1. Зафиксируйте код сообщения на фото.

2. Сфотографируйте шильдик пароконвектомата.

3. Оправьте данную информацию, по WhatsApp, (можно использовать форму обратной связи) вашему сервис инженеру вместе с заявкой на диагностику.

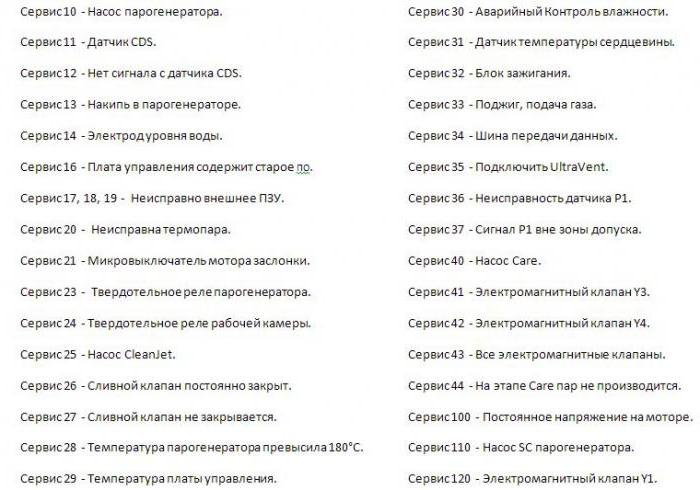

Сервис Проверить или заменить

10 Насос парогенератора, контейнер наполнения, шланг насоса

11 Электрод уровня, пропускная способность датчика CDS, плата вхвых.

12 Неисправен датчик CDS

13 Проверить электрод уровня

14 Проверить электрод уровня, измерить электропроводность воды

17 Связаться с RATIONAL, использовать ПО для восстановления

19 Заменить SD-карту

20.x Неисправна термопара, -1 = рабочая камера B1; -2 = коллектор охлаждения B2; -4 = термопара влажности B4; -8 = парогенератор B5; -16: Рабочая камера внизу B9 (напольный аппарат); ; -32: отек для установки B10 (XS)

23 Твердотельные реле по контуру «Пар»

24 Твердотельные реле по контуру «Сухой жар»

25 Нет увеличения нагрузки на мотор при попадании воды на вентилятор: Проверить подачу идавление воды, шланги, датчик CDS, положение навесных рам и рам-тележек с направляющими

26 Только XS: Шаровой клапан не открывается; проверить в функциональном тесте, при необходимости заменить

27 Только XS: Шаровой клапан не закрывается; проверить в функциональном тесте, при необходимости заменить

28.x Термопара: -1: Парогенератор B5 слишком горячий (>170 C); -2: рабочая камера B1 слишком горячая (>350 °C); -4: рабочая камера B1 слишком холодная (<2 °C)

29 Слишком высокая температура платы: проверить воздушный фильтр, вентилятор охлажде-

ния и уплотнение панели управления.

30 Ошибка контроля влажности; проверить датчик дифференциального давления P1

31.x Термопара термокерна В3: -1: Неисправен термокерн рабочей камеры; -2: Аварийный режим термокерна рабочей камеры; -11/12: Термокерн USB 1 неисправен/аварийный режим; -21/22: Термокерн USB 2 неисправен/аварийный режим

32.x Блок зажигания: газовый кран; замените блок зажигания только, если газовые ошибки 33, 36, 39 или 42 возникли более 5-ти раз

33.x Газовая ошибка: проверить газовый кран, газовый клапан или управление от блока зажигания к газовому клапану

34.xx Ошибка сигнала шины: -1 верхний мотор; -2 средний моторе; -4 нижний мотор; -8 плата насоса; -16 подача питания платы вх./вых.; -32 блок зажигания

35 UltraVent: Сигнал шины / внутренняя коммуникация

35.x Ошибка UltraVent: -1 ошибка напряжения; -2 ошибка распознавания фильтра; -3 ошибка контроля термопары; -4 неисправность термопары защиты мотора; -5: Предварительное уведомление (замена фильтра) -6 загрязнение фильтра (немедленная замена); -7 фильтр не установлен/не измеряется дифференциальное давление

36 Ошибка датчика дифференциального давления (нет сигнала 0,5 В; проверить входной сигнал 12 В на P1); P1 должен быть установлен горизонтально

37 Сбой упр. микроклиматом: Проверить подключения шлангов

40 Проверить насос Care (M18) в функциональном тесте (Внимание! одновременно включается Y4 , запустить программу ополаскивания)

41 Функция увлажнения: Проверить клапан Y3, форсунку и трубку впрыска на наличие накипи; CDS не измеряет импульсы; Сбросить ошибку, запустив программу ополаскивания

42.x Не открывается клапан: -1: клапан Y1; -2: Клапан Y2; -3: увлажнение Y3; -4: клапан Care Y4; -5: клапан Klima Y5 / Y15; -6: промывочный клапан Y14

44 Нет нагрева парогенератора или нагрев недостаточен;

46.x SC-насос (M4); -1: неисправен; -2: слишком низкая производительность

47.x Сливной насос M15; -1: неисправен; -2: Слишком низкая производительность

48.x Циркуляционный насос M17; -1: неисправен; -2: Слишком низкая производительность

49.x Насос Care (M18): -1: неисправен; -2: слишком низкая производительность

50 Реальное время (дата и время)

51 Проверить батарейку, при необходимости замените

52 Ошибка светодиодного освещения дверцы: -1 слева; -2 справа

55, 56, 57 Ошибка мотора вентилятора (только в сервисном отчете)

60 Блок зажигания не инициализируется или его работа замедлена — Ошибка в сигнале скорости вращения; выключить и включить аппарат. Изменить тип газа и вернуться к исходному типу газа, при необходимости применить восстановительный файл.

63 Аппарат обнаруживает воду в первый раз после сухой калибровки, после самодиагностики без воды: заново провести калибровку.

70.x -1: Электроотказ вентилятора охлаждения настольного аппарата

-2: Вентилятор охлаждения газового настольного аппарата, электро-/газоотказ напольного аппарата

71.x -1: Сетевая ошибка; -2: Пониженное напряжение блока питания

72 Термостат eSTB для сухого жара или пара: Мигание светодиода на eSTB — ошибка

73.x Ошибка повышенной температуры: -1 верхний мотор; -2 нижний мотор; -4 средний мотор;

-8 плата насоса; -16 блок управления платы вх./вых.; -32 блок зажигания;

75.x 75: Полный отказ интерфейса шины (I2C); -1: Отказ оптимизации энергопотребления; -2: Отказ платы 4-вентильного реле; -3: Отказ платы очистки (XS);

76.x Только США:

-1: ограничено напряжение; -2: ошибка внутренней проверки; -3: неправильная настройка напряжения; -4: слишком большое число каналов; -5: неправильные каналы; -6: неправильное время; -7: ошибка аппаратного обеспечения

110 Ошибка SC-насоса при наличии в парогенераторе раствора Care

120 Нет сигнала электрода уровня при наличии в парогенераторе раствора Care;

130 Необходима ручная очистка от накипи (объем заполнения соответствует 80 % эталонного значения)

Сервис Проверить и при необходимости заменить

2 Оптимизация энергопотребления активна (только со встроенной платой оптимизации энергопотребления)

10 Ошибка автоматики SCНасос парогенератора, контейнер наполнения, шланг насоса

11 Датчик CDS сообщает о слишком большом количестве импульсов

Электрод уровня, пропускная способность датчика CDS, плата вхвых.

12 Датчик CDS не подает сигналовДатчик CDS, плата вхвых., подача воды

14 Электрод уровня не обнаруживает воду несмотря на обнаружение импульсов датчиком CDS Электрод уровня воды, электропроводимость воды

16 Структура ЭСППЗУ была создана более новым по сравнению с установленным программным обеспечением, обновите аппарат до актуальной версии программного обеспечения

17.X Ошибка данных аппарата (суб-ошибка только для внутренних целей)

Связаться с RATIONAL, использовать ПО для восстановления

19.X x= тип ошибки; -1= ЭСППЗУ отсутствует или не распознано;

-2 = ошибка внутренней памяти (возможно, извлечен аккумулятор)

20.X Неисправна термопара, x= термопара; -1 = рабочая камера B1; -2 = коллектор охлаждения

B2; -4 = термопара влажности B4; -8 = парогенератор B5; -9 = неисправна термопара B9 —только напольные аппараты

23 Повышение температуры в парогенераторе без запроса Проверка нагрева парогенератора

24 Повышение температуры в рабочей камере без запроса

Проверка парогенератора Сервис Проверить и при необходимости заменить

25 Не обнаруживается вода во время очистки

Не работают вентиляторы/нет увеличения нагрузки на мотор при попадании воды на вентилятор. Проверить подачу и давление воды, шланги, датчик CDS, положение рам и теле жек с направляющими

28.x Термопара, x= ошибка: -1: Парогенератор B5 слишком горячий (>170 C); -2: рабочая камера B1 слишком горячая (>350 °C); -4: парогенератор B5 слишком холодный (<2 °C, возмо жен нагрев до 4 °C)

29 Слишком высокая температура платы (платы вх./вых., насосов, ЦП): воздушный фильтр,вентилятор охлаждения

30 Некорректное функционирование измерения влажности

Датчик давления P1, подключения шлангов, измерительные патрубки, датчик влажности B4

31.xx Термопара В3 термокерна, x = ошибка: -1: дефект термокерна; -11: дефект внешнего термокерна

32.x Блок зажигания, x= ошибка

-1: 5 сбоев зажигания (проверить подачу газа)

-2: Обнаружение тока пламени без требования нагрева

-3: Горелка 5 раз выключается при требовании нагрева

33.x Ошибка газовой горелки, x= ошибка

-1: внутренняя ошибка блока зажигания (выключите и снова включите аппарат)

-2: Ошибка инициализации блока поджига (смените тип газа и вернитесь к исходному типу газа)

-3: Частота тока в сети за пределами допустимого диапазона

-4: Фаза/нейтраль перепутаны (переверните сетевой штекер или поправьте кабель)

-5: Внутренний дефект блока зажигания, замените блок зажигания

34.xx Ошибка сигнала шины: -1 верхний мотор; -2 средний мотор; -4 нижний мотор (только для напольных аппаратов); -8 плата насоса; -16 подача питания платы вх./вых.; -32 блок зажигания;

35 UltraVent: Сигнал шины / внутренняя коммуникация

35.x Ошибка UltraVent: -1 ошибка напряжения; -2 ошибка распознавания фильтра (только для UV Plus); -3 ошибка контроля термопары; -4 неисправность термопары защиты мотора; -5/6 загрязнение фильтра (предварительное уведомление/немедленная замена); -7 фильтр не установлен/не измеряется дифференциальное давление

36 Ошибка датчика дифференциального давления (нет сигнала 0,5 ; проверьте 12 В на P1); P1 должен быть установлен горизонтально

37 Сбой упр. микроклиматом: Проверить подключения шлангов

40 Проверьте насос Care (M18) в функциональном тесте (Внимание: одновременно включается Y4, запустите программу ополаскивания)

42.x Не открывается клапан: -1: Заполните Y1; -2: Управление Y2; -4 Care Y4; -5 климат Y5 / Y15

43.x Не закрывается клапан: -1: клапан Y1; -2: клапан Y2; -3: клапан Y3; -4: клапан Care Y4; -5: клапан ClimaY5 / Y15; -6: клапан CleanJet Y14

44 Во вемя очистки нет нагрева парогенератора или нагрев недостаточен;

46.x Насос парогенератора M4; x = тип ошибки: Слишком низкая производительность

47 Сливной насос (M15); -1: дефект; -2: Слишком низкая производительность

48 Циркуляционный насос (M17); -1: дефект; -2: Слишком низкая производительность

49 Насос Care (M18) ; x= тип ошибки: -1: дефект; -2: Слишком низкая производительность

50 Реальное время (дата и время) не запущено

51 Проверить батарейку, при необходимости замените

52 Ошибка светодиодного освещения рабочей камеры

63 Обнаружена вода после сухой калибровки, выполнить самотестирование с водой.

70 Ошибка охл. вент.

71.x Ошибка питания -1: Общая ошибка; -2: Пониженное напряжение (<170 В)

72 Термостат eSTB рабочей камеры или парогенератора: Мигание светодиода на eSTB — ошибка, см. описание ниже

73.x Ошибка повышенной температуры: -1 верхний мотор; -2 нижний мотор; -4 средний мотор; -8 плата насоса; -32 блок управления; -32 блок зажигания платы вх./вых.

75.x Внутренний интерфейс шины: -1 Не распознана оптимизация энергопотребления дополнительной платы; -2: 4-канальное реле дополнительной платы не обнаружено, -4 (только США) плата переключения напряжения не обнаружена

76.xx Аппарата только в США

Ошибка платы переключения напряжения -1: Напряжение слишком низкое; -2: Ошибка внутренней перепроверки; -3 неправильная настройка напряжения от 4 до -7: внутренние

ошибки

90 Аппарат еще не откалиброван, выполните калибровку

110 Ошибка насос парогенератора при наличии в парогенераторе раствора Care

(Устраните ошибку и разъедините в Основных настройках «Очистка разблокировки»)

120 Электрод уровня без сигнала при наличии в парогенераторе химикатов Care;

(Устраните ошибку и разъедините в Основных настройках «Очистка разблокировки»)

121 Дополнительная функция при работе аппарата без воды: Примечание о заполнении водой коллектора охлаждения

200 Сбой автоматического позиционирования мотора (в дальнейшем в основном ошибка 201)

201 Выполнить распределение мотора

900.x -48: Батарейка извлечена, ошибка данных устройства и инициализации времени

1000 Нехватка воды, проверьте подачу воды

1016 USB-накопитель уже присутствует

1017 Неисправность USB-накопителя

1022 отсутствует вода во время процедуры включения (измерение CDS)

1025 Сбой загрузки и выгрузки программы из-за ошибки ЭСППЗУ

1026 Загрузка программы невозможна из-за ошибки создания программы

1033.x Система здорова: -1: несовместимое ПО плата вхвых; -2: неизвестная версия ПО платы вхвых; -3: Проверить систему шины

От ПО версии 5.0.X: Нажатие кнопки 1 (см. предыдущую страницу) отображается соответствующий узел шины.

2000.x Ошибка обновления ПО: -1: Превышено время ожидания; -2-3: макс. время обновления превышено; -4: Устройство в режиме диагностики или самодиагностики; -5: Попытка обновления во время готовки; -6: Попытка обновления при отключении питания; -7: Попытка обновления в демо-режиме

Начиная с версии ПО 5.0.X отменяются коды ошибок

Сервис Проверить и при необходимости заменить

1001 Перезапуск горелки, проверить подачу газа

1002 Проверить подключение к сети и полярность

1003 Нехватка воды >15 минут

1010 Проверить воздушный фильтр

1011 Проверить батарейку

1012 Выполнить калибровку

1018 Ошибка вытяжного зонта

1020 Неисправность мотора

1021.x Неисправность модуля оптимизации энергопотребления: -1-2: 4-канальное реле неисправно; 3: Неправильное напряжение США

1024 Прерывание из-за неисправного термокерна

E10

Where

does it display? Timer

What’s

the cause? External EEPROM

Why? Defective

NOTE: PLEASE SUBSCRIBE E-MAIL AND YOUTUBE CHANNEL

E11

Where

does it display? Timer

What’s

the cause? Mode switch

Why? Cooking mode couldn’t be identified five seconds after the unit

was switched on

E12 / 1 St

Where

does E12 display? Timer

Where

does 1 St alternate display? Internal Cabinet

Display

What’s

the cause? Bottom fan motor issue,make sure 3 phase getting in to the machine

Why? Motor is defective (St=Status)

E12 / 1 Co

Where

does E12 display? Timer

Where

does 1 Co display? Internal Cabinet Display

What’s

the cause? Bottom fan motor issue,make sure 3 phase getting in to the machine

Why? Bus failure (Co=Communication)

E12 / 2 St

Where

does E12 display? Timer

Where

does 2 St alternate display? Internal Cabinet

Display

What’s

the cause? Top fan motor issue,make sure 3 phase getting in to the machine

Why? Motor is defective (St=Status)

E12 / 2 Co

Where

does E12 display? Timer

Where

does 2 Co alternate display? Internal Cabinet

Display

What’s

the cause? Top fan motor issue,make sure 3 phase getting in to the machine

Why? Bus failure (Co=Communication)

E13

Where

does it display? Timer

What’s

the cause? M4 SC pump

Why? Malfunction,need to changing or some time pump area getting scaling and blocked

E14

Where

does it display? Timer

What’s

the cause? Solenoid valve filling Y1

Why? Malfunction

E15

Where

does it display? Timer

What’s

the cause??PCB temperature

Why? Above 185?F (85?C)

E16

Where

does it display? Timer

What’s

the cause??Steam generator

Why? B5 temperature above 356?F (180?C)

E17

Where

does it display? Timer

What’s

the cause??Steam generator

Why? B5 temperature below 23?F (-5?C)

E18

Where

does it display? Timer

What’s

the cause??Interior cabinet temperature

Why? B1 temperature above 644?F (340?C)

E20 / 1

Where

does E20 display? Timer

Where

does 1_ alternate display? Internal Cabinet Display

What’s

the cause??Ignition box 1

Why??Ignition box isn’t replying due to bus failure

E21 / 2

Where

does E21 display? Timer

Where

does 2_ alternate display? Internal Cabinet Display

What’s

the cause??Ignition box 2

Why??Ignition box isn’t replying due to bus failure

E21 / 1

Where

does E21 display? Timer

Where

does 1xx display? Internal Cabinet Display

What’s

the cause??Ignition box 1 steam

Why??Defective ignition box

E22 / 2

Where

does E22 display? Timer

Where

does 2xx alternate display? Internal Cabinet Display

What’s

the cause??Ignition box 1 hot air

Why??Defective ignition box

E22 / 3

Where

does E22 display? Timer

Where

does 3xx alternate display? Internal Cabinet Display

What’s

the cause??Ignition box 2 hot air

Why??Defective ignition box

E22 / 1

Where

does E22 display? Timer

Where

does 1xx alternate display? Internal Cabinet Display

What’s

the cause??Ignition box 1 steam

Why??Testing and monitoring ignition is required

E23 / 2

Where

does E23 display? Timer

Where

does 2xx alternate display? Internal Cabinet Display

What’s

the cause??Ignition box 1 hot air

Why??Testing and monitoring ignition is required

E23 / 3

Where

does E23 display? Timer

Where

does 3xx alternate display? Internal Cabinet Display

What’s

the cause??Ignition box 2 hot air

Why??Testing and monitoring ignition is required

E24

Where

does E24 display? Timer

What’s

the cause? EEPROM

Why??EEPROM’s data structure doesn’t match with software

Contributions

from the Community

Our

community members have posted about service codes associated with other

Rational SCC models or software versions. These are some of the most helpful

from over the years.

On models produced up to October 2011 (index E

& G), Service 21 meant only that the cam on clima motor did not do a?360

degree rotation in the?allowed 20 seconds.? Possible it did not rotate at

all.

Every time the door is opened and closed while

the unit is on, it does a check (initialization of the Clima Valve and times

it).

While

we addressed this code above,PLEASE SEND MAIL provided more details on it:

33-1 means bottom ignition module.? But this only

applies on floor models such as 201 & 202.? In this case of a 102 (table

model) there is only one ignition module so the -1 has no need.? But it shows

anyway.

Требуется руководство для вашей Rational CombiMaster Plus духовой шкаф? Ниже вы можете просмотреть и загрузить бесплатно руководство в формате PDF. Кроме того, приведены часто задаваемые вопросы, рейтинг изделия и отзывы пользователей, что позволит оптимально использовать ваше изделие. Если это не то руководство, которое вы искали, – свяжитесь с нами.

Ваше устройство неисправно, и в руководстве отсутствует решение? Перейдите в Repair Café для получения бесплатных ремонтных услуг.

Руководство

Рейтинг

Сообщите нам, что вы думаете о Rational CombiMaster Plus духовой шкаф, оставив оценку продукта. Хотите поделиться вашими впечатлениями от данного изделия или задать вопрос? Вы можете оставить комментарий в нижней части страницы.

Довольны ли вы данным изделием Rational?

Да Нет

Будьте первым, кто оценит это изделие

0 голоса

Часто задаваемые вопросы

Наша служба поддержки выполняет поиск полезной информации по изделиям и отвечает на часто задаваемые вопросы. Если вы заметили неточность в наших часто задаваемых вопросах, сообщите нам об этом с помощью нашей контактной формы.

Духовка недостаточно нагревается. Что мне делать? Проверенный

За нагревание духовки до заданной температуры отвечает термостат. Скорее всего, термостат неисправен. Его следует заменить. В случае сомнений обратитесь к производителю.

Это было полезно (2201)

Что такое пиролиз? Проверенный

Некоторые духовки оснащены функцией пиролиза. Это система очистки, которая сжигает грязь и жир в духовке за счет очень высоких температур. После пиролиза вся грязь превратится в золу, и ее легко удалить. Если духовка имеет функцию пиролиза, рекомендуется использовать ее 3-4 раза в год, чтобы духовка оставалась чистой.

Это было полезно (2025)

Почему в духовке при разогреве накапливается дым? Проверенный

Вероятно, в духовке остались остатки пищи от предыдущего использования. При нагревании особенно жирные остатки пищи могут выделять дым. Тщательно очистите духовку.

Это было полезно (486)

Когда я использую духовку, продукты часто падают на дно, вызывая дым. Как я могу предотвратить это? Проверенный

Многие духовки поставляются с решеткой и противнем. Когда пища готовится на решетке, противень можно ставить на дно, чтобы остатки пищи не пригорали и не задымились.

Это было полезно (486)

Могу ли я приготовить несколько блюд одновременно, используя несколько противней для гриля? Проверенный

Технически это возможно. Однако это зависит от типа продуктов, нужно ли вам регулировать время приготовления или менять противни на полпути во время приготовления.

Это было полезно (485)

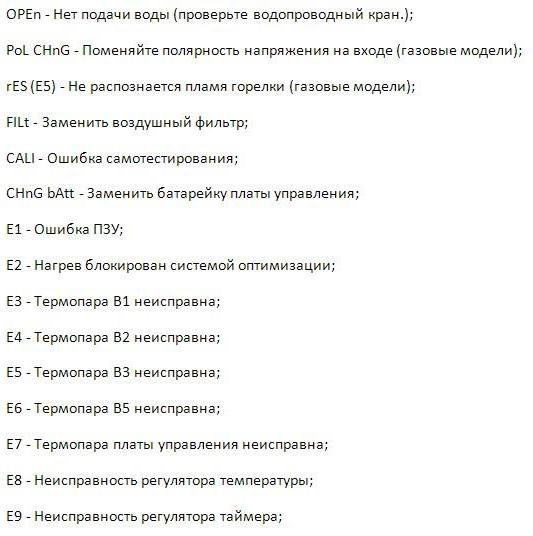

1. Зафиксируйте код сообщения на фото.

2. Сфотографируйте шильдик пароконвектомата.

3. Оправьте данную информацию, по WhatsApp, (можно использовать форму обратной связи) вашему сервис инженеру вместе с заявкой на диагностику.

Сервис Проверить или заменить

10 Насос парогенератора, контейнер наполнения, шланг насоса

11 Электрод уровня, пропускная способность датчика CDS, плата вхвых.

12 Неисправен датчик CDS

13 Проверить электрод уровня

14 Проверить электрод уровня, измерить электропроводность воды

17 Связаться с RATIONAL, использовать ПО для восстановления

19 Заменить SD-карту

20.x Неисправна термопара, -1 = рабочая камера B1; -2 = коллектор охлаждения B2; -4 = термопара влажности B4; -8 = парогенератор B5; -16: Рабочая камера внизу B9 (напольный аппарат); ; -32: отек для установки B10 (XS)

23 Твердотельные реле по контуру «Пар»

24 Твердотельные реле по контуру «Сухой жар»

25 Нет увеличения нагрузки на мотор при попадании воды на вентилятор: Проверить подачу идавление воды, шланги, датчик CDS, положение навесных рам и рам-тележек с направляющими

26 Только XS: Шаровой клапан не открывается; проверить в функциональном тесте, при необходимости заменить

27 Только XS: Шаровой клапан не закрывается; проверить в функциональном тесте, при необходимости заменить

28.x Термопара: -1: Парогенератор B5 слишком горячий (>170 C); -2: рабочая камера B1 слишком горячая (>350 °C); -4: рабочая камера B1 слишком холодная (<2 °C)

29 Слишком высокая температура платы: проверить воздушный фильтр, вентилятор охлажде-

ния и уплотнение панели управления.

30 Ошибка контроля влажности; проверить датчик дифференциального давления P1

31.x Термопара термокерна В3: -1: Неисправен термокерн рабочей камеры; -2: Аварийный режим термокерна рабочей камеры; -11/12: Термокерн USB 1 неисправен/аварийный режим; -21/22: Термокерн USB 2 неисправен/аварийный режим

32.x Блок зажигания: газовый кран; замените блок зажигания только, если газовые ошибки 33, 36, 39 или 42 возникли более 5-ти раз

33.x Газовая ошибка: проверить газовый кран, газовый клапан или управление от блока зажигания к газовому клапану

34.xx Ошибка сигнала шины: -1 верхний мотор; -2 средний моторе; -4 нижний мотор; -8 плата насоса; -16 подача питания платы вх./вых.; -32 блок зажигания

35 UltraVent: Сигнал шины / внутренняя коммуникация

35.x Ошибка UltraVent: -1 ошибка напряжения; -2 ошибка распознавания фильтра; -3 ошибка контроля термопары; -4 неисправность термопары защиты мотора; -5: Предварительное уведомление (замена фильтра) -6 загрязнение фильтра (немедленная замена); -7 фильтр не установлен/не измеряется дифференциальное давление

36 Ошибка датчика дифференциального давления (нет сигнала 0,5 В; проверить входной сигнал 12 В на P1); P1 должен быть установлен горизонтально

37 Сбой упр. микроклиматом: Проверить подключения шлангов

40 Проверить насос Care (M18) в функциональном тесте (Внимание! одновременно включается Y4 , запустить программу ополаскивания)

41 Функция увлажнения: Проверить клапан Y3, форсунку и трубку впрыска на наличие накипи; CDS не измеряет импульсы; Сбросить ошибку, запустив программу ополаскивания

42.x Не открывается клапан: -1: клапан Y1; -2: Клапан Y2; -3: увлажнение Y3; -4: клапан Care Y4; -5: клапан Klima Y5 / Y15; -6: промывочный клапан Y14

44 Нет нагрева парогенератора или нагрев недостаточен;

46.x SC-насос (M4); -1: неисправен; -2: слишком низкая производительность

47.x Сливной насос M15; -1: неисправен; -2: Слишком низкая производительность

48.x Циркуляционный насос M17; -1: неисправен; -2: Слишком низкая производительность

49.x Насос Care (M18): -1: неисправен; -2: слишком низкая производительность

50 Реальное время (дата и время)

51 Проверить батарейку, при необходимости замените

52 Ошибка светодиодного освещения дверцы: -1 слева; -2 справа

55, 56, 57 Ошибка мотора вентилятора (только в сервисном отчете)

60 Блок зажигания не инициализируется или его работа замедлена — Ошибка в сигнале скорости вращения; выключить и включить аппарат. Изменить тип газа и вернуться к исходному типу газа, при необходимости применить восстановительный файл.

63 Аппарат обнаруживает воду в первый раз после сухой калибровки, после самодиагностики без воды: заново провести калибровку.

70.x -1: Электроотказ вентилятора охлаждения настольного аппарата

-2: Вентилятор охлаждения газового настольного аппарата, электро-/газоотказ напольного аппарата

71.x -1: Сетевая ошибка; -2: Пониженное напряжение блока питания

72 Термостат eSTB для сухого жара или пара: Мигание светодиода на eSTB — ошибка

73.x Ошибка повышенной температуры: -1 верхний мотор; -2 нижний мотор; -4 средний мотор;

-8 плата насоса; -16 блок управления платы вх./вых.; -32 блок зажигания;

75.x 75: Полный отказ интерфейса шины (I2C); -1: Отказ оптимизации энергопотребления; -2: Отказ платы 4-вентильного реле; -3: Отказ платы очистки (XS);

76.x Только США:

-1: ограничено напряжение; -2: ошибка внутренней проверки; -3: неправильная настройка напряжения; -4: слишком большое число каналов; -5: неправильные каналы; -6: неправильное время; -7: ошибка аппаратного обеспечения

110 Ошибка SC-насоса при наличии в парогенераторе раствора Care

120 Нет сигнала электрода уровня при наличии в парогенераторе раствора Care;

130 Необходима ручная очистка от накипи (объем заполнения соответствует 80 % эталонного значения)

Сервис Проверить и при необходимости заменить

2 Оптимизация энергопотребления активна (только со встроенной платой оптимизации энергопотребления)

10 Ошибка автоматики SCНасос парогенератора, контейнер наполнения, шланг насоса

11 Датчик CDS сообщает о слишком большом количестве импульсов

Электрод уровня, пропускная способность датчика CDS, плата вхвых.

12 Датчик CDS не подает сигналовДатчик CDS, плата вхвых., подача воды

14 Электрод уровня не обнаруживает воду несмотря на обнаружение импульсов датчиком CDS Электрод уровня воды, электропроводимость воды

16 Структура ЭСППЗУ была создана более новым по сравнению с установленным программным обеспечением, обновите аппарат до актуальной версии программного обеспечения

17.X Ошибка данных аппарата (суб-ошибка только для внутренних целей)

Связаться с RATIONAL, использовать ПО для восстановления

19.X x= тип ошибки; -1= ЭСППЗУ отсутствует или не распознано;

-2 = ошибка внутренней памяти (возможно, извлечен аккумулятор)

20.X Неисправна термопара, x= термопара; -1 = рабочая камера B1; -2 = коллектор охлаждения

B2; -4 = термопара влажности B4; -8 = парогенератор B5; -9 = неисправна термопара B9 —только напольные аппараты

23 Повышение температуры в парогенераторе без запроса Проверка нагрева парогенератора

24 Повышение температуры в рабочей камере без запроса

Проверка парогенератора Сервис Проверить и при необходимости заменить

25 Не обнаруживается вода во время очистки

Не работают вентиляторы/нет увеличения нагрузки на мотор при попадании воды на вентилятор. Проверить подачу и давление воды, шланги, датчик CDS, положение рам и теле жек с направляющими

28.x Термопара, x= ошибка: -1: Парогенератор B5 слишком горячий (>170 C); -2: рабочая камера B1 слишком горячая (>350 °C); -4: парогенератор B5 слишком холодный (<2 °C, возмо жен нагрев до 4 °C)

29 Слишком высокая температура платы (платы вх./вых., насосов, ЦП): воздушный фильтр,вентилятор охлаждения

30 Некорректное функционирование измерения влажности

Датчик давления P1, подключения шлангов, измерительные патрубки, датчик влажности B4

31.xx Термопара В3 термокерна, x = ошибка: -1: дефект термокерна; -11: дефект внешнего термокерна

32.x Блок зажигания, x= ошибка

-1: 5 сбоев зажигания (проверить подачу газа)

-2: Обнаружение тока пламени без требования нагрева

-3: Горелка 5 раз выключается при требовании нагрева

33.x Ошибка газовой горелки, x= ошибка

-1: внутренняя ошибка блока зажигания (выключите и снова включите аппарат)

-2: Ошибка инициализации блока поджига (смените тип газа и вернитесь к исходному типу газа)

-3: Частота тока в сети за пределами допустимого диапазона

-4: Фаза/нейтраль перепутаны (переверните сетевой штекер или поправьте кабель)

-5: Внутренний дефект блока зажигания, замените блок зажигания

34.xx Ошибка сигнала шины: -1 верхний мотор; -2 средний мотор; -4 нижний мотор (только для напольных аппаратов); -8 плата насоса; -16 подача питания платы вх./вых.; -32 блок зажигания;

35 UltraVent: Сигнал шины / внутренняя коммуникация

35.x Ошибка UltraVent: -1 ошибка напряжения; -2 ошибка распознавания фильтра (только для UV Plus); -3 ошибка контроля термопары; -4 неисправность термопары защиты мотора; -5/6 загрязнение фильтра (предварительное уведомление/немедленная замена); -7 фильтр не установлен/не измеряется дифференциальное давление

36 Ошибка датчика дифференциального давления (нет сигнала 0,5 ; проверьте 12 В на P1); P1 должен быть установлен горизонтально

37 Сбой упр. микроклиматом: Проверить подключения шлангов

40 Проверьте насос Care (M18) в функциональном тесте (Внимание: одновременно включается Y4, запустите программу ополаскивания)

42.x Не открывается клапан: -1: Заполните Y1; -2: Управление Y2; -4 Care Y4; -5 климат Y5 / Y15

43.x Не закрывается клапан: -1: клапан Y1; -2: клапан Y2; -3: клапан Y3; -4: клапан Care Y4; -5: клапан ClimaY5 / Y15; -6: клапан CleanJet Y14

44 Во вемя очистки нет нагрева парогенератора или нагрев недостаточен;

46.x Насос парогенератора M4; x = тип ошибки: Слишком низкая производительность

47 Сливной насос (M15); -1: дефект; -2: Слишком низкая производительность

48 Циркуляционный насос (M17); -1: дефект; -2: Слишком низкая производительность

49 Насос Care (M18) ; x= тип ошибки: -1: дефект; -2: Слишком низкая производительность

50 Реальное время (дата и время) не запущено

51 Проверить батарейку, при необходимости замените

52 Ошибка светодиодного освещения рабочей камеры

63 Обнаружена вода после сухой калибровки, выполнить самотестирование с водой.

70 Ошибка охл. вент.

71.x Ошибка питания -1: Общая ошибка; -2: Пониженное напряжение (<170 В)

72 Термостат eSTB рабочей камеры или парогенератора: Мигание светодиода на eSTB — ошибка, см. описание ниже

73.x Ошибка повышенной температуры: -1 верхний мотор; -2 нижний мотор; -4 средний мотор; -8 плата насоса; -32 блок управления; -32 блок зажигания платы вх./вых.

75.x Внутренний интерфейс шины: -1 Не распознана оптимизация энергопотребления дополнительной платы; -2: 4-канальное реле дополнительной платы не обнаружено, -4 (только США) плата переключения напряжения не обнаружена

76.xx Аппарата только в США

Ошибка платы переключения напряжения -1: Напряжение слишком низкое; -2: Ошибка внутренней перепроверки; -3 неправильная настройка напряжения от 4 до -7: внутренние

ошибки

90 Аппарат еще не откалиброван, выполните калибровку

110 Ошибка насос парогенератора при наличии в парогенераторе раствора Care

(Устраните ошибку и разъедините в Основных настройках «Очистка разблокировки»)

120 Электрод уровня без сигнала при наличии в парогенераторе химикатов Care;

(Устраните ошибку и разъедините в Основных настройках «Очистка разблокировки»)

121 Дополнительная функция при работе аппарата без воды: Примечание о заполнении водой коллектора охлаждения

200 Сбой автоматического позиционирования мотора (в дальнейшем в основном ошибка 201)

201 Выполнить распределение мотора

900.x -48: Батарейка извлечена, ошибка данных устройства и инициализации времени

1000 Нехватка воды, проверьте подачу воды

1016 USB-накопитель уже присутствует

1017 Неисправность USB-накопителя

1022 отсутствует вода во время процедуры включения (измерение CDS)

1025 Сбой загрузки и выгрузки программы из-за ошибки ЭСППЗУ

1026 Загрузка программы невозможна из-за ошибки создания программы

1033.x Система здорова: -1: несовместимое ПО плата вхвых; -2: неизвестная версия ПО платы вхвых; -3: Проверить систему шины

От ПО версии 5.0.X: Нажатие кнопки 1 (см. предыдущую страницу) отображается соответствующий узел шины.

2000.x Ошибка обновления ПО: -1: Превышено время ожидания; -2-3: макс. время обновления превышено; -4: Устройство в режиме диагностики или самодиагностики; -5: Попытка обновления во время готовки; -6: Попытка обновления при отключении питания; -7: Попытка обновления в демо-режиме

Начиная с версии ПО 5.0.X отменяются коды ошибок

Сервис Проверить и при необходимости заменить

1001 Перезапуск горелки, проверить подачу газа

1002 Проверить подключение к сети и полярность

1003 Нехватка воды >15 минут

1010 Проверить воздушный фильтр

1011 Проверить батарейку

1012 Выполнить калибровку

1018 Ошибка вытяжного зонта

1020 Неисправность мотора

1021.x Неисправность модуля оптимизации энергопотребления: -1-2: 4-канальное реле неисправно; 3: Неправильное напряжение США

1024 Прерывание из-за неисправного термокерна

Training Manual

Basics, Maintenance and Accessories

SelfCookingCenter® whitefficiency® (SCC_WE)

CombiMaster Plus (CM_P)

Voltage

Software

Installation

Water quality

Accessories

Air supply Gas

Original components

Flue venting

Type of gas

Drain

V02 en, Basic_Maintenance_Accessories

General hints:

Isolate the appliance from mains supply before opening the appliance

When working with chemicals, i.e. aggressive cleaning materials always wear protective clothing, goggles and gloves!

After maintenance / repair the appliance must be checked for electrical safety in accordance with your national, state and local requirements!

Whenever working on any gas component like:

Gas valve, gas blower and / or changing connected type of gas a detailed flue gas analysis MUST be done using adequate CO and CO2 measuring equipment! This shall ONLY be done by trained technicians! Always check appliance for possible gas leakages!

© 2011 Rational Technical Services. All rights reserved.

Please note that any technical information concerning Rational products must NOT be forwarded to any third party.

|

V02 en, Basic_Maintenance_Accessories |

— 2 — |

List of content

Basic topics

|

Company history |

4 |

||

|

History of the Combi Steamer |

5 |

||

|

Structure of serial number |

6 |

||

|

Unit history: Control panel Layout |

7 |

||

|

Unit sizes |

8 |

||

|

Basic principle |

9 |

||

|

General information about water |

10 |

||

|

Installation — Duties and responsibilities |

12 |

||

|

Relationship: Installation — Components — Environment |

13 |

||

|

Check list |

|||

|

Preinstallation checklist |

14 |

||

|

Installation sheet — Electric / Gas units — Electrical connection |

18 |

||

|

Installation sheet — Electric / Gas units — Water connection |

19 |

||

|

Installation sheet — Electric / Gas units — Drain connection |

20 |

||

|

Installation sheet — Gas units — Gas connection |

21 |

||

|

Commissioning — Preventive maintenance |

|||

|

Installation/Commissioning Checklist |

22 |

||

|

Preventive maintenance |

27 |

||

|

Descaling — Cleaning |

|||

|

Instruction for manual descaling |

30 |

||

|

Additional information for manual descaling |

33 |

||

|

User instruction electrical descaler pump |

34 |

||

|

Daily care — Unit and Door Gasket |

36 |

||

|

Instruction for manual cleaning |

37 |

||

|

Accessories |

|||

|

Ultravent (UV) |

38 |

||

|

CombiDuo, Thermo cabinet |

41 |

||

|

Condensation breaker steam |

42 |

||

|

Draft Diverter Gas units |

42 |

||

|

Sicotronic |

43 |

||

|

Ethernet Connection |

43 |

||

|

Reporting forms |

|||

|

Product surveillance guideline |

44 |

||

|

Registration form product surveillance |

45 |

||

|

Registration form „dead on arrival“ |

46 |

|

— 3 — |

V02 en, Basic_Maintenance_Accessories |

Company history

Milestone of an extraordinary company history

1973 Foundation of RATIONAL GmbH as a company for producing and selling of hot air ovens in

Germany

1976 Invention of the RATIONAL Combi-Steamer

1993 Opening of plant number 2

1993 Invention of the RATIONAL Clima Combi®

1997 Invention of the RATIONAL ClimaPlus Combi®

2000 Going public RATIONAL AG

2000 CleanJet® – World wide the first full automatic self clean system

2004 Invention of the first SelfCooking Center® of the world

2005 Invention of the first VarioCooking Center® of the world by our daughter company FRIMA. Cooking, roasting, frying, simply better, in one appliance, with double speed.

2008 Opening of the third and biggest plant in Landsberg

2008 CleanJet+Care® – cleaning intelligence for a maximum reliability

2011 Invention of SelfCooking Center whitefficiency with Efficient Level Control

The following subsidiaries were founded:

UK, France, Japan, USA, Italy, Scandinavia, Switzerland, Canada, Spain,

Germany, Russia, Austria, Poland, China, Greece, Middle East and Brasil

|

V02 en, Basic_Maintenance_Accessories |

— 4 — |

— 5 —

Accessories_Maintenance_Basic en, V02

|

Product line: |

Designation: |

Serial number |

Produced |

Produced |

||

|

as of |

up to |

|||||

|

Classic Line |

CD |

Steam, Hot air, Combi (S, HA, CS) |

1018909 1234 |

1976 |

05-1997 |

|

|

CM |

(S, HA, CS) Vario-Steam (VS) |

11M8610 1234 |

1986 |

11-1989 |

||

|

CM |

(S, HA, CS, VS), Reheating (R) |

11M8904 1234 |

04-1989 |

04-1991 |

||

|

CC |

(S, HA, CS, VS, R) Low Temp Cook (LT) |

11C9103 1234 |

03-1991 |

05-1997 |

||

|

CM |

S, HA, CS, VS, R |

11M9104 1234 |

04-1991 |

05-1997 |

||

|

CM Gas (101) |

14G9104 1234 |

04-1991 |

10-1997 |

|||

|

CM Gas (201) |

21G9301 1234 |

01-1993 |

10-1997 |

|||

|

CM Gas (62) |

62G9403 1234 |

03-1994 |

10-1997 |

|||

|

C-Line |

||||||

|

C-Line 61, 101 |

CCD – CCM — CCC |

CCM, CCC: humidity control |

C11D93101234 |

10-1993 |

05-1995 |

|

|

C-Line 201, 202 |

CCD – CCM — CCC |

C11M93101234 |

10-1993 |

05-1997 |

||

|

C-Line 61, 101 |

CCD – CCM — CCC |

C11C95051234 |

05-1995 |

05-1997 |

||

|

C-Line 102 |

CCD – CCM — CCC |

C12C95101234 |

10-1995 |

05-1997 |

||

|

CPC Line : |

||||||

|

ClimaPlus Combi® |

CD – CM — CPC |

CPC: ClimaPlus control |

E11CA97051234 |

05-1997 |

02-1999 |

|

|

CM Gas, CPC Gas |

G11CA97101234 |

10-1997 |

02-1999 |

|||

|

CPC |

New humidity control |

E11CB99021234567 |

02-1999 |

03-2004 |

||

|

CPC |

IQT Sensor |

E11CB99101234567 |

10-1999 |

03-2003 |

||

|

CPC |

CleanJet®, CDS® |

E11CC00031234567 |

03-2000 |

03-2004 |

||

|

CM Gas, CPC Gas |

Electronic motor control, |

G11CD01011234567 |

01-2001 |

03-2004 |

||

|

230V burner control |

||||||

|

CM, CPC Electric |

Electronic motor control |

E11CD01031234567 |

03-2001 |

03-2004 |

||

|

CD – CM — CPC |

Elimination of motor protector |

E11CD01121234567 |

12-2001 |

03-2004 |

||

|

SCC Line |

||||||

|

SelfCooking Center® |

CM Electric / Gas |

E11ME04042345678 |

04-2004 |

01-2006 |

||

|

CM Electric / Gas |

New CPU pcb |

E11MF06022345678 |

02-2006 |

09-2008 |

||

|

CM Electric / Gas |

Extension of warranty |

E11MG08102355678 |

10-2008 |

09-2011 |

||

|

SCC Electric / Gas |

E11SE04042345678 |

04-2004 |

09-2008 |

|||

|

SCC Electric / Gas |

CareControl / Extension of warranty |

E11SG08102445678 |

10-2008 |

09-2011 |

||

|

CM_P Electric / Gas |

Programmable and humidity control |

E11MH1109 |

09-2011 |

|||

|

SCC_WE Electric / Gas |

Efficient Level Control |

E21SH1109 |

09-2011 |

Steamer Combi the of History

Structure of serial number

|

Classic Line — 05 / 1997 |

Serial number |

||||||||

|

Unit size |

Type |

||||||||

|

06 |

— 6×1/1GN |

Size |

Type |

Year |

Month |

Serial-# |

|||

|

11 — 10×1/1GN |

CD |

006 |

94 |

07 |

1234 |

||||

|

21 |

— 20×1/1GN |

CM |

06 |

M |

95 |

08 |

1235 |

||

|

20 |

— 20×2/2GN |

CC |

20 |

C |

96 |

10 |

1236 |

||

|

14G — CM 101 Gas (1×1/1GN) |

21G — CM 201G (21×1/1GN) |

62G — CM 62G (6×2/1GN) |

|||||||

|

C — Line — 10 /1993 — 05 /1997 |

Serial number |

||||||||

|

Unit size |

Type |

||||||||

|

61 |

— 6×1/1GN |

Family |

Size |

Type |

Year |

Month |

Serial-# |

||

|

11 — 10×1/1GN |

|||||||||

|

12 |

— 10×2/1GN |

CCD |

C |

61 |

D |

95 |

08 |

1234 |

|

|

21 |

— 20×1/1GN |

CCM |

C |

11 |

M |

95 |

11 |

1235 |

|

|

22 |

— 20×2/2GN |

CCC |

C |

21 |

C |

96 |

05 |

1236 |

|

|

CPCLine — 06/1997 — 04/2004 |

Serial number |

|||||||||||

|

Unit size |

Type |

E — Elec. |

||||||||||

|

G — Gas |

||||||||||||

|

61 |

— 6×1/1GN |

Family |

Size |

Type |

Version |

Year |

Month |

Serial-# |

||||

|

11 — 10×1/1GN |

A |

|||||||||||

|

12 |

— 10×2/1GN |

CD |

E |

61 |

D |

B |

98 |

12 |

1234 |

|||

|

21 |

— 20×1/1GN |

CM |

E |

12 |

M |

C |

99 |

01 |

1234567 |

|||

|

22 |

— 20×2/2GN |

CPC |

G |

22 |

C |

D |

96 |

05 |

1458967 |

|

SCCLine — 04/2004 — |

Serial number |

|||||||||||

|

Unit size |

Type |

E — Elec. |

||||||||||

|

G — Gas |

||||||||||||

|

61 |

— 6×1/1GN |

Family |

Size |

Type |

Version |

Year |

Month |

Serial-# |

||||

|

11 — 10×1/1GN |

||||||||||||

|

12 |

— 10×2/1GN |

E |

21 |

S |

E |

04 |

05 |

2345678 |

||||

|

21 |

— 20×1/1GN |

CM |

E |

06 |

M |

F ( CM) |

06 |

02 |

2434567 |

|||

|

22 |

— 20×2/2GN |

SCC |

G |

11 |

S |

G |

08 |

10 |

2534567 |

|||

|

CM_P |

E |

11 |

M |

H |

11 |

09 |

2567892 |

|||||

|

SCC_WE |

G |

21 |

S |

H |

11 |

09 |

2569812 |

|

V02 en, Basic_Maintenance_Accessories |

— 6 — |

Unit history: Control panel Layout

Classic Line, CD, CM, CC

C-Line, CCD, CCM, CCC

CPC Line, CD, CM, CPC

SCC Line, CM, SCC

Combi Master Plus , SCC_WE „whitefficiency“

|

— 7 — |

V02 en, Basic_Maintenance_Accessories |

Unit sizes

Serial number

|

SelfCooking Center® |

SelfCooking Center® |

|

|

6 x 1/1 GN |

6 x 2/1 GN |

SelfCooking Center® |

|

Thermo Cabinet |

Base stand |

10 x 1/1 GN |

|

Serial number |

|

SelfCooking Center® |

SelfCooking Center® |

SelfCooking Center® |

|

10 x 2/1 GN |

20 x 1/1 GN |

20 x 2/1 GN |

|

V02 en, Basic_Maintenance_Accessories |

— 8 — |

— 9 —

Accessories_Maintenance_Basic en, V02

|

Cabinet sensor |

|||

|

B1 |

F4 |

Safety thermostat STB |

|

|

Venting pipe |

B3.1 — 3.6 |

||

|

Check valve |

Core sensor (CT) |

||

|

Level electrode |

Diff. pressure sensor |

||

S2

|

Sensor steam |

||||

|

generator |

B5 |

|||

|

F3 |

Safety |

|||

|

thermostat |

||||

|

Steam heating element |

||||

|

Steam generator |

M4 |

|||

|

Self Clean (SC) pump |

||||

|

Solenoid valve |

||||

|

moistening |

||||

|

Care |

||||

|

Solenoid valve |

M12 |

|||

|

fillling |

Solenoid valve |

|||

|

Care |

||||

|

Y1 |

Y3 |

Y4 |

Quenching |

|

|

B2 |

||||

|

sensor |

Solenoid valve

S11

Y2

|

P1 |

Cabinet |

|

|

Y5 |

||

|

Clima valve |

||

|

Fan motor |

||

|

M1 |

||

|

Humidity |

||

|

thermocouple |

Air baffle |

|

|

B4 |

||

Hot air heating element

S3

Door contact switch

Emergency drain

Quenching box

M6

Drain valve

S12

Hand shower roll guide

principle Basic

General information about water

Water- / Steam ratio

|

Hot air |

1dm3 |

E+ |

2dm3 |

||||||||||||||

|

volume |

30°C |

300°C |

|||||||||||||||

|

Steam |

E+ |

||||||||||||||||

|

1l Water |

Expansion through |

||||||||||||||||

|

heat energy |

|||||||||||||||||

|

approx.1700l Steam |

|||||||||||||||||

|

E- |

|||||||||||||||||

|

cold water |

|||||||||||||||||

|

Volume reduction |

1l |

Water |

|||||||||||||||

|

1700l Steam |

|||||||||||||||||

|

through quenching |

|||||||||||||||||

The conductivity of the connected water should be above 50µS/cm (micro Siemens).

The measured total hardness (TH) is normally higher than the measured amount of Carbonate hardness — calcium or magnesium carbonat (CaCO3, MgCO3).

Should the total hardness be less than the Carbonate hardness, most likely a water treatment system is connected.

|

Common terms: |

||

|

Total hardness |

TH |

is the measure of carbonate (CH) and non-carbonate |

|

hardness (NCH) in the water |

||

|

Carbonate hardness |

CH |

is the measure of bicarbonate (HCO3-) and carbonate |

|

(CO3—) ions in the water; |

||

|

Temporary water hardness; Forms sediments when |

||

|

boiled; |

||

|

Non-carbonate hardness |

NCH |

Calcium and Magnesum ions in the water; |

|

permanent water hardness which can not be removed by |

||

|

boiling |

||

|

Water hardness |

e |

1°dH = 1,25°e = 1,78°f = 17,8 ppm/l = 0,178 mmol/l |

|

Chlorine |

Cl |

Gaseous, (used in swimming pools), limit 0,2mg/l |

|

Chloride |

Cl—— |

chemical bond of chloride e.g. NaCl, limit 80mg/l |

Water Analysis

Which values are required?

—Total hardness TH

—Carbonate hardness CH

—Conductivity in micro Siemens/cm

—Ideal: Water analysis with chloride content value

Possible reasons for corrosion

—excessive usage

—ferritic accessories

—rusting water pipes

—cleaning procedure (Unit is not dry over night)

—water

|

V02 en, Basic_Maintenance_Accessories |

— 10 — |

Water Info

Because of continuous examinations of systems for water treatment we would like to offer you some information on different systems.

The given statements are only related to Rational units.

1.Recommended systems for water treatment

A)With pure scale problems in the steam generator we recommend hydrogen-(H+)-Ionic exchanger. This type of filter will extend the intervals between descales by approx. 5 to 8-times of the normal descaling intervals. Please note that even with this type of filter it is still necessary to descale the steam generator.

B)With a high chloride content above 80mg/l of water it is possible, that the interior cabinet will start to corrode. To remedy this problem it is necessary to install a reverse osmosis filter.

C)With chlorine-contents above 0,2 mg/l of water an active carbon filter should be installed, to avoid corrosive radicals when chlorine is heated up.

D)If the water is soiled with sand, iron particles or suspended matter a particle filter with 5-15 μm is recommended.

2.Limited recommended systems for water treatment

Physical systems for water treatment:

On some sites this type of water treatment showed satisfactory results. On other sites there was no positive effect visible. Because of these circumstances we can not make a final assessment of this system.

3.Non recommended systems for water treatment

A)Sodium-Ionic exchanger:

With this filter system calcium is replaced by sodium. On chloride contents of the water above 50mg/l, sodium reacts with chloride to NaCl (=salt). This increase of salt in the water results in a delay in boiling of the water. This delay in boiling can cause ”spitting” steam generators.

B)Silicate-dosing systems:

This kind of systems is problematic, as the adding of non conductive silicates, will influence the water level measurement.

|

— 11 — |

V02 en, Basic_Maintenance_Accessories |

Installation — Duties and responsibilities

Installation

Responsibilities Designer / Architect

Make sure that during construction all dimensions needed are correct and sufficient (Doors, corridors etc)

Make sure that all services (energy, water, drain and exhaust air) are available in immediate vicinity of the unit

1.Drain

2.Water (Pressure, Water treatment)

3.Power supply and breaker specification

4.Gas connection (type of gas, dimension of supply pipe)

5.Vent hood (possible interconnection with gas supply)

6.Exhaust air for gas units (exhaust hood, ventilation ceiling, chimney, spacing between top edge of unit to lower edge of fat filters / ceiling)

7.possible need for levelling device for trolley with sloped floor

Document: Pre Installation checklist

Designer Manual

Installer

Make sure the installation complies with the installation manual (part of starter kit) and the local and / or national legislation / codes

1.Installed horizontally

2.Secured to the ground / stand secured from moving

3.Uneven floor levelled

4.Connected to cold water, possibly treated water, (water line rinsed)

5.Connected to power (equipotential bonding included — where required))

6.Connected to drain (steam temperature resistant pipe, permanent slope, P-trap)

7.Connected to gas supply (correct type of gas), leakage test up to unit connection point

8.Installation of accessories (Ultravent)

9.Testing of electrical safety

Document: Installation manual

RSP, Dealer

Commissioning and hand over to the customer

1.Confirm installation according to installation manual

2.Commissioning

3.Gas unit: Leakage test inside the unit

4.Gas unit: Flue gas analysis

5.Successful completion of Self Test

6.Function test of all components and cooking modes

7.Demonstration of cleaning mode for customer

8.Demonstration of preventive maintenance for customer (daily cleaning)

9.Download of Service Data

10.Photos of installation site

Document: Installation and commissioning checklist

Installation manual

Operator manual

|

V02 en, Basic_Maintenance_Accessories |

— 12 — |

Relationship: Installation — Components — Environment

The unit will only function properly, when all components are designed correctly and the installation is done according to the manufacturers instructions.

Therefore during maintenance and troubleshooting it is mandatory to observe all components together with the connected services such as electricity, water etc. and the kitchen surrounding and venting.

Every deviation from the installation manual can cause different errors.

|

Voltage |

Software |

|||

|

Installation |

Water quality |

|||

|

Accessories |

Air supply Gas |

|||

|

Original components |

Flue venting |

|||

|

Type of gas |

Drain |

|||

|

— 13 — |

V02 en, Basic_Maintenance_Accessories |

Preinstallation checklist

Preinstallation checklist

Company name:

Name of contact person:

Street:

City:

Country:

Telephone number:

Fax-Number:

E-Mail:

Number of RATIONAL units already installed:

Serial number of installed units:

How many units shall be installed?

What type of unit shall be installed?

Please fill in the form either by making a tick in the corresponding box or writing down the measured values in the corresponding lines.

All measures, distances, services like electricity, water, drain and gas connection are properly installed and complying with the list attached.

|

Yes |

No |

additional comments: Yes |

||

|

Signature: Customer |

Sales |

Date |

|

V02 en, Basic_Maintenance_Accessories |

— 14 — |

Preinstallation checklist

1. Check all doors and corridors for sufficient space

|

Required door width “X”: |

|||

|

Unit size |

without pallet |

with pallet |

|

|

6×1/1GN |

840 mm (33 1/8”) |

920mm (36 1/4“) |

|

|

6×2/1GN |

1040 mm (41”) |

1120mm (44 1/8“) |

|

|

10×1/1GN |

840 mm (33 1/8”) |

920mm (36 1/4“) |

|

|

10×2/1GN |

1040 mm (41”) |

1120mm (44 1/8“) |

|

|

20×1/1GN |

920 mm (36 1/4”) |

950mm (37 1/2“) |

|

|

20×2/1GN |

1140mm (45“) |

1150mm (45 1/4“) |

|

|

Dimensions of doors |

Dimension of corridors |

20×1/1 GN / 20×2/1 GN: 1900mm/75″

_____________mm ______________mm

_____________mm ______________mm

_____________mm ______________mm

Hints:

—Dismounting door handle reduces depth minus 20 mm.

—Table models are with left hinged doors available.

2. Check site

yes no

a) Floor level?

if no, what is the approximate slope

(in case the slope is more than 3% use access ramp)

b)Space left/right/rear

Write down distances on page 3

Breite

Tiefe

Attention: No fryers at the left side of the unit Install heat shield if necessary

c)Other appliances left of the unit (seen from front side) within 500 mm (20“)

Yes No

If yes, which appliance?

_______________________________

d) In case of floor models, is parking space for trolleys available Yes No

|

Unit size |

depth: |

width |

e) Is an extraction hood installed? |

|

6×1/1GN |

840 mm (33 1/8”) |

847mm (33 3/8“) |

|

|

6×2/1GN |

1040 mm (41”) |

1069 mm (42 1/8“) |

|

|

10×1/1GN |

840 mm (33 1/8”) |

847 mm (33 3/8“) |

|

|

10×2/1GN |

1040 mm (41”) |

1069 mm (42 1/8“) |

|

|

20×1/1GN |

920 mm (36 1/4”) |

879 mm (34 5/8“) |

|

|

20×2/1GN |

1140mm (45“) |

1084 mm (42 5/8“) |

|

— 15 — |

V02 en, Basic_Maintenance_Accessories |

Preinstallation checklist

|

P |

||

|

C |

||

|

B |

||

|

A |

||

|

D |

||

|

F |

||

|

G |

H |

|

|

E |

||

|

I |

||

|

J |

||

|

L |

K |

|

|

O |

||

|

M |

Please fill in values measured at the site:

For calculating the distances see unit sizes on page 2.

If the connection points are at complete different position show the correct position in the sketch

Side/top distances

A=

B=

C =

P=

Power supply

D=

E =

Gas supply (in case of gas units)

F =

G =

Type of gas connection

Water supply

H =

I =

Drain:

|

Table model |

Floor model |

|

J = |

M = |

|

K = |

N = |

|

L = |

O = |

3. Elecrical connection

a) Which mains is available (fill in rest)?

1NAC………..

2AC…………..

3NAC………..

3AC…………..

b) What fuses are installed in the mains

……………….. A

ELCB / Residual current device (30mA) installed?

Yes

|

V02 en, Basic_Maintenance_Accessories |

— 16 — |

Preinstallation checklist

4. Water supply

Yes No

a) Water treatment system installed

If yes, which system_________________________________________

b)Separate water tap for every unit (Attention: Unit has 3/4” connection)

c)Measured water pressure:_________________________________________________

d)Measured water temperature:______________________________________________

4.Drain

a)Location of drain (fill in page 3)?

b)Material of drain pipe______________

Suggestion for drain connection

|

200-300mm |

|

(8 — 12 “) |

|

3×45° |

|

250-300mm |

|

(10 — 12 “) |

|

min. 3° / 5% |

|

Ø 50mm (2”) |

|

max. 1m |

|

(3 ft.) |

|

min. 3° / 5% |

|

|

Ø 50mm (2”) |

|

|

70mm |

max. 1m |

|

(2 3/4“) |

(3 ft.) |

NOTE:

Only use steam temperature resistant pipes for drain connection, no hoses!

5.Gas supply (in case of gas units)

a)Which gas type is foreseen?__________________________________________

b)Attention: Unit has 3/4” connection

c)Inform customer to discuss room size and flue gas system with local gas authority

yes no

6. Customer was informed about 2 years warranty?

7. Connection set complete (#60.70.464) required?

7. Comments / Notes

|

— 17 — |

V02 en, Basic_Maintenance_Accessories |

Installation sheet — Electric / Gas units — Electrical connection

Electrical unit connection

61-102

Gas units:

Integrated cable w/o plug top,

length approx. 2,5m,

Remove left side panel

Loosen 7 mm hex head screw

Opening for power cable

Electrical unit connection

201-202

Gas units:

Integrated cable w/o plug top,

length approx.. 2,5m

Remove left side panel

Loosen 7 mm hex head screw

Opening for power cable

Mains supply cable (Observe your local code for maximum cable length)

|

Terminal connection |

3NAC400V |

3AC440V |

Gas: 1NAC230V |

||||||||||||||

|

N |

L1 |

L2 |

L3 |

||||||||||||||

|

61 |

5×2,5mm² |

4×2,5mm² |

3×2,5mm² |

||||||||||||||

|

Fig. 1 |

Ye/gn |

blue |

grey |

grey |

grey |

||||||||||||

|

62 |

5x4mm² |

4x4mm² |

3×2,5mm² |

||||||||||||||

|

N |

L1 |

L2 |

L3 |

||||||||||||||

|

101 |

5x4mm² |

4x4mm² |

3×2,5mm² |

||||||||||||||

|

102 |

5x10mm² |

4x10mm² |

3×2,5mm² |

||||||||||||||

ELCB Breaker — residual current device 30 mA recommended.

Electrical connection gas units: observe polarity!

All services must comply to local rules and regulations!

|

V02 en, Basic_Maintenance_Accessories |

— 18 — |

Installation sheet — Electric / Gas units — Water connection

Table units 61 — 102

Treated water

Fresh water Fresh water

(common water supply)

|

Floor units |

|

|

201 — 202 |

|

|

Treated water |

Fresh water |

|

Fresh water |

|

|

(common water supply) |

Dimension water supply hose: 1/2“ pressure hose with 3/4” connection at the unti; Water pressure:150-600 kPa with 20/25 l/min water quantity

Maximum water temperature for fresh and treated water: 30°C (87°F)

Note:

For selection of water filter please refer to installation manual!

Filter might be necessary in case of:

|

Cl2 |

>0,2 mg/l |

|

Cl— |

>80 mg/l |

very hard water (details: Water info and Installation manual)

All services must comply to local rules and regulations!

|

— 19 — |

V02 en, Basic_Maintenance_Accessories |

Installation sheet — Electric / Gas units — Drain connection

Drain connection table model

Note: See install manual for leveling unit

Rear view

3×45°

DN 50 HT pipe

weight of piping not to be placed on unit drain

Fixed to stand

Air gap per local code

Floor drain sink with grease trap

|

Drain connection floor model |

|

Note: See install manual for leveling unit |

|

Side view left |

|

Length approx. |

|

250 mm |

|

Drain connected |

|

to unit leg |

|

DN 50 HT pipe |

|

Floor drain sink with grease trap |

Fixed drain connection table model

Note: See install manual for leveling unit

|

Rear view |

|

3×45° |

|

DN 50 HT pipe |

|

approx. 550 mm |

|

approx. 720 mm |

|

approx. 300 mm |

Installation kit available # 60.70.464 (Water supply hose

Drain pipe set DN50 HT)

All services must comply to local rules and regulations!

|

V02 en, Basic_Maintenance_Accessories |

— 20 — |

Installation sheet — Gas units — Gas connection

Gas connection 61 — 102

Note: Observe local rules and regulations

Unit under extraction hood

min. 400mm

Gas stop

valve

Gas supply

Gas quick

RATIONAL

Gas connection

Natural gas 1,8 — 2,5 kPa LPG 2,5 — 5,75 kPa

¾“ for 61 — 202

Gas connection 201 — 202

Note: Observe local rules and regulations

Gas stop valve

Gas supply

Gas quick disconnect hose 1,5m

All services must comply to local rules and regulations!

Unit under extraction hood

Fat filter

min. 400mm

Gas connection

Natural gas 1,8 — 2,5 kPa LPG 2,5 — 5,75 kPa

¾“ for 61 — 202

|

— 21 — |

V02 en, Basic_Maintenance_Accessories |

Installation/Commissioning Checklist

Installation and Commissioning Checklist

To be completed individually for each Rational Combi installation. This checklist is to be completed and returned to your closest RATIONAL office (details are listed on the last page of the operation manual) within 14 days of installation / commission to validate warranty.

Customer name: Contact person: Street:

Town:

Country:

Telephone number:

Fax-Number: E-Mail:

Serial number of installed units:

Commissioned by company:

Date of installation:

Date of commissioning:

|

Installation complies |

does not comply |

with manufacturers specifications. |

||

Please fill all information required into the embossed fields.

If the measured values do NOT comply with the values in the installation manual please inform the customer and your Rational dealer.

We confirm the installation was done according to the attached installation checklist, the installation manual and all national and local codes which ever may apply. The equipment was handed over free of defects. Operation and maintenance of the equipment was explained.

|

———————————————- |

————————————- |

|

Signature / Date RSP / Dealer |

Signature / Date customer |

|

V02 en, Basic_Maintenance_Accessories |

— 22 — |

Installation/Commissioning Checklist

1. Perimeter clearances

|

Left side all units (except 201/202 E) minimum: |

50mm |

||||||

|

Left side 201/202 electric units minimum: |

500mm |

||||||

|

Left side recommended for all units for service |

|||||||

|

or with adjacent heat source: |

500mm |

||||||

|

Rear side all units minimum: |

50mm |

||||||

|

Right side all units minimum: |

50mm |

||||||

|

P |

|||||||

|

C |

B |

||||||

|

A |

|||||||

|

D |

|||||||

|

F |

|||||||

|

G |

H |

||||||

|

E |

|||||||

|

I |

|||||||

|

J |

|||||||

|

L |

K |

||||||

|

O |

|||||||

|

M |

|||||||

|

Perimeter clearances |

Gas supply (in case of gas |

Drain: Table models, |

|||||

|

units) |

floor models or Combi Duo |

||||||

|

A: |

C: |

F: |

G: |

J: |

M: |

||

|

B: |

P: |

Type of gas supply: |

K: |

N: |

|||

|

Power supply |

L: |

O: |

|||||

|

D: |

E: |

Water supply |

|||||

|

H: |

I: |

||||||

|

2. Levelling and floor fixing |

YES |

NO |

|||||

|

Mounting surface / stand is level? |

|||||||

|

Unit is level? |

|||||||

|

Electric and gas 61, 62, 101, 102 |

Stand is fixed to floor (Gas)? |

||||||

|

Unit is secured to mounting surface (Gas)? |

|||||||

|

Transport trolley is level with unit and stand? |

|||||||

|

Unit is level? |

|||||||

|

Unit is fixed to floor? |

|||||||

|

Electric and gas 201, 202 |

Mounting surface is level? |

||||||

|

Trolley stands level inside the unit? |

|||||||

|

Access ramp is installed? |

|||||||

|

Unit and trolley extension installed? |

|

— 23 — |

V02 en, Basic_Maintenance_Accessories |

Installation/Commissioning Checklist

|

3. Water connection |

YES |

NO |

||||||

|

Water shut off valve available for each unit (also for each Combi Duo unit)? |

||||||||

|

Water shut off valve accessible by operator? |

||||||||

|

Measured water pressure at the water inlet of the unit |

bar |

|||||||

|

All units: minimum 150KPa (1,5 bar), maximum 600 KPa, (6 bar) |

||||||||

|

Measured water temperature at the water inlet of the unit |

°C |

|||||||

|

Water filtration / treatment system installed? |

||||||||

|

Manufacturer and type of water filter / treatment system: |

||||||||

|

Measured water hardness |

Measured water hardness |

|||||||

|

at filter inlet |

____________ppm/l |

at filter outlet |

____________ppm/l |

|||||

|

1°dH = 1,25°e = 1,78°f = 17,8 ppm/l = 0,178 mmol/l |

||||||||

|

4. Drain |

YES |

NO |

||||||

|

Steam temperature resistant pipe, no flexible hose? (I.e. drain kit # 8720.1031)? |

||||||||

|

Drain table units: P-trap or open drain? (please fill in) |

||||||||

|

Drain floor units: P-trap or open drain? (please fill in) |

||||||||

|

(open drain MUST NOT end underneath unit) |

||||||||

|

Separate drain for each unit (also Combi Duo units)? |

||||||||

|

Additional vent pipe installed |

||||||||

|

Example table units |

Example floor models |

Rear view

|

Example additional vent pipe |

|

|

3×45° |

|

|

DN 50 |

8 mm |

|

HT pipe |

1/8″ |

|

approx. 550 mm |

|

|

3×90° |

|

|

approx. 720 mm |

|

|

approx. 300 mm |

|

|

V02 en, Basic_Maintenance_Accessories |

— 24 — |

Installation/Commissioning Checklist

|

5. Electrical connection — Observe Local and National Codes! |

YES |

NO |

|||||

|

Indicated voltage on data plate |

|||||||

|

Available voltage on site |

|||||||

|

Measured voltage |

L1L2:_______V |

L1 — L3: _______V |

L2 — L3: _______V |

||||

|

L1 — N: _______V |

L2 — N: ________V |

L3 — N: _______V N — PE: ______V |

|||||

|

Unit connected to equipotential bonding? |

|||||||

|

3 phase breaker installed? |

|||||||

|

Power switch / outlet accessible from front by operator? |

|||||||

|

Installed fuse rating? |

|||||||

|

Isolation/discharge current measurement carried out? |

|||||||

|

Amp draw at 100% steam heating |

L1:____A |

L2: ____A |

L3: ____A |

||||

|

Amp draw at 100% hot air heating |

L1:____A |

L2: ____A |

L3: ____A |

||||

|

Amp draw gas units |

A |

||||||

|

6. Gas connection — Observe Local and National Codes! |

YES |

NO |

|

Available diameter of gas line to each unit (all units 3/4“ minimum): |

||

|

Flue gas and fresh air system sufficiently dimensioned? |

||

|

Gas pressure regulator installed? |

||

|

Individual gas shut off valve installed for each unit? |

||

|

Gas shut off valve accessible by operator? |

||

|

Indicated gas type on data plate: |

||

|

Available gas type on site: |

||

|

Measured gas pressure with unit switched off (static gas pressure): |

mbar |

|

|

Measured gas flow pressure with unit switched on, |

||

|

when all other gas consumers in the kitchen are switched on (dynamic gas pressure): |

mbar |

|

|

Altitude above / below sea level? |

m |

|

|

Flue gas analysis carried out (write down values in below list)? |

||

|

Burner |

Values at max. RPM |

Values at min. RPM |

||||||

|

CO2 |

CO |

Flame current |

CO2 |

CO |

Flame current |

|||

|

Steam |

______% |

______ppm |

______μA |

______% |

______ppm |

______μA |

||

|

Hot air |

______% |

______ppm |

______μA |

______% |

______ppm |

______μA |

||

|

top |

||||||||

|

Hot air |

______% |

______ppm |

______μA |

______% |

______ppm |

______μA |

||

|

bottom |

||||||||

|

— 25 — |

V02 en, Basic_Maintenance_Accessories |

Installation/Commissioning Checklist

|

7. Exhaust / vent hood |

YES |

NO |

|

|

Exhaust / vent hood installed? |

|||

|

Serial number of installed UltraVent or extraction hood |

|||

|

In case of gas units is hood interlocked with gas supply? |

|||

|

Free space between top edge of unit and lower edge of exhaust hood / ceiling |

cm |

||

|

8. Function test / commissioning |

YES |

NO |

|

|

All electrical connections and plugs tight and in accordance with local regulation? |

|||

|

All water and drain connections tight and not leaking? |

|||

|

All modes operational? |

|||

|

All additional functions / features operational? |

|||

|

Self test completed successfully? |

|||

|

Customer was informed about 2 years warranty? |

|||

|

Customer advised in basic operation? |

|||

|

Customer advised in daily cleaning routine incl. door gasket? |

|||

|

Customer advised in preventative maintenance |

|||

|

(changing air inlet filter, door gasket, etc) |

|||

|

9. Miscellaneous |

YES |

NO |

|

|

Service data downloaded? |

|||

|

Photos of installation taken? |

|||

|

V02 en, Basic_Maintenance_Accessories |

— 26 — |

Preventive maintenance

Please fill in one form for every installed unit.

This checklist contains all works that have to be carried out during a maintenance.

Customer address Name

Company

Street

ZIP / Post code

City

Country

Telephone

Serial number of the unit

Software Version:

|

Checks / maintenance work scope |

Comment |

||

|

Installation (conforms to install instruction) |

YES |

NO |

|

|

All gas units and units 201-202 fixed to floor |

|||

|

Water connection |

|||

|

Manufacturer of water treatment system |

|||

|

Drain |

|||

|

Gas connection |

|||

|

Electrical connection |

|||

|

Cabinet door (Functional) |

YES |

NO |

|

|

Door lock |

|||

|

door catch |

|||

|

Door mounting / screws |

|||

|

Fastening of inner glass pane |

|||

|

Door gasket (steam tight in steam mode) |

|||

|