- Home

- Forums

- Design & Engineering

Hi all friends

Please help me for the problem facing (Error code 303)

TCM Counterbalance FB15-7, 2009 year.

all systems do not function steering, traction, and lifting.

What should I do.

Thank you for your help and advice

- Posted

18 Dec 2019 18:48 - Discussion started by

FNGLOBAL - south sumatra, Indonesia

grow and develop together

Showing items 1 — 2 of 2 results.

Sort messages by:

Thank you for the information provided.

I want to check the system does not have a shop manual for the unit.

can I be assisted for the shop manual

Regards

Feeza

- Posted

23 Dec 2019 09:52 - Reply by

FNGLOBAL - south sumatra, Indonesia

grow and develop together

Hello Friend,

Error code 303 : Traveling power modul short

Regards

- Posted

19 Dec 2019 01:34 - Reply by

stefano_tcm - ITALIA, Italy

Cozzolino Stefano

Having trouble using the Discussion Forums? Contact us for help.

Forkliftaction.com accepts no responsibility for forum content and requires forum participants to adhere to the rules. Click here for more information.

TCM Forklift Truck Fault Codes list

TCM FB-6 Error Codes

101

Accelerator wire broken

102

Drive motor current sensor defective

103

Drive safety circuit turns on

105

Abnormal plugging of regenerative circuit

106

Controller thermo sensor defective

107

Drive motor current abnomal on the key switch.

Trouble occurs during operation.

201

Lift lever sensor wire broken

202

Load handling motor current abnomal

203

Load handling safety circuit turns on

301

Accelerator wire broken

303

Drive safety circuit turns on

401

Lift lever sensor wire broken

403

Load handling safety circuit turns on

TCM FB-7 Error Codes

Display error code Detail of error LED error code

301 Accelerator output defective 17

302 Traveling current sensor output defective 19

303 Drive FET power module short-circuited 01

Drive FET power module open 02

Drive quick charge error 69

305 Drive contactor short-circuited 03

306 Drive contactor open 04

307 Blown main fuse for drive 20

308 Rotation sensor A defective 41

Rotation sensor B defective 42

401 Load handling lift potentiometer defective 35

402 Load handling current sensor output defective 34

403 Load handling FET power module short-circuited 30

Load handling quick charge error 70

Power steering transistor short-circuited 50

404 Load handling FET power module open 31

Power steering transistor open 56

405 Load handling contactor short-circuited 37

Power steering contactor short-circuited 51

406 Load handling contactor open 33

Power steering fuse/contactor open 52

407 Blown main fuse for load handling 45

501 MD contactor drive transistor coil defective 07

F/R switch defective 16

Load dump error (battery overvoltage protection) 86

Load handling contactor drive transistor / coil defective 38

EPROM sum error (Other serious error) 82

EPROMACK error (Other serious error) 83

Power steering contactor drive transistor coil defective 53

502 Drive motor temperature rise 25

Drive motor thermo sensor defective 27

Inching over 67

Drive motor overspeed 91

503 Power steering torque sensor output defective 54

504 Drive controller thermo sensor defective 22

Load handling controller thermo sensor defective 36

3. CONTROL SYSTEM

■ Checking procedure by error code

(1) Traveling system

No.

Problem

01

Traveling power module

shorted

[303]

05

Traveling power

[303]

module’s upper FET is

short-circuited

Traveling power

06

module’s lower FET is

[303]

short-circuited

Traveling power module

02

is open.

[304]

13

Traveling power

[304]

module’s phase «U» is

open .

Traveling power

14

[304]

module’s phase «V» is

open.

Traveling power

15

module’s phase «W» is

[304]

open.

03

Traveling contactor

[305]

(MD) shorted or sensor

circuit harness defective

Traveling contactor

04

(MD) is stuck open or

[306]

sensor circuit harness is

defective

07

Traveling contactor

[501]

(MD) drive Tr is

defective (Tr3 on

CPU board), traveling

contactor coil is stuck

open or sensor circuit

harness is defective.

16

Fwd or Rev direction

[501]

switch is defective.

Numbers in brackets are error codes that appear on the meter panel.

Error

Proceed with remedy in numerical order of encircled numbers.

The truck won’t move.

① Check traveling power modules (TMDU,

(MD contactor does not

TMDV, TMDW) and change if needed.

close.)

(When changing any power module, change

(Traveling quick charge

the power supply board, too.)

error: error code 69)

② Check harness between CN3R (power supply

(Occurrence is also

board) and each power module, and repair or

detected.)

change if needed.

③ Check harness between CN4-2 (CPU board)

and P3 terminal, and repair or change if

needed.

④ Check harness between CN4-8 (CPU board)

and P1 terminal, and repair or change if

needed.

⑤ If no defect is found throughout the above

steps, change power supply board.

Truck won’t move.

① Check harness between CN2R (power supply

board) and CN8 (CPU board), and repair or

change if needed.

② C heck traveling power modules (TMDU,

TMDV, TMDW), and repair or change if

needed. When changing any defective power

module, change power supply board, too.

③ Check harness between CN3R (power supply

board) and each power module, and repair or

change if needed.

④ Check harness between CN4-2 (CPU board)

and P3 terminal, and repair or change if

needed.

⑤ Check harness between CN4-8 (CPU board)

and P1 terminal, and repair or change if

needed.

⑥ If no defect is found throughout the above

steps, change power supply board.

The truck won’t move.

① Check traveling contactor (MD) (for welding

or mechanical hitch) and repair or change if

needed.

② Check harness between CN5-11 (CPU board)

and P2 terminal, and repair or change if

needed.

③ Check harness between CN4-2 (CPU board)

and P3 terminal, and repair or change if

needed.

The truck won’t move.

① Check traveling contactor (MD) (for foreign

matter between contact points or mechanical

hitch) and repair or change if needed.

② Check harness between CN5-11 (CPU board)

and P2 terminal, and repair or change if

needed.

③ Check harness between CN4-2 (CPU board)

and P3 terminal, and repair or change if

needed.

The truck won’t move.

① Check traveling contactor (MD) coil for

disengagement of connectors or broken coil,

and repair or change if needed.

② Check harness between contactor oil connector

and CN4-4,12 (CPU board), and repair or

change if needed.

③ Change CPU board (drive Tr defective).

The truck won’t move.

① Check for a shorted harness between CN1-8,21

(CPU board) and FR switch, and repair or

change if needed.

② Repair or change F/R switch.

Remedy

— 38 —

Reset

Remarks

Turn off the

If any power module is

key switch.

shorted, the capacitor

between P and N cannot

be charged and thus the

error code 69 is issued.

Turn off

key switch.

Turn off

key switch.

Turn off

key switch.

Turn off

key switch.

Restore to

Both fwd and rev switch

normal.

turn of simultaneously.

Master

Administrator

- Joined

- Sep 3, 2012

- Messages

-

17,165

- Likes

- 701

Dear you, do not worry. We are checking and maintenance our serve so please wait some hours. It will be normally. Thanks for your responding.

Master

Administrator

- Joined

- Sep 3, 2012

- Messages

-

17,165

- Likes

- 701

Hello Friend! Link doesn`t work.

Dear you, please download again. Serve is running back ok. Thanks.

mvMax666

- Joined

- Sep 7, 2014

- Messages

-

4

- Likes

- 0

TCM Forklift Truck Fault Codes list

TCM FB-6 Error Codes

101

Accelerator wire broken

102

Drive motor current sensor defective

103

Drive safety circuit turns on

105

Abnormal plugging of regenerative circuit

106

Controller thermo sensor defective

107

Drive motor current abnomal on the key switch.

Trouble occurs during operation.

201

Lift lever sensor wire broken

202

Load handling motor current abnomal

203

Load handling safety circuit turns on

301

Accelerator wire broken

303

Drive safety circuit turns on

401

Lift lever sensor wire broken

403

Load handling safety circuit turns on

TCM FB-7 Error Codes

Display error code Detail of error LED error code

301 Accelerator output defective 17

302 Traveling current sensor output defective 19

303 Drive FET power module short-circuited 01

Drive FET power module open 02

Drive quick charge error 69

305 Drive contactor short-circuited 03

306 Drive contactor open 04

307 Blown main fuse for drive 20

308 Rotation sensor A defective 41

Rotation sensor B defective 42

401 Load handling lift potentiometer defective 35

402 Load handling current sensor output defective 34

403 Load handling FET power module short-circuited 30

Load handling quick charge error 70

Power steering transistor short-circuited 50

404 Load handling FET power module open 31

Power steering transistor open 56

405 Load handling contactor short-circuited 37

Power steering contactor short-circuited 51

406 Load handling contactor open 33

Power steering fuse/contactor open 52

407 Blown main fuse for load handling 45

501 MD contactor drive transistor coil defective 07

F/R switch defective 16

Load dump error (battery overvoltage protection) 86

Load handling contactor drive transistor / coil defective 38

EPROM sum error (Other serious error) 82

EPROMACK error (Other serious error) 83

Power steering contactor drive transistor coil defective 53

502 Drive motor temperature rise 25

Drive motor thermo sensor defective 27

Inching over 67

Drive motor overspeed 91

503 Power steering torque sensor output defective 54

504 Drive controller thermo sensor defective 22

Load handling controller thermo sensor defective 36

Обновлено: 06.06.2023

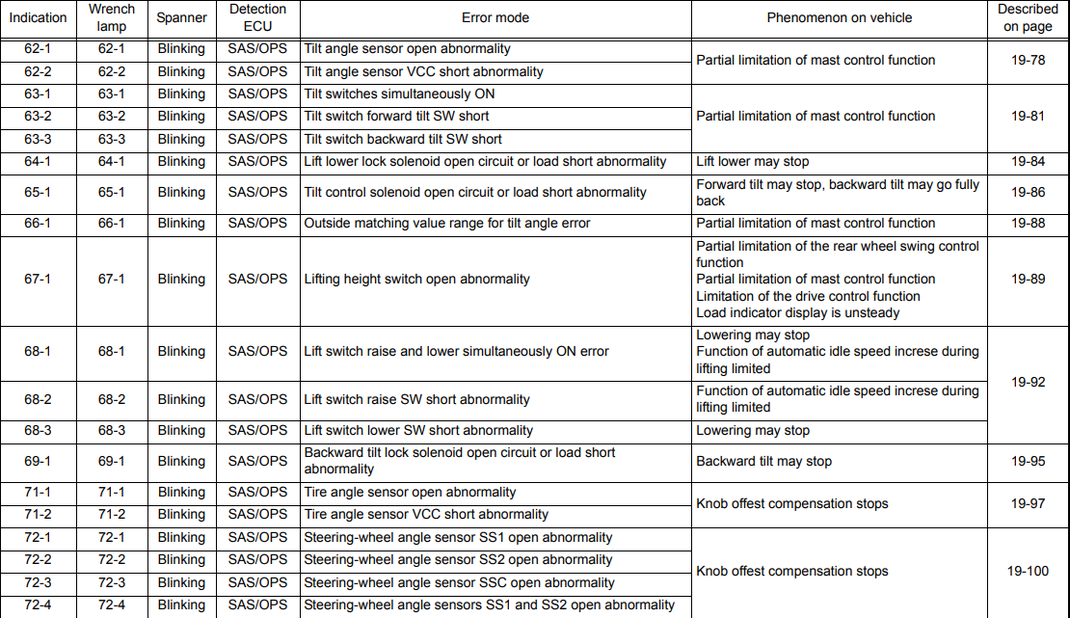

Continuation of engine idling status after acceleration off.

Idle switch open abnormality

Continuation of engine idling status

Idle switch short abnormality

Cam angle sensor open abnormality

Engine speed sensor open abnormality

Partial limitation of the drive control function.

Cam angle sensor open abnormality (on start up)

Engine will not start

Engine speed sensor GND short abnormality

Partial limitation of the drive control function.

Crank angle sensor open abnormality

Continuation of engine idling status

Maximum speed may be limited

Function of automatic idle speed increse during lifting limited

Matching connector open abnormality

Speed sensor open abnormality

The vehicle speed indicator shows 0 km/h Partial limitation of the rear wheel swing control function.

Knob offest compensation stops

Partial limitation of the drive control function.

Speed sensor GND short abnormality

Yaw rate sensor open abnormality

Partial limitation of the rear wheel swing control function

Yaw rate sensor VCC short abnormality

Yaw rate sensor neutral voltage error

Swing lock solenoid open circuit or load short abnormality

Partial limitation of the rear wheel swing control function

Load sensor open abnormality

Partial limitation of the rear wheel swing control function

Partial limitation of mast control function Limitation of the drive control function

Load indicator cannot display

Load sensor VCC short abnormality

Detection ECU

Phenomenon on vehicle

Unload solenoid open circuit or load short abnormality

Travelling and material handling enabled even after leaving the seat.

SAS/OPS data reception error

Display not stable

Lift lever potentiometer open abnormality

Lift lever potentiometer VCC short abnormality

Lift lever potentiometer assembly error

Lift lever potentiometer neutral abnormality

Material handling disabled

Lift lever potentiometer matching value abnormality

Tilt lever potentiometer open abnormality

Tilt lever potentiometer VCC short abnormality

Tilt lever potentiometer assembly error

Tilt lever potentiometer neutral error abnormality

Material handling disabled

Tilt lever potentiometer matching error

Attachment 1 lever potentiometer open abnormality

Attachment 1 stop

Attachment 1 lever potentiometer VCC short abnormality

Attachment 1 lever potentiometer combination error

Attachment 1 lever potentiometer neutral abnormality

Material handling disabled

Attachment 1 lever potentiometer matching value abnormality

Attachment 1 stop

Attachment 2 lever potentiometer open abnormality

Attachment 2 lever potentiometer VCC short abnormality

Attachment 2 lever potentiometer combination error

Attachment 2 lever potentiometer neutral abnormality

Material handling disabled

Attachment 2 lever potentiometer matching value abnormality

Lift PUSH solenoid open abnormality

Lift PULL solenoid open abnormality

Tilt PUSH solenoid open abnormality

Tilt PULL solenoid open abnormality

Attachment 1 PUSH solenoid open abnormality

Attachment 1 may stop

Attachment 1 PULL solenoid open abnormality

Wrench lamp

Detection ECU

Phenomenon on vehicle

Knob position compensation solenoid open circuit or load short abnormality

Knob offest compensation stops

Outside matching value range for tire angle error

Knob offest compensation stops

Seat switch GND short abnormality

Traveling and material handling possible even after leaving the seat.

Parking brake reminder and release reminder alarm partially disabled.

Brake switch GND short abnormality

Partial limitation of the drive control function

CAN communication 4Y-ECS or ASC data reception error

Partial limitation of the drive control function

CAN communication SAS/OPS data reception error

Partial limitation of the drive control function

CAN communication display data reception error

Limitation of the drive control function

Function of automatic idle speed increse during lifting limited

Display warning function operation failure

CAN communication SAS/OPS data reception error

Display not stable

Various control operations not stable

Accelerator sensor 1 open

Limting speed of traveling and materials handling due to limited engine power output

Accelerator sensor 1 short

Accelerator sensor 2 open

Accelerator sensor 2 short

Accelerator sensor offset abnormality

Accelerator sensor out of range error

Shift lever forward and reverse travel switch open abnormality

Travel return to neutral operation disabled Partial limitation of the drive control function.

Shift lever forward and reverse travel switches simultaneously ON error

Travelling may stop

Partial limitation of the drive control function.

Forward and reverse travel T/C relay open circuit or load short abnormality

Travelling and material handling enabled even after leaving the seat.

WARNING LIST

If the wrench lamp illuminates and the following phenomena occur on the vehicle without an error being displayed, it is not a fault. Take the appropriate corrective action.

Wrench lamp

Detection ECU

Phenomenon on vehicle

Content of warning

Appropriate corrective action

Water temperatur e gauge flashing

Top speed and load lifting speed are limited. (Only when OPT equipped)

Leave the vehicle at idle for a while

Swing lock control is always locked Knob offset occurrence

Material handling disabled (mini lever) Material handling except lifting disabled

High battery voltage

Use a battery of the specified voltage

Swing lock control is always locked

Low battery voltage

Charge or replace the battery

Tilt operates to forward most tilt position

Forward tilt restriction angle not matching

Carry out matching for each item

Tilt disabled with the knob switch in the ON position

Auto leveling angle not matching

Tilt operates to forward most tilt position Tilt disabled with the knob switch in the ON position

SAS/OPS NIL load not matching (NL: No-load)

Knob offset occurrence

Tire angle not matching

Swing lock control disabled

Swing leveling not matching

Lift lever not matching

Tilt lever not matching

Attachment 1 stop

Attachment 1 not matching

Attachment 2 stop

Attachment 2 not matching

Baker Akbar (Sunday, 06 March 2022 08:08)

How to solve problem error code H3-4

Alexander (Tuesday, 04 January 2022 14:37)

Tanks for pdf code

Nguyễn Đình Tri (Thursday, 30 December 2021 02:32)

Harish kumar (Wednesday, 28 July 2021 09:53)

8fb error code C0-2

ANTHONY GARMAN (Tuesday, 27 April 2021 17:26)

Jimbonious (Saturday, 17 April 2021 00:44)

Im getting a e c7-2 when neutral is engaged through seat presence switch. Try to put it back in gear and this code pops up. If you power down then you’re golden pony boy. It clears until you exit seat again. Try to shift once back on and nothin. . Please help

zoltan (Tuesday, 16 March 2021 09:30)

1C-2 code 52-8FDF25 (1ZS engine)

Anybody knows this code?

Pat Simkins (Thursday, 04 March 2021 20:35)

Toyota 8BPEU15 order picker showing code 88.

Ken (Tuesday, 24 November 2020 16:36)

mutiibwa Simon (Thursday, 19 November 2020 12:57)

Hi My CAT forklift while in operation reached a point and disengages gears and becomes free after displaying Error F88

Lee (Sunday, 01 November 2020 18:54)

How do I read fault codes on the dash of a Toyota 7FBMF18 fork truck please?

She is only moving at about 1 mph..

Frank (Wednesday, 28 October 2020 19:51)

My apology I need service manual for a Toyota forklift 5fbc15

Daniel (Friday, 23 October 2020 02:40)

Rafael cagud jr (Wednesday, 21 October 2020 09:07)

Error H4-1 no boom up & down

No side shift

Whats the problem of this

belkacem (Wednesday, 07 October 2020 21:44)

Code 92 in 7FBEST no traveling no material handling. I couldnt find 92 error code

Pete Stoor (Tuesday, 29 September 2020 09:22)

Electric Toyota 25 fault code F-01 the FLT will not move but all other items work?

Please advise

HAIDER (Saturday, 29 August 2020 21:21)

No tilt alarm buzzer continuesly sounding with the spanner signal on the dash board flashing. The truck is a Toyota 7FBE20 ERROR CODE 64-3

Rishi raj (Friday, 17 July 2020 03:16)

Forklift not working

Fault code

H1-2 62 -2 71-2

C4-3 C5 -3 FB-1

6700 .0 h

Ali (Thursday, 16 July 2020 15:25)

NELZON LIMA (Friday, 12 June 2020 15:25)

BUEN DIA ESTIMADO NECESITO ME AYUDE TENGO UN TOYOTA 7FBEU15 TENGO LAS FALLAS, AD-1, AD-2, AD-3 AD-4 POR FAVOR SI ME PUEDEN AYUDAR CON ESO

LO TENGO YA PARADO ASE MUCHO TIEMPO

mohammad (Thursday, 11 June 2020 07:24)

Hi Dear

What is Error code C 1 Toyota forklift electric?

Fork truck services (Wednesday, 20 May 2020 09:25)

No tilt alarm buzzer continuesly sounding with the spanner signal on the dash board flashing. The truck is a Toyota 7FBEST 15. Sr n.o. E11565

Model 8FGCU25 (Thursday, 14 May 2020 18:07)

Audrius (Sunday, 10 May 2020 14:36)

Error code 5:183. Toyota reach truck electric any ideas

Jose (Tuesday, 05 May 2020 11:59)

hello can someone help me I have a forlift toyota 8fgu32 and I have the code E 06-2

frederick kissi (Monday, 13 April 2020 17:39)

Error code CB-3 on toyota electric forklift truck

Vinod (Saturday, 07 December 2019 05:41)

7FBCU15, 7FBCU18, 7FBCU20, 7FBCU25, 7FBCU30, 7FBCU32 7FBCU35, 7FBCU45, 7FBCU55, 7FBCHU18, 7FBCHU25 7FBEU15, 7FBEU18, 7FBEU20, 7FBEHU18, 7FGU15, 7FGU18 7FGU20, 7FGU25, 7FGU30, 7FGU32, 7FDU15, 7FDU18, 7FDU20 7FDU25, 7FDU30, 7FDU32, 8FGU15, 8FGU18, 8FGU20, 8FGU25 8FGU30, 8FGU32, 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30 8FDU32, 7FGCU15, 7FGCU18, 7FGCU20, 7FGCSU20, 7FGCU25 7FGCU30, 7FGCU32, 8FGCU18, 8FGCU20, 8FGCSU20, 8FGCU25 8FGCU30, 8FGCU32, 7FGU35, 7FDU35, 7FGKU40, 7FDKU40 7FGU45, 7FDU45, 7FGAU50, 7FDAU50, 7FGU60, 7FDU60, 7FGU70 7FDU70, 7FGU80, 7FDU80, 7FGCU35, 7FGCU45, 7FGCU55 7FGCU60, 7FGCU70

GENERAL INFORMATION:

Further information concerning these codes can be found in the following manuals:

7FBCU15-55 ►OPSS Manual CU335 page 3-9 7FBEU15-20 ►OPSS Manual CU341 page 1-10 7FGCU15, 18, S20 ►OPSS Manual CU042 page 1-19 7FGU15-32, 7FDU15-32, 7FGCU20-32 ►OPSS Manual CU040 page 1-18 7FGU35-80, 7FDU35-80, 7FGCU35-70 ►OPSS Manual CU041 page 1-17 8FGCU15, 18, S20 ►Service manual 00700-X8880-71 page 19.1-82 8FGU15-32, 8FDU15-32, 8FGCU20-32 ►Service manual 00700-X8880-71 page 19-111

DIAGNOSIS DISPLAY METHOD

1. Diagnosis display method The diagnosis is displayed by means of an error code as shown in the illustration to the left, and by the lights turning on. When the ignition key switch is turned ON, the lamp lights once to allow checking for the bulb, and then turns off again if the status is normal. With the ignition key switch ON, if an abnormality is detected when the vehicle is stopped, travelling or performing meterials handling operations, an error code is displayed and the lamps turn on as a warning. When this happens, stop the vehicle immediately and check the error code.

(3) Connect the matching connector and turn the ignition key switch OFF.

LIST OF DIAGNOSIS CODES

Translated from Indonesian!

Original text error codes Download

41-1 Matching connector abnormal Only the Connector display is faulty

Matching cable is broken

Controller is broken

51-1 Speed sensor abnormal Speed indicator keeps showing 0 km/h Connector is faulty

51-2 Rear wheel swing control Damaged connector cable

Steer knob is not in position Speed sensor is broken

Controller is broken

52-1 Yaw rate sensor abnormal Rear wheel swing control is limited. Broken connector

52-2 Connector cable is damaged

52-3 Yaw rate sensor is faulty

Controller is broken

54-1 Swing lock solenoid abnormal Rear wheel swing control is limited. Broken connector

Broken connector cable

Swing lock solenoid is broken

Controller is broken

61-1 Load sensor abnormal Rear wheel swing control is limited. Broken connector

61-2 Control mast function is partially restricted Connector cable is damaged

Drive control function is limited (MFD opt) Load sensor is faulty

Load indicator does not appear on the display (MFD) The controller is broken

Error mode Symptoms on forklift Possible causes

62-1 Tilt angle sensor abnormal Mast control function is partially restricted Connector is faulty

62-2 Connector cable is damaged

Broken tilt angle sensor

Controller is broken

63-1 Tilt lever switch abnormal Mast control function is partially restricted Connector is faulty

63-2 Forward tilt switch is broken

63-3 Backward tilt switch is broken

Faulty switch installation

Controller is broken

64-1 Lift lock solenoid abnormal Fork won’t come down Connector is broken

Broken connector cable

Broken lift lock solenoid

Controller is broken

65-1 Tilt control solenoid abnormal Forward tilt cannot operate, but Connector is damaged

backward tilt operable. Broken connector cable

Broken tilt control solenoid

Controller is broken

66-1 Abnormal matching measurement value The control mast function is partially restricted. The horizontal tilt angle value does not match.

Tilt forward angle value

it is not in accordance with.

Measuring value of load sensor

it is not in accordance with.

67-1 Lifting height switch abnormal Partial rearwheel swing control function Faulty connector

restricted. Broken connector cable

Mast control function is partially restricted Lifting height swt is broken

Drive control function is restricted Controller is faulty

Load indicator display changes IG fuse blown

Broken connector cable

The swt elevator installation is broken

Controller is broken

Error mode Symptoms on the forklift Possible cause of failure

69-1 Backward tilt lock solenoid Backward tilt does not operate Connector is faulty

abnormal Connector cable is damaged

Backward tilt lock solenoid is faulty.

Controller is broken

71-1 Tire angle sensor abnormal Steer knob is not in position Connector is faulty

71-2 Connector cable is damaged

tire angle sensor joint,

rear axle link syst. damaged

Controller is broken

72-1 Steering angle sensor abnormal Steer knob is not in position Connector is faulty

72-2 Connector cable is damaged

72-3 Sensor is faulty

72-4 Controller is faulty

73-1 Abnormal solenoid knob position Steer knob out of position Connector is faulty

Broken connector cable

Controller is broken

74-1 Measuring value of matching tire angle Steer knob is not in position Matching value

wheel alignment error no in accordance

A5-1 Seat switch abnormal Drive & hydraulic system can operate Connector is faulty

even if the operator is not sitting in the operating chair The connector cable is damaged

Controller is broken

A7-1 Abnormal brake switch Function of partially restricted drive control Connector is faulty

Broken brake switch

Broken connector cable

Controller is broken

AF-1

AF-2

AF-3

AF-4

AF-5

AF-6

AF-7

AF-8 CPU abnormal All control functions are unstable Controller is faulty

C7-1 Shift lever switch abnormal Cannot be positioned to neutral Connector is faulty

C7-2 Drive control function is partially restricted Forward switch is faulty

Reverse switch is broken

Faulty switch installation

Controller is broken

CA-1 Forward-reverse travel Torque Drive system and hydraulic system can Connector damaged

converter relay abnormal is operated even when operator is not seated Forward travel cable

the relay operator seat is broken

Forward travel relay

reverse travel cable

Reverse travel relay

Controller is broken

EC-1 Unload solenoid abnormal Drive system and hydraulic system can Connector is faulty

operated even if the operator is not seated Connector cable is damaged

in operator seat Unload solenoid is broken

Controller is broken

F1-1 Combination meter abnormal Problem on the display Connector is damaged

F1-2 Hour meter cable is damaged

Hour meter is broken

Controller is broken

F4-1~8 CPU error CPU abnormal Multi-function board

H1-1 Lift lever potentiometer abnormal Lift cannot operate Connectro is faulty

H1-2 The potentiometer wire is damaged

H1-3 Potentiometer is broken

H1-4 Controller is broken

H1-5 Fuse blown

H2-1 Tilt lever potentiometer abnormal Tilt does not operate Connectro is faulty

H2-2 The potentiometer wire is damaged

H2-3 Potentiometer is broken

H2-4 Controller is broken

H2-5 Fuse blown

H3-1 Attachment 1 lever potentiometer Attachment 1 does not operate Connectro is faulty

H3-2 abnormal Potentiometer cable is damaged

H3-3 The potentiometer is faulty

H3-4 Controller is broken

H3-5 Fuse blown

H4-1 Attachment 2 lever potentiometer Attachment 2 does not operate Connectro is damaged

H4-2 abnormal Potentiometer cable is damaged

H4-3 The potentiometer is faulty

H4-4 Controller is broken

H4-5 Fuse blown

H5-1 Lift solenoid abnormal Elevator may not operate Faulty connector

H5-2 Elevator cable (PUSH) is damaged

Solenoid lift (PUSH) is broken

Elevator cable (PULL) is broken

Solenoid lift (PULL) is broken

Controller is broken

H6-1 Solenoid Tilt Abnormal Tilt may not operate Connector is faulty

H6-2 Faulty tilt (PUSH) cable

Solenoid tilt (PUSH) faulty

Broken tilt (PULL) cable

Solenoid tilt (PULL) faulty

Controller is broken

H7-1 Attachment 1 abnormal solenoid Attachment 1 may not work Connector is damaged

H7-2 operating Att 1 (PUSH) cable is faulty

Solenoid Att 1 (PUSH) is faulty

Att 1 (PULL) cable is damaged

Solenoid Att 1 (PULL) is faulty

Controller is broken

Solenoid Att 2 (PUSH) is faulty

Att 2 (PULL) cable is damaged

Solenoid Att 2 (PULL) is faulty

Controller is broken

HA-1 3/4-way change relay abnormal Attachment transfer is not possible Connector is damaged

operating Relay cable 1 is damaged

Relay 1 is broken

Relay cable 2 is damaged

Relay 2 is broken

Controller is broken

Error mode Symptoms on forklift Possible causes

broken WARNING LIST

IF THE WRENCH LAMP IS ON AND WITH THESE SYMPTOMS BELOW ON

владимир (Monday, 21 March 2022 05:06)

ERROR 107 вилочный погрузчик HANGCNA

Kasco (Wednesday, 09 March 2022 12:10)

Error code C5-5 not moving

si (Monday, 02 August 2021 18:42)

Omar orduno (Sunday, 13 June 2021 22:45)

montacargas eléctrico Toyota modelo 7fcu15 presenta error c3-1

nam (Friday, 11 June 2021 11:18)

toyota 7fbrs 15 error code f5-1 , f5-4

Ravindu Bandara (Tuesday, 08 June 2021 08:15)

What is the meaning of E 59-1 error code in GENEO 35

zoltan (Tuesday, 16 March 2021 09:41)

1C-2 code 52-8FDF25 (1ZS engine)

Anybody knows this code?

de Vries (Wednesday, 24 February 2021 19:51)

Mijn toyota traico heeft foutcode 73 wat houdt dat in?

Joel (Friday, 13 November 2020 23:05)

Just serviced 7 series 7fbcu30 and need to reset the maintenance timer

Joel (Friday, 13 November 2020 23:02)

How to reset maintenance hours reminder

Armando garrido (Wednesday, 23 September 2020 21:14)

Ole (Monday, 21 September 2020 08:30)

does anyone know the error code «joy M not connected»

Robert Sieow (Tuesday, 28 July 2020 16:22)

Gustavo D (Tuesday, 14 April 2020 16:01)

I have a Toyota diesel forklift model 8FDU20 a code came up on the display (E AD 1) the machine won’t start. I checked many different connectors and sensors but nothing seemed wrong.

I need some fresh ideas from someone smart, please help!

Jose (Thursday, 30 January 2020 21:49)

Tengo un equipo Toyota 8fdu30 serie 60532 me da código 11-5 y deja de caminar hacia el frente

manish chauhan (Wednesday, 29 January 2020 17:27)

it is most usebal document

JIM K (Monday, 27 January 2020 13:07)

Working on a Hyster ROES30 order picker which has a code A5 31 on display board in the lower part of the compartment, NEED HELP

Josh Gering (Tuesday, 21 January 2020 23:26)

Code 72-4 Steering angle sensor.

Lift does not have said sensor. How do I remove/disable this parameter? Everything working fine, but lift won’t quit alarming. Customer getting irritated.

kwan (Tuesday, 05 November 2019 15:59)

Rick (Wednesday, 07 August 2019 21:33)

I have a toyota Electric Fork lift That has had some serious problems as I had to get into it pretty deep to find out why when the owners guys turned on the key nothing powered up? Im not a class A electric fork lift technician but I know enough about electrical that I chased down a Five pin plug that was all melted together and shorted out I removed burnt socket and replaced the burnt wires and got power back to the ignition and truck I got it so it powers the hoist and power steering but have do final drive forward or reverse I have a wrench and a Code A 8 I did see another electrical socket that looked burnt pretty badly I didnt play with it but I’m thinking I’m probably going to have to cut that socket out and clean wires back and reconnect them together to get the drive motor to start so the fork truck can move back and forth! I’m trying to find out what the A 8 code is and the proper way to reset the computer to remove the wrench symbol and clear all codes. Thank you for your time, Rickey

Kevin Stahl (Wednesday, 29 May 2019 19:18)

Please could you email me the code sheet of a Toyota electric forklift Model number 5FBE15

Pepo (Wednesday, 15 May 2019 22:07)

I’ve been fighting with this code h5-1

Robert Shamonski (Monday, 22 April 2019 20:45)

EA5-1 trying to identify code

Jose Sanchez (Monday, 15 April 2019 17:58)

I have a forklift 3 wheel sit down model number 7FBEU15 and a code pops up that is AD6 and AD5 if you can help me what those code mean I’ll appreciate it

Sammy G. Polinar (Thursday, 04 April 2019 09:13)

Please provide me the Electrical Diagram of Toyota Electric Fork Lift Model: 7FBE20.

My Fork Lift is stop due to Electrical Problem

If you are the copyright holder of a user manual, please contact us by mail and we will remove it from the site and leave a link to your store if there is one.

При возникновении неисправности на технике, информационный дисплей EMS сразу отображает на экране ошибки, при этом зуммер (сигнализатор) начинает пищать. Для отключения зуммера нужно нажать на кнопку ACK на мониторе JCB.

Подробное описание ошибок электронных блоков управления гидравлики ECU1 728/29900 728/35700 728/29900 728/35700 и блока электроники ECUW 728/35800 728/18500 728/15500 JCB.

Коды ошибок JCB (гидравлики и электроники)

| Коды ошибок |

Надпись на дисплее монитора | Описание неисправности |

| 101 | CRANK | ЭБУ1 не обнаруживает сигнал от коленвала. |

| 102 | FUEL | Цепь датчика топлива разомкнута |

| 103 | EN TMP | Цепь датчика температуры двигателя разомкнута. |

| 104 | HYD TMP | Цепь датчика температуры гидравлической жидкости разомкнута. |

| 105 | SET PT | Цепь потенциометра заданного положения дроссельной заслонки разомкнута. |

| 106 | SENS PT | Цепь потенциометра фактического положения дроссельной заслонки разомкнута. |

| 107 | OIL SW | Датчик давления масла выдает сигнал наличия давления при отключенном двигателе. |

| 108 | FLYWHEEL | Датчик карданной передачи выдает сигнал оборотов двигателя при отключенном |

| 109 | ALT | Генератор выдает сигнал наличия напряжения при отключенном двигателе. |

| 110 | THR SOL | Цепь электромагнитного клапана дроссельной заслонки разомкнута. Обнаруживается только при отключенном двигателе. |

| 111 | BOOM SP | Цепь регулирования малой скорости стрелы разомкнута. |

| 113 | MAX FLW | Цепь электромагнитного клапана максимального расхода разомкнута. Для машин JS200W данная ошибка может быть обнаружена тольк |

| 115 | BOOM | Цепь электромагнитного клапана приоритета разомкнута |

| 116 | FL PMP | Цепь выходного контура насоса дозаправки разомкнута. |

| 117 | HORN | Цепь выходного контура клаксона разомкнута. |

| 118 | HYD PMP | Цепь гидравлического насоса разомкнута. Поскольку клапан является пропорциональным, ошибка обнаруживается только при отключенном двигателе |

| 119 | SLW LCK | Цепь электромагнитного клапана блокиратора стрелы разомкнута. |

| 120 | HYD FAN | Цепь выходного контура вентилятора гидросистемы разомкнута. Обнаруживается только при отключенном двигателе |

| 121 | SLW BRK | Цепь электромагнитного клапана разблокировки стрелы разомкнута |

| 122 | SLW ST | Цепь электромагнитного клапана отключения стрелы разомкнута. |

| 127 | TL CHNG | Цепь электромагнитного клапана переключения скорости движения разомкнута. |

| 128 | WASHER | Цепь двигателя омывателя разомкнута. |

| 129 | DOZER | Цепь электромагнитного клапана отвала разомкнута. |

| 130 | GRB CW | Цепь электромагнитного клапана вращения грейфера по часовой стрелке разомкнута. |

| 131 | GRB CCW | Цепь электромагнитного клапана вращения грейфера против часовой стрелки разомкнута. |

| 132 | LW FLOW | Цепь электромагнитного клапана низкого расхода разомкнута. |

| 133 | ISOL | Цепь электромагнитного клапана гидроизолятора разомкнута. |

| 135 | 2 STAGE | Цепь предохранительного электромагнитного клапана ступени 2 разомкнута. |

| 136 | QK HTCH | Цепь электромагнитного клапана быстрой сцепки разомкнута. |

| 138 | HAMMER | Цепь электромагнитного клапана молота разомкнута. |

| 139 | CUSHION | Цепь электромагнитного клапана твердой/мягкой подушки разомкнута. |

| 142 | ENG SD | Цепь выходного контура отключения двигателя разомкнута. |

| 143 | GLW PLG | Цепь выходного контура свечей накаливания разомкнута. |

| 156 | TL FLW3 | Цепь электромагнитного клапана расхода 3 движения разомкнута. |

| 157 | TL FLW2 | Цепь электромагнитного клапана расхода 2 движения разомкнута. |

| 158 | GR CHNG | Цепь электромагнитного клапана М2 или переключения передач разомкнута. |

| 159 | BRKE LT | Цепь выходного контура лампы тормоза разомкнута. |

| 160 | AXLE LK | Цепь электромагнитного клапана блокировки моста разомкнута. |

| 161 | STAB UP | Цепь электромагнитного клапана подъема стабилизатора разомкнута. |

| 162 | STAB DIN | Цепь электромагнитного клапана опускания стабилизатора разомкнута. |

| 163 | STAB LH | Цепь электромагнитного клапана левого стабилизатора разомкнута. |

| 164 | STAB RH | Цепь электромагнитного клапана правого стабилизатора разомкнута. |

| 165 | CRUISE | Цепь электромагнитного клапана круиз-контроля разомкнута. |

| 166 | DIG ISL | Цепь электромагнитного клапана изолятора режущей кромки разомкнута. |

| 167 | PRK BK | Цепь электромагнитного клапана М1 или стояночного тормоза разомкнута. |

| 168 | DRV ISL | Цепь электромагнитного клапана изолятора привода разомкнута. |

| 202 | FUEL | Короткое замыкание цепи датчика уровня топлива. |

| 203 | EN TMP | Короткое замыкание цепи датчика температуры двигателя. |

| 204 | HYD TMP | Короткое замыкание цепи датчика температуры гидравлической жидкости. |

| 205 | SET PT | Короткое замыкание цепи потенциометра заданного положения дроссельной заслонки. |

| 206 | SENS PT | Короткое замыкание цепи потенциометра фактического положения дроссельной заслонки. |

| 210 | THR SOL | Короткое замыкание цепи электромагнитного клапана дроссельной заслонки. Обнаруживается только при отключенном двигателе. |

| 211 | BOOM SP | Короткое замыкание цепи регулирования малой скорости стрелы. |

| 212 | INT LT | Короткое замыкание цепи внутреннего освещения. |

| 213 | MAX FLW | Короткое замыкание цепи электромагнитного клапана максимального расхода. Для машин JS200W данная ошибка может быть обнаружена только при отключенном двигателе, т. к. на этих машинах имеется пропорциональный клапан. |

| 214 | BEACON | Короткое замыкание цепи маячка. |

| 215 | BOOM PR | Короткое замыкание цепи электромагнитного клапана приоритета. |

| 216 | FL PMP | Короткое замыкание цепи электромагнитного клапана насоса дозаправки. |

| 217 | HORN | Короткое замыкание цепи клаксона. |

| 218 | HYD PMP | Короткое замыкание цепи гидравлического насоса. Поскольку клапан является пропорциональным, ошибка обнаруживается только при отключенном двигателе. |

| 218 | HYD PMP | Короткое замыкание цепи гидравлического насоса. Поскольку клапан является пропорциональным, ошибка обнаруживается только при отключенном двигателе. |

| 219 | SLW LCK | Короткое замыкание цепи электромагнитного клапана блокиратора стрелы. 220 HYD FAN Короткое замыкание цепи электромагнитного клапана вентилятора гидросистемы |

| 220 | HYD FAN | Короткое замыкание цепи электромагнитного клапана вентилятора гидросистемы. Обнаруживается только при отключенном двигателе. |

| 221 | SLW BRK | Короткое замыкание цепи электромагнитного клапана разблокировки стрелы. |

| 222 | SLW ST | Короткое замыкание цепи электромагнитного клапана отключения стрелы. |

| 223 | LW WIPR | Короткое замыкание цепи нижнего стеклоочистителя. |

| 224 | WIPER | Короткое замыкание цепи стеклоочистителя. |

| 225 | LH CAB LT | Короткое замыкание цепи рабочего освещения стрелы. |

| 226 | RH CAB LT | Короткое замыкание цепи рабочего освещения инструментального ящика. |

| 227 | TL CHNG | Короткое замыкание цепи электромагнитного клапана переключения скорости движения. |

| 228 | WASHER | Короткое замыкание цепи двигателя омывателя. |

| 229 | DOZER | Короткое замыкание цепи электромагнитного клапана отвала. |

| 230 | GRB CW | Короткое замыкание цепи электромагнитного клапана вращения грейфера по часовой стрелке. |

| 231 | GRB CCW | Короткое замыкание цепи электромагнитного клапана вращения грейфера против часовой стрелки. |

| 232 | LW FLOW | Короткое замыкание цепи электромагнитного клапана низкого расхода. |

| 233 | ISOL | Короткое замыкание цепи электромагнитного клапана изолятора. |

| 234 | EMG STP | Короткое замыкание цепи электромагнитного клапана аварийной остановки. |

| 235 | 2 STAGE | Короткое замыкание цепи предохранительного электромагнитного клапана ступени 2. |

| 236 | QK HTCH | Короткое замыкание цепи электромагнитного клапана быстрой сцепки. |

| 237 | TL ALRM | Короткое замыкание цепи сигнализации трогания с места. |

| 238 | HAMMER | Короткое замыкание цепи электромагнитного клапана молота. |

| 239 | CUSHION | Короткое замыкание цепи электромагнитного клапана твердой/мягкой подушки. |

| 240 | BOOM LT | Короткое замыкание цепи рабочего освещения стрелы. |

| 241 | ENG SD | Короткое замыкание цепи электромагнитного клапана остановки двигателя. |

| 242 | ENG SD | Короткое замыкание цепи электромагнитного клапана остановки двигателя. |

| 243 | GLW PLG | Короткое замыкание цепи свечей накаливания. |

| 244 | CNT LT | Короткое замыкание цепи рабочего освещения противовеса. |

| 244 | LH IND | Короткое замыкание цепи индикатора левого поворота. |

| 245 | LH IND | Короткое замыкание цепи индикатора левого поворота. |

| 246 | LH SIDE | Короткое замыкание цепи левого бокового освещения. |

| 247 | LH FOG | Короткое замыкание цепи левой противотуманной фары. |

| 248 | LH MAIN | Короткое замыкание цепи левой фары дальнего света. |

| 249 | LH DIP | Короткое замыкание цепи левой фары ближнего света. |

| 250 | RH IND | Короткое замыкание цепи индикатора правого поворота. |

| 251 | RH SIDE | Короткое замыкание цепи правого бокового освещения. |

| 252 | RH FOG | Короткое замыкание цепи правой противотуманной фары. |

| 253 | RRH MAIN | Короткое замыкание цепи правой фары дальнего света. |

| 254 | RH DIP | Короткое замыкание цепи правой фары ближнего света. |

| 255 | HZD LED | Короткое замыкание цепи светодиода опасности. |

| 256 | TL FLW3 | Короткое замыкание цепи электромагнитного клапана расхода 3 движения. |

| 257 | TL FLW2 | Короткое замыкание цепи электромагнитного клапана расхода 2 движения. |

| 258 | GR CHNG | Короткое замыкание цепи электромагнитного клапана М2 или переключения передач. |

| 259 | BRKE LT | Короткое замыкание цепи выходного контура лампы тормоза. |

| 260 | AXLE LK | Короткое замыкание цепи электромагнитного клапана блокировки моста. |

| 261 | STAB UP | Короткое замыкание цепи электромагнитного клапана подъема стабилизатора. |

| 262 | STAB DIN | Короткое замыкание цепи электромагнитного клапана опускания стабилизатора. |

| 263 | STAB LH | Короткое замыкание цепи электромагнитного клапана левого стабилизатора. |

| 264 | STAB RH | Короткое замыкание цепи электромагнитного клапана правого стабилизатора. |

| 265 | CRUISE | Короткое замыкание цепи электромагнитного клапана круиз-контроля. |

| 266 | DIG ISL | Короткое замыкание цепи электромагнитного клапана изолятора режущей кромки. |

| 267 | PRK BK | Короткое замыкание цепи электромагнитного клапана М1 или стояночного тормоза. |

| 268 | DRV ISL | Короткое замыкание цепи электромагнитного клапана изолятора привода. |

| 300 | EC1 CAN | Прервана связь ЭБУ1 с шиной CAN. |

| 301 | ECW CAN | Прервана связь ECUW с шиной CAN. |

| 302 | THRT CAL | Разница между точкам максимальной и минимальной калибровки для циферблатного потенциометра дроссельной заслонки меньше 100 точек A/D. |

| 304 | THRT CAL | Положение циферблатного потенциометра изменено более, чем на 10%, но двигатель продолжает работать в положении холостого хода. Данное состояние должно длиться не менее 15 секунд, чтобы быть зафиксированным. Данная ошибка не существует на машинах с EEC (Electronic Engine Controller — блок электронного управления двигателем).. |

Коды ошибок Двигателя JCB (Isuzu 4HK, 6HK)

Вопрос-Ответ

Добрый день.

Вилочный погрузчик Тойота 02-8FG25, при включении зажигания горит ошибка Е67-1 и гаечный ключ.

Расшифровку не подскажете?

Где можно узнать коды ошибок на электропогрузчик HYUNDAI 25B-9. Особенно ошибка M4F — incorrect start. Все лючки закрыты, ручник — в нужном положении, ручка движения — в нейтрали.

Не могу дозвониться

Здраствуйте на вилочном погрузчике nissan загорелись ошибки f-16 и e-30, как рассшифровываются?

Подскажите, погрузчик nissan 3тонник выскакивает ошибка f-34, что за она и как с ней бороться?

Погрузчик mitsubishi FD15N Перииодически выскакивает ошибка F40 + красный восклицательный знак. В книжке нашел что это ошибка «рулевого управления». Так как ошибка не постоянна возможно дело в контакте. Подскажите какой датчик, провод или реле искать. Ошибка стала появляться после ремонта заднего моста и капиталки двигателя.

Электропогрузчик Hyster 1,6 выдает ошибку 21569. Что она означает.

К сожалению по Хайстер не смогу Вам подсказать. Если у Вас не будет других вариантов — напишите мне на почту, я покапаюсь в каталогах.

Добрый день!

Как проверить кол-во наработанных моточасов на погрузчике Maximal M16?

Спасибо!

На вилочном погрузчике YOYОTA «горит» ошибка: Е 67-14; Е 54-1; Е 71-1 и Е 85-1.

подскажите, пожалуйста, что это значит.

На дизельном вилочном погрузчике Ниссан мигает ошибка F-34 и мигает вся панель,плохо заводиться(такое ощущение что оходит топливо с насоса) и коптит при нажатии на педаль газа

Добрый день! Подскажите пожалуйста, на вилочном погрузчике NISSAN FL01A15 горят ошибки:

P-22 и F-80, что это за ошибки?

Спасибо!

Р22 это сбой рычага управления — его нужно выставить в нейтральное положение.

здравствуйте, у нас погрузчик ниссан L01 двигатель К15 , выдает ошибки Е34, Е39, F40 что это за ошибки. Заранее спасибо

Здравствуйте, у нас электропогрузчик sumitomo, после зарядки высвечивается ошибка 201, и сбрасывается, недозаряжает одно деление, через несколько секунд сбрасывается, в чем может быть причина?

Здравствуйте, у нас электрический транспалет HELI DC15. лампа ошибок мигает код отказа 13 (1 пауза 3). Что означает этот код? Спасибо заранее ха помощь

нет движения у вилочного погрузчика GPOWER FB 15-35.Появилась ошибка al-8/менял акселератор с рабочего погрузчика -тот же результат.Что может быть

Здравствуйте. Для диагностики электропогрузчиков нужно либо современное оборудование или подробные руководства. Для Вашего погрузчика, к сожалению, у меня ни того, ни того нет. Советую обратиться в сервисный центр Тойота Цусе.

Здравствуйте! Подскажите пожалуйста, где ( в каком месте ), установлен датчик температуры охлаждающей жидкости вилочного погрузчика MITSUBICHI

на вилочном Ниссане PL01 15 установлено заводское японское оборудование газ-бензин. На бензине все прекрасно а на газе троит двигатель моргает вся панель и ошибка Е-27, что это может быть и что делать?

Ошибка Е-27 это ошибка сенсора. Думаю, что у Вас вышел из строя переключатель газ/бензин. Вызовите специалиста по газовому оборудованию.

Добрый день! Приобрели вилочный погрузчик мицубиси fd25nt, дизельный двигатель (б/у). После того как погрузчик прогревается выдает ошибку F87 и перестает ехать назад. Подскажи пожалуйста в чем может быть причина и на что указывают данная ошибка. Заранее благодарны.

Данная ошибка — это ошибка электромагнитного клапана.на задний ход. Думаю, что требуется замена соленоида. Ремонтировать его бесполезно.

Здравствуйте, подскажите как проверить уровень масла в акпп погрузчика коматсу

FO18Y630 двигатель 4D92E-1B59B?

Посмотреть на щуп))) Рядом с фильтром АКПП Вы должны увидеть щуп АКПП. Выньте его и посмотрите — должны быть метки.

Спецпредложения

Грузоподъемность 1,8 тонны

Высота подъема 4,34 метра

Год выпуска 2013,

Мачта трехсекционная со свободным ходом (вагонник)

Находится в г. Саратов

ЦЕНА: 1 170 000 рублей

Грузоподъемность 1,5 тонны

Высота подъема 3,0 метров

Год выпуска 2013

Мачта двухсекционная

Свободный ход мачты (вагонный вариант)

Каретка бокового смещения вил

Шины суперэластик новые

Вилы 1070

Наработка 4631 м/ч

ПСМ в наличии

ЦЕНА: 1 150 000 рублей

Грузоподъемность 3 тонны

Высота подъема 3,0 метра

Год выпуска 2008

Мачта двухсекционная без свободного хода

Вилы 1070

Шины пневматические новые

Состояние нового погрузчика.

7FBCU15, 7FBCU18, 7FBCU20, 7FBCU25, 7FBCU30, 7FBCU32 7FBCU35, 7FBCU45, 7FBCU55, 7FBCHU18, 7FBCHU25 7FBEU15, 7FBEU18, 7FBEU20, 7FBEHU18, 7FGU15, 7FGU18 7FGU20, 7FGU25, 7FGU30, 7FGU32, 7FDU15, 7FDU18, 7FDU20 7FDU25, 7FDU30, 7FDU32, 8FGU15, 8FGU18, 8FGU20, 8FGU25 8FGU30, 8FGU32, 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30 8FDU32, 7FGCU15, 7FGCU18, 7FGCU20, 7FGCSU20, 7FGCU25 7FGCU30, 7FGCU32, 8FGCU18, 8FGCU20, 8FGCSU20, 8FGCU25 8FGCU30, 8FGCU32, 7FGU35, 7FDU35, 7FGKU40, 7FDKU40 7FGU45, 7FDU45, 7FGAU50, 7FDAU50, 7FGU60, 7FDU60, 7FGU70 7FDU70, 7FGU80, 7FDU80, 7FGCU35, 7FGCU45, 7FGCU55 7FGCU60, 7FGCU70

GENERAL INFORMATION:

Further information concerning these codes can be found in the following manuals:

7FBCU15-55 ►OPSS Manual CU335 page 3-9 7FBEU15-20 ►OPSS Manual CU341 page 1-10 7FGCU15, 18, S20 ►OPSS Manual CU042 page 1-19 7FGU15-32, 7FDU15-32, 7FGCU20-32 ►OPSS Manual CU040 page 1-18 7FGU35-80, 7FDU35-80, 7FGCU35-70 ►OPSS Manual CU041 page 1-17 8FGCU15, 18, S20 ►Service manual 00700-X8880-71 page 19.1-82 8FGU15-32, 8FDU15-32, 8FGCU20-32 ►Service manual 00700-X8880-71 page 19-111

DIAGNOSIS DISPLAY METHOD

1. Diagnosis display method The diagnosis is displayed by means of an error code as shown in the illustration to the left, and by the lights turning on. When the ignition key switch is turned ON, the lamp lights once to allow checking for the bulb, and then turns off again if the status is normal. With the ignition key switch ON, if an abnormality is detected when the vehicle is stopped, travelling or performing meterials handling operations, an error code is displayed and the lamps turn on as a warning. When this happens, stop the vehicle immediately and check the error code.

(3) Connect the matching connector and turn the ignition key switch OFF.

LIST OF DIAGNOSIS CODES

Translated from Indonesian!

Original text error codes Download

41-1 Matching connector abnormal Only the Connector display is faulty

Matching cable is broken

Controller is broken

51-1 Speed sensor abnormal Speed indicator keeps showing 0 km/h Connector is faulty

51-2 Rear wheel swing control Damaged connector cable

Steer knob is not in position Speed sensor is broken

Controller is broken

52-1 Yaw rate sensor abnormal Rear wheel swing control is limited. Broken connector

52-2 Connector cable is damaged

52-3 Yaw rate sensor is faulty

Controller is broken

54-1 Swing lock solenoid abnormal Rear wheel swing control is limited. Broken connector

Broken connector cable

Swing lock solenoid is broken

Controller is broken

61-1 Load sensor abnormal Rear wheel swing control is limited. Broken connector

61-2 Control mast function is partially restricted Connector cable is damaged

Drive control function is limited (MFD opt) Load sensor is faulty

Load indicator does not appear on the display (MFD) The controller is broken

Error mode Symptoms on forklift Possible causes

62-1 Tilt angle sensor abnormal Mast control function is partially restricted Connector is faulty

62-2 Connector cable is damaged

Broken tilt angle sensor

Controller is broken

63-1 Tilt lever switch abnormal Mast control function is partially restricted Connector is faulty

63-2 Forward tilt switch is broken

63-3 Backward tilt switch is broken

Faulty switch installation

Controller is broken

64-1 Lift lock solenoid abnormal Fork won’t come down Connector is broken

Broken connector cable

Broken lift lock solenoid

Controller is broken

65-1 Tilt control solenoid abnormal Forward tilt cannot operate, but Connector is damaged

backward tilt operable. Broken connector cable

Broken tilt control solenoid

Controller is broken

66-1 Abnormal matching measurement value The control mast function is partially restricted. The horizontal tilt angle value does not match.

Tilt forward angle value

it is not in accordance with.

Measuring value of load sensor

it is not in accordance with.

67-1 Lifting height switch abnormal Partial rearwheel swing control function Faulty connector

restricted. Broken connector cable

Mast control function is partially restricted Lifting height swt is broken

Drive control function is restricted Controller is faulty

Load indicator display changes IG fuse blown

Broken connector cable

The swt elevator installation is broken

Controller is broken

Error mode Symptoms on the forklift Possible cause of failure

69-1 Backward tilt lock solenoid Backward tilt does not operate Connector is faulty

abnormal Connector cable is damaged

Backward tilt lock solenoid is faulty.

Controller is broken

71-1 Tire angle sensor abnormal Steer knob is not in position Connector is faulty

71-2 Connector cable is damaged

tire angle sensor joint,

rear axle link syst. damaged

Controller is broken

72-1 Steering angle sensor abnormal Steer knob is not in position Connector is faulty

72-2 Connector cable is damaged

72-3 Sensor is faulty

72-4 Controller is faulty

73-1 Abnormal solenoid knob position Steer knob out of position Connector is faulty

Broken connector cable

Controller is broken

74-1 Measuring value of matching tire angle Steer knob is not in position Matching value

wheel alignment error no in accordance

A5-1 Seat switch abnormal Drive & hydraulic system can operate Connector is faulty

even if the operator is not sitting in the operating chair The connector cable is damaged

Controller is broken

A7-1 Abnormal brake switch Function of partially restricted drive control Connector is faulty

Broken brake switch

Broken connector cable

Controller is broken

AF-1

AF-2

AF-3

AF-4

AF-5

AF-6

AF-7

AF-8 CPU abnormal All control functions are unstable Controller is faulty

C7-1 Shift lever switch abnormal Cannot be positioned to neutral Connector is faulty

C7-2 Drive control function is partially restricted Forward switch is faulty

Reverse switch is broken

Faulty switch installation

Controller is broken

CA-1 Forward-reverse travel Torque Drive system and hydraulic system can Connector damaged

converter relay abnormal is operated even when operator is not seated Forward travel cable

the relay operator seat is broken

Forward travel relay

reverse travel cable

Reverse travel relay

Controller is broken

EC-1 Unload solenoid abnormal Drive system and hydraulic system can Connector is faulty

operated even if the operator is not seated Connector cable is damaged

in operator seat Unload solenoid is broken

Controller is broken

F1-1 Combination meter abnormal Problem on the display Connector is damaged

F1-2 Hour meter cable is damaged

Hour meter is broken

Controller is broken

F4-1~8 CPU error CPU abnormal Multi-function board

H1-1 Lift lever potentiometer abnormal Lift cannot operate Connectro is faulty

H1-2 The potentiometer wire is damaged

H1-3 Potentiometer is broken

H1-4 Controller is broken

H1-5 Fuse blown

H2-1 Tilt lever potentiometer abnormal Tilt does not operate Connectro is faulty

H2-2 The potentiometer wire is damaged

H2-3 Potentiometer is broken

H2-4 Controller is broken

H2-5 Fuse blown

H3-1 Attachment 1 lever potentiometer Attachment 1 does not operate Connectro is faulty

H3-2 abnormal Potentiometer cable is damaged

H3-3 The potentiometer is faulty

H3-4 Controller is broken

H3-5 Fuse blown

H4-1 Attachment 2 lever potentiometer Attachment 2 does not operate Connectro is damaged

H4-2 abnormal Potentiometer cable is damaged

H4-3 The potentiometer is faulty

H4-4 Controller is broken

H4-5 Fuse blown

H5-1 Lift solenoid abnormal Elevator may not operate Faulty connector

H5-2 Elevator cable (PUSH) is damaged

Solenoid lift (PUSH) is broken

Elevator cable (PULL) is broken

Solenoid lift (PULL) is broken

Controller is broken

H6-1 Solenoid Tilt Abnormal Tilt may not operate Connector is faulty

H6-2 Faulty tilt (PUSH) cable

Solenoid tilt (PUSH) faulty

Broken tilt (PULL) cable

Solenoid tilt (PULL) faulty

Controller is broken

H7-1 Attachment 1 abnormal solenoid Attachment 1 may not work Connector is damaged

H7-2 operating Att 1 (PUSH) cable is faulty

Solenoid Att 1 (PUSH) is faulty

Att 1 (PULL) cable is damaged

Solenoid Att 1 (PULL) is faulty

Controller is broken

Solenoid Att 2 (PUSH) is faulty

Att 2 (PULL) cable is damaged

Solenoid Att 2 (PULL) is faulty

Controller is broken

HA-1 3/4-way change relay abnormal Attachment transfer is not possible Connector is damaged

operating Relay cable 1 is damaged

Relay 1 is broken

Relay cable 2 is damaged

Relay 2 is broken

Controller is broken

Error mode Symptoms on forklift Possible causes

broken WARNING LIST

IF THE WRENCH LAMP IS ON AND WITH THESE SYMPTOMS BELOW ON

владимир (Monday, 21 March 2022 05:06)

ERROR 107 вилочный погрузчик HANGCNA

Kasco (Wednesday, 09 March 2022 12:10)

Error code C5-5 not moving

si (Monday, 02 August 2021 18:42)

Omar orduno (Sunday, 13 June 2021 22:45)

montacargas eléctrico Toyota modelo 7fcu15 presenta error c3-1

nam (Friday, 11 June 2021 11:18)

toyota 7fbrs 15 error code f5-1 , f5-4

Ravindu Bandara (Tuesday, 08 June 2021 08:15)

What is the meaning of E 59-1 error code in GENEO 35

zoltan (Tuesday, 16 March 2021 09:41)

1C-2 code 52-8FDF25 (1ZS engine)

Anybody knows this code?

de Vries (Wednesday, 24 February 2021 19:51)

Mijn toyota traico heeft foutcode 73 wat houdt dat in?

Joel (Friday, 13 November 2020 23:05)

Just serviced 7 series 7fbcu30 and need to reset the maintenance timer

Joel (Friday, 13 November 2020 23:02)

How to reset maintenance hours reminder

Armando garrido (Wednesday, 23 September 2020 21:14)

Ole (Monday, 21 September 2020 08:30)

does anyone know the error code «joy M not connected»

Robert Sieow (Tuesday, 28 July 2020 16:22)

Gustavo D (Tuesday, 14 April 2020 16:01)

I have a Toyota diesel forklift model 8FDU20 a code came up on the display (E AD 1) the machine won’t start. I checked many different connectors and sensors but nothing seemed wrong.

I need some fresh ideas from someone smart, please help!

Jose (Thursday, 30 January 2020 21:49)

Tengo un equipo Toyota 8fdu30 serie 60532 me da código 11-5 y deja de caminar hacia el frente

manish chauhan (Wednesday, 29 January 2020 17:27)

it is most usebal document

JIM K (Monday, 27 January 2020 13:07)

Working on a Hyster ROES30 order picker which has a code A5 31 on display board in the lower part of the compartment, NEED HELP

Josh Gering (Tuesday, 21 January 2020 23:26)

Code 72-4 Steering angle sensor.

Lift does not have said sensor. How do I remove/disable this parameter? Everything working fine, but lift won’t quit alarming. Customer getting irritated.

kwan (Tuesday, 05 November 2019 15:59)

Rick (Wednesday, 07 August 2019 21:33)

I have a toyota Electric Fork lift That has had some serious problems as I had to get into it pretty deep to find out why when the owners guys turned on the key nothing powered up? Im not a class A electric fork lift technician but I know enough about electrical that I chased down a Five pin plug that was all melted together and shorted out I removed burnt socket and replaced the burnt wires and got power back to the ignition and truck I got it so it powers the hoist and power steering but have do final drive forward or reverse I have a wrench and a Code A 8 I did see another electrical socket that looked burnt pretty badly I didnt play with it but I’m thinking I’m probably going to have to cut that socket out and clean wires back and reconnect them together to get the drive motor to start so the fork truck can move back and forth! I’m trying to find out what the A 8 code is and the proper way to reset the computer to remove the wrench symbol and clear all codes. Thank you for your time, Rickey

Kevin Stahl (Wednesday, 29 May 2019 19:18)

Please could you email me the code sheet of a Toyota electric forklift Model number 5FBE15

Pepo (Wednesday, 15 May 2019 22:07)

I’ve been fighting with this code h5-1

Robert Shamonski (Monday, 22 April 2019 20:45)

EA5-1 trying to identify code

Jose Sanchez (Monday, 15 April 2019 17:58)

I have a forklift 3 wheel sit down model number 7FBEU15 and a code pops up that is AD6 and AD5 if you can help me what those code mean I’ll appreciate it

Sammy G. Polinar (Thursday, 04 April 2019 09:13)

Please provide me the Electrical Diagram of Toyota Electric Fork Lift Model: 7FBE20.

My Fork Lift is stop due to Electrical Problem

If you are the copyright holder of a user manual, please contact us by mail and we will remove it from the site and leave a link to your store if there is one.

Читайте также:

- Электрическая схема ваз 2104 инжектор с описанием

- Схема предохранителей тойота матрикс 2003

- C1142 ошибка форд фокус 2

- Схема вакуумных трубок мерседес 123

- Заднее правое сиденье не зафиксировано bmw x7 ошибка

- Главная

- О нас

- Вопрос-ответ

- Подскажите, пожалуйста, что может быть. Панель светится, а на органы управления не реагирует. У нас используется вилочный погрузчик модели TCM FB25-8V. Отображает много ошибок. Что может быть?

День добрый! Внимательно посмотрите на список ошибок. Их расшифровки имеются в описании, которое можно скачать с нашего сайта. Если не сможете разобраться, то обращайтесь к специалистам СПЕЦТЕХНИКА Великан в Москве.

Copyright © 2023 www.tcm-russia.ru