Spur cam sensor detector failure

03130031-2E23 – Cutter unit failure

03130031-2F13 – A/D converter external trigger output stop

03130031-2F14 – ASIC register not writable

03130031-2F16 – Mist fan error

03130031-2F17 – Platen fan lock detection error

03130031-2F1F – Purge sensor error

03130031-2F20 – Cap motor cam positioning error

03130031-2F22 – Pump shift timeout

03130031-2F23 – Purge motor error

03130031-2F24 – Cutter shift timeout error

03130031-2F25 – Carriage motor HP not detectable

03130031-2F26 – Carriage Motion Error

03130031-2F27 – Carriage shift timeout

03130031-2F28 – Lift shift timeout

03130031-2F2A – Cannot detect the LF home position

03130031-2F2B – LF operation failure

03130031-2F2C – Cassette shift timeout

03130031-2F2E – Roll shift timeout

03130031-2F3A – Ink supply valve open/close monitor timeout

03130031-2F3B – CS communication error

03130031-2F3C – LP nip sensor error

03130031-2F3D – HP pre-ejection pump motor overload error

03130031-2F3E – HP pre-ejection pump motor shift timeout

03130031-2F3F – An error other than overload error or shift timeout error

03130031-2F46 – The shutter HP sensor did not respond at startup

03130031-2F48 – VHT (heater drive power supply for printhead) error

03130031-2F49 – Left side printhead

03130031-2F4A – Main controller PCB error

03130031-2F4D – VHT leak detection error of left printhead

03130031-2F4E – VHT leak detection error of right printhead

03130031-2F4F – VHT leak detection error of left and right printhead or a single printhead

03130031-2F50 – Right side printhead

03130031-2F51 – Both printheads

03130031-2F52 – Detect that a carriage unit of a legacy model has been mounted

03130031-2F53 – Supply valve motor error of the left ink tank

03130031-2F54 – Supply valve motor error of the right ink tank

03130031-2F6C – Failed self-testing

03130031-2F70 – Indication at ink priming error in both sub tanks

03130031-2F71 – Indication at ink priming error in the left sub tank

03130031-2F72 – Indication at ink priming error in the right sub tank

03130031-4027 – Lift shift timeout error

How to fix Canon imagePROGRAF Hardware Error 03130031

Fixing Canon imagePROGRAF Hardware Error 03130031 can be a simple power-cycle or a replacement of very expensive spare parts. The first thing you need to do is to make sure there isn’t any paper stuck inside the Canon imagePROGRAF Plotter. And that the carriage assembly is in the docked state on the right side hand side of the plotter. You can verify this by opening the top cover or the Canon imagePROGRAF Plotter.

The second step is to turn off the Canon Plotter by pressing the power button. You should NEVER unplug the Plotter power code while it is ‘ON’. Once you turn the power off, turn the plotter ‘ON’ in the usual way. If it clears the error message, consider you are lucky and continue your print job as usual.

If the steps as mentioned above, don’t fix the error, you will need to may need to call Plotter Service Center in Dubai.

Cube’about Technology LLC. has been rated

4.5 out of

5 based on

4 reviews as of May 2018. —

Read all customer reviews.

-

09-01-2015

#1

Technician

- Rep Power

- 16

Canon IPF750 hardware error 03130031-2F26

Hi

I own a Canon IPF750 witch has a error

03130031-2F26.When i power on the printer, it starts to initialize and then the printhead moves to the left for a distance like abouth 80 cm.

This is the distance from the starting point completely from the right side.

When i shut down the printer and move the printhead like 15 cm to the left from the starting point and the turn on the printer again, then the printhead also moves about the same distance to the left. So 80 cm + 15 cm. When the printhead starts from the middle then it moves also to left with a big clunck at the end of the movement (banging against the end of the rail).I have cleaned the transport rail and checked the optical ribbon for stains or other malicious substances.

The weird thing is, that the distance the head moves is almost always exactly the same (like abouth 80 cm).

Also i cant seem to enter service mode to update the firmware wich is needed to do the upgrade.I have disassembled the printhead to see if there is no durt or stains on the optical sensor and/or if the ribbon cables are not broken.

I don’t see any breaks in the cable (not visually).All suggestions are welcome.

Roverius

-

09-01-2015

#2

Re: Canon IPF750 hardware error 03130031-2F26

Originally Posted by Roverius

Hi

I own a Canon IPF750 witch has a error

03130031-2F26.When i power on the printer, it starts to initialize and then the printhead moves to the left for a distance like abouth 80 cm.

This is the distance from the starting point completely from the right side.

When i shut down the printer and move the printhead like 15 cm to the left from the starting point and the turn on the printer again, then the printhead also moves about the same distance to the left. So 80 cm + 15 cm. When the printhead starts from the middle then it moves also to left with a big clunck at the end of the movement (banging against the end of the rail).I have cleaned the transport rail and checked the optical ribbon for stains or other malicious substances.

The weird thing is, that the distance the head moves is almost always exactly the same (like abouth 80 cm).

Also i cant seem to enter service mode to update the firmware wich is needed to do the upgrade.I have disassembled the printhead to see if there is no durt or stains on the optical sensor and/or if the ribbon cables are not broken.

I don’t see any breaks in the cable (not visually).All suggestions are welcome.

Roverius

Carriage is moving to the left and then displays a 2F26.

There is anoise when the Carriage moves to the left-most position.The Feed Roller shaft bushing, shown below, may be broken.

The Carriage was striking it when moving to the left. Replacing the bushing resolved the issue. QC3-1478-000———————————————————————————————-

or

iPF750After Power On and at the time of printer initialization while the Carriage Unit has moved to the Left and it starts moving toward Right (home position) printer stops and error 2F26 would show on the control panel display.

In this case in this iPF750, the following parts were replaced to resolve the problem:

Pulley Unit (part # QM3-5833-000)

Spring, Compression (part # QU1-2441-000)

Retainer, Pulley (part # QC3-1531-000)================================================== =============================

imagePROGRAF Unusual Noises Location Type of Noise Cause/Remedy/Action Carriage Drive Rasping /Check the carriage drive ldler Pulley

/Check the Carriage Tension Unit

/Refer to the causes for 2F26 errors in the Service Manual and /Trouibleshooting GuideChattering /Check if the Tube Unit is striking the exterior walls

/Try opening and closing the Platen Suction Path Selection Valve (this is normal)Creaky /Make sure the Carriage Rail is dry and not soiled (never apply oil)

/Replace the Rail Cleaner

/Replace the Carriage Bearing if applicable (large printers only)

/Check if the Print Head open/close lever is broken (replace as required)Head rubbing Abrasive /Check the Print Head height setting

/Check for jams in the paper path near the Print Head

/Check the Paper Type settingsCutter Chattering /Replace the Cutter unit if it is damaged Near the lnk Tank Unit Chattering /The Ink stirring operation is in process (this is normal) Roll Spool Chattering /Check if the drive belt is loose

/Set the Rubber Pad to the correct positionPaper Feed / Back Feed Chattering /Check the LF Backup Roller

/Replace as neededCaterpillar Mylar Chattering /Check if the Catepillar Mylar sheet is out of position

/Replace the Tube Unit as requiredPlaten Suction Hole Whistling /Clean the Platen suction hole **Knowledge is time consuming, exhausting and costly for a trained Tech.**

-

09-01-2015

#3

Technician

- Rep Power

- 16

Re: Canon IPF750 hardware error 03130031-2F26

Hello,

Thank you for the reply.

I will check if that bushing is defective or not.

Meanwhile i am going to try to make a video and place it on the web for you to see what is happening.Regards,

Roverius

-

09-01-2015

#4

Technician

- Rep Power

- 16

Re: Canon IPF750 hardware error 03130031-2F26

Hello again.

I have checked the bushing and it seems OK.

I have made a video of the problem:

I hope this helps to understand the problem.

Regards,

Roverius

-

09-03-2015

#5

Re: Canon IPF750 hardware error 03130031-2F26

[QUOTE=Roverius;487426]Hi

I own a Canon IPF750 witch has a error

03130031-2F26.When i power on the printer, it starts to initialize and then the printhead moves to the left for a distance like abouth 80 cm.

This is the distance from the starting point completely from the right side.

When i shut down the printer and move the printhead like 15 cm to the left from the starting point and the turn on the printer again, then the printhead also moves about the same distance to the left. So 80 cm + 15 cm. When the printhead starts from the middle then it moves also to left with a big clunck at the end of the movement (banging against the end of the rail).I have cleaned the transport rail and checked the optical ribbon for stains or other malicious substances.

The weird thing is, that the distance the head moves is almost always exactly the same (like abouth 80 cm).

Also i cant seem to enter service mode to update the firmware wich is needed to do the upgrade.I have disassembled the printhead to see if there is no durt or stains on the optical sensor and/or if the ribbon cables are not broken.

I don’t see any breaks in the cable (not visually).All suggestions are welcome.

Roverius[/QUOTE

Hi Roverius,

I would recommend you replace the Carriage Relay PCB then if that doesn’t change anything its most likely the Main Controller PCB

Hate to tell you this but for me, 9 out of 10 times that I have had this error, it was the Main Controller PCB, and unfortunately its quite expensive to replace, if you have a second hand one to test with first, it would be a lot cheaper than committing to a new board, as once the part is opened canon wont refund you if it doesn’t fix your issue, unless you get a canon tech to fit the part for you.hope this helps,

Cheers,

SAZ911……….

-

09-03-2015

#6

Technician

- Rep Power

- 16

Re: Canon IPF750 hardware error 03130031-2F26

Hi Roverius,

I would recommend you replace the Carriage Relay PCB then if that doesn’t change anything its most likely the Main Controller PCB

Hate to tell you this but for me, 9 out of 10 times that I have had this error, it was the Main Controller PCB, and unfortunately its quite expensive to replace, if you have a second hand one to test with first, it would be a lot cheaper than committing to a new board, as once the part is opened canon wont refund you if it doesn’t fix your issue, unless you get a canon tech to fit the part for you.hope this helps,

Cheers,

Hi,

I am going to try to find the Carriage relay PCB (QM3-4932-000 ) and see what happens.

Else, maybe i can find a refurbished Main controller PCB.Hopefully, i can repair it with the relay pcb, because i dont want to spend to much to repair this printer.

Regards,

Roverius

-

09-04-2015

#7

Technician

- Rep Power

- 16

Re: Canon IPF750 hardware error 03130031-2F26

Hi,Question:

The Carriage relay PCB (QM3-4932-000 ), is this the board that looks like a power supply?

I only see 2 boards, a power supply looking board and a systemboard.Also, i hear a high pitched noise at the coverlock. Is this normal.

Sorry for the questions, but i never had a printer like this before and just got it as a present (well allmost) with the problems included.Regards,

Roverius

-

09-04-2015

#8

Re: Canon IPF750 hardware error 03130031-2F26

Originally Posted by Roverius

Hi,

Question:

The Carriage relay PCB (QM3-4932-000 ), is this the board that looks like a power supply?

I only see 2 boards, a power supply looking board and a systemboard.Also, i hear a high pitched noise at the coverlock. Is this normal.

Sorry for the questions, but i never had a printer like this before and just got it as a present (well allmost) with the problems included.Regards,

RoveriusHi Roverius,

The board that looks like a power supply at the back of the machine is the power supply (QK1-5056).

Carriage pcb unit should be (QM3-4569).

Main controller should be (QM3-5820).The carriage pcb unit is a small board that is in the Carriage assy that carries the printhead, it connects the ribbon cable from the carriage pcb to the main controller at the back of the machine.Please Note:

Please double check the part numbers as the numbers i have provided are for the European market and so the voltages on the power supply may vary from region to region.

good luck,

cheers….

SAZ911……….

-

09-04-2015

#9

Technician

- Rep Power

- 16

Re: Canon IPF750 hardware error 03130031-2F26

Originally Posted by SAZ911

Hi Roverius,

The board that looks like a power supply at the back of the machine is the power supply (QK1-5056).

Carriage pcb unit should be (QM3-4569).

Main controller should be (QM3-5820).The carriage pcb unit is a small board that is in the Carriage assy that carries the printhead, it connects the ribbon cable from the carriage pcb to the main controller at the back of the machine.Please Note:

Please double check the part numbers as the numbers i have provided are for the European market and so the voltages on the power supply may vary from region to region.

good luck,

cheers….

Hi,

Thank you for the reply.

The machine is european, so 220Volt power input.I have looked for the cariage pcb, but it seems i can not locate where it is placed.

I only see 2 boards at the back of the printer w.i. the powerboard and the main pcb board.

Can you explain where the cariage pcb is located please.Regards,

Roverius

-

09-04-2015

#10

Re: Canon IPF750 hardware error 03130031-2F26

Originally Posted by Roverius

Hi,

Thank you for the reply.

The machine is european, so 220Volt power input.I have looked for the cariage pcb, but it seems i can not locate where it is placed.

I only see 2 boards at the back of the printer w.i. the powerboard and the main pcb board.

Can you explain where the cariage pcb is located please.Regards,

RoveriusHi

The board would be just behind where you put the printhead in the carriage assy.(see pic below) Also might be worth replacing the whole carriage assy(QM3-58244).

roverius.JPG* If you haven’t replaced this board before it can be quite a challenge so it may be worth getting a canon tech to have a look at it for you.

cheers………

SAZ911……….

iPF750After Power On and at the time of printer initialization while the Carriage Unit has moved to the Left and it starts moving toward Right (home position) printer stops and error 2F26 would show on the control panel display.

iPF750After Power On and at the time of printer initialization while the Carriage Unit has moved to the Left and it starts moving toward Right (home position) printer stops and error 2F26 would show on the control panel display.

In this case in this iPF750, the following parts were replaced to resolve the problem:

In this case in this iPF750, the following parts were replaced to resolve the problem: