- Page 1

Schindler 3100/3300/6300 Owner’s Manual September 2017 J 43402603 / 01… - Page 2

Any reproduction, translation, copying or storing in data processing units in any form or by any means without prior permission of INVENTIO AG is regarded as infringement and will be prosecuted. Schindler 3100/3300/6300 J 43402603 / 01 2/269 Copyright ©… -

Page 3: Table Of Contents

Description of the Installation……. . 3.2.1 Control Elements in the Car Schindler 3100/3300/6300 . . . 3.2.2…

- Page 4

Maintenance Task List ……4.12.4.3 Maintenance Checks ……Schindler 3100/3300/6300 J 43402603 / 01 4/269… - Page 5

Control Functions……… 267 Schindler 3100/3300/6300… - Page 6

Schindler 3100/3300/6300 J 43402603 / 01 6/269 Copyright © 2017 INVENTIO AG… -

Page 7: About This Document

Completely installed passenger elevator or goods passenger elevator or accessible goods only elevator. Installer Natural or legal person who takes responsibility for the design, manufacture, installation, commissioning and placing on the market of elevators. Schindler 3100/3300/6300 J 43402603 / 01 7/269 Copyright © 2017 INVENTIO AG…

-

Page 8: Duties Of The Owner

If there are no specific regulations, the owner of the installation must ensure that periodic inspections must be carried out by a competent person according to the instructions given by the installer. Schindler 3100/3300/6300 J 43402603 / 01 8/269 Copyright © 2017 INVENTIO AG…

- Page 9

To meet the legal requirements, all safety components for lifts manufactured and/or supplied by Schindler will be labelled with a standard type label that among other information includes one or several of the following items: Ident, serial and batch number, name and address of the manufacturer and importer of the safety component for lifts, as well as a traceability tag (QR-Tag) for Schindler internal purposes. - Page 10

Lubricants and in particular motor and hydraulic oils belong to the classes of materials causing dangerous water pollution. Lead accumulators and batteries containing lead have to be transported to the local Schindler company for an adequate disposal. -

Page 11: Recommendations To The Owner

Availability of Parts Schindler guarantees the availability of original parts for 20 and 10 years for electro- mechanical parts and electronic parts respectively. Handling of…

- Page 12

Plan — Guideline are carried out. After an earthquake a full check of the whole shaft situation regarding deformation or damage, fallen debris must be before placing the lift back into service. Schindler 3100/3300/6300 J 43402603 / 01 12/269 Copyright © 2017 INVENTIO AG… -

Page 13: Periodic Checks By The Owner

– normal car light – door reversal devices – safety signs / pictograms Schindler 3100/3300/6300 J 43402603 / 01 13/269 Copyright © 2017 INVENTIO AG…

-

Page 14: Basic Information For The Customer

In the case where the building/elevator is used by other persons, or if the ownership of the building changes, the Owner Documentation has to be passed on. Signature Place / Date: Signature of the owner: Signature of the installer: Schindler 3100/3300/6300 J 43402603 / 01 14/269 Copyright © 2017 INVENTIO AG…

-

Page 15: Logbook

Owner: Put into Service Date: Observation: Maintenance Name: Company Address: City: Country: Telephone: Fax: Start date for maintenance: Major Repairs / Description Date Name and Important Signature Modifications Schindler 3100/3300/6300 J 43402603 / 01 15/269 Copyright © 2017 INVENTIO AG…

-

Page 16: Basic Characteristics Of The Installation

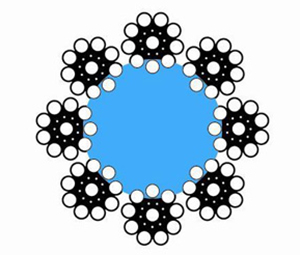

Number of traction media: Car safety gear type: Safety gear on counterweight: Machine Positioning Machine located inside the hoistway fixed on guide rail. Type of Drive Gearless machine with closed loop. Schindler 3100/3300/6300 J 43402603 / 01 16/269 Copyright © 2017 INVENTIO AG…

-

Page 17: Removing The Elevator Out Of Service For Some Time

– If there is no power, then the car and counterweight should ideally be suspended and the weight taken off the machine. Schindler 3100/3300/6300 J 43402603 / 01 17/269 Copyright © 2017 INVENTIO AG…

-

Page 18: Notification To The Installer

Notification to the Installer Purpose According to the product liability laws, Schindler as manufacturer must keep track of its installation(s) even after commissioning and handover. Therefore Schindler must be informed about any possible existence of dangerous conditions in the installation. Also changes in ownership should be communicated to Schindler.

-

Page 19: Declaration Of Conformity

For transport of passengers and goods according to the data plate in the car and the instruction manual. Place: Date: Company / Department: Last name / First name: Signature: Schindler 3100/3300/6300 J 43402603 / 01 19/269 Copyright © 2017 INVENTIO AG…

-

Page 20: Instruction For Use

The load must be evenly distributed over the car floor. A single heavy load being brought into the car all at once can cause damage to the car. [38966; 22.03.2011] Schindler 3100/3300/6300 J 43402603 / 01 20/269 Copyright © 2017 INVENTIO AG…

-

Page 21: Description Of The Installation

Power Transmission Monitored by the controller, the motor (7) drives the traction sheave (8), which transmits the force to the car (11) by the suspension media (14) and counterweight (1). Schindler 3100/3300/6300 J 43402603 / 01 21/269 Copyright © 2017 INVENTIO AG…

- Page 22

(*). The fireman’s control is turned on or off either: – by the fire emergency key switch, located on main floor (BR1) Schindler 3100/3300/6300 J 43402603 / 01 22/269 Copyright © 2017 INVENTIO AG… - Page 23

Visitors control is an option linked with the «Penthouse option». When a penthouse’s visitor dials the top floor on the COP, the landing button at the penthouse floor makes an intermittent acoustic signal and a visual signal blinks. Schindler 3100/3300/6300 J 43402603 / 01 23/269… - Page 24

The scope of this system is to authorize the access to restricted areas in a sure and simple way, or to select a floor without pushing any button. Each passenger using this function shall have a transponder (Schindler or customer card) with its own identification code. -

Page 25: Control Elements In The Car Schindler 3100/3300/6300

3.2.1 Control Elements in the Car Schindler 3100/3300/6300 Car Operating Panel Pick-up and collective control: COP [41853; 17.03.2017] Includes: – Travel command keyboard (6). It is used to select the destination floor. As soon as a key pad (with Braille identification) is touched, a local short beep is generated and the destination floor is displayed on the lower indicator (5) to acknowledge.

- Page 26

Protected car call (PIN code). The pin code is used to enable a protected destination floor previously entered. – Floor access protection on COP with Schindler card or additional key under the COP (not shown on the picture). – Out of service indicator. - Page 27

Emergency light in long COP Long COP For long COP (5), emergency light (4) is behind the glass panel (3). 3.2.2 Control Elements on the Landings Schindler 3100/3300/6300 Landing Call The landing call button is used to call a car. Sensitive Button [39321;… - Page 28

Landing Call Push Includes: Button – Landing call – Also available Schindler 3100 indicator type (See 3.2.4). [39323; 21.08.2013] Indicator [39324; 23.09.2015] Includes: – Direction arrows (pick-up) – Pre-announcing arrows (collective/selective) – with / without acoustic signal – Car position –… -

Page 29: Guide To Safe Operation Of The Installation

Do not throw objects, especially burning matches or cigarettes, through the gap between the door and the landing sill into the hoistway pit. This may cause a fire and dangerous smoke. [38965; 22.03.2011] Schindler 3100/3300/6300 J 43402603 / 01 29/269 Copyright © 2017 INVENTIO AG…

- Page 30

The following measures must be taken to serve disabled persons: – Door opening and closing times are to be adjusted. – Special operating panels must be installed in the car. Schindler 3100/3300/6300 J 43402603 / 01 30/269 Copyright © 2017 INVENTIO AG… -

Page 31: En81 — 28: Remote Alarm On Passenger And Goods Passenger Elevators

The functioning of the communication facility with the emergency rescues service must be guaranteed during the entire lifetime of the installation. A competent person must Schindler 3100/3300/6300 J 43402603 / 01 31/269…

-

Page 32: Emergency Rescue Procedure

Periodic and automatic checks. The owner of the installation can ask for human response in a more specific language(s) in addition to the official language(s) (see EN 81-1:1998,0.2.5 and EN 81-2:1998, 0.2.5). Schindler 3100/3300/6300 J 43402603 / 01 32/269 Copyright © 2017 INVENTIO AG…

-

Page 33: Short Customer Configuration Guide

— sends Installation ID #12xxxxxxxxxxxx# (x=0 to 999999999999) #13# → — ask the Unit ID with Verify Unit ID ← #15abcd# — sends Unit ID (a=1 to

Schindler 3100/3300/6300 J 43402603 / 01 33/269 Copyright © 2017 INVENTIO AG…

- Page 34

TA device hangs up the phone line If the alarm device answers with #99# then the TA device did not get the DTMF commands right. Try again to send the command. Schindler 3100/3300/6300 J 43402603 / 01 34/269 Copyright © 2017 INVENTIO AG… - Page 35

Optional. Necessary only when connection required to other unit than master unit. If the alarm device answers with #99# then the TA device did not get the DTMF commands right. Try again to send the command. Schindler 3100/3300/6300 J 43402603 / 01 35/269… - Page 36

TA device hangs up the phone line If the alarm device answers with #99# then the TA device did not get the DTMF commands right. Try again to send the command. Schindler 3100/3300/6300 J 43402603 / 01 36/269 Copyright © 2017 INVENTIO AG… - Page 37

TA device hangs up the phone line If the alarm device answers with #99# then the TA device did not get the DTMF commands right. Try again to send the command. Schindler 3100/3300/6300 J 43402603 / 01 37/269 Copyright © 2017 INVENTIO AG… - Page 38

All headers and all line endings must be present in the SMS. If there are only one or two alarm number, reuse the same phone number for the others or leave it empty. Schindler 3100/3300/6300 J 43402603 / 01 38/269… - Page 39

Header of the third SMS number +4179123458 Third SMS number (can be empty) SNUM4 Header of the fourth SMS number +4179123459 Fourth SMS number (can be empty) Declares the end of the SMS Schindler 3100/3300/6300 J 43402603 / 01 39/269 Copyright © 2017 INVENTIO AG… - Page 40

// header of the serial number of this ETMA-GSM (for security) 2345678901 // example of a ETMA-GSM 10 digit serial number REQ ETMA GSM will only answer, if it is properly configured with the SMS. Schindler 3100/3300/6300 J 43402603 / 01 40/269 Copyright © 2017 INVENTIO AG… - Page 41

A reboot of the device will reset the flags, which means that the message will be sent again if the event is still there. The flags shall be reset in any case after 24 hours. Schindler 3100/3300/6300 J 43402603 / 01 41/269… - Page 42

Once the ETMA WL is configured with third party, it is not possible anymore to recover to Third Party the factory state. In this case, contact the Schindler second level support. Configuration Factory reset command with DTMF or with the PTT button on the device will only reset the SMS phone numbers and as well the installation ID. - Page 43

TA device hangs up the phone line If the alarm device answers with #99# then the TA device did not get the DTMF commands right. Try again to send the command. Schindler 3100/3300/6300 J 43402603 / 01 43/269 Copyright © 2017 INVENTIO AG… -

Page 44: Rescue Of Trapped Passengers

Turn ON the Manual Evacuation Switch, JEM Press with 3-second intervals the manual evacuation button, DEM When the blue floor indicator LED, LUET, lights up, turn OFF the manual evacuation switch, JEM Schindler 3100/3300/6300 J 43402603 / 01 44/269 Copyright © 2017 INVENTIO AG…

-

Page 45: Inspection And Emergency Recall Operations According En81-20

The interlock and priorities are defined and guaranteed by the hardware circuit design of the safety circuit and the switches and buttons of the inspection and emergency recall panels. Schindler 3100/3300/6300 J 43402603 / 01 45/269 Copyright © 2017 INVENTIO AG…

- Page 46

Release DRH_U or DRH_D to stop the car movement – Press JHM to stop the car movement Deactivation: – Switch JRH to «Normal» – Check that JHM is not pressed Schindler 3100/3300/6300 J 43402603 / 01 46/269 Copyright © 2017 INVENTIO AG… - Page 47

Press and hold DREC_D and DREC_E to move the car downwards – Release DREC_U or DREC_D or DREC_E to stop the car movement – Press JHC to stop the car movement Schindler 3100/3300/6300 J 43402603 / 01 47/269 Copyright © 2017 INVENTIO AG… - Page 48

Switch JRESG to «Inspection» – If necessary, return the pit ladder to its designated location – Release JHSG1 on Pit Box only if JRESG has been switched to «Inspection» Schindler 3100/3300/6300 J 43402603 / 01 48/269 Copyright © 2017 INVENTIO AG… - Page 49

2 s, the controller will disregard the current pulse pattern and continue to wait for a valid pulse pattern. [604620_038; 23.08.2017] A controller reset will not reset the pit inspection mode. Schindler 3100/3300/6300 J 43402603 / 01 49/269 Copyright © 2017 INVENTIO AG… - Page 50

Activation: – Activate the TSD21 lever. – If necessary, extract/unfold the balustrade. – Switch JREC to «Inspection» – Release JHC only if JREC has been switched to «Inspection» Schindler 3100/3300/6300 J 43402603 / 01 50/269 Copyright © 2017 INVENTIO AG… - Page 51

See table below). Inspection Operation in Pit with TSD21 STOP NORMAL STOP JHSG1 DRESG_E JRESG JHSG DRESG_U DRESG_D JHSG1 Pit Inspection Panel RESG [604620_036; 23.08.2017] Pit box Schindler 3100/3300/6300 J 43402603 / 01 51/269 Copyright © 2017 INVENTIO AG… - Page 52

– If necessary, return the pit ladder to its designated location. – Release JHSG1 only after leaving the shaft pit. – Close the shaft door for pit access. Schindler 3100/3300/6300 J 43402603 / 01 52/269 Copyright © 2017 INVENTIO AG… - Page 53

(if TSD21 lever and any) extract balustrade (if any). On car roof, cycle top of car inspection Access pit 1) Foldable balustrade only required if short head. Schindler 3100/3300/6300 J 43402603 / 01 53/269 Copyright © 2017 INVENTIO AG… -

Page 54: Safe Access To Car Top — Normal Car Top Safety Height Of 1 M En81-1 And En81-20

Open the hoistway door and access the car top – Switch ON the inspection mode – The buzzer stops – The system is now ready in inspection mode. Schindler 3100/3300/6300 J 43402603 / 01 54/269 Copyright © 2017 INVENTIO AG…

-

Page 55: Safe Access To Car Top And/Or Pit In Case Of Limited Safety Space In Endposition En81-1 And En81-20

(shaft) as long as the TSD21 system is deactivated due to risk of crushing. Schindler 3100/3300/6300 J 43402603 / 01 55/269 Copyright © 2017 INVENTIO AG…

- Page 56

In addition, a safety system is connected to the controller. Any landing door or other opening point giving access to an area where the clearances are reduced is fitted with a safety contact (KNET) monitoring the activation of the Schindler 3100/3300/6300 J 43402603 / 01 56/269… -

Page 57: Tsd21 — Safe Access To Car Top And/Or Pit In Case Of Limited Refuge Space Per En 81-1 And En

The manual opening of any landing door (KNETs), the retracted position of the movable bolts (KSR-A), if the balustrade (if any) is retracted (KBC-A/KFB) are monitored, which are parts of the safety circuit. Schindler 3100/3300/6300 J 43402603 / 01 57/269…

- Page 58

B Inspection mode Metal bolt Buffer Stopper TSD21 lever Option in case of low pit or low Bolts expanded (generating pit and head only safety space in end positions) Schindler 3100/3300/6300 J 43402603 / 01 58/269 Copyright © 2017 INVENTIO AG… - Page 59

(shaft) as long as the TSD21 system is deactivated due to risk of crushing. Correct working of shaft access detection (KNET) must be guaranteed . Schindler 3100/3300/6300 J 43402603 / 01 59/269 Copyright © 2017 INVENTIO AG… -

Page 60: Main Additional Safety Measures With Tsd21

(KENT) and a special sequence for the shaft access and shaft exit need to be followed. The following tables highlight the main shaft access and exit procedure steps required for proper use of the TSD21 system. Schindler 3100/3300/6300 J 43402603 / 01 60/269…

-

Page 61: Inspection Operation At Top Of Car With Tsd21

The whole sequence for the inspection at top of car with TSD21 consists of the following steps: – Preparation for entering car roof – Activating the inspection mode – Inspection operation – Deactivation of inspection mode – Reset of TSD21. Schindler 3100/3300/6300 J 43402603 / 01 61/269 Copyright © 2017 INVENTIO AG…

- Page 62

Release JHC only if JREC has been switched to «Inspection» The elevator status indication on the HMI changes to «54», which means that the top of car inspection mode is active. Schindler 3100/3300/6300 J 43402603 / 01 62/269 Copyright © 2017 INVENTIO AG… - Page 63

Press and hold DREC_D and DREC_E to move the car downwards – Release DREC_U or DREC_D or DREC_E to stop the car movement – Press JHC to stop the car movement. Schindler 3100/3300/6300 J 43402603 / 01 63/269 Copyright © 2017 INVENTIO AG… - Page 64

The movable bolts are in the inactive position (KSR-A) – Inspection operation is not active anymore (JREC/JRESG) – No stop switch is active (JHC, JHSG, JHM, …) – The balustrade (if any) is retracted (KBC-A/KFB). Schindler 3100/3300/6300 J 43402603 / 01 64/269 Copyright © 2017 INVENTIO AG… -

Page 65: Inspection Operation In Pit With Tsd21

Switch JREC to “Inspection” – Release JHC only if JREC has been switched to “Inspection” – Press the top of car stop button (JHC) – Switch JREC to “Normal” Schindler 3100/3300/6300 J 43402603 / 01 65/269 Copyright © 2017 INVENTIO AG…

- Page 66

– If necessary, return the pit ladder to its designated location – Release JHSG1 only after leaving the shaft pit – Close the shaft door for pit access. Schindler 3100/3300/6300 J 43402603 / 01 66/269 Copyright © 2017 INVENTIO AG… - Page 67

(Activation of TSD21 lever on top of car is not necessary, reset of the TSD21 system is also not necessary), But the reset procedure to exit pit inspection mode is still the same and must be carried out to leave inspection mode. Schindler 3100/3300/6300 J 43402603 / 01 67/269… - Page 68

RS232 SEM3x [604639_008; 23.08.2017] A CAN termination = OFF ESE normal B JH = OFF Bypass normal RBV relay SPH fuse CAN option RTTV relay Option SMICHMI connector Schindler 3100/3300/6300 J 43402603 / 01 68/269 Copyright © 2017 INVENTIO AG… - Page 69

DWNLD RESE T LUET BBUS INSP NORM DUEISK- A INSP DRZS BDM CM2 BDM SCPU1 [604639_009; 23.08.2017] A DRZS locking device (only for SMICHMI21) SIM card MM card Schindler 3100/3300/6300 J 43402603 / 01 69/269 Copyright © 2017 INVENTIO AG… -

Page 70: Instruction For Local Car Floor Finishing On Naked Honeycomb Floor

® non corrosive glue, for example Sikacryl S (Schindler ID No. 996985) or Sika Bond T8. The selected glue needs to have similar properties as the above mentioned glue types. Any corrosive glue or cement must be avoided as it could lead to serious damages of the honeycomb structure.

-

Page 71: Maintenance Information And Instructions

The maintenance visits depend on various factors relating to the specific installation and to the environment. Any legal requirements must also be complied with. The standards define the minimum requirements. Schindler 3100/3300/6300 J 43402603 / 01 71/269…

-

Page 72: Cleaning

CAUTION When electrical cleaning equipment is used in the car, care must be taken to ensure that the car doors cannot close while the equipment is connected to the power supply. Schindler 3100/3300/6300 J 43402603 / 01 72/269 Copyright © 2017 INVENTIO AG…

-

Page 73: Safety Equipment

Allow to dry and then buff with a clean, dry, white cotton cloth. Colored Stainless Steel requires extreme care. Clean following the same procedure as for Patterned/Etched Stainless Steel. Schindler 3100/3300/6300 J 43402603 / 01 73/269 Copyright © 2017 INVENTIO AG…

- Page 74

Cloth dampened with soapy water (not a detergent). Clean off surface using a dry cloth. Buttons, Indicators, To be treated as per instructions with the recommended cleaning agents for the specific and Faceplates material as described in this part of the manual. Schindler 3100/3300/6300 J 43402603 / 01 74/269 Copyright © 2017 INVENTIO AG… -

Page 75: Special Tools

Special Tools The following tools will be required to carry out specific maintenance tasks and can be purchased at your local Schindler office. Tool Name Description Part Number Used to test machine brake effectiveness 55502285 for products sold from 2004 to…

- Page 76

Lubricants and in particular motor and hydraulic oils belong to the classes of materials which could cause water pollution. Used lubricants and oils must be taken back by the maintenance company and disposed of in accordance with the legal requirements. Schindler 3100/3300/6300 J 43402603 / 01 76/269 Copyright © 2017 INVENTIO AG… -

Page 77: Repairs

Registration in the Major repairs or corrective actions must be recorded in the logbook. Logbook Unauthorized Unauthorized interventions or manipulations can cause damage or accidents. Interventions Schindler 3100/3300/6300 J 43402603 / 01 77/269 Copyright © 2017 INVENTIO AG…

-

Page 78: List Of Lubricants

Registration in the Periodical examinations and tests after significant modifications or critical incidents must Logbook be recorded in the logbook and a copy of the inspection report must be attached. Schindler 3100/3300/6300 J 43402603 / 01 78/269 Copyright © 2017 INVENTIO AG…

-

Page 79: General Maintenance Instructions For The Elevator

The overall responsibility for safe and correct execution of maintenance activities remains with the maintenance company. It is the obligation of the maintenance company to guarantee safety and availability of the elevator through the relevant maintenance program. Schindler 3100/3300/6300 J 43402603 / 01 79/269 Copyright © 2017 INVENTIO AG…

-

Page 80: Maintenance Plan — Guideline

Buffers including all safety devices and switches Speed governor pit pulley / rope / tension Speed governor pit safety device and switches Safety gear including all safety devices and switches Schindler 3100/3300/6300 J 43402603 / 01 80/269 Copyright © 2017 INVENTIO AG…

- Page 81

Task Car and counterweight frame retainers Protection of snag points Schindler 3100/3300/6300 J 43402603 / 01 81/269 Copyright © 2017 INVENTIO AG… -

Page 82: Bionic Control

JHSG LBSG, PSG, JLBS KSSBV KLSG Pit Box RESG Schindler 3100/3300/6300 Main Components BIC 7 [43402603_001; 24.07.2017] A Car bottom components 220 … 400 V in building Power supply lines Car light supply Phone Line / intercom Building interface Control cabinet…

-

Page 83: Bionic 7 Bus System

Default fixtures for Bionic 7 (FI GS LOP/LIP/COP with CANCP) Biobus Extension (LCU2 and LCUM2 interfaces) Building interface BIOGIO and machine room located LCUX Synchronization cable XCF is required only in case of LCU teaching Varidor V15 Schindler 3100/3300/6300 J 43402603 / 01 83/269 Copyright © 2017 INVENTIO AG…

-

Page 84: User Interface (Hmi)

Position no. 3, 4, 5, 6 show the name of the first safety chain tap, which is inactive if the up button is pressed. Description and Remarks Number = Actual floor level of the car Schindler 3100/3300/6300 J 43402603 / 01 84/269 Copyright © 2017 INVENTIO AG…

- Page 85

If Varidor 15 door detected further status are shown: h) Door power failure i) Door communication lost j) Door inspection mode k) Door over-temperature l) Door internal error m) Door background error recovery [604639_020; 01.12.2015] Schindler 3100/3300/6300 J 43402603 / 01 85/269 Copyright © 2017 INVENTIO AG… -

Page 86: Elevator Status (Indication On Hmi)

Out of service from remote Elevator startup Out of service STM monitoring failure Elevator breakdown persistent limited operation Installation travel Elevator breakdown Configuration mode Elevator breakdown persistent Schindler 3100/3300/6300 J 43402603 / 01 86/269 Copyright © 2017 INVENTIO AG…

-

Page 87: Buttons Navigation

Diagnostics, error log Learning Travel, Car Calls, etc. Automatic (Assisted) acceptance Statistics tests Status, system info ACVF monitoring (Biodyn xx C BR, Vacon NXP) Configuration Overview Main Menu Schindler 3100/3300/6300 J 43402603 / 01 87/269 Copyright © 2017 INVENTIO AG…

-

Page 88: Maintenance Checks

Light OFF if ’CLC1’ input frequency ≥ 10 kHz and ≤ 20 XCOP Light ON when input ’COP_DETECT’ not µC active DOOR/CANT Light ON when door front side not µC connected Schindler 3100/3300/6300 J 43402603 / 01 88/269 Copyright © 2017 INVENTIO AG…

- Page 89

Yellow LED — indicates that the booster output voltage (PEBO) is OK JEM ON Yellow LED inside DEM pushbutton — flashing indicates that the JEM switch is set to ON (evacuation enabled) Schindler 3100/3300/6300 J 43402603 / 01 89/269 Copyright © 2017 INVENTIO AG… -

Page 90: Access To Control Parameters (Menu 40)

Submenu: Parameter Submenu: Level – Applies to CF40 and CF41 only “L00” → All floor levels, “L01” → Floor level 1, “L02” → Floor level – 2, etc. Schindler 3100/3300/6300 J 43402603 / 01 90/269 Copyright © 2017 INVENTIO AG…

- Page 91

Either press the UP or DOWN button as required to V L _ u y z change the digit to the desired value (for example x to u) Or go directly to the next step. Schindler 3100/3300/6300 J 43402603 / 01 91/269 Copyright © 2017 INVENTIO AG… - Page 92

Press the ESC button to exit the main menu level. _ _ _ _ 0 5 The HMI will display the current car position again (for example car at floor 5) Schindler 3100/3300/6300 J 43402603 / 01 92/269 Copyright © 2017 INVENTIO AG… -

Page 93: Reset And Synchronization Travel

DWNLD RESE T LUET BBUS INSP NORM DUEISK- A INSP DRZS BDM CM2 BDM SCPU1 [604639_009; 23.08.2017] A DRZS locking device (only for SMICHMI21) SIM card MM card Schindler 3100/3300/6300 J 43402603 / 01 93/269 Copyright © 2017 INVENTIO AG…

- Page 94

– JHC stop button must be pressed → Press the ENABLE, UP and DOWN buttons (DRESG-E, DRESG-U and DRESG-D) simultaneously. This will reset the elevator control. INSPECTION [604639_019; 26.07.2017] Schindler 3100/3300/6300 J 43402603 / 01 94/269 Copyright © 2017 INVENTIO AG… -

Page 95: Synchronization Travel

The synchronization travel sequence will differ depending on the starting position of the car. At the end of the synchronization trip, the car remains stationary at the lowest level and the system returns to normal operation. Schindler 3100/3300/6300 J 43402603 / 01 95/269…

-

Page 96: Fixtures Keypad Configuration

Repeat the steps 3 … 7 for all the next higher floor levels (1 → 2 → 3, etc.) FI GS100 10 keypad COP FI GS 10 keypad COP will be configured automatically after COP detection (Menu 129). Schindler 3100/3300/6300 J 43402603 / 01 96/269…

-

Page 97: Fi Gs100 Lop Configuration

Wait until you hear another short beep. This indicates that the countdown has ended. → The CPID on COP shows “Ac” (or “Br” if a JBF has been detected). Schindler 3100/3300/6300 J 43402603 / 01 97/269 Copyright © 2017 INVENTIO AG…

- Page 98

After LOP counting is finished leave configuration mode by pressing “ESC” and by deactivating menu 40. (Change [40_ _ _1] to [40_ _ _0] and press “OK”) Schindler 3100/3300/6300 J 43402603 / 01 98/269 Copyright © 2017 INVENTIO AG… -

Page 99: Error Codes

C2:The car load measuring signal is faulty A2:Check general wiring to the car load measuring device.Redo calibration if signal is present but invalid. 0005 ELEVATOR POWER FAIL MODE 0008 ELEVATOR JRVC MODE *) Schindler 3100/3300/6300 J 43402603 / 01 99/269 Copyright © 2017 INVENTIO AG…

- Page 100

(PCB). 0012 C1:No SIM card, no Schindler SIM card, a SIM card of another elevator or a manipulated SIM card is inserted A1:Check if SIM card is present or if a invalid SIM card is inserted. Check error log for SIM card errors (#19xx). - Page 101

A2:Check data line connection (CAN). Check for correct data line termination (termination switch in ECU or control cabinet, termination in ACVF) C3:Mismatch of car node software and elevator main controller software A3:Update the software accordingly Schindler 3100/3300/6300 J 43402603 / 01 101/269 Copyright © 2017 INVENTIO AG… - Page 102

In the course of a car backup battery failure, this (informative) error message is created to indicate that the car backup battery is again in working order. 0073 A1:No action required Schindler 3100/3300/6300 J 43402603 / 01 102/269 Copyright © 2017 INVENTIO AG… - Page 103

A1:Elevator recovers automatically from this error by user (or recall) traveling in up-direction 0080 ELEVATOR CAR EMERGENCY EXIT MISUSE DETECTED The controller detects a misuse of the emergency exit trap. Schindler 3100/3300/6300 J 43402603 / 01 103/269 Copyright © 2017 INVENTIO AG… - Page 104

0302 and not emulated, depending on door type) for dirt or bad mechanical adjustment.Check general wiring door opened position contact. C2:See 0301 A2:See 0301 C3:See 0301 A3:See 0301 Schindler 3100/3300/6300 J 43402603 / 01 104/269 Copyright © 2017 INVENTIO AG… - Page 105

PHUETx).Check position of door unlocking zone indicators in hoistway (for example, vanes on same level) C3:Failure at door safety circuit (KTS, KTC) bypass device A3:Replace PCB containing this bypass mechanism (for example, SUET) Schindler 3100/3300/6300 J 43402603 / 01 105/269 Copyright © 2017 INVENTIO AG… - Page 106

(For some seconds the SDIC7x does not receive the CAN bus signal anymore.) A3:None DOOR D1 DOD DIP WRONG This error does not apply to Schindler 3100/3300/6300 0333 A1:Check: Door 1 DOD DIP switches configuration. DOOR D2 DOD DIP WRONG… - Page 107

DOOR DESTRUCTIVE OVERTEMPERATURE 0345 The door drive (motor) has exceeded its the destructive over-temperature limit DOOR POSITION RECOVERY SUCCESSFUL 0351 The door was able to recover from a position problem Schindler 3100/3300/6300 J 43402603 / 01 107/269 Copyright © 2017 INVENTIO AG… - Page 108

Auto setup failed 0x31 Over current 0x32 Over voltage 0x33 Under voltage (should never occur) 0x37 Internal software 0x38 Software internal parameter 0x39 Sensor position 0x3A CAN overrun Schindler 3100/3300/6300 J 43402603 / 01 108/269 Copyright © 2017 INVENTIO AG… - Page 109

Set the parameter Nr. 169 0x38 56 Software internal parameter At startup the parameters are SetParamToDef to value Run autosetup corrupted If no success replace DDE-VD35 Schindler 3100/3300/6300 J 43402603 / 01 109/269 Copyright © 2017 INVENTIO AG… - Page 110

If found wrong, correct The contact KET-S2 is overbridged Remove jumper Code Door Locking Message DOOR LOCKING UNLOCKING OBSTRUCTED 0371 The clutch locking respectively unlocking motion is obstructed Schindler 3100/3300/6300 J 43402603 / 01 110/269 Copyright © 2017 INVENTIO AG… - Page 111

Only valid for Japan’s country code *) So marked error descriptions are not released officially by R&D. If necessary, contact a specialist or the Locarno hotline for more information. Schindler 3100/3300/6300 J 43402603 / 01 111/269 Copyright © 2017 INVENTIO AG… - Page 112

C3:Closed loop: tacho defective or motor not energized and car moves slowly by unbalancing situation C4:Drive doesn’t generate sufficient torque DRIVE SHAFT INFORMATION 0405 A1:Check: CAN cable, Check: CAN wiring Schindler 3100/3300/6300 J 43402603 / 01 112/269 Copyright © 2017 INVENTIO AG… - Page 113

The drive (frequency converter, open loop) got technically unavailable while the car was standing still. C1:Bad electrical connection from the drive frequency converter to the elevator main contactors connection board (MCCE board) (Not applicable for Schindler 3000) 0407 A1:Check corresponding cables and connectors (for example, the drive ready signal) - Page 114

DRIVE BRAKE CAPABILITY PERIODIC TEST ABORTED The brake capability test has been postponed by 24 h because: – Safety chain opened during test 0423 – Internal drive error – Test timeout Schindler 3100/3300/6300 J 43402603 / 01 114/269 Copyright © 2017 INVENTIO AG… - Page 115

Actions to be taken MGB-T board disconnected Check soft stop cabling Soft stop function enabled without Check soft stop enable parameter hardware Soft stop hardware failure Replace soft stop hardware Schindler 3100/3300/6300 J 43402603 / 01 115/269 Copyright © 2017 INVENTIO AG… - Page 116

C2:Malfunction of the car load measuring device A2:Replace the car load measuring device (for example, CLC) C3:Malfunction of the car load signal receiving stage A3:Replace corresponding PCB (for example, SDIC7x) Schindler 3100/3300/6300 J 43402603 / 01 116/269 Copyright © 2017 INVENTIO AG… - Page 117

A3:Check general wiring to the car load measuring device.Check shielding (if present).Check power supply of car load measuring device. C4:Malfunction of the car load measuring device A4:Replace the car load measuring device Schindler 3100/3300/6300 J 43402603 / 01 117/269 Copyright © 2017 INVENTIO AG… - Page 118

A1:Check: Rated load weight configuration file LMS MULTIPLE SOURCE 1133 Due to wrong configuration more than one source of load is provided to the controller (two frequencies or two open contacts) Schindler 3100/3300/6300 J 43402603 / 01 118/269 Copyright © 2017 INVENTIO AG… - Page 119

C1:Vacon frequency converter has detected faulty operation in the gate 1504 drivers or IGBT bridge — interference fault (EMC)- component failure A1:- Reset the fault and restart. If the fault occurs again replace frequency converter. Schindler 3100/3300/6300 J 43402603 / 01 119/269 Copyright © 2017 INVENTIO AG… - Page 120

C2:The brake resistor is broken A2:Replace brake resistor C3:The brake chopper is broken A3:Replace drive inverter (FC) FC CONVERTER UNDER TEMPERATURE 1513 C1:Temperature of heat sink below 10C A1:none Schindler 3100/3300/6300 J 43402603 / 01 120/269 Copyright © 2017 INVENTIO AG… - Page 121

FC ANALOGUE INPUT FAULT – Wrong analogue input polarity 1518 – Component failure on control board – Irrelevant for Schindler Closed Loop application A1:Check: polarity of the analogue input, Check: replace frequency converter FC OPTION BOARD IDENTIFICATION C1:Reading the frequency converter option board has failed… - Page 122

C1:- Thermistor input of the I/O-expander board has detected increase of 1529 the motor temperature- Irrelevant for Schindler Closed Loop application A1:Check: motor cooling and loading. Check: thermistor connection (if thermistor input of the expander board is not in use, it has to be bridged) - Page 123

1/3 of rated output frequency. FC LN CHOKE OVERTEMPERATURE 1537 Over temperature of line choke FC FAN ERROR 1538 The fan of the inverter is not running Schindler 3100/3300/6300 J 43402603 / 01 123/269 Copyright © 2017 INVENTIO AG… - Page 124

C2:Elevator controller (EC) logical error.(new speed level= ZERO, EVACUATION or UNKNOWN) FC BRAKING RESISTOR OVERTEMPERATURE 1554 C1:FC (Close Loop) Braking resistor overtemperature A1:Check: Brake resistor temperature, wiring and/or the bi-metal itself Schindler 3100/3300/6300 J 43402603 / 01 124/269 Copyright © 2017 INVENTIO AG… - Page 125

(if present) of all devices connected to the data bus.Check shielding of data line (if present).Perform a manual reset respectively perform the persistent fatal error reset procedure to set the elevator back in operation. Schindler 3100/3300/6300 J 43402603 / 01 125/269 Copyright © 2017 INVENTIO AG… - Page 126

Periodic brake capability test failed or brake capability test triggered by 1566 excessive releveling failed. The recovery from this fatal error requires clearing by setting the special command 164 to «1», followed by an elevator controller reset. Schindler 3100/3300/6300 J 43402603 / 01 126/269 Copyright © 2017 INVENTIO AG… - Page 127

C1:The brake position feedback signal KB1 is faulty A1:Check brake contact KB1 for dirt. Check general wiring KB1. 1571 C2:Brake opens only partially A2:Check brake supply voltage C3:The brake is mechanically bad adjusted A3:Replace brake Schindler 3100/3300/6300 J 43402603 / 01 127/269 Copyright © 2017 INVENTIO AG… - Page 128

A2:Check positions of the PHNR_U/PHNR_D sensors. Check that the displacement of the releveling sensors (PHNR_U/PHNR_D) is according to the schematics. They should be inactive when the car is about 15 mm below or above floor level. Schindler 3100/3300/6300 J 43402603 / 01 128/269 Copyright © 2017 INVENTIO AG… - Page 129

The control deviation of the mains current controller exceeds the supervisor parameter im_diff_lim. FC IGBT OVERTEMPERATURE 1581 Over temperature of the IGBT power module FC MC CURNT SUM FAILURE 1582 Current sum failure Schindler 3100/3300/6300 J 43402603 / 01 129/269 Copyright © 2017 INVENTIO AG… - Page 130

CHIP CARD WRONG DEVICE The elevator main controller has a software internal problem accessing the SIM card 1901 C1:Internal elevator main controller software error A1:Upgrade elevator main controller software (SCIC) Schindler 3100/3300/6300 J 43402603 / 01 130/269 Copyright © 2017 INVENTIO AG… - Page 131

SIM card. CHIP CARD WRONG FILE SYSTEM VERSION Invalid Schindler SIM card inserted on the elevator main controller board. C1:SIM card has a wrong file system version respectively a wrong data format. This means the SIM card does not contain the data (for example,… - Page 132

C2:Signal of door zone detection faulty A2:Check door zone sensors (for example, PHSx) and wiring. 2006 TRIP WARNING TRIP POSITION TARGET NOT REACHED *) Schindler 3100/3300/6300 J 43402603 / 01 132/269 Copyright © 2017 INVENTIO AG… - Page 133

This can only happen, if we do not allow overwriting of the shaft image (for example, while traveling upwards, where no value 2062 should have been set before). A1:Redo learning trip C2:EMC disturbance? Schindler 3100/3300/6300 J 43402603 / 01 133/269 Copyright © 2017 INVENTIO AG… - Page 134

C1:The EC application tried to set the height of a lower flag edge smaller 2070 than the height of the upper lower flag. A1:Check flags, Check light barrier cable, Check encode, Redo learning trip Schindler 3100/3300/6300 J 43402603 / 01 134/269 Copyright © 2017 INVENTIO AG… - Page 135

FC parameter traction «PULLEY_DIAMETER» results in a value bigger than the tolerated limit. A1:Check shaft information. Check flags length. Check FC parameter 11.26 «Traction Pulley Diameter-DD», Redo learning trip Schindler 3100/3300/6300 J 43402603 / 01 135/269 Copyright © 2017 INVENTIO AG… - Page 136

A2:Check sensors PHNR_U/PHNR_D for dirt or defect. Check general wiring PHNR_U/PHNR_D. 2082 TRIP HOURS IN SERVICE MISMATCH 2083 TRIP HOURS IN SERVICE ENTERED MANUALLY 2084 TRIP COUNTER MISMATCH 2085 TRIP COUNTER ENTERED MANUALLY Schindler 3100/3300/6300 J 43402603 / 01 136/269 Copyright © 2017 INVENTIO AG… - Page 137

PHS respectively KS indicator changes. A1:See 2110. SHAFT INVALID CURRENT LEVEL C1:This error can result from an invalid respectively incomplete 2113 signaling of PHS respectively KS indicator changes. A1:See 2110. Schindler 3100/3300/6300 J 43402603 / 01 137/269 Copyright © 2017 INVENTIO AG… - Page 138

A1:Check: Shaft information, flags length. Do: Learning trip SHAFT WRONG INITIALIZATION 2130 C1:Shaft image: wrong initialization A1:Do: Learning trip SHAFT LUET KS KS1 INCONSISTENT 2131 A1:Check: KS/ KS1 presence and position. Do: Learning trip Schindler 3100/3300/6300 J 43402603 / 01 138/269 Copyright © 2017 INVENTIO AG… - Page 139

C1:Wiring to the upper hoistway end position sensor is faulty. 2136 A1:Check wiring at the corresponding sensor. C2:The upper hoistway end position sensor is faulty. A2:Check functionality of corresponding sensor. Replace it if necessary. Schindler 3100/3300/6300 J 43402603 / 01 139/269 Copyright © 2017 INVENTIO AG… - Page 140

C1:At application startup (reset): While setting up the levels in the RAM 2161 shaft image an intolerable flag length is detected. A1:Check: for rope slippage. Check: encoder. Redo: learning trip. Warning: do not change the load during learning Schindler 3100/3300/6300 J 43402603 / 01 140/269 Copyright © 2017 INVENTIO AG… - Page 141

C1:While setting up the RAM shaft image at the application startup a missing door entrance side is detected. A1:Redo: learning trip 2167 C2:Problems with shaft info circuit (PHS, PHUET, light barrier, magnet switch) C3:EMC disturbances Schindler 3100/3300/6300 J 43402603 / 01 141/269 Copyright © 2017 INVENTIO AG… - Page 142

2170 A1:Redo: learning trip C2:See 2165 C3:See 2165 Code FA Message FA drive errors (2 speed systems) Not used with Schindler 2200 3100/3300/6300 2205 If one of these error occurs please contact hotline Locarno or a specialists. Code Frequency Converter Alarming Message… - Page 143

New trip cannot be started before bimetal temp switch is closed again (5 min.) A1:Check brake resistors temperature. Check wiring and/or the bimetal temperature switch itself Schindler 3100/3300/6300 J 43402603 / 01 143/269 Copyright © 2017 INVENTIO AG… - Page 144

C2:See 2402, C3 A2:See 2402, A3 C3:The elevator main controller and the drive are out of sync. A3:Perform a reset of the entire system Schindler 3100/3300/6300 J 43402603 / 01 144/269 Copyright © 2017 INVENTIO AG… - Page 145

C1:EC application (internal) error. EC tried to recover from a fatal error. FC PROXY WARNING SAFETY CHAIN WILL BE DISABLED 2415 C1:Due to FC error the safety chain will be disabled (via RH1 relay). Schindler 3100/3300/6300 J 43402603 / 01 145/269 Copyright © 2017 INVENTIO AG… - Page 146

2427 FC PROXY WARNING FC SW VERSION UNKNOWN YET 2428 FC PROXY WARNING FC HARDWARE VERSION UNKNOWN YET FC PROXY PARAMETER DOWNLOAD FAILED 2429 C1:Drive (FC) reports a parameter download failure A1:Check FC parameter values Schindler 3100/3300/6300 J 43402603 / 01 146/269 Copyright © 2017 INVENTIO AG… - Page 147

EEPROM BASE NORMAL FILE ERROR *) 2611 C1/A1: See 2604 EEPROM PASSWORD FILE ERROR *) 2612 C1/A1: See 2604 EEPROM TRAFFIC CTRL FILE ERROR *) 2613 C1/A1: See 2604 Schindler 3100/3300/6300 J 43402603 / 01 147/269 Copyright © 2017 INVENTIO AG… - Page 148

The EEPROM with configuration/custom data is detected as virgin and has been formatted *) Error descriptions are not officially released by R&D. If necessary, contact a specialist or the Locarno hotline for more information. Schindler 3100/3300/6300 J 43402603 / 01 148/269 Copyright © 2017 INVENTIO AG… - Page 149

Code Hydraulic Message 2701 Hydraulic errors. Not used with Schindler 3100/3300/6300 If one of these errors occurs: Please contact a specialist or hotline Locarno. 2710 Code AAT Message 3101 AAT Automatic Acceptance Tests Errors For further description and solutions refer to documentation Automatic… - Page 150

31 75 AAT STM MONITORING CANCELED 31 76 AAT STM MONITORING ABORTED Code CANIO Message 3201 CANIO PCB errors. Not used with Schindler 3100/3300/6300 If one of these errors occurs: Please contact a specialist or hotline Locarno. 3216 Code TSD Message… - Page 151

3402 HMI VALUE OUT OF UPPER BOUND *) *) Error description is not officially released by R&D. If necessary, contact a specialist or the Locarno hotline for more information. Schindler 3100/3300/6300 J 43402603 / 01 151/269 Copyright © 2017 INVENTIO AG… - Page 152

C2:Wiring from/to overbridging relays bad A2:Check wiring of relays RUESG, RUESG1 and RSG_A C3:Fieldbus communication problem (please check previous errors in error log) A3:Check error 3603 for cause and actions Schindler 3100/3300/6300 J 43402603 / 01 152/269 Copyright © 2017 INVENTIO AG… - Page 153

A1:Check connections between SUET board and SIAP board 3510 C2:SIAP PCB defect (for example, relays simulating door zone (PHS/PHS1) defect) A2:Replace SIAP board C3:Door safety circuit overbridging lost A3:Check errors 0339 for cause and actions Schindler 3100/3300/6300 J 43402603 / 01 153/269 Copyright © 2017 INVENTIO AG… - Page 154

(for example, used in fire operation Korea) has failed. 3516 C1:SIAP PCB defect (for example, relays simulating door zone (PHS/PHS1) defect) A1:Replace SIAP board Schindler 3100/3300/6300 J 43402603 / 01 154/269 Copyright © 2017 INVENTIO AG… - Page 155

Safety circuit not opened at tap ‘IKTC’ when expected to be opened (for example, while opening door) Possible Causes Actions to be taken KTC contact detected always closed Check proper KTC operation. Check if bridges are installed on KTC Schindler 3100/3300/6300 J 43402603 / 01 155/269 Copyright © 2017 INVENTIO AG… - Page 156

A4:Close and lock the car emergency exit door C5:Safety circuit wiring faulty or safety circuit contact(s) defective or bad adjusted A5:Check general wiring safety circuit and safety circuit contacts at corresponding safety circuit section Schindler 3100/3300/6300 J 43402603 / 01 156/269 Copyright © 2017 INVENTIO AG… - Page 157

The maintenance person placed «LAND» connector on bypass socket with automatic door system SAFETY CIRCUIT MANUAL BYPASS HW FAILURE 3590 The elevator detects an HW failure on the bypass socket Schindler 3100/3300/6300 J 43402603 / 01 157/269 Copyright © 2017 INVENTIO AG… - Page 158

Redo LOP count (CF00, LE00). C2:Bad bus power supply A2:Check supply voltage on bus for instability.Redo LOP count (CF00, LE00). C3:EMC problems A3:Check entire bus for interferences. Redo LOP count (CF00, LE00). Schindler 3100/3300/6300 J 43402603 / 01 158/269 Copyright © 2017 INVENTIO AG… - Page 159

TM RESIDUAL STRENGTH INSUFFICIENT Traction media residual strength insufficient 4602 C1:The maximal permitted bend cycle count or trip count for the traction media had been exceeded A1: Replace traction media Schindler 3100/3300/6300 J 43402603 / 01 159/269 Copyright © 2017 INVENTIO AG… - Page 160

The reference key consists of the 4611 manufacturing date of the oldest traction media and the commission number. C1:Commissioning number differs between controller and chip card A1:Replace chip card with correct commissioning number Schindler 3100/3300/6300 J 43402603 / 01 160/269 Copyright © 2017 INVENTIO AG… - Page 161

The STM stress count (trip or tend cycle counter) was set. 4618 C1:A new STM bending counter has been entered. The advanced STM configuration has been used. A1:None Schindler 3100/3300/6300 J 43402603 / 01 161/269 Copyright © 2017 INVENTIO AG… - Page 162

C2:ECM heartbeat is lost A2:Check communication cable C3:ECM reports a self test failure A3:Replace hardware TM ECM AVAILABLE 4626 The conductivity device for STM is back in normal monitoring operation. Schindler 3100/3300/6300 J 43402603 / 01 162/269 Copyright © 2017 INVENTIO AG… - Page 163

A1:To better understand what causes the issue it is advised to check the overlay monitoring menu (HMI menu 30 > 309) as the values there can be a certain help in pinpointing where the group problem might be. Schindler 3100/3300/6300 J 43402603 / 01 163/269… - Page 164

5006 exceeded. The connection is aborted. C1:Too slow data transmission due to bad signal connection A1:Check quality of data connection Schindler 3100/3300/6300 J 43402603 / 01 164/269 Copyright © 2017 INVENTIO AG… - Page 165

An alarm was received while the discriminator was active, the system tried to 8008 free the passenger in time but did fail and thus the alarm is automatically forwarded by the system. Schindler 3100/3300/6300 J 43402603 / 01 165/269 Copyright © 2017 INVENTIO AG… - Page 166

Temperature in the ECU is normal. ECU TEMPERATURE OUT OF RANGE 8031 Temperature in the ECU is out of range. MAIN SWITCH ON 8032 Main switches (JH) has been switched on. Schindler 3100/3300/6300 J 43402603 / 01 166/269 Copyright © 2017 INVENTIO AG… -

Page 167: En81-20/50 Door Bypassing Function

– The bypass connector is monitored by the controller and the elevator will be blocked if a false plug has been detected by the controller. Schindler 3100/3300/6300 J 43402603 / 01 167/269 Copyright © 2017 INVENTIO AG…

- Page 168

Note: there are no restrictions when the plug can be disconnected – All drive and door movements are blocked – All car calls and landings calls are canceled and disabled. Schindler 3100/3300/6300 J 43402603 / 01 168/269 Copyright © 2017 INVENTIO AG… - Page 169

Pressing «UP» button again the HMI shows main information page. Note: The bridging done by for example recall panel or SUET does not affect the evaluation of first opened tap. [604639_013; 23.08.2017] A Press «UP» button Schindler 3100/3300/6300 J 43402603 / 01 169/269 Copyright © 2017 INVENTIO AG… - Page 170

In case of fully closed safety chain, HMI shows «CLOSED»: [604639_014; 26.11.2015] In case of unknown safety chain tap to display, HMI shows «UNKNOWN»: [604639_015; 26.11.2015] Schindler 3100/3300/6300 J 43402603 / 01 170/269 Copyright © 2017 INVENTIO AG… -

Page 171: Machine Brake Leroy-Somer

In case of a brake switch failure, adjust the switch position. Repair Repair is not allowed. If needed, always replace the complete component by a new original part. Schindler 3100/3300/6300 J 43402603 / 01 171/269 Copyright © 2017 INVENTIO AG…

-

Page 172: Maintenance Checks

If a feeler gauge of 0.65 mm passes through the air gap, put the elevator out of service and replace the brake. Machine Brake Leroy-Somer Air Gap Adjustment [42115; 09.12.2011] Adjusting screw Feeler gauge Brake yoke Air gap Brake armature Schindler 3100/3300/6300 J 43402603 / 01 172/269 Copyright © 2017 INVENTIO AG…

-

Page 173: Brake Test During Maintenance

Press «OK». HMI shows [15/__/_1]. – The door closes. – The car travels to the bottom floor. The door remains closed. – HMI shows [15/__/_2], indicating «Test ready to run». Schindler 3100/3300/6300 J 43402603 / 01 173/269 Copyright © 2017 INVENTIO AG…

- Page 174

As the test acceptance criterion depends on the rated balancing factor (KG) , it is necessary to first determine the rated KG of the installation to be tested. Applicable values are KG = 50 % and KG < 50 %. Schindler 3100/3300/6300 J 43402603 / 01 174/269… - Page 175

The control triggers an emergency stop. – The machine brake stops the car. – HMI shows [65/__/_4]. Unplug the test connector TEST-MGB on PCBA SNGL or PCBA SEM3x. Schindler 3100/3300/6300 J 43402603 / 01 175/269 Copyright © 2017 INVENTIO AG… -

Page 176: Machine And Brake Replacement Tests

Test after brake replacement must be performed with 100 % and 125 % of GQ Perform ‘Dynamic Full Brake Test Down’ (Test 14) Perform ‘Dynamic Single Brake Test Down’ (Test 64) Schindler 3100/3300/6300 J 43402603 / 01 176/269 Copyright © 2017 INVENTIO AG…

- Page 177

Press ESC The elevator performs a synchronization trip. Dynamic Single Car load 0 % GQ Brake Test Upward (Test 65) Travel speed 100 % VKN Car travel direction Schindler 3100/3300/6300 J 43402603 / 01 177/269 Copyright © 2017 INVENTIO AG… - Page 178

The car reaches rated speed – HMI display shows a blinking «65» [65/__/_1] – The controller triggers an emergency stop below the KSE-U magnet – HMI display shows [65/__/_4] Schindler 3100/3300/6300 J 43402603 / 01 178/269 Copyright © 2017 INVENTIO AG… - Page 179

The car travels to the control cabinet floor and opens the door. The door remains open [__/__/—] Load car with 125 % GQ Load the car with the test load (125 % rated load) Schindler 3100/3300/6300 J 43402603 / 01 179/269 Copyright © 2017 INVENTIO AG… - Page 180

(Brake Test Connectors) in his tool box. The plugs are not delivered with the elevator. Make sure the load measuring device is enabled. The ‘Single Brake Test Up’ must not be performed if the ‘Full Brake Test Up’ was not passed. Schindler 3100/3300/6300 J 43402603 / 01 180/269 Copyright © 2017 INVENTIO AG… - Page 181

– HMI display shows [65/__/_4] – Unplug the «TEST-MGB» connector from the «MGB-T» socket at control cabinet (on the SNGL or SEM3x PCB) – HMI display shows [64/__/_4] Schindler 3100/3300/6300 J 43402603 / 01 181/269 Copyright © 2017 INVENTIO AG… - Page 182

Post Requisites Step Remove labels «Out of service» Perform a test ride over the whole travel distance Record «Brake replaced and acceptance test fulfilled» in the maintenance log Schindler 3100/3300/6300 J 43402603 / 01 182/269 Copyright © 2017 INVENTIO AG… -

Page 183: Mechanical Hoistway Components

Check of the STM adherence 3.0 million trips or 15 years Replacement of all STM In case a Schindler’s telemonitoring device featuring trip counting is not connected, an alternative mean for trip counting (electromechanical or similar) has to be implemented by the maintenance organization.

- Page 184

Check for visible damages according to the following table and example pictures. If any of the findings apply, all suspension traction media must be replaced. Type of Damage Action Cord break Always replace Schindler 3100/3300/6300 J 43402603 / 01 184/269 Copyright © 2017 INVENTIO AG… - Page 185

Type of Damage Action Coat damage — STM piercing Always replace Coat damage — longitudinal cracks Always replace STM corrosion / rust Always replace Schindler 3100/3300/6300 J 43402603 / 01 185/269 Copyright © 2017 INVENTIO AG… - Page 186

Damaged STM edges, outermost cord visible Always replace Worn or damaged profile Always replace Coat damage — transversal cracks Replace if more than five cracks per meter are found. Schindler 3100/3300/6300 J 43402603 / 01 186/269 Copyright © 2017 INVENTIO AG… - Page 187

If necessary, adjust the STM tension: – Schindler 3100/3300/6300: at the car suspension point by screwing in or out the hex nut and counter nut on the STM connection assembly. After adjustment, travel five meters down the hoistway and check the STM tension again. - Page 188

Move the empty car with the inspection control and stop it in the upper part of the hoistway. Check that the stopping distance has not been extended by an STM slip. Schindler 3100/3300/6300 J 43402603 / 01 188/269 Copyright © 2017 INVENTIO AG… - Page 189

Repeat the stopping accuracy test. Emergency Stop Step Move the empty car upward in inspection mode and stop before you reach the top floor. The STM should not slip. Schindler 3100/3300/6300 J 43402603 / 01 189/269 Copyright © 2017 INVENTIO AG… - Page 190

STM Monitoring In case that the maintenance is performed by a company other than Schindler, this Device maintenance company has two possibilities to handle the STM monitoring: – either procure the STM-MD from Schindler and perform STM monitoring according to relevant instructions or –… -

Page 191: Buffers P+S

Check the buffer for any visible contamination or deterioration due to contact with liquids such as detergent, water, oil, etc. If required, replace the buffer(s) in chapter «Replacement». Schindler 3100/3300/6300 J 43402603 / 01 191/269 Copyright © 2017 INVENTIO AG…

-

Page 192: Buffer Oleo

The switch returns to its original state once the plunger has returned to its original position. [49423; 05.12.2013] Oil reservoir Metering tube Dipstick (Oil filling point) Plunger Gas chamber Rubber block Control switch Schindler 3100/3300/6300 J 43402603 / 01 192/269 Copyright © 2017 INVENTIO AG…

- Page 193

Use HLP 68/ISO 6743/4 L-HM68, in accordance with DIN 51524. These are mineral oils with additives for improvement of anti-corrosion properties, anti-aging and improved performance under boundary lubrication conditions (anti-seize additives). Schindler 3100/3300/6300 J 43402603 / 01 193/269 Copyright © 2017 INVENTIO AG… -

Page 194: Maintenance Task List

Switch Check that the safety switch operates smoothly and works correctly. 4.11.3.4 Replacement Worn and / or defective safety components must be replaced by original spare parts only. Schindler 3100/3300/6300 J 43402603 / 01 194/269 Copyright © 2017 INVENTIO AG…

-

Page 195: Sa Gbp 201

Check governor rope 60 M Test of rope friction force FC and engagement of safety gear 60 M Test tripping speed 1) Minimum frequency Key of abbreviations: M = month Schindler 3100/3300/6300 J 43402603 / 01 195/269 Copyright © 2017 INVENTIO AG…

-

Page 196: Maintenance Checks

Check wear of the bearing by measuring dimension A > 1 mm. If A ≤ 1 mm, – replace the complete overspeed governor. Overspeed Governor [17962; 26.06.2009] Schindler 3100/3300/6300 J 43402603 / 01 196/269 Copyright © 2017 INVENTIO AG…

- Page 197

Safety Switch Check SA GBP 201 [38602; 25.02.2011] Contact plate Safety switch Tension Device Checks Tension Device Checks [17964; 19.03.2009] Slack rope switch (KSSBV / KSSBVG) Weight block Schindler 3100/3300/6300 J 43402603 / 01 197/269 Copyright © 2017 INVENTIO AG… - Page 198

Check that the washers (1), clevis pins (3), cotter pins (2) and spring wire (5) are in place. Note: There are different types of rope couplings. The type with spring wire is one option. Schindler 3100/3300/6300 J 43402603 / 01 198/269 Copyright © 2017 INVENTIO AG… - Page 199

The rope is showing signs of red dust or rust, or is damaged or disfigured in any way – The diameter of the rope has reduced by more than the rope manufacturers recommended limit (usually 5 … 10 %). Schindler 3100/3300/6300 J 43402603 / 01 199/269 Copyright © 2017 INVENTIO AG… -

Page 200: Periodic Tests

Move the car/counterweight upwards until the overspeed governor and safety gear have disengaged. Reset safety switches on overspeed governor and actuating mechanism. Reinstall the weight block onto the tension device. Schindler 3100/3300/6300 J 43402603 / 01 200/269 Copyright © 2017 INVENTIO AG…

- Page 201

Use the free hand to catch the side of the rope which moves upward. Write down the indicated value and reset the tachometer. Schindler 3100/3300/6300 J 43402603 / 01 201/269 Copyright © 2017 INVENTIO AG… -

Page 202: Replacement

Check the safety switch head (3) does not touch the precontact plate (1) when the pendulum is moving. Move the precontact plate (1) to check that the safety switch (2) is actuated in both directions. Perform the tripping speed VCA test. Schindler 3100/3300/6300 J 43402603 / 01 202/269 Copyright © 2017 INVENTIO AG…

-

Page 203: Reset

Raise the pendulum and disengage the pendulum nose from the pulley. – Check the overspeed governor pulley turns freely. – Release the safety switch. – Reset the safety switch with the Electrical Remote Reset (ERR). Schindler 3100/3300/6300 J 43402603 / 01 203/269 Copyright © 2017 INVENTIO AG…

-

Page 204: Car Door

(completely wired). Furthermore, the mechanical interface to the landing door (door lock) is carried out by means of the clutch in the landing area. Overview [41353545_008; 03.07.2014] Schindler 3100/3300/6300 J 43402603 / 01 204/269 Copyright © 2017 INVENTIO AG…

- Page 205

Clutch sword KET-S2 contact bridge KTC contact arm Lock hook KTC contact housing Lock latch KTC contact bridge 10 Carriers Clutch release lever 11 Stopper rubber Clutch cam Schindler 3100/3300/6300 J 43402603 / 01 205/269 Copyright © 2017 INVENTIO AG… - Page 206

Door panel alignment Special Tools Tool Figure Description Belt Calibration Tool This calibration tool is used to find the correct tension of the tooth belt. ID no. 59351709 Schindler 3100/3300/6300 J 43402603 / 01 206/269 Copyright © 2017 INVENTIO AG… -

Page 207: Maintenance Task List

Description [Months] Check door performance Check complete closure of door Check function of light curtain Check function of door contacts Check correct adjustment of clutch against door lock Schindler 3100/3300/6300 J 43402603 / 01 207/269 Copyright © 2017 INVENTIO AG…

-

Page 208: Maintenance Checks

Check on clean and dry rail, carrier roller, counter roller, transmission roller, cable, guide shoes, sill, belt pulley and belt. If necessary: clean and dry them, no oiling. Schindler 3100/3300/6300 J 43402603 / 01 208/269 Copyright © 2017 INVENTIO AG…

- Page 209

Clean the car door sill profiles (1) with a cloth. Do not use abrasive paper. Check holes on sill are free from debris, etc. [41353545_011; 03.07.2014] Car door sill profile Schindler 3100/3300/6300 J 43402603 / 01 209/269 Copyright © 2017 INVENTIO AG… - Page 210

(2). If the clearance is > 1 mm, replace the guide shoe (4). 1 mm [34537; 10.07.2014] Sill profile Feeler gauge Door panel Guide shoes Guide Shoe E1 [41353545_039; 10.07.2014] Schindler 3100/3300/6300 J 43402603 / 01 210/269 Copyright © 2017 INVENTIO AG… - Page 211

Check the lock washers (3) are damaged. If necessary, replace the lock washers (3). [41353545_013; 03.07.2014] Steel ruler Door panel Lock washer Transmission pulley Transmission cable M6x20 cutting screw Schindler 3100/3300/6300 J 43402603 / 01 211/269 Copyright © 2017 INVENTIO AG… - Page 212

– Heavy rattling: Check / exchange the main roller. – Uneven movement: Check adjustment of counter roller. Check / exchange the main roller. Schindler 3100/3300/6300 J 43402603 / 01 212/269 Copyright © 2017 INVENTIO AG… - Page 213

Move the KTC contact bridge (1) into the housing (2) until a first contact is established. Check the CDL engagement is ≥ 7 mm. [41353545_025; 03.07.2014] Contact bridge Contact housing Schindler 3100/3300/6300 J 43402603 / 01 213/269 Copyright © 2017 INVENTIO AG… - Page 214

Check complete closure of landing and car door. – No visible gaps between door panels. – No light from hoistway visible, if doors are closed. If necessary, adjust door panels and carrier stop. Schindler 3100/3300/6300 J 43402603 / 01 214/269 Copyright © 2017 INVENTIO AG… - Page 215

Door is in standby state — slowly Blinking Referencing not Close door until slowly executed locked Blinking KSKB / KOKB / RPHT / Remove obstacle slowly KTL / KTFP active Flashing Torque off Schindler 3100/3300/6300 J 43402603 / 01 215/269 Copyright © 2017 INVENTIO AG… - Page 216

Door has stopped due to externally triggered command Door has stopped due to the activation of a safety device Timeout occurred, for example in case of AutoSetup failure Schindler 3100/3300/6300 J 43402603 / 01 216/269 Copyright © 2017 INVENTIO AG… - Page 217

150 N, no setting is required. If closing force is > 150 N, repeat AutoSetup. Schindler 3100/3300/6300 J 43402603 / 01 217/269 Copyright © 2017 INVENTIO AG… -

Page 218: Sematic 2000 C-Mod

Sematic car door Overview Sematic Car Door (T3 version shown) [43350; 01.05.2012] Sill Belt Door panel Clutch / car door lock / Carrier rollers emergency release mechanism Header Closing edge Schindler 3100/3300/6300 J 43402603 / 01 218/269 Copyright © 2017 INVENTIO AG…

-

Page 219: Maintenance Task List

Check that the closing edge gap of the door panels is maximum 6 mm. Key of abbreviations: – M = month – F = Thousands of cycles Schindler 3100/3300/6300 J 43402603 / 01 219/269 Copyright © 2017 INVENTIO AG…

-

Page 220: Wittur Fine Line

Wittur Fine Line 4.12.3.1 Overview Information Component Title Car door Description Car door Overview [43402603_014; 28.07.2017] Mechanism Coupler Door panel Safety edge Landing sill Guiding shoes Main/counter roller Belt Schindler 3100/3300/6300 J 43402603 / 01 220/269 Copyright © 2017 INVENTIO AG…

-

Page 221: Maintenance Task List

Check the car door lock interface 12 M Check condition of the car door lock Key of abbreviations: – M = month Replacement to be done based on the condition. Schindler 3100/3300/6300 J 43402603 / 01 221/269 Copyright © 2017 INVENTIO AG…

-

Page 222: Fep

Guide shoe assembly Motor with encoder Clutch / car door lock / restrictor Motor pulley Guiding roller and guiding rail 10 KTC switch Synchronization cable 11 Closing bumper Synchronization pulley Schindler 3100/3300/6300 J 43402603 / 01 222/269 Copyright © 2017 INVENTIO AG…

-

Page 223: Maintenance Task List

500 F For C2 car door, visually check the teeth on the belt. Replace if necessary. Key of abbreviations: – M = month – F = Thousands of cycles Schindler 3100/3300/6300 J 43402603 / 01 223/269 Copyright © 2017 INVENTIO AG…

-

Page 224: Maintenance Checks

If necessary, clean the contacts of the KTC bridge (2) using a lint free cloth. Function Check of the KTC Switch for T2-EU and C2-EU/AP [14123; 09.07.2013] KTC switch Fastening bolt KTC bridge Schindler 3100/3300/6300 J 43402603 / 01 224/269 Copyright © 2017 INVENTIO AG…

- Page 225

1 … 2 1 … 2 [43402603_009; 17.03.2016] KTC switch KTC bridge Schindler 3100/3300/6300 J 43402603 / 01 225/269 Copyright © 2017 INVENTIO AG… - Page 226

Check the rubber buffer (7) and closing bumper (4) and replace them if they have sign of cracks. 1 … 2 1 … 2 Noise Check for DO FEP T2-EU/NA (T2-EU shown) [43402603_010; 17.03.2016] VF5+/VF7 control Door carrier Schindler 3100/3300/6300 J 43402603 / 01 226/269 Copyright © 2017 INVENTIO AG… - Page 227

Check the rubber buffer and closing bumper (5) and replace them if they have sign of cracks. 30 mm Noise Check for C2-EU/NA (DO FEP C2-EU shown) [41141759_010; 26.03.2015] Door drive Door carrier VF5+/VF7 control Closing bumper Set screw Schindler 3100/3300/6300 J 43402603 / 01 227/269 Copyright © 2017 INVENTIO AG… - Page 228

Synchronization Check for T2-EU/NA [42121; 13.12.2011] Set screw Jamb Closing bumper Slow door panel Clamp Fast door panel M6 x 16 bolt Alignment tool (spirit level or other) Synchronization cable Schindler 3100/3300/6300 J 43402603 / 01 228/269 Copyright © 2017 INVENTIO AG… - Page 229

C2-EU/AP/LA: BKE + 15 C2-NA: BKE Synchronization Check for C2-EU/AP/NA (C2-EU shown) [13923; 09.07.2013] Door panel Synchronization cable Jamb Clamp Set screw M6 x 16 bolt Closing bumper Schindler 3100/3300/6300 J 43402603 / 01 229/269 Copyright © 2017 INVENTIO AG… - Page 230

Check the guiding rollers (1) for any damage. Clean the guiding rollers (1) if they are dirty, using a lint free cloth. Guiding Rollers shown [2512; 05.06.2006] Guiding rollers Guiding rails Schindler 3100/3300/6300 J 43402603 / 01 230/269 Copyright © 2017 INVENTIO AG… - Page 231

Panels Positions [mm] T2-EU and 750 Opened Opened T2-EU and 800 Opened Opened T2-EU and 900 Opened Opened T2-NA and 915 Opened Opened T2-NA and 1067 Opened Opened Schindler 3100/3300/6300 J 43402603 / 01 231/269 Copyright © 2017 INVENTIO AG… - Page 232

Area tension is correctly adjusted Clutch Belt Motor pulley Pulley Dimension X Type and BKE [mm] Skate Position Panels Positions [mm] C2-EU and 800 Opened Closed C2-EU and 900 Opened Closed Schindler 3100/3300/6300 J 43402603 / 01 232/269 Copyright © 2017 INVENTIO AG… - Page 233

Synchronization Cable Pulleys Synchronization Cable and Pulleys [11400; 09.07.2013] Synchronization pulleys Synchronization cable Compression spring Clutch base plate Spring holder Clutch M6 nut Schindler 3100/3300/6300 J 43402603 / 01 233/269 Copyright © 2017 INVENTIO AG… -

Page 234: Safety Gears

It can be used either as a double acting safety gear or simply as protection in downward direction. Overview SA GED Series [26967; 18.08.2008] Safety gear housing Supporting bolt Disk springs Brake plate Brake shoe Eccentric disk Schindler 3100/3300/6300 J 43402603 / 01 234/269 Copyright © 2017 INVENTIO AG…

-

Page 235: Maintenance Task List

Check the correct running clearance (s ) of 2 mm. If necessary adjust the gap to 2 mm using the setting screw (1). Schindler 3100/3300/6300 J 43402603 / 01 235/269 Copyright © 2017 INVENTIO AG…

- Page 236

Check whether the reset unit (6) can hold the governor lever (5) in its initial position. Check the seal and wire for completeness. Check fixation of rope coupling for governor lever (5). Schindler 3100/3300/6300 J 43402603 / 01 236/269 Copyright © 2017 INVENTIO AG… -

Page 237: Perodic Tests

HMI display shows [ / /xy] – Release the safety gear of the car with the help of the recall control. Check for damages on the guide rails. Schindler 3100/3300/6300 J 43402603 / 01 237/269 Copyright © 2017 INVENTIO AG…

-

Page 238: Safety Gear — Rf0002

Its observance will help to avoid risks, to reduce repair cost and outage time, and to increase the reliability and the operating life of the safety gear. Schindler 3100/3300/6300 J 43402603 / 01 238/269…

- Page 239

The roller is released when the car is moved upward by means of the elevator drive. The safety gear may be used only in combination with a rope rupture tripping device. Prior to commissioning, check whether the rope rupture tripping device functions properly. Schindler 3100/3300/6300 J 43402603 / 01 239/269 Copyright © 2017 INVENTIO AG… -

Page 240: Maintenance Checks

Excessive wear of the braking rollers and the safety gear base. – Deformations – Smooth running The braking marks on the guide face are to be filed down. Schindler 3100/3300/6300 J 43402603 / 01 240/269 Copyright © 2017 INVENTIO AG…

-

Page 241: Hoistway Door

4.14 Hoistway Door 4.14.1 Preventive Maintenance on Hoistway Door Overview [43402603_019; 10.08.2017] Landing sill Guiding shoe Door panel Main track Main/counter roller Safety contact Landing door Schindler 3100/3300/6300 J 43402603 / 01 241/269 Copyright © 2017 INVENTIO AG…

- Page 242

Check lock roller 12 M Check safety contact (KTS, KNET…) 12 M Check contact bridge Key of abbreviations: – M = month Replacement to be done based on the condition. Schindler 3100/3300/6300 J 43402603 / 01 242/269 Copyright © 2017 INVENTIO AG… -

Page 243: Hoistway Door Lock — Wittur Evo

Door contact Hook lock Counter lock Lock fixing bolt Step Close the door fully so that the hangers (1) are against the buffers (2). Check the lock function. Schindler 3100/3300/6300 J 43402603 / 01 243/269 Copyright © 2017 INVENTIO AG…

- Page 244

Door contact Hook lock Counter lock Lock fixing bolt Step Close the door fully so that the hangers (1) are against the buffers (2). Check the lock function. Schindler 3100/3300/6300 J 43402603 / 01 244/269 Copyright © 2017 INVENTIO AG… - Page 245

Due to safety reasons it is not allowed to untight the lock fixing bolt (6). Adjustment of the Lock Rollers Lock Rollers Adjustment [43402603_004; 16.02.2016] Screw Lock roller Screw Schindler 3100/3300/6300 J 43402603 / 01 245/269 Copyright © 2017 INVENTIO AG… - Page 246

Position of the Coupler between the Landing Lock Rollers Coupler Position between Landing Lock Rollers [43402603_005; 16.02.2016] Door Type Landing Door C2 17.5 100.5 Landing Door T2 22.5 105.5 Schindler 3100/3300/6300 J 43402603 / 01 246/269 Copyright © 2017 INVENTIO AG… -

Page 247: Hoistway Door Lock — Wittur Fine Line

The lock gap does not break the door contact (3) when panels are moved apart. – The hook lock (6) is engaged 7 mm to the counter lock (5) before closing the contact (3) with the bridge (4). Schindler 3100/3300/6300 J 43402603 / 01 247/269 Copyright © 2017 INVENTIO AG…

-

Page 248: Hoistway Door Lock — Sematic

Loosen all the screws of the slave and the lock. [49424; 29.11.2013] Step Loosen the nut of the rear roller of the master. [49425; 29.11.2013] Step Couple the slave with the skate. Schindler 3100/3300/6300 J 43402603 / 01 248/269 Copyright © 2017 INVENTIO AG…

- Page 249

[49426; 29.11.2013] Adjust horizontally the slave to reach the distances indicated in the drawing above. Step Apply the template centering the rollers of the master. [49427; 29.11.2013] Schindler 3100/3300/6300 J 43402603 / 01 249/269 Copyright © 2017 INVENTIO AG… - Page 250

[49428; 29.11.2013] Step Tighten the screws of the front roller of the master. [49429; 29.11.2013] Step Tighten the nut of the rear roller of the master. [49430; 29.11.2013] Schindler 3100/3300/6300 J 43402603 / 01 250/269 Copyright © 2017 INVENTIO AG… -

Page 251: Maintenance Checks

Check that the re-opening device operates properly – When necessary, grease with a lithium based grease which can be used with temperatures between — 30° and + 120° – Check the bottom track cleaning. Schindler 3100/3300/6300 J 43402603 / 01 251/269 Copyright © 2017 INVENTIO AG…

-

Page 252: Sliding Guide Shoes — I/L 10~14

BFK + 0.5 ( ± 0.4) Guide Shoe I10 [40042; 14.07.2011] Guide Shoe L10 [20026; 04.12.2008] Material Type Weight [kg] Liner Casing Isolation PA, PE, Vulkollan AL diecast PA, UHM-PE AL diecast Schindler 3100/3300/6300 J 43402603 / 01 252/269 Copyright © 2017 INVENTIO AG…

- Page 253

63 … 64 Guide Shoe I14 [20027; 14.07.2010] Guide Shoe L14 [40043; 14.07.2011] Material Type Weight [kg] Liner Casing Isolation PA, UHM-PE AL diecast PA, UHM-PE AL diecast Schindler 3100/3300/6300 J 43402603 / 01 253/269 Copyright © 2017 INVENTIO AG… -

Page 254: Maintenance Task List

Material Type Weight [kg] Damper Casing Liner AL diecast UHM-PE 4.15.2 Maintenance Task List Task List Interval Description 12 M Check the guide shoes and lubricator (if fitted) Schindler 3100/3300/6300 J 43402603 / 01 254/269 Copyright © 2017 INVENTIO AG…

-

Page 255: Maintenance Checks

≥ 14 mm, see pictures. Else replace all four guide shoe linings (2). Guide Shoes [26937; 29.07.2008] Guide shoe Fastening screw Guide shoe lining Wedge Guide rail Lubricator Upright Lubricator felt Schindler 3100/3300/6300 J 43402603 / 01 255/269 Copyright © 2017 INVENTIO AG…

- Page 256

Close the oil tank afterwards and clean up any spilled oil. Check that the dimension is ≥ 14 mm. If not, the guide shoe liner must be replaced. Guide Shoe Check [11459; 07.03.2005] Schindler 3100/3300/6300 J 43402603 / 01 256/269 Copyright © 2017 INVENTIO AG… -

Page 257: Technical Documentation

Wittur, type FINELINE TÜV-A-AT-1/07/147 CETV TÜV Austria 0408 Schindler — Ets Henri Peignen 0071/0199 0071 Schindler — Ets Henri Peignen T11 0071/0199 Car Safety Gear Schindler, type GED 10/BS ABFV 489 Counterweight Safety SLC, type RF 0002 AFV 765 TÜV SÜD 0036…

- Page 258

12 Tracability tag (QR tag) – Parts that have to be taken as shown are marked in black. – Parts that have to be added individually are shown in grey/italic. Schindler 3100/3300/6300 J 43402603 / 01 258/269 Copyright © 2017 INVENTIO AG… -

Page 259: Manufacturer For Safety Components

43052 Colorno (Parma) Malpica, Calle E,num. 8 96301 Krupina Italy 50016 Zaragoza Slovakia Spain Sematic type H153ACTX Sematic Italia Spa Italy Via Zappa COMM.FRANCESCO, 5 I-26064 OSIO SOTTO (BG) Italy Schindler 3100/3300/6300 J 43402603 / 01 259/269 Copyright © 2017 INVENTIO AG…

- Page 260

Sematic Italia Spa Italy including glass door panel Via Zappa COMM.FRANCESCO, 5 I-26064 OSIO SOTTO (BG) Italy Schindler — Ets Henri Peignen Fermator (peignen) 3 rue de la Borne Blanche 77380 Combs la Ville France Schindler — Ets Henri Peignen… - Page 261

Plant A15 Xinfei Garden No. 802 Shengang Road, Songjiang Shanghai 201612 Popular Republic China Leroy Somer FCRD Leroy-Somer / Nidec Group Usine de Rabion 16015 Angoulême cedex France Schindler 3100/3300/6300 J 43402603 / 01 261/269 Copyright © 2017 INVENTIO AG… -

Page 262: Basic Characteristics Of Traction Media And Governor Rope

Rope Dia. (kg/m) Construction Breaking GQ (kg) (mm) Force FZM (kN) + 2/+ 6 % 0.13 Seal 6 x 19 > 21.0 320 … 1000 fibre core chemical PP Schindler 3100/3300/6300 J 43402603 / 01 262/269 Copyright © 2017 INVENTIO AG…

-

Page 263: Miscellaneous

Installation arranged between the owner of the installation and the installer. In those cases, where the new installation is delivered by Schindler, the company will arrange for disposal of the old installation in consultation with the owner of the installation.

- Page 264

Documentation control system is modified, the schematic wiring diagrams must be brought up-to-date. Your Partner for Based on many years of experience, Schindler the original manufacturer of this Modernization installation, can guarantee a speedy and professional modernization. Schindler 3100/3300/6300… -

Page 265: Abbreviations

Friction force of rope at speed governor (in down/up direction) Engagement force of safety gear at governor lever Weight of counterweight frame + filling GG+GU+ GH (for a counterweight) Schindler 3100/3300/6300 J 43402603 / 01 265/269 Copyright © 2017 INVENTIO AG…

- Page 266

Maximum admissible speed of impact on buffer VKNZ Maximum admissible rated speed GPZ1 Minimum admissible mass for one buffer GPZ2 Maximum admissible mass for one buffer Weight of the buffer (without oil) Schindler 3100/3300/6300 J 43402603 / 01 266/269 Copyright © 2017 INVENTIO AG… -

Page 267: Control Functions

Visitors Control Automatic Evacuation Unit in hoistway User Interface HMI Incremental Encoder IRTS Safety circuit indication hoistway doors Interface Safety circuit indication ISPT Safety circuit indication blocking door Schindler 3100/3300/6300 J 43402603 / 01 267/269 Copyright © 2017 INVENTIO AG…

- Page 268

Landing fixtures LEFC Lamp Evacuation Travel Car Floor indicator/travel LIFD Long distance between two floors Load Measurement Unit Lamp Emergency Light Car Landing operation panel LUET Lamp Overbridging Door Schindler 3100/3300/6300 J 43402603 / 01 268/269 Copyright © 2017 INVENTIO AG… - Page 269

Manual evacuation and emergency power PCB SUET Door Bridging PCB Software TACC Tele alarm control center TDIF Travel direction indicator TELA Telealarm device Transformer Elevator Control Ventilator car Schindler 3100/3300/6300 J 43402603 / 01 269/269 Copyright © 2017 INVENTIO AG…

| Автор | Сообщение | |||

|---|---|---|---|---|

|

Заголовок сообщения:

|

||||

|

Есть Шиндлер 9300 (эскалатор). вышла ошибка Е17. Как ее сбросить? |

|||

| Вернуться к началу |

|

|||

|

LiftMechanic |

Заголовок сообщения:

|

||

|

E17 — это концевой выключатель на натяжение цепей в натяжной станции (в низу). Они не самовозвратные. Его надо «отщёлкнуть», и всё заработает. |

||

| Вернуться к началу |

|

||

|

Alex-chlm |

Заголовок сообщения:

|

|

|

отшелкнули, проверили, но ошибка не сбросилась |

| Вернуться к началу |

|

|

LiftMechanic |

Заголовок сообщения:

|

||

|

А два эти концевика прозванивали? Дело в том эта ошибка не подвисает. Другие да. Но эта в практике не встречалась, что бы висела. |

||

| Вернуться к началу |

|

||

|

soltanov |

Заголовок сообщения: Re: Проблемы с эскалатором Schindler

|

|

|