Ch 2

Ch 2

92

92

page

page

The basic functions of the automatic system

are the automatic shifting of gears, adaption

of the optimum shifting points, the

comprehensive safety functions in relation

to operating errors and overloads of the

power-transmitting components with a

comprehensive fault storage.

Due to the great number of the available

TCU, the exact Technical Data must be

taken from the respective installation

drawing.

Description of the Basic functions:

The Powershift transmission of the Ergopower-

Series 6 WG-310 is equipped with the Electronic

transmission control EST-37A, developped for it.

The system is processing the desire of the driver accord-

ing to the following criteria:

•

Gear determination dependent on controller

position driving speed and load condition.

•

Protection from operating error as far as

necessary, is possible via electronic protection

(programming).

•

Protection from over-speeds (on the base of

engine and turbine speed).

•

Automatic reversing (driving speed-dependent,

depending on vehicle type).

•

Pressure cut-off possible (vehicle-specific, only

after contact with ZF).

•

Change-over possibility for Auto- / Manual

mode.

Important parts information

If the Transmission 6WG310 is to be returned to Moxy Trucks AS or ZF for repair or any

others reasons, the Transmission controller EST-37A is to be returned together with the

Transmission.

1.

Fasten the controller to the Transmission.

2.

Indicate in the delivery note the serial number of the

Transmission and the controller.

This information will help us if the controller should be

separated from the Transmission under transport.

3.

If the Transmission shoud have a waranty repair at

other workshop, it is necessery that the testreport

printing are following with the claim.

Pole 23

Pole 45

Pole 68

23

68

45

2

24

46

1

Pole 46

Pole 24

Pole 1

SHOP MANUAL MT26/31 — 08.2006

SHOP MANUAL MT26/31 — 08.2006

EST-37A; with filterbypass; Smart Software;

CAN; engine brake; AutoRetarder; KD only

via ED7

(TCU must be ordered separate)

TRANSMISSION

TRANSMISSION

АКПП ZF: 4,5,6,8-ступенчатые автоматы

АКПП ZF: 4,5,6,8-ступенчатые автоматы

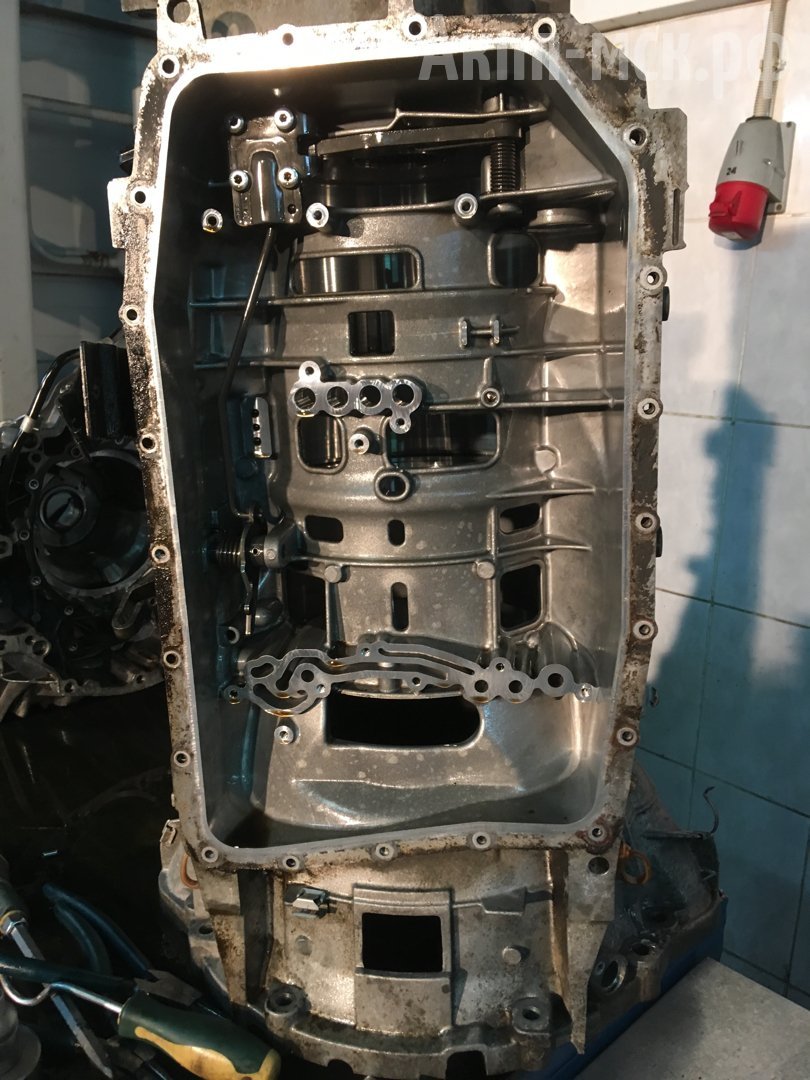

Коробки от ZF устанавливались практически на всю линейку немецкого автопрома. Это BMW, Audi, VW, Skoda, а также на ряд корейский производителей.

В данной статье мы обозначим общие неисправности 4-5-6-8-ступенчатых автоматов ZF.

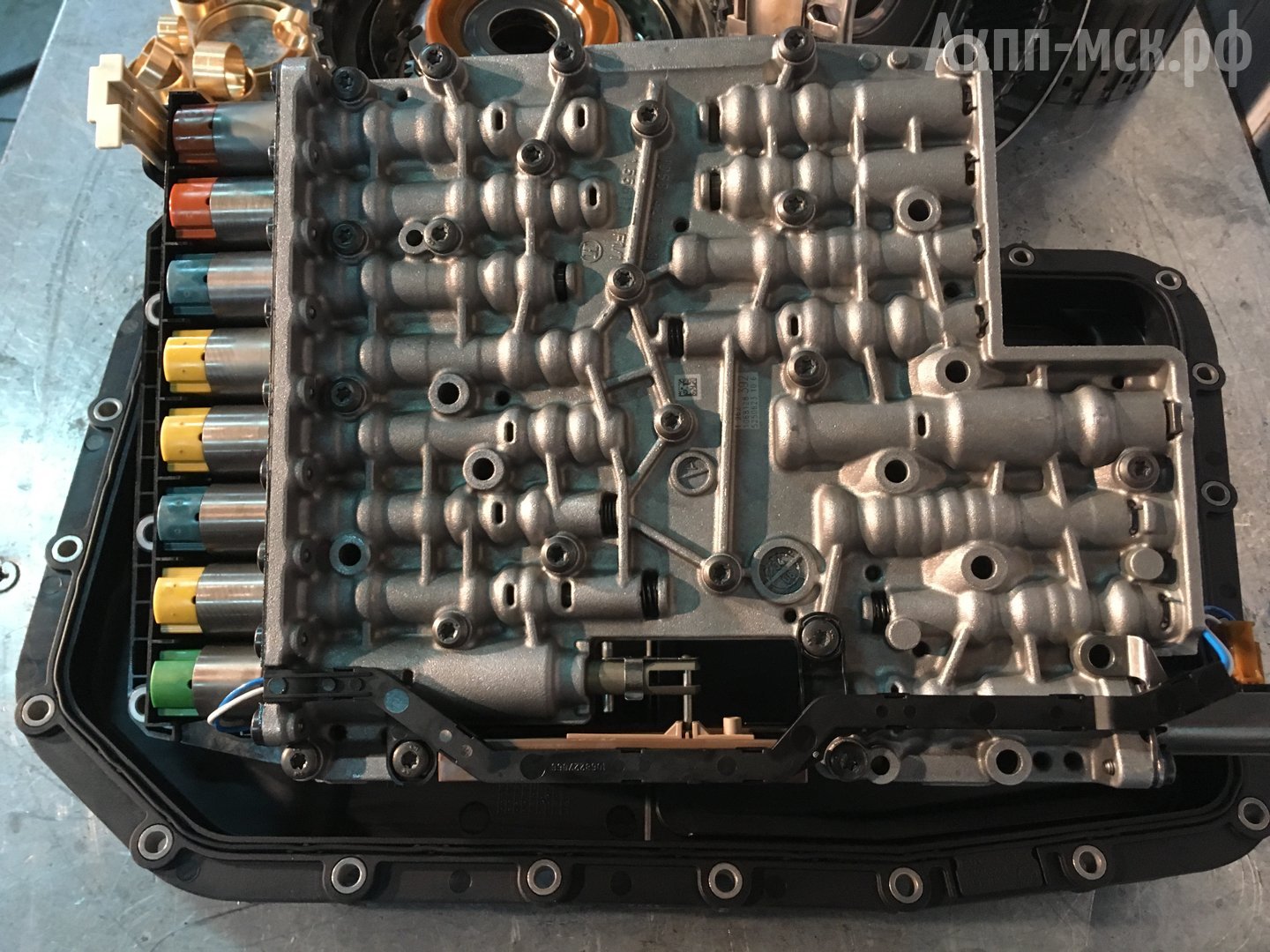

У всех этих линеек продольных трансмиссий, вплоть до 8-ступенчатых, конструкция примерно одинаковая. Главное отличие — на 4-х и 5-ступенчатых автоматах идет обычный гидроблок. На 6-ти и 8-ступенчатых автоматах уже вместо гидроблока идет мехатроник.

Основные неисправности АКПП ZF.

Ключевые неисправности 4-ступенчатых АКПП ZF – это гидроблок, насос и центральный суппорт. В результате поломок данных узлов выходят из строя фрикционы.

5-ступенчатые АКПП ZF — 5HP19, 5HP24 – имеют гидроблок как главную неисправность. В нем в обязательном порядке требуется менять основной соленоид давления черного, либо желтого цвета. Первое и более дорогое поколение – это соленоид черного цвета. Последующее поколение этого соленоида на гидроблоках 2000-2004 годов выпуска – желтого цвета.

Также подлежат замене механические клапаны в самой гидроплите. В них идут гидрокомпенсаторы на резиновой основе, которые со временем просто сдавливает и клапаны перестают держать давление.

Еще одна неисправность 5-ступок – насос. В нем на втулке установлен подшипник. Втулку проворачивает, в результате чего вытекает масло и коробка сгорает. Некоторые автосервисы по ремонту АКПП стараются просто заменить втулку на ремонтную. Поскольку посадка по втулке все равно изнашивается, наш техцентр этого не делает и ставит новый насос в сборе.

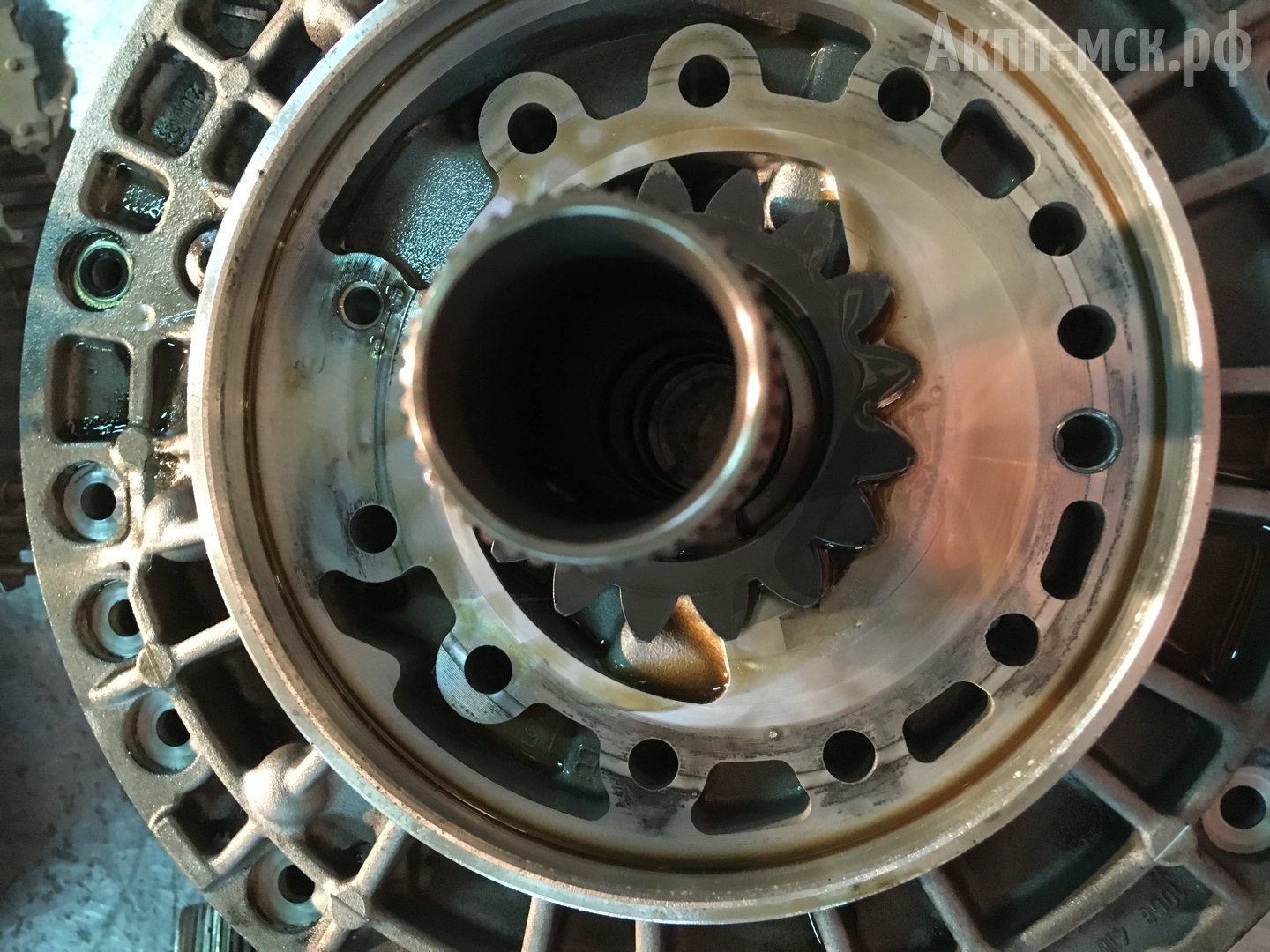

Часто на линейке ZF 5HP.. выявляются неполадки по центральному суппорту. В суппорте установлен поршень, который нередко обламывает. В результате этого на АКПП пропадают передачи. Как следствие, выходит из строя задний планетарный редуктор (для 5HP19).

Центральный суппорт ZF 6HP28

Поршень суппорта ZF 6HP28

У 5HP24 основная проблема – в гидроплите. Она идет составная из верхней и нижней пластины. Одна из этих частей лопается в результате перегрева. Давление пропадает. Решение – пластина идет под замену.

В результате неисправности насоса и гидроблока горят фрикционы. Все это выражается в следующих симптомах неисправности:

- толчки/рывки;

- пробуксовки;

- отказ в движении.

У агрегата 5HP19 частый симптом – сильные толчки/рывки при переключении селектора в положение D, или R.

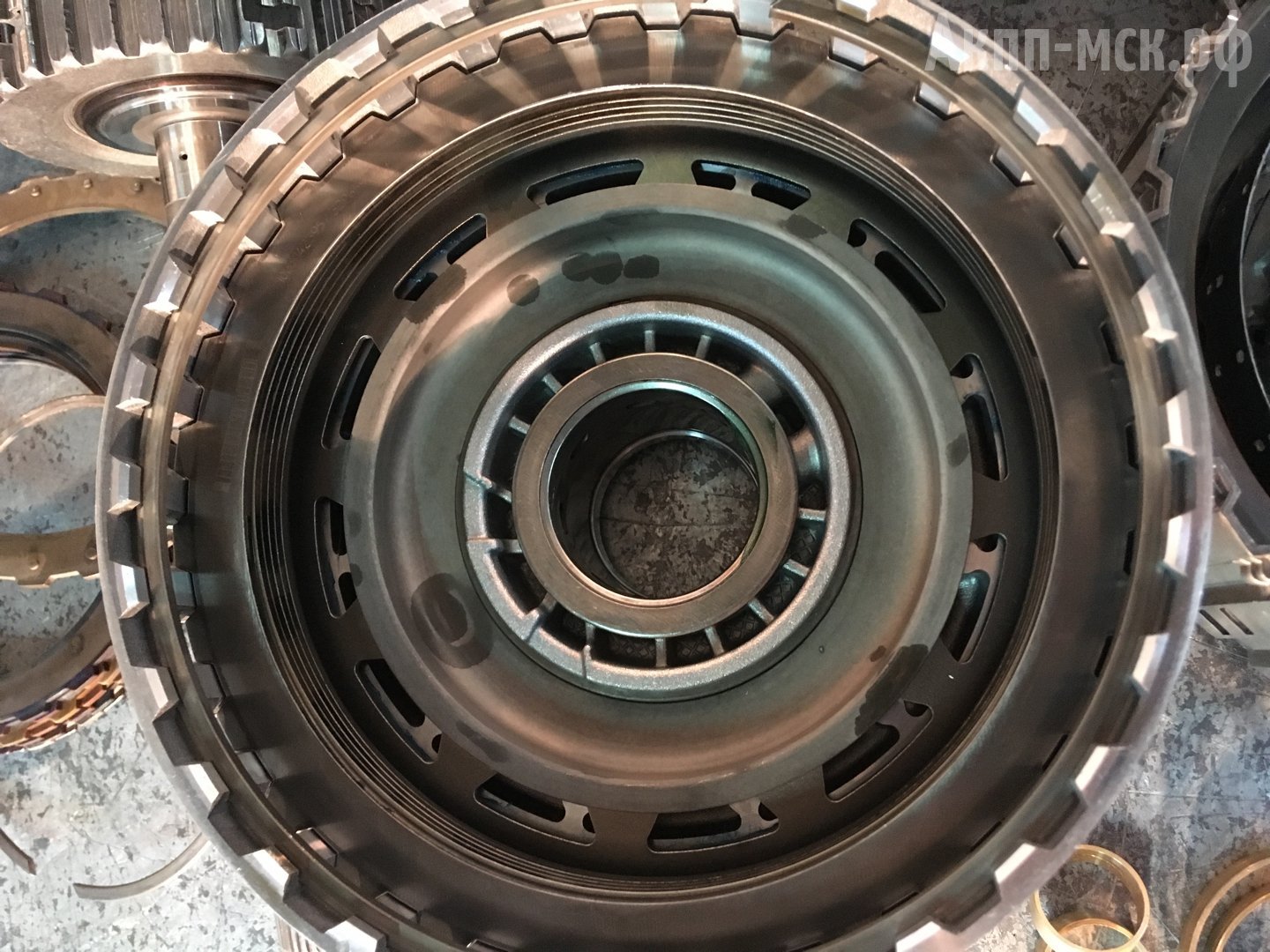

В линейке 6HP19, 6HP21, 6HP26, 6HP28, 6HP32 (Audi Q7 6.0 diesel) главная неисправность — достаточно редкий и дорогостоящий барабан Е. Его рвет по корпусу, и он начинает «давить» масло не туда, куда надо. Чаще, естественно, это случается на 6HP32. Барабан идет под замену.

Основные неисправности линейки 6HP – мехатроник, насос и втулки. По посадкам в АКПП везде стоят наборные втулки. Когда втулка изношена, через нее уходит давление канала. Соответственно барабан перестает работать – коробка начинает буксовать, толкаться и горят фрикционы.

По фрикционным дискам 6-ступенчатых автоматов желательно прибегать к оригинальным комплектам. Получаем максимальное качество, по стоимости сравнимое с аналогами. По цене оригинал и неоригинал особо не отличаются.

Оригинальные комплекты фрикционов ZF

По втулкам завод-изготовитель производит биметаллические втулки. Наш техцентр большее предпочтение отдает бронзовым втулкам. По опыту, они более надежные и долговечные.

Бронзовые втулки для ремонта АКПП ZF

При ремонте обязательна замена комплекта соленоидов мехатроника. На каждой линейке 6-ти и 8-ступенчатых автоматов может быть несколько разновидностей соленоидов. Бывает 7 соленоидов; бывает 9. Также это зависит от привода ручки КПП. При наличии джойстика (например, на БМВ) имеется отдельный привод и соленоид на него и переключение происходит за счет электрики.

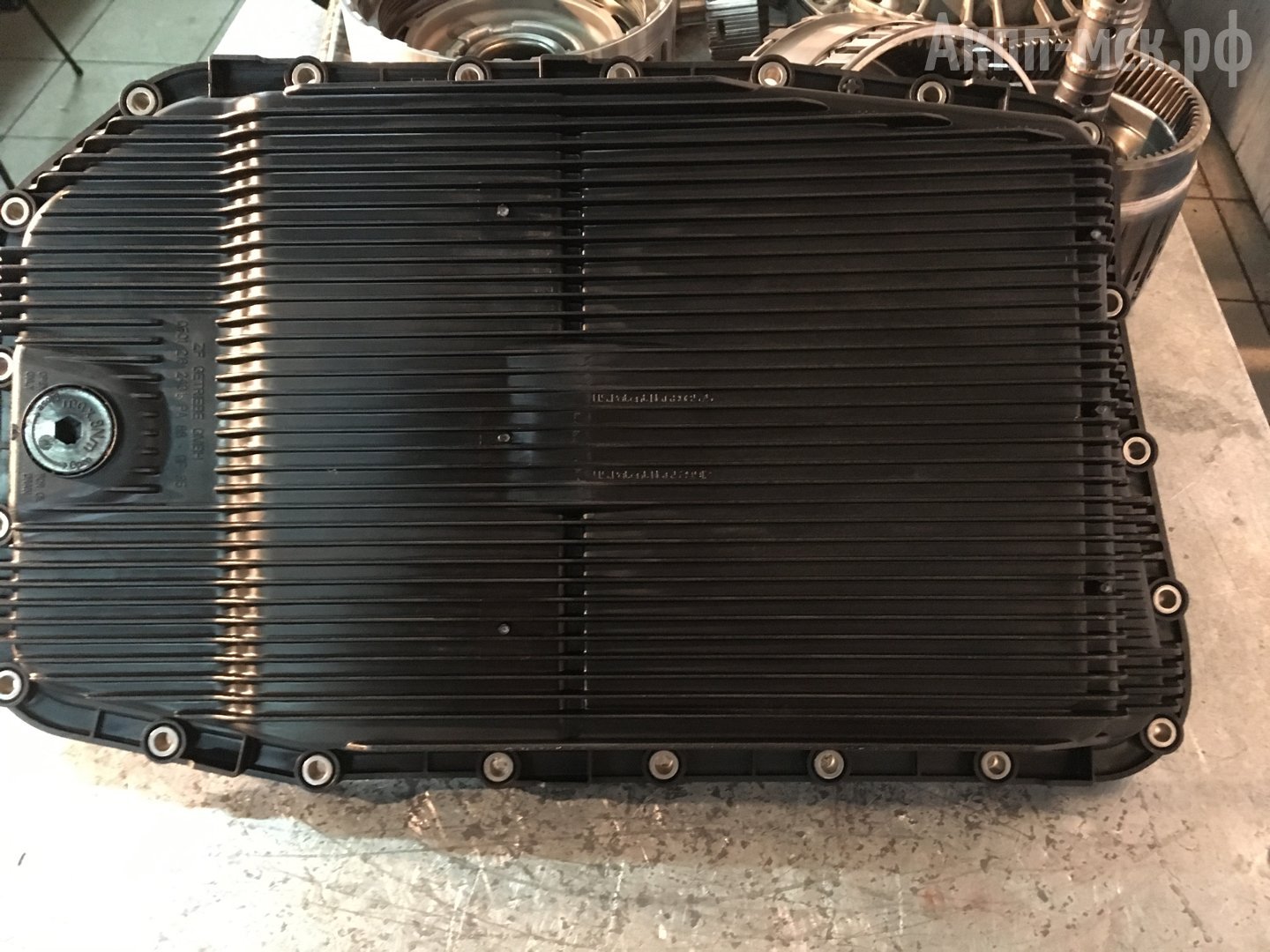

Неудобство – фильтр меняется вместе с поддоном. Поэтому фильтр ценой в 1,5-2 тысячи рублей оборачивается комплексной заменой вместе с поддоном на 7 тысяч рублей.

Частая неисправность – барабан С. В нем появляются микротрещины и он начинает пропускать масло.

По планетарным редукторам износ очень редок. Такая неисправность встречается, если автовладелец совсем запустил своевременный ремонт и эксплуатировал автомобиль до последнего.

В целом, по ремонту данные трансмиссии — неприхотливые. Особых сложностей нет. Квалифицированный сервис по ремонту АКПП сможет починить коробку за 1-4 дня. Гарантия в нашем техцентре – 1 год без ограничения по пробегу.

Агрегаты ZF – достаточно прочные. Впервые с ремонтом автовладелец может столкнуться, в среднем, не ранее 150 тыс. км. пробега. Все зависит от того, где и как эксплуатируют автомобиль, как проводят техническое обслуживание АКПП.

Диагностика АКПП ZF.

На большинство вопросов о причинах неисправности можно ответить сразу после первичной диагностики.

Первичная диагностика заключается, во-первых, в компьютерной диагностике, когда считываются параметры работы электрики и мехатроника. Если по электрике ошибок нет, проводится тест-драйв автомобиля на прогретой и непрогретой АКПП. Смотрится симптоматика коробки при работе в данных условиях.

Если трансмиссия толкается/пинается – проблема, скорее всего, в гидроблоке, либо втулках.

Если имеем полный отказ в движении – вышел из строя барабан и поэтому коробку следует снимать и дефектовать. После полного разбора уже будет точно установлен перечень вышедших из строя узлов.

Также если компьютерная диагностика ничего не выявила, берется проба масла на присутствие частиц. Если масло чистое, прозрачное и отсутствует запах гари, нужно обращать внимание лишь на мехатроник/гидроблок. Если движения нет, но масло чистое – значит срезало барабан.

То есть первичная диагностика нам покажет – стоит ли делать только мехатроник/гидроблок, или нужно полностью разбирать коробку. Это мы будем знать после диагностики на 100%. Что же произошло непосредственно с механической частью АКПП (фрикционы, барабан, втулки) станет известно после разбора. Но уже точно будет известно, что трансмиссию надо разбирать.

При наличии неисправности какая-либо буксировка запрещается. При серьезной неисправности (пробуксовки, отказ в движении, вытекло масло) в настоятельном порядке рекомендуем воспользоваться эвакуатором. При небольших рывках только на прогретой коробке, что говорит о сбоях в работе гидроблока/мехатроника, своим ходом недалеко до сервиса добраться можно.

Механика процесса следующая. Насос подключен к гидротрансформатору. Гидротрансформатор подключен к мотору. При буксировке Вы ставите автомобиль на нейтраль. Откуда Вы знаете, что в нейтрали не заклинит пакет, или планетарный механизм? Данные узлы даже в нейтралипродолжают работать. На заведенном автомобиле насос работает не в полную силу – происходит масляное голодание. Происходит перегрев гидротрансформатора и насоса. На заглушенном двигателе насос также крутится и может выходить из строя.

Поэтому любую АКПП не стоит буксировать ни в каком виде. Иначе стоимость ремонта может возрасти раза в 2, а то и больше. Лучше заплатить несколько тысяч рублей за эвакуатор.

Стоит ли покупать б/у АКПП ZF?

Подержанная коробка ZF совсем недешева. 5-ступенчатая коробка стоит в районе 50 тыс. руб., 6-ступенчатая — около 70-80 тыс. руб., 8-ступенчатая коробка может иметь ценник в 120 тыс. руб. Добавьте затраты на масло, фильтр, прошивку, снятие и установку АКПП. И гарантия будет 2 недели, либо месяц максимум. Если купленная «бэушка» не поехала – расходы на снятие/установку и масло вам никто не вернет.

Ремонт, например, 8HP70 обходится в районе стоимости подержанной коробки. Если же Вашей коробке требуется только ремонт гидроблока/мехатроника, такой ремонт с годовой гарантией обойдется гораздо дешевле любой подержанной коробки.

Важный момент. Трансмиссии, которые продает сама компания ZF – это не новые, а восстановленные трансмиссии. Новая АКПП ZF ставится только на конвейере и в рознице не представлена.

Обслуживание трансмиссий ZF.

На рынке нет коробок-автомат, предназначенных для гонок. АКПП с трущимися поверхностями – это не «механика» с прочным набором шестерен. У автоматов есть фрикционы со своим моментом и прочностью, за пределы которых они выйти не могут. Тем более у автоматической трансмиссии с пробегом больше 100 тыс. км. в любом случае имеется их износ.

- несвоевременное техническое обслуживание;

- пробки;

- нагрузки.

После ремонта АКПП прослужит как минимум не меньше, чем новая – те же 150-200 тыс. километров пробега. Прирост составит порядка 25-30%. Например, за счет использования более мощных втулок. Это не исключает необходимость проведения своевременного ТО коробки.

Под своевременным техническим обслуживанием подразумевается замена масла, профилактический осмотр и диагностика АКПП.

Регламент замены масла в АКПП ZF:

- первая замена на 60 тыс. км. пробега;

- вторая замена на 120 тыс. км. пробега;

- последующие замены каждые 35 тыс. км. пробега.

Обязательно меняйте масло. «Вечных» масел не существует. Износ идет в любом случае даже при бережной эксплуатации коробки. Те же фрикционы — трутся, осыпаются. Продукты износа попадают в фильтр. Поддон фильтра ZF удержать все это не может. Продукты износа, тем самым, попадают в гидравлическую часть трансмиссии (гидроблок/мехатроник).

Если автовладелец проехал на автомобиле 200 тысяч и решил поменять масло – это может закончится плачевными последствиями. Свежее масло обладает хорошими очищающими свойствами. Когда на изношенный фрикцион попадает свежее масло – фрикционный элемент может отслоиться от стального основания.

При больших пробегах также не рекомендуется менять масло целиком через аппарат (полная замена масла). Под давлением все продукты износа проходят через мехатроник/гидроблок. Это делается на работающем двигателе, когда все агрегаты трансмиссии работают. Клапаны гидроблока начинают клинить, забиваются и выходят из строя электромагнитные клапаны. В итоге автомобиль может даже не сойти с подъемника.

Если появились какие-либо симптомы неисправности АКПП, замена масла не поможет! Надо делать комплексную диагностику, выявлять и устранять неисправность. Зачастую, многие на замену масла просто «выбрасывают деньги на ветер» 15-20 тыс. руб., надеясь, что эта процедура поможет.

- чистый гидроблок/мехатроник;

- нормальное охлаждение.

Следите за охлаждением коробки. Многие автовладельцы выводят дополнительное охлаждение АКПП. В основном, это практикуют владельцы Range Rover. Для автомобилей, находящихся в режимах постоянного перегрева, устанавливают целых 2 больших радиатора охлаждения.

Если остались вопросы – пишите комментарии под данной статьей, либо звоните напрямую нашему мастеру. Телефон указан в разделе «Контакты». Также через любой мессенджер можно отправить мастеру фотографии запчастей, кодов ошибок и т.п., либо также позвонить и проконсультироваться по любому вопросу.

Источник

Error code list. Ergopower- EST37/A. Z F P a s s a u G m b h Donaustraße D Passau

1 Error code list Ergopower- EST37/A Z F P a s s a u G m b h Donaustraße D Passau

2 DIAGNOSE — UND PROGRAMMIERUNG EST 37 ERGOPOWER mit LAPTOP und DPA-05 Pentium Laptop min. 1,0 GHz Zulässiges Betriebssystem Windows 95 / 98 / Me oder NT Windows 2000 / Win XP Software auf CD Testman Pro und Getriebe Applikation ERGOPOWER Adapterkabel = RS = USB Programmieradapter DPA — 05 Diagnose — Set Adapterkabel ZFP Diagnose Software auf CD-ROM für ERGOPOWER EST — 37 WG 110 WG 115 EST — 37 WG 130/131 WG 160/161 EST — 37 WG 190/191 WG 210/211 EST — 37 WG 260/261 WG 310/311 Enthaltene Sprachversionen : DEUTSCH / ENGLISH / FRANCAI`S / ITALIANO Gewicht : 2,060 kg ASDT ZF Passau G.m.b.H / 11 Ducu..CorelPerspektivdarst5870AB200220017

6 codes ERGO-Control EST37A 1 Introduction 1.1 Abbreviations o.c. s.c. OP-Mode TCU EEC PTO open circuit short circuit operating mode transmission control unit electronic engine controller power take off 1.2 ZF — Display: If a fault is detected, the display shows a spanner symbol (g) for a fault. The display shows the fault code, if the gear selector is on neutral position. If more than one fault is detected, each fault code is shown for about 1 second. h f e d left character right character S T O P a b c g (special symbols a-h) 1.3 Display during operation Symbol meaning remarks 1F, 1R 2F, 2R 3F, 3R 4F 5F 6F LF, LR F or R, no gear F or R flashing actual gear and direction left digit shows actual gear right digit shows actual direction limp home gear Clutch Cutoff direction F or R selected while turbine speed is too high NN not neutral, waiting for neutral after power up or a severe fault ** oil temperature too low, no gear available *N oil temperature low, only one gear available CAUTION gear will engage if turbine speed drops to engage a gear, first move shift selector to neutral position and again to F or R position warm up engine / transmission warm up engine / transmission TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 3 von 53

7 codes ERGO-Control EST37A 1 bar (special manual mode 1 st gear symbol) 2 bars manual mode 2 nd gear 3 bars manual mode 3 rd gear 4 bars manual mode 4 th gear and also 5 th and 6 th gear in 6WG 4 bars and 2 arrows automatic mode Bars flashing 6 WG: converter lockup clutch open difference of engine and turbine speed above a certain limit and lockup clutch not activated 4 WG: Downshift mode activ Spanner at least one fault activ select neutral to get fault code displayed code see faultcode list WS warning sump temperature changes between actual gear/direction while driving, in neutral only displayed if no fault is detected (spanner) WR warning retarder temperature changes between actual gear/direction while driving, in neutral only displayed if no fault is detected (spanner) WT warning torque converter temperature changes between actual gear/direction while driving, in neutral only displayed if no fault is detected (spanner) WE warning high engine speed changes between actual gear/direction while driving, in neutral only displayed if no fault is detected (spanner) PN direction F or R selected while parking brake engaged transmission in neutral until parking brake is released CAUTION: vehicle starts to move after release of parking brake EE flashing no communication with display checked wiring from TCU to display TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 4 von 53

8 AEB Clutch Calibration instructions Before starting the AEB following instructions must be followed. Parking Brake must be on Gear selector lever in Neutral Transmission sump temperature between Celsius Engine Idle speed between rpm if to low increase engine speed with gas pedal and keep RPM. Correct Oil Level check Dip stick Vehicle must be on flat surfice level. Please make shure that safety instructions are followed and no persons next to the vehicle! When connecting AEB Starter symbol PL will show up on display. To start AEB please push red botton at least 3 seconds till K1 show up on display after that release the button AEB will continiue itself. Finally if clutches could be calibrated OK will show up on display! Switch off ignition, for at least 5 seconds. Any Errors appear during AEB procedure please read the Error code book German englisch copyright Hermann Wagner ASI

9 codes ERGO-Control EST37A 1.4 Display during AEB-Mode symbol meaning remarks PL AEB — Starter is plugged at the ST diagnostic plug AEB-Starter-button is pressed K1..K4,KV,KR calibrating clutch K1..K4, KV or KR resp. _ and Kx wait for start, initialization of clutch Kx, x: 1, 2, 3, 4, V, R fast fill time determination of clutch Kx and Kx = and Kx compensating pressure determination of clutch Kx OK calibration for all clutches finished Transmissions stays in neutral, you have to restart the TCU (ignition off/on) after removing AEB-Starter STOP AEB canceled (activation stopped) Transmissions stays in neutral, you have to restart the STOP and Kx AEB stopped, clutch Kx can’t be calibrated Spanner and Kx Kx couldn’t be calibrated, AEB finished E E T T FT FB engine speed too low, raise engine speed engine speed too high, lower engine speed transmission oil temperature too low, heat up transmission transmission oil temperature too high cool down transmission transmission temperature not in defined range during calibration operating mode not NORMAL or transmission temperature sensor defective or storing of Calibrated values to EEPROM-has failed. TCU (ignition off/on) Transmissions stays in neutral, you have to restart the TCU (ignition off/on) Transmissions stays in neutral, you have to restart the TCU (ignition off/on) Transmissions stays in neutral, you have to restart the TCU (ignition off/on) Transmissions stays in neutral, you have to restart the TCU (ignition off/on) FO Outputspeed_not_zero Transmissions stays in neutral, you have to restart the TCU (ignition off/on) FN Shift lever not in Neutral position Transmissions stays in neutral, you have to restart the TCU (ignition off/on) FP Parkbrake_not_applied Transmissions stays in neutral, you have to restart the STOP AEB — Starter was used incorrect or is defective. Wrong device or wrong cable used TCU (ignition off/on) Transmissions stays in neutral, you have to restart the TCU (ignition off/on) TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 5 von 53

10 codes ERGO-Control EST37A 2 definition of operating modes NORMAL: There’s no failure detected in the transmission-system or the failure has no or slight effects on transmission control. TCU will work without or in special cases with little limitations. (see following table) SUBSTITUTE CLUTCH CONTROL: TCU can’t change the gears or the direction under the control of the normal clutch modulation. TCU uses the substitute strategy for clutch control. All modulations are only time controlled. (Comparable with EST 25) LIMP-HOME: The detected failure in the system has strong limitations to transmission control. TCU can engage only one gear in each direction. In some cases only one direction will be possible. TCU will shift the transmission into neutral at the first occurrence of the failure. First, the operator must shift the gear selector into neutral position. If output speed is less than a threshold for neutral to gear and the operator shifts the gear selector into forward or reverse, the TCU will select the limp-home gear. If output speed is less than a threshold for reversal speed and TCU has changed into the limp-home gear and the operator selects a shuttle shift, TCU will shift immediately into the limp-home gear of the selected direction. If output speed is greater than the threshold, TCU will shift the transmission into neutral. The operator has to slow down the vehicle and must shift the gear selector into neutral position. TRANSMISSION-SHUTDOWN: TCU has detected a severe failure that disables control of the transmission. TCU will shut off the solenoid valves for the clutches and also the common power supply (VPS1). Transmission shifts to Neutral. The park brake will operate normally, also the other functions which use ADM 1 to ADM 8. The operator has to slow down the vehicle. The transmission will stay in neutral. TCU-SHUTDOWN: TCU has detected a severe failure that disables control of system. TCU will shut off all solenoid valves and also both common power supplies (VPS1, VPS2). The park brake will engage, also all functions are disabled which use ADM 1 to ADM 8. The transmission will stay in neutral. TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 6 von 53

11 3 table of fault codes LOGICAL ERROR AT GEAR RANGE SIGNAL TCU detected a wrong signal combination for the gear range cable from shift lever to TCU is broken or vehicle shift lever is defective TCU shifts transmission to neutral OP-Mode: transmission shutdown check the cables from TCU to shift lever check signal combinations of shift lever positions for gear range failure cannot be detected in systems with DW2/DW3 shift lever fault is taken back if TCU detects a valid signal for the position all LOGICAL ERROR AT DIRECTION SELECT SIGNAL TCU detected a wrong signal combination for the direction cable from shift lever to TCU is broken or vehicle shift lever is defective TCU shifts transmission to neutral OP-Mode: transmission shutdown check the cables from TCU to shift lever check signal combinations of shift lever positions F-N-R fault is taken back if TCU detects a valid signal for the direction at the shift lever all LOGICAL ERROR AT ENGINE DERATING DEVICE TCU detected of engine while derating device activ after selecting neutral, TCU changes to OP-Mode limp home check engine derating device This fault is reset after power up of TCU all LOGICAL ERROR AT PARKBRAKE STATUS Parkbrake-status-signal measured by TCU and parkbrake-status-signal send by CAN don’t fit one of the cables from status-switch to electronic box is broken one of the status-switches is defective TCU shifts transmission to DCO- State check the cables from electronic boxes to status switches check signals of the status switches Case TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 7 von 53

12 LOGICAL ERROR AT DIRECTION SELECT SIGNAL 2. SHIFT LEVER TCU detected a wrong signal combination for the direction cable from shift lever 2 to TCU is broken or vehicle shift lever is defective TCU shifts transmission to neutral if selector activ OP-Mode: transmission shutdown if selector activ check the cables from TCU to shift lever 2 check signal combinations of shift lever positions F-N-R fault is taken back if TCU detects a valid neutral signal for the direction at the shift lever all case LOGICAL ERROR AT AXLE CONNECTION feedback axle connection measured by TCU and output signal axle connection don’t fit axle can t be connected or disconnected due to mechanical problem one of the cables from feedback axle connection -switch to TCU is broken check the cables from TCU to feedback axle connection switch check signals of the feedback axle connection switch all S.C. TO GROUND AT CUSTOMER SPECIFIC FUNCTION NO. 1 output pin, that looks like a s.c. to vehicle vehicle customer specific function no. 1 device has an internal defect connector pin is contacted to vehicle customer specific check the cable from TCU to customer specific function no. 1 device check the connectors from customer specific function no. 1 to TCU check the resistance of customer specific function no. 1 device 1) see chapter 4 Z- Funkti on S.C. TO BATTERY VOLTAGE AT CUSTOMER SPECIFIC FUNCTION NO. 1 customer specific check the cable from TCU to customer specific function no. 1 device check the connectors from customer 1) see chapter 4 Z- Funkti on1 TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 8 von 53

13 output pin, that looks like a s.c. to battery customer specific function no. 1 device has an internal defect connector pin is contacted to battery specific function no. 1 to TCU check the resistance of customer specific function no. 1 device O.C. AT CUSTOMER SPECIFIC FUNCTION NO. 1 output pin, that looks like a o.c. for this output pin cable is defective and has no connection to TCU customer specific function no. 1 device has an internal defect connector has no connection to TCU customer specific check the cable from TCU to customer specific function no. 1 device check the connectors from customer specific function no. 1 device to TCU check the resistance of customer specific function no. 1 device 1) see chapter 4 Z- Funkti on1 1A S.C. TO GROUND AT CUSTOMER SPECIFIC FUNCTION NO. 2 output pin, that looks like a s.c. to vehicle vehicle customer specific function no. 2 device has an internal defect connector pin is contacted to vehicle customer specific check the cable from TCU to customer specific function no. 2 device check the connectors from customer specific function no. 2 device to TCU check the resistance of customer specific function no. 2 device 1) see chapter 4 Z- Funkti on2 1B S.C. TO BATTERY VOLTAGE AT CUSTOMER SPECIFIC FUNCTION NO. 2 customer specific check the cable from TCU to customer specific function no. 2 device check the connectors from customer 1) see chapter 4 Z- Funkti on2 TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 9 von 53

14 output pin, that looks like a s.c. to battery customer specific function no. 2 device has an internal defect connector pin is contacted to battery specific function no. 2 device to TCU check the resistance of customer specific function no. 2 device 1C O.C. AT CUSTOMER SPECIFIC FUNCTION NO. 2 output pin, that looks like a o.c. for this output pin cable is defective and has no connection to TCU customer specific function no. 2 device has an internal defect connector has no connection to TCU customer specific check the cable from TCU to customer specific function no. 2 device check the connectors from customer specific function no. 2 device to TCU check the resistance of customer specific function no. 2 device 1) see chapter 4 Z- Funkti on2 1D S.C. TO GROUND AT CUSTOMER SPECIFIC FUNCTION NO. 3 output pin, that looks like a s.c. to vehicle vehicle customer specific function no. 3 device has an internal defect connector pin is contacted to vehicle customer specific check the cable from TCU to customer specific function no. 3 device check the connectors from customer specific function no. 3 device to TCU check the resistance of customer specific function no. 3 device 1) see chapter 4 Z- Funkti on3 1E S.C. TO BATTERY VOLTAGE AT CUSTOMER SPECIFIC FUNCTION NO. 3 customer specific check the cable from TCU to customer specific customer specific function no. 3 device 1) see chapter 4 Z- Funkti on3 TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 10 von 53

15 output pin, that looks like a s.c. to battery customer specific function no. 3 device has an internal defect connector pin is contacted to battery check the connectors from customer specific function no. 3 device to TCU check the resistance of customer specific function no. 3 device 1F O.C. AT CUSTOMER SPECIFIC FUNCTION NO. 3 output pin, that looks like a o.c. for this output pin cable is defective and has no connection to TCU customer specific function no. 3 device has an internal defect connector has no connection to TCU customer specific check the cable from TCU to customer specific function no. 3 device check the connectors from customer specific function no. 3 device to TCU check the resistance of customer specific function no. 3 device 1) see chapter 4 Z- Funkti on S.C. TO BATTERY VOLTAGE AT CLUTCH CUTOFF INPUT the measured is too high: clutch cut off sensor has an internal defect connector pin is contacted to battery clutch cutoff function is disabled check the cable from TCU to the sensor check the connectors check the clutch cutoff sensor John Deere S.C. TO GROUND OR O.C. AT CLUTCH CUTOFF INPUT the measured is too low: clutch cutoff function is disabled check the cable from TCU to the sensor check the connectors check the clutch cutoff sensor John Deere TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 11 von 53

16 vehicle cable has no connection to TCU clutch cut off sensor has an internal defect connector pin is contacted to vehicle or is broken S.C. TO BATTERY VOLTAGE AT LOAD SENSOR INPUT the measured is too high: load sensor has an internal defect connector pin is contacted to battery retarder function is affected TCU uses default load check the cable from TCU to the sensor check the connectors check the load sensor sensor check the assembly tolerances of load sensor availability of retarder depends on default load ohne CAN S.C. TO GROUND OR O.C. AT LOAD SENSOR INPUT the measured is too low: vehicle cable has no connection to TCU load sensor has an internal defect connector pin is contacted to vehicle or is broken retarder function is affected TCU uses default load check the cable from TCU to the sensor check the connectors check the load sensor sensor check the assembly tolerances of load sensor availability of retarder depends on default load ohne CAN S.C. TO BATTERY VOLTAGE OR O.C. AT TRANSMISSION SUMP TEMPERATURE SENSOR INPUT the measured is too high: cable has no connection to TCU temperature sensor has an internal defect, TCU uses default temperature check the cable from TCU to the sensor check the connectors check the temperature sensor TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 12 von 53

17 connector pin is contacted to battery or is broken S.C. TO GROUND AT TRANSMISSION SUMP TEMPERATURE SENSOR INPUT the measured is too low: vehicle temperature sensor has an internal defect connector pin is contacted to vehicle, TCU uses default temperature check the cable from TCU to the sensor check the connectors check the temperature sensor S.C. TO BATTERY VOLTAGE OR O.C. AT RETARDER TEMPERATURE SENSOR INPUT the measured is too high: cable has no connection to TCU temperature sensor has an internal defect connector pin is contacted to battery or is broken, TCU uses default temperature check the cable from TCU to the sensor check the connectors check the temperature sensor 6WG S.C. TO GROUND AT RETARDER TEMPERATURE SENSOR INPUT the measured is too low: vehicle temperature sensor has an internal defect connector pin is contacted to vehicle, TCU uses default temperature check the cable from TCU to the sensor check the connectors check the temperature sensor 6WG TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 13 von 53

18 S.C. TO BATTERY VOLTAGE OR O.C. AT PARKING BRAKE SENSOR INPUT the measured is too high: cable has no connection to TCU sensor has an internal defect connector pin is contacted to battery or is broken TCU uses default value check the cable from TCU to the sensor check the connectors check the parking brake sensor all 2A S.C. TO GROUND PARKING BRAKE SENSOR INPUT the measured is too low: vehicle sensor has an internal defect connector pin is contacted to vehicle TCU uses default value check the cable from TCU to the sensor check the connectors check the parking brake sensor all 2B INCHSENSOR-SIGNAL MISMATCH the measured from CCO and CCO2 signal don t match: cable is defective sensor has an internal defect During inching mode: TCU shifts to neutral While not inching: no change check the cable from TCU to the sensor check the connectors check sensor all S.C. TO BATTERY VOLTAGE OR O.C. AT ENGINE SPEED INPUT TCU measures a higher than 7.00 V at speed input pin cable has no connection to TCU speed sensor has an internal defect OP-Mode: substitute clutch control check the cable from TCU to the sensor check the connectors check the speed sensor TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 14 von 53

19 connector pin is contacted to battery or has no contact S.C. TO GROUND AT ENGINE SPEED INPUT TCU measures a less than 0.45V at speed input pin cable / connector is defective and is contacted to vehicle speed sensor has an internal defect OP-Mode: substitute clutch control check the cable from TCU to the sensor check the connectors check the speed sensor LOGICAL ERROR AT ENGINE SPEED INPUT TCU measures a engine speed over a threshold and the next moment the measured speed is zero cable / connector is defective and has bad contact speed sensor has an internal defect sensor gap has the wrong size OP-Mode: substitute clutch control check the cable from TCU to the sensor check the connectors check the speed sensor check the sensor gap This fault is reset after power up of TCU S.C. TO BATTERY VOLTAGE OR O.C. AT TURBINE SPEED INPUT TCU measures a higher than 7.00 V at speed input pin cable has no connection to TCU speed sensor has an internal defect connector pin is contacted to battery or has no contact OP-Mode: substitute clutch control if a failure is existing at output speed, check the cable from TCU to the sensor check the connectors check the speed sensor S.C. TO GROUND AT TURBINE SPEED INPUT TCU measures a less than 0.45V at speed input pin OP-Mode: substitute clutch control if a failure is existing at output speed, check the cable from TCU to the sensor check the connectors check the speed sensor TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 15 von 53

20 cable / connector is defective and is contacted to vehicle speed sensor has an internal defect LOGICAL ERROR AT TURBINE SPEED INPUT TCU measures a turbine speed over a threshold and at the next moment the measured speed is zero cable / connector is defective and has bad contact speed sensor has an internal defect sensor gap has the wrong size OP-Mode: substitute clutch control if a failure is existing at output speed, check the cable from TCU to the sensor check the connectors check the speed sensor check the sensor gap This fault is reset after power up of TCU S.C. TO BATTERY VOLTAGE OR O.C. AT INTERNAL SPEED INPUT TCU measures a higher than 7.00 V at speed input pin cable has no connection to TCU speed sensor has an internal defect connector pin is contacted to battery or has no contact OP-Mode: substitute clutch control check the cable from TCU to the sensor check the connectors check the speed sensor S.C. TO GROUND AT INTERNAL SPEED INPUT TCU measures a less than 0.45V at speed input pin cable / connector is defective and is contacted to vehicle speed sensor has an internal defect OP-Mode: substitute clutch control check the cable from TCU to the sensor check the connectors check the speed sensor LOGICAL ERROR AT INTERNAL SPEED INPUT OP-Mode: substitute clutch control check the cable from TCU to the sensor check the connectors This fault is reset after power up of TCU TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 16 von 53

21 TCU measures a internal speed over a threshold and at the next moment the measured speed is zero cable / connector is defective and has bad contact speed sensor has an internal defect sensor gap has the wrong size check the speed sensor check the sensor gap 3A S.C. TO BATTERY VOLTAGE OR O.C. AT OUTPUT SPEED INPUT TCU measures a higher than 12.5 V at speed input pin cable has no connection to TCU speed sensor has an internal defect connector pin is contacted to battery or has no contact special mode for gear selection OP-Mode: substitute clutch control if a failure is existing at turbine speed, check the cable from TCU to the sensor check the connectors check the speed sensor 3B S.C. TO GROUND AT OUTPUT SPEED INPUT TCU measures a less than 1.00V at speed input pin cable / connector is defective and is contacted to vehicle speed sensor has an internal defect special mode for gear selection OP-Mode: substitute clutch control if a failure is existing at turbine speed, check the cable from TCU to the sensor check the connectors check the speed sensor 3C LOGICAL ERROR AT OUTPUT SPEED INPUT TCU measures a output speed over a threshold and at the next moment the measured speed is zero cable / connector is defective and has bad contact speed sensor has an internal defect special mode for gear selection OP-Mode: substitute clutch control if a failure is existing at turbine speed, check the cable from TCU to the sensor check the connectors check the speed sensor check the sensor gap This fault is reset after power up of TCU TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 17 von 53

22 sensor gap has the wrong size 3D 71 TURBINE SPEED ZERO DOESN T FIT TO OTHER SPEED SIGNALS — — not used 3E OUTPUT SPEED ZERO DOESN T FIT TO OTHER SPEED SIGNALS if transmission is not neutral and the shifting has finished, TCU measures outputspeed zero and turbine speed or internal speed not equal to zero. speed sensor has an internal defect sensor gap has the wrong size special mode for gear selection OP-Mode: substitute clutch control if a failure is existing at turbine speed, check the sensor signal of output speed sensor check the sensor gap of output speed sensor check the cable from TCU to the sensor This fault is reset after power up of TCU GEAR RANGE RESTRICTION SIGNAL CAN signal for gear range restriction is defective cluster controller is defective no gear range restriction check cluster controller check cable to cluster controller Case FCAN MESSAGE GEAR RANGE SELECT (ZF_3_IDENT) contains invalid data DECLUTCH MODULATION SELECTION SIGNAL gear range set from 1 st to 5 th check FWD controller O&K — — not used Case TCU RECEIVES MESSAGES GEAR RANGE SELECT (ZF_3_IDENT) AND FRONT WHEEL DRIVE STATUS (V_IDENT_FWD) ALTHOUGH CONFIGURATION STATES THAT FWD CONTROLLER IS NOT INSTALLED FMR1 TIMEOUT Timeout of CAN-message FMR1 from ignore FWD commands reconfigure with TCU Configuration Command (ID PC) TCU operates like jake brake is off and exhaut brake is off. check engine controller O&K IES TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 18 von 53

23 engine controller CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or engine controller is defective check cable to engine controller FMR2 TIMEOUT Timeout of CAN-message FMR2 from engine controller CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or engine controller is defective OP-Mode: substitute clutch control check engine controller check cable to engine controller IES EAMODUL1 TIMEOUT Timeout of CAN-message EAM1 from I/O — controller CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or and uses substitute gear selector check I/O controller check cable to I/O controller Liebh err ABS TIMEOUT Timeout of CAN-message ABS from ABS — controller CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or check ABS controller check cable to ABS controller IES TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 19 von 53

24 MDU1 TIMEOUT Timeout of CAN-message MDU1 from cluster controller CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or TCU keeps old auto downshift information and old manual downshift information check cluster controller check cable to cluster controller John Deere DCT1 TIMEOUT Timeout of CAN-message DCT1 from display computer CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or check display computer check cable to display computer JCB, Kalma r GEAR RANGE SELECT TIMEOUT Timeout of CAN-message Gear Range Select (ZF_3_IDENT) CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or FWD Controller is defective gear range set from 1 st to 5 th check FWD controller O&K DNS1 TIMEOUT Timeout of CAN-message DNS1 from OMRON-master CAN wire/connector is broken check OMRON-master check cable to OMRON-master TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 20 von 53

25 CAN wire/connector is defective and has contact to vehicle or SCT1 TIMEOUT Timeout of CAN-message SCT 1 from steering computer CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or check steering computer check cable to steering computer Kalma r FLC1 TIMEOUT Timeout of CAN-message FCL1 from cluster controller CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or TCU keeps old auto/man selection, old Clutch cutoff selection and old Clutch Cuttoff Setting check cluster controller check cable to cluster controller John Deere FRONT WHEEL DRIVE STATUS TIMEOUT Timeout of CAN-message Front Wheel Drive Status (V_IDENT_FWD) CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or FWD Controller is defective check FWD controller O&K ENGINE CONF TIMEOUT Timeout of CAN-message ENGINE CONF OP-Mode: substitute clutch control check engine controller J1939 TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 21 von 53

26 from engine controller CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or check cable to engine controller EEC1 TIMEOUT Timeout of CAN-message EEC1 from EEC controller CAN wire/connector is broken CAN wire/connector is defective and has contact to vehicle or OP-Mode: substitute clutch control check EEC controller check cable to EEC controller J EEC3 TIMEOUT Timeout of CAN-message EEC3 from EEC controller CAN wire/connector is broken CAN wire/connector is defective an has contact to vehicle or OP-Mode: substitute clutch control check EEC controller check cable to EEC controller J TEST MODE SIGNAL CAN signal for test mode status is defective cluster controller is defective Testmode is aborted, if activ check cluster controller check cable to cluster controller Case 5A PARKBRAKE STATUS SIGNAL CAN signal for parkbrake status is defective cluster controller is defective. check cluster controller check cable to cluster controller Case, TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 22 von 53

27 5B SHIFT QUALITY SEL SIGNAL CAN signal for shift qualtiy selection is defective cluster controller is defective check cluster controller check cable to cluster controller Not used Case 5C AUTO DOWNSHIFT SIGNAL CAN signal for automatic downshift is defective cluster controller is defective last selection is kept check cluster controller check cable to cluster controller John Deere 5D MANUAL DOWNSHIFT SIGNAL CAN signal for manual downshift is defective cluster controller is defective last selection is kept check cluster controller check cable to. controller John Deere 5E CCO REQUEST SIGNAL CAN signal for CCO request is defective cluster controller is defective last selection is kept check cluster controller check cable to. controller John Deere 5F SHIFT LEVER SIGNAL CAN signal for shift lever is defective I/O controller is defective and uses informations from substitute shift lever check I/O controller check cable to I/O controller Liebh err, 5F TRANSMISSION NEUTRAL REQUEST SIGNAL CAN signal for transmission Neutral Request is defective check steering computer check cable to steering computer Kalma r TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 23 von 53

28 steering computer is defective 5F CAN MESSAGE FRONT WHEEL DRIVE STATUS (V_IDENT_FWD) CONTAINS INVALID DATA ADDITIONAL BRAKE STATUS SIGNAL CAN signal for additional park brake status is defective I/O controller is defective check FWD controller O&K check I/O controller check cable to I/O controller Liebh err AEB REQUEST SIGNAL CAN signal for AEB request is defective I/O controller is defective PTO TORQUE SIGNAL CAN signal for PTO torque is defective I/O controller is defective Last selection is kept, TCU uses default PTO torque signal check I/O controller check cable to I/O controller check I/O controller check cable to I/O controller Liebh err,, John Deere Liebh err DRIVING MODE SIGNAL CAN signal for driving mode is defective I/O controller is defective, TCU uses default driving mode signal check I/O controller check cable to I/O controller Liebh err STARTING GEAR SIGNAL CAN signal for starting gear is defective I/O controller is defective (illegal starting gear), TCU uses default starting gear check I/O controller check cable to I/O controller Liebh err ENGINGE TORQUE SIGNAL OP-Mode:substitute clutch check engine controller IES, TE-AB N:AsttElektrikneuFc_37_V912.doc Seite 24 von 53

Источник

Пояснения к таблице

- Коды неисправностей могут быть считаны в двух стандартах, в ВАГовском формате, без буквы Р впереди и в OBD-формате, с буквой Р вначале. Правильнее конечно первый вариант, при показе кодов неисправностей в OBD-формате ( обычно мультимарочными сканерами) могут возникать ошибки в интерпретации. В любом случае определенному коду в ВАГ-формате соответствует определенный код в OBD-формате. Оба приведены в таблице.

- У блоков управления примерно с 2007 года коды неисправностей могут быть в другом обозначении, но интерпретация (название ошибки) будет прежним, найти ошибку в таблице будет легко

- Графа “Устранение неисправности” чаще имеет справочный характер — это то, как производитель предлагал бороться с проблемой. Обычно не стоит этому следовать.

- После каждой ошибки приведен мой комментарий что за ошибка и как её устранить

- Внизу добавил две актуальные ошибки, которых не было в таблице

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

16889 / P0505 |

|

|

Встречается на старых коробках, проблемы с мотором, к АКПП не относится

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

16987 / P0603 |

|

Внутренняя ошибка блока. Можно попытаться залить новую прошивку, но обычно блок под замену

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

16988 / P0604 |

|

Внутренняя ошибка блока. Можно попытаться залить новую прошивку, но 90 процентов, что блок под замену

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

16989 / P0605 |

|

Внутренняя ошибка блока. Можно попытаться залить новую прошивку, но 90 процентов, что блок под замену

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

17086 / P0702 |

|

Внутренняя ошибка блока. Можно попытаться залить новую прошивку, но 90 процентов, что блок под замену

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

17087 / P0703 |

|

|

||||

|

|

|||||

|

|

t |

Сигнал от выключателя стоп-сигнала -F- передается с блока управления двигателя на блок управления АКПП -J217-. |

|

t |

Обмен данными между блоками управления производится через CAN-шину → Глава. |

|

t |

После десяти последовательных появлений несоответствия между выключателями стоп-сигнала -F- (один выключатель срабатывает, другой нет) данная ошибка сохраняется в блоке управления коробки передач. К ЭБУ не относится.Обычно замена “лягушки” тормоза |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

17090 / P0706 |

|

|||

|

||||

|

||||

|

|

t |

Электрическое обозначение датчика диапазона измерения передаточного отношения мультифункциональный переключатель -F125-. |

|

t |

Магнит вала переключения передает на датчики Холла мультифункционального переключателя -F125- фактическое положение вала переключателя. При правильной установке рычага управления КП эта позиция соответствует положению селектора АКПП. |

|

t |

Мультифункциональный переключатель -F125- интегрирован в блок управления АКПП -J217-. |

|

Неисправен ЭБУ АКПП, требуется (всегда возможен) ремонт ЭБУ |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

17094 / P0710 |

|

|

t |

Датчик температуры масла КП -G93- интегрирован в блок управления АКПП -J217-. |

|

Обычно ремонт блока НЕ возможен, замена |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

17095 / P0711 |

|

|

t |

Датчик температуры масла КП -G93- интегрирован в блок управления АКПП -J217-. |

|

Обычно ремонт блока не возможен, замена |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

17096 / P0712 |

|

|

t |

Датчик температуры масла КП -G93- интегрирован в блок управления АКПП -J217-. |

|

t |

Условие для распознавания ошибки: измеряемый уровень температуры опустился ниже –40 °C. |

|

Обычно ремонт блока не возможен, замена |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

17097 / P0713 |

|

|||

|

|

t |

Датчик температуры масла КП -G93- интегрирован в блок управления АКПП -J217-. |

|

t |

Условие для распознавания ошибки: измеряемый уровень температуры превысил 150 °C. |

|

Обычно ремонт блока не возможен, замена |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

17100 / P0716 |

|

|

t |

Датчик числа оборотов на входе КП -G182- интегрирован в блок управления Getriebe -J217- integriert. |

|

t |

Условие для распознавания ошибки: блок управления АКПП -J217- временно распознает число оборотов входного вала более 7000об/мин. (бензиновые двигатели) либо более 5500об/мин. (двигатели TDI). |

Неисправен ЭБУ, либо (ЧАЩЕ) эта ошибка будет появляться вторично при ошибке 17105 по датчику скорости выходного вала G195 . В любом случае ремонт ЭБУ

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

17101 / P0717 |

|

|||

|

|

t |

Датчик числа оборотов на входе КП -G182- интегрирован в блок управления АКПП -J217-. |

|

t |

Условие для распознавания ошибки: блок управления коробки передач временно распознает число оборотов входного вала менее или равное 1об/мин. и одновременно число оборотов входного вала более 100об/мин. Неисправен ЭБУ, либо (ЧАЩЕ) эта ошибка будет появляться вторично при ошибке 17105 по датчику скорости выходного вала G195 . В любом случае ремонт ЭБУ |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

17105 / P0721 |

|

|

t |

Датчик числа оборотов на выходе КП -G195- интегрирован в блок управления АКПП -J217-. Неисправен ЭБУ. Ремонт возможен. Обычно сопровождается второй ошибкой- 17101 |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

17106 / P0722 |

|

|||

|

|

t |

Датчик числа оборотов на выходе КП -G195- интегрирован в блок управления АКПП -J217-. |

Неисправен ЭБУ. Ремонт возможен. Обычно сопровождается второй ошибкой- 17101

Ошибка 17110 / P0726

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||||

|

17110 / P0726 |

|

|

||||||||

|

|

|||||||||

|

|

|||||||||

|

||||||||||

|

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||

|

17111 / P0727 |

|

|

||||||

|

|

|||||||

|

||||||||

|

|

t |

При прерывании передачи числа оборотов запасной сигнал числа оборотов двигателя передается от блока управления двигателя по CAN-шине на блок управления АКПП -J217-. |

В первую очередь проверить, нет ли проблем с датчиком коленвала на моторе и видит ли ЭБУ МОТОРА обороты двигателя . Если видит, но в измеряемых группах по АКПП значение не отображается, то неисправен ЭБУ. Ремонт возможен

Ошибка 17114 / P0730

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

17114 / P0730 |

||||

|

|

ВАЖНО! Если это единственная ошибка, то вероятнее действительно механические проблемы в АКПП. НО! Если эта ошибка присутствует ОДНОВРЕМЕННО с ЕЩЕ ДВУМЯ- 17105 и 17101( по датчикам G195 И G182), но она является вторичной, рассчетной и пропадет при устранении первых двух ошибок. Это частая ситуация! |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||

|

17134 / P0750 |

|

|

||||||

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||

|

17137 / P0753 |

|

|

|

t |

Провода интегрированы в блок управления АКПП -J217- и могут быть заменены только вместе с блоком управления коробки передач. |

ВАЖНО! Если присутствует ТОЛЬКО ошибка 17134, то это функциональный сбой ГИДРОБЛОКА, Эбу не причем. Требуется замена гидроблока( сам клапан N88 также не причем!). НО если присутствуют обе ошибки 17134 и 17137 одновременно, То проблема только в ЭБУ. Чаще ремонт возможен

Ошибка 18031 / P1623

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18031 / P1623 |

|

|

||||

|

|

|||||

|

||||||

|

||||||

|

|

t |

Шина данных также называется CAN-шиной. |

|

t |

Обмен данными между блоками управления производится через CAN-шину → Глава. |

|

t |

Хотя блок управления и может отправлять сигналыи данные, но он ничего не может принимать. |

Довольно запутанная ситуация при ошибке “нет связи по КАН-шине” Вкратце.Более новые, примерно с 2007 года блоки имеют диагностику по CAN-шине, и если вы видите эту ошибку в ТАКОМ Эбу, это значит чио проблема с Кан- внешняя, проводка или другой блок, иначе бы вы в этот блок не вошли диагностикой. Для более старых блоков, с диагностикой по К-линии, проблема может быть с КАН-интерфейсом ЭБУ АКПП. Проверяется опросом других блоков- моторника, АБС, приборки. В блоках измерений 125й канал. Если связь с ЭБУ АКПП стоит как “0”, то проблема в ЭБУ АКПП, если “1”, надо искать другую причину

Ошибка 18112 / P0704

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||

|

18112 / P1704 |

|

|

||||||

|

|

|||||||

|

||||||||

|

|

|

t |

Не является самостоятельной деталью. |

|

t |

У автомобилей с двигателями TDI в блоке с датчиком положения педали акселераора -G79- |

|

t |

У автомобилей с бензиновым двигателем функцию берут на себя датчик положения педали акселератора -G79- и датчик 2 положения педали акселератора -G185-, оба интегрированы в модуль педали акселератора |

|

t |

Сигнал от датчика положения педали акселератора -G79- или модуля педали акселератора передается с блока управления двигателя на блок управления АКПП -J217-. |

|

t |

Обмен данными между блоками управления производится через CAN-шину → Глава. |

|

Такая ошибка не встречается |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18113 / P1705 |

|

|

||||

|

||||||

|

|

Механические проблемы в АКПП |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18132 / P1724 |

|

|||||

|

|

|

t |

Блок управления не может определить обрыв цепи. |

Ошибка означает, что в исполнительной цепи блокировки стартера есть какой-то обрыв, обычно дополнительный иммобилайзер.Эбу и коробка не причем, ничего делать не надо

Ошибка 18137 / P1729

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18137 / P1729 |

|

|||||

|

|

|

t |

Блок управления не может определить обрыв цепи. |

Ошибка означает, что в исполнительной цепи блокировки стартера есть какой-то обрыв, обычно дополнительный иммобилайзер.Эбу и коробка не причем, ничего делать не надо

Ошибка 18141 / P1723

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||||

|

18141 / P1733 |

|

|

||||||||

|

|

t |

В случае этой ошибки блок измерительных величин 003 всегда показывает „выключатель понижения передачи“. |

В подавляющем большинстве случаев ошибки по переключателю типтроника F189 (не путать с F125 !) не связаны с ЭБУ АКПП. Эта деталь (F189) находится в салоне, под накладкой селектора. Могут быть сломана, (чаще залита) плата F189 либо сами шторки, на которых стоят магниты. Необходима замена этих деталей. ЭБУ не причем.Наличие этой ошибки никак не влияет на работу АКПП

Ошибка 18147 / P1739

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||||

|

18147 / P1739 |

|

|

||||||||

|

|

t |

Появится сообщение об ошибке, если помимо положения селектора АКПП „D“ было распознано срабатывание переключателя повышения передач. |

|

t |

В случае этой ошибки блок измерительных величин 003 всегда показывает „выключатель повышения передачи“. |

В подавляющем большинстве случаев ошибки по переключателю типтроника F189 (не путать с F125 !) не связаны с ЭБУ АКПП. Эта деталь (F189) находится в салоне, под накладкой селектора. Могут быть сломана, (чаще залита) плата F189 либо сами шторки, на которых стоят магниты. Необходима замена этих деталей. ЭБУ не причем.Наличие этой ошибки никак не влияет на работу АКПП

Ошибка 18148 / P1740

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

18148 / P1740 |

|

|||

|

|

t |

Сообщение об ошибке появится, если температура сцепления слишком высокая. |

|

t |

Вращающий момент двигателя автоматически снижается до тех пор, пока температура вновь не опустится до допустимого рабочего уровня. |

Обычно возникает при избыточном трении, сильной пробуксовке сцепления. Причина в несправном гидроблоке, ЭБУ не причем

Ошибка 18149 / P1741

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

18149 / P1741 |

|

|

t |

Если данная ошибка возникает спорадически, очистить память неисправностей. Затем совершить пробную поездку и заново опросить память неисправностей. Если ошибка возникает снова, заменить гидравлический блок управления. |

Самая частая ошибка при неисправном гидроблоке, почти всегда “старого образца”, до 2005 года. Обычно сопровождается рывками при старте и ошибкой по датчику давления G193. Не лечится, только замена гидроблока. Иногда может пройти само после пары дней езды

Ошибка 18151 / P1743

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

18151 / P1743 |

|

|||

|

||||

|

t |

Сообщение об этой ошибке появляется, если была установлена неверная коробка передач, например, коробка для 2,4 л двигателя в автомобиле с 2,8 л двигателем. |

Несколько причин этой ошибки

-Установлена не подходящая АКПП

-может возникать при “троении” двигателя, часто на 1.8Т( проверять пропуски сгорания)

-сильно сгоревшее сцепление (редко)

Ошибка 18152 / P1744

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||||

|

18152 / P1744 |

|

|

||||||||

|

|

t |

Сообщение об ошибке появится, если было распознано включение Tiptronic, несмотря на то, что селектор АКПП не находится в пазу Tiptronic. |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

18156 / P1748 |

|

|

Замена ЭБУ. Иногда помогает перезаливка софта |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18158 / P1750 |

|

|||||

|

|

|||||

|

|

|||||

|

Низкое напряжение в сети (севший аккумулятор и т.д.) Эбу не причем

Ошибка 18159 / P1751

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

|||||

|

18159 / P1751 |

|

||||||

|

|

||||||

|

|

|

Вначале проверить напряжение в проводке,если ниже 15-16 вольт( бывает редко при неисправном регуляторе), то неисправен ЭБУ. Достаточно частая ситуация. Замена блока, ремонт не возможен, причина обычно в попадании металлизированного масла внутрь ЭБУ |

||||

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||||||

|

18161 / P1753 |

|

|||||||||||

|

||||||||||||

|

|

|||||||||||

|

|

В подавляющем большинстве случаев ошибки по переключателю типтроника F189 (не путать с F125 !) не связаны с ЭБУ АКПП. Эта деталь (F189) находится в салоне, под накладкой селектора. Могут быть сломана, (чаще залита) плата F189 либо сами шторки, на которых стоят магниты. Необходима замена этих деталей. ЭБУ не причем.Наличие этой ошибки никак не влияет на работу АКПП |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||

|

18162 / P1754 |

|

|

||||||

|

|

|

В подавляющем большинстве случаев ошибки по переключателю типтроника F189 (не путать с F125 !) не связаны с ЭБУ АКПП. Эта деталь (F189) находится в салоне, под накладкой селектора. Могут быть сломана, (чаще залита) плата F189 либо сами шторки, на которых стоят магниты. Необходима замена этих деталей. ЭБУ не причем.Наличие этой ошибки никак не влияет на работу АКПП |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||

|

18163 / P1755 |

|

|

||||||

|

|

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18164 / P1756 |

|

|

||||

|

|

В подавляющем большинстве случаев ошибки по переключателю типтроника F189 (не путать с F125 !) не связаны с ЭБУ АКПП. Эта деталь (F189) находится в салоне, под накладкой селектора. Могут быть сломана, (чаще залита) плата F189 либо сами шторки, на которых стоят магниты. Необходима замена этих деталей. ЭБУ не причем.Наличие этой ошибки никак не влияет на работу АКПП

Ошибка 18165 / P1757

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18165 / P1757 |

|

|||||

|

|

Не верное определение ошибки. Это так называемый “обрыв второго питания”( в ЭБУ с 2002 года два питания). ПОВАЛЬНО на А6 С5 из-за неисправного реле в боксе ЭБУ МОТОРА( заменить его на любое обычное реле из магазина). Либо проводка, чаще сгнившие коннекторы там же в глубине бокса мотроника. Если это все в порядке- проблема в ЭБУ. Чаще чинится |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||

|

18169 / P1761 |

|

|

||||||

|

|

|||||||

|

|

t |

Магнит блокиратора селектора АКПП -N110- не может быть выключен, т.е. селектор при нажатой педали тормоза не может быть переключен из положения „P“ или „N“. |

Ошибка не важная, обычно вторичная при других проблемах с селектором. Проводка или сам магнит. ЭБУ не причем

Ошибка 18172 / P1764

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

18172 / P1764 |

|

|

t |

Сообщение об ошибке появится, если температура сцепления слишком высокая. |

|

t |

Вращающий момент двигателя снижается до тех пор, пока температура вновь не опустится до допустимого рабочего уровня. |

Такой ошибки не бывает, вероятно убрали из софта

Ошибка 18173 / P1765

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18173 / P1765 |

|

|

||||

|

|

Проверить показания по датчику G194 (в блоках измерений 18/1) на незаведенном моторе . Если не ноль- замена ЭБУ. Редко. Если ноль- скорее механические проблемы в АКПП |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

18181 / P1773 |

|

Основная ошибка при неисправном гидроблоке АКПП. (также смотри. ошибку 18149). Появляется обычно одновременно. Замена ГИДРОБЛОКА. Изредка может проходить само

Ошибка 18183 / P1775

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18183 / P1775 |

|

|

||||

|

Проверить показания по датчику G193 (в блоках измерений 18/3) на не заведенном моторе. Если не НОЛЬ- заменить ЭБУ. Иногда можно заменить датчик давления на ЭБУ. Если ноль- вероятно проблемы с гидроблоком

Ошибка 18185 / P1777

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18185 / P1777 |

|

|

||||

|

Частая ошибка. Проверить стартовый ток вперед( в блоках измерений 10/1) Если значение низкое, типа 0.195А, то проблема во внешнем фильтре АКПП. Актуально для старых дизелей. Если стартовый ток в норме, чаще проблема механическая,

Ошибка 18194 / P1786

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

18194 / P1786 |

|

|||

|

||||

|

|

К коробке не относится, ЭБУ не причем. В исполнительной цепи какое-то нарушение, обрыв или замыкание |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18195 / P1787 |

|

|

||||

|

||||||

|

К коробке не относится, ЭБУ не причем. В исполнительной цепи какое-то нарушение, обрыв или замыкание

Ошибка 18196 / P1788

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18196 / P1788 |

|

|

||||

|

||||||

|

|

К коробке не относится, ЭБУ не причем. В исполнительной цепи какое-то нарушение, обрыв или замыкание |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18198 / P1790 |

|

|

||||

|

|

|||||

|

||||||

|

|

t |

Индикатор позиции селектора АККП -Y6- интегрирован в комбинацию приборов и не может быть заменен отдельно. |

Такая ошибка не существует

Ошибка 18199 / P1791

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18199 / P1791 |

|

|

||||

|

|

|||||

|

||||||

|

|

t |

Нет индикации на комбинации приборов |

|

t |

Индикатор позиции селектора АККП -Y6- интегрирован в комбинацию приборов и не может быть заменен отдельно. |

Такая ошибка не существует

Ошибка 18200 / P1792

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18200 / P1792 |

|

|

||||

|

|

|||||

|

||||||

|

|

t |

Индикатор позиции селектора АККП -Y6- интегрирован в комбинацию приборов и не может быть заменен отдельно. |

Такая ошибка не существует

Ошибка 18201 / P1793

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

18201 / P1793 |

|

|

t |

Если дополнительно отображается ошибка 18181 / P1773, то, вероятно, неисправна звездочка датчика. |

Самая частая ошибка по ЭБУ АКПП. Возможен ремонт. “Пояснение” выше не верное. Если одновременно с ошибкой 18181- то это либо ЭБУ( часто0, либо механические проблемы( Кратковременная остановка вала,обычно при тотальном износе)

Ошибка 18203 / P1795

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

18203 / P1795 |

|

|||

|

||||

|

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18204 / P1796 |

|

|

||||

|

||||||

|

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18205 / P1797 |

|

|

||||

|

||||||

|

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

18206 / P1798 |

|

|||

|

Ошибка не встречается

Ошибка 18221 / P1813

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18221 / P1813 |

|

|

||||

|

|

Неисправен ЭБУ. Сам клапан не причем! Ремонт ЭБУ обычно НЕ ВОЗМОЖЕН, замена |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18226 / P1818 |

|

|

||||

|

|

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

|||

|

18249 / P1841 |

|

||||

|

|

|

t |

В идентификации блока управления коробки передач указывается кодировка „00000“. |

Установлен не подходящий ЭБУ, сверяться по совместимости. Не решается. Замена прошивки или ЭБУ

Ошибка 18258 / P1850

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18258 / P1850 |

|

|

||||

|

|

|

t |

Шина данных также называется CAN-шиной. |

|

t |

Обмен данными между блоками управления производится через CAN-шину → Глава. |

Нет CAN от соответствующего блока управления.В блоках измерений группа 125( в большинстве блоков).”1” -связь есть,”0”-связи нет.Проблема в КАН проводке к соответствующему блоку или сам блок. ЭБУ АКПП не причем

Ошибка 18259 / P1851

“

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18259 / P1851 |

|

|

||||

|

|

t |

Шина данных также называется CAN-шиной. |

|

t |

Обмен данными между блоками управления производится через CAN-шину → Глава. |

Нет CAN от соответствующего блока управления.В блоках измерений группа 125( в большинстве блоков).”1” -связь есть,”0”-связи нет.Проблема в КАН проводке к соответствующему блоку или сам блок. ЭБУ АКПП не причем

Ошибка 18260 / P1852

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18260 / P1852 |

|

|

|

t |

Шина данных также называется CAN-шиной. |

|

t |

Обмен данными между блоками управления производится через CAN-шину → Глава. |

Нет CAN от соответствующего блока управления.В блоках измерений группа 125( в большинстве блоков).”1” -связь есть,”0”-связи нет.Проблема в КАН проводке к соответствующему блоку или сам блок. ЭБУ АКПП не причем

Ошибка 18262 / P1854

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18262 / P1854 |

|

|

||||

|

|

t |

Шина данных также называется CAN-шиной. |

|

t |

Обмен данными между блоками управления производится через CAN-шину → Глава. |

|

Проверить связи по CAN ото всех блоков ( АКПП, Мотор ,АБС, приборка) в канале 125 блоков измерений, можно снимать разъемы по одному.По результатам определить причинный блок (чаще АКПП или АБС) или неисправна проводка CAN |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18263 / P1855 |

|

|

||||

|

||||||

|

|

|

t |

Шина данных также называется CAN-шиной. |

|

t |

Обмен данными между блоками управления производится через CAN-шину → Глава. |

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||||

|

18265 / P1857 |

|

|

||||||

|

|

|

t |

Сигнал „выключателя стоп-сигнала“ передается с блока управления двигателя на блок управления АКПП -J217-. |

|

t |

Обмен данными между блоками управления производится через CAN-шину → Глава. |

Коробка не причем. Мотор. Обычно дроссельная заслонка или ДМРВ

Ошибка 18269 / P1861

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18269 / P1861 |

|

|

||||

|

|

|

t |

Сигнал датчика положения педали акселератора -G79- передается от блока управления Motronic -J220- на блок управления АКПП -J217-. |

|

t |

Автомобили с бензиновым двигателем наряду с датчиком положения педали акселератора -G79- дополнительно оснащены датчиком 2 положения педали акселератора -G185-, оба интегрированы в модуль педали акселератора |

|

t |

Обмен данными между блоками управления производится через CAN-шину → Глава. |

Коробка не причем. Мотор. Обычно проводка

Ошибка 18270 / P1862

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

18270 / P1862 |

|

|

||||

|

|

t |

Шина данных также называется CAN-шиной. |

|

t |

Обмен данными между блоками управления производится через CAN-шину → Глава. |

|

Коробка не причем. Мотор. Обычно проводка Ошибка 006031/P178F |

||||

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||

|

006031 / P178F Регулятор давления заедает или загрязнен |

|

|||

Ошибка появилась на ЭБУ с 2008 года. Часто страдают машины 2009-2010 годов. Обычно сопровождается рывками на большой скорости( размыкание сцепления)Регулятор давления- механическая часть гидроблока, заменить естественно нельзя. Электрические клапана не причем. ЭБУ НЕ ПРИЧЕМ! Сброс этой ошибки возможен только после сброса адаптации

Ошибка 005889/P1701

|

Вывод данных на -VAS 5051 A- |

Возможная причина неисправности |

Устранение неисправности |

||||

|

005889 / P1701 Модуль ЭБУ АКПП заблокирован |

|

|

||||

На Ауди А6, А8 с 2006 модельного года введена Защите компонентов, основные блоки прошиты, привязаны к иммобилайзеру. При замене ЭБУ АКПП даже на блок полностью с таким же номером будет появляться эта ошибка и ошибки по иммобилайзеру.Авто заводится, но не трогается с места. Требуется адаптация иммобилайзера через дилерский онлайн. Не всегда возможно, при привязке блока проверяются серийный номера. Если аналогичный ЭБУ уже привязывался в другому авто может последовать отказ

ZF FRIEDRICHSHAFEN Aktiengesellschaft

Benennung:Zusatzbenennung:

fault codesdescription of fault codes for Ergo control

Nr.:

DINA4

Seite 1von 52