Error 0 – STATUS_OK

All Good, This is an error code suggesting that there is NO error

Error 1 – STATUS_EXPECTED_COMMAND_LETTER

Gcodes should start with a Letter, what ever was just sent to GRBL did not

Error 2 – STATUS_BAD_NUMBER_FORMAT

The number part of the Gcode was invalid

Error 3 – STATUS_INVALID_STATEMENT

Usualy a bad GRBL Specific $ instruction

Error 4 – STATUS_NEGATIVE_VALUE

Negative value received for an expected positive value.

Error 5 – STATUS_SETTING_DISABLED

A call to a disabled function was issued – EG you issued $H for homing but your $20 (homing enable) parameter is set to 0 (off)

Error 6 – STATUS_SETTING_STEP_PULSE_MIN

Your $0 (step pulse time) is to short, set it back to its default value, $0=10

Error 7 – STATUS_SETTING_READ_FAIL

Corrupt EEPROM values, you will need to reconfigure all your $ values as they have been reset to default – this time once you have worked them all out, make a copy! This is a rare error.

Error 8 – STATUS_IDLE_ERROR

You have issued a command only allowed when the machine active state is Idle. Example you sent $$ while the Active state was run (job was in progress)

Error 9 – STATUS_SYSTEM_GC_LOCK

machine is locked in error of some sort, and you tried to issue a movement command. Did you forget to $X the machine? Or is it sitting on a Limit Switch?

Error 10 – STATUS_SOFT_LIMIT_ERROR

You will see this if you try to enable soft limits without also enabling homing cycle. Soft limits cannot work unless you first home the machine so it knows where it is!

Error 11 – STATUS_OVERFLOW

GRBL has a max number of charactors it will accept in one command, it received on that was too long – often happens when CAM software puts long comments in file

Error 12 – STATUS_MAX_STEP_RATE_EXCEEDED

You tried to set a Step rate that was too high, look at your $110, $111,$112 values!

Error 13 – STATUS_CHECK_DOOR

You have the safety door funtion turned on and it is showing not closed…close it

Error 14 – STATUS_LINE_LENGTH_EXCEEDED

You should not see this error and if you do you should know what it means!

Error 15 – STATUS_TRAVEL_EXCEEDED

You have got soft limits turned on and configured, and the job your trying to run is larger than you have told grbl that your machine actualy is. Either fix your soft limit values and if they are correct, look at why your cam setup is trying to use more space than you actually have.

Error 16 – STATUS_INVALID_JOG_COMMAND

Jogging command issued was not valid, possibly forgot the =… part

Error 17 – STATUS_SETTING_DISABLED_LASER

Probrably happened when you turned on $32 wthout enableing PWM – We don’t know a lot about this error – email us if you work it out and we can add it to this list

Error 20 – STATUS_GCODE_UNSUPPORTED_COMMAND

Unsupported or invalid g-code command found in block.

Error 21 – STATUS_GCODE_MODAL_GROUP_VIOLATION

Read: http://linuxcnc.org/docs/html/gcode/overview.html#_modal_groups

Error 22 – STATUS_GCODE_UNDEFINED_FEED_RATE

You cannot issue a movement if no feed rate has been set – so issue something like F1000 (feed at 1000mm/min) before sending a movement command. You will likely only see this error when bashing stuff into the command prompt and not when using a gui

Error 23 – STATUS_GCODE_COMMAND_VALUE_NOT_INTEGER

Look into the command you sent, did it include a non integer value?

Error 24 – STATUS_GCODE_AXIS_COMMAND_CONFLICT

Two G-code commands that both require the use of the XYZ axis words were detected in the block.

Error 25 – STATUS_GCODE_WORD_REPEATED

A G-code word was repeated in the block.

Error 26 – STATUS_GCODE_NO_AXIS_WORDS

A G-code command implicitly or explicitly requires XYZ axis words in the block, but none were detected.

Error 27 – STATUS_GCODE_INVALID_LINE_NUMBER

N line number value is not within the valid range of 1 – 9,999,999 – why not turn off line numbers in your CAM software

Error 28 – STATUS_GCODE_VALUE_WORD_MISSING

A G-code command was sent, but is missing some required P or L value words in the line.

Error 29 – STATUS_GCODE_UNSUPPORTED_COORD_SYS

Grbl supports six work coordinate systems G54-G59. G59.1, G59.2, and G59.3 are not supported.

Error 30 – STATUS_GCODE_G53_INVALID_MOTION_MODE

The G53 G-code command requires either a G0 seek or G1 feed motion mode to be active. A different motion was active.

Error 31 – STATUS_GCODE_AXIS_WORDS_EXIST

There are unused axis words in the block and G80 motion mode cancel is active.

Error 32 – STATUS_GCODE_NO_AXIS_WORDS_IN_PLANE

A G2 or G3 arc was commanded but there are no XYZ axis words in the selected plane to trace the arc.

Error 33 – STATUS_GCODE_INVALID_TARGET

The motion command has an invalid target. G2, G3, and G38.2 generates this error, if the arc is impossible to generate or if the probe target is the current position.

Error 34 – STATUS_GCODE_ARC_RADIUS_ERROR

A G2 or G3 arc, traced with the radius definition, had a mathematical error when computing the arc geometry. Try either breaking up the arc into semi-circles or quadrants, or redefine them with the arc offset definition.

Error 35 – STATUS_GCODE_NO_OFFSETS_IN_PLANE

A G2 or G3 arc, traced with the offset definition, is missing the IJK offset word in the selected plane to trace the arc.

Error 36 – STATUS_GCODE_UNUSED_WORDS

There are unused, leftover G-code words that aren’t used by any command in the block.

Error 37 – STATUS_GCODE_G43_DYNAMIC_AXIS_ERROR

The G43.1 dynamic tool length offset command cannot apply an offset to an axis other than its configured axis. The Grbl default axis is the Z-axis.

Error 38 – STATUS_GCODE_MAX_VALUE_EXCEEDED

You sent a number higher than expected, maybe for a tool change you tried to select tool 50000 or something?

ALARM 1 – EXEC_ALARM_HARD_LIMIT

Hard Limit Error, A limit switch was triggered, this always results in the end of your job. The only time a limit switch should be hit is during a homing cycle, at any other time it will stop the system. Either your machine went to far in one direction and hit a switch or you have electrical noise getting into your limit switch wiring. Do not restart your jhob without rehoming or resetting / confirming the machines position, it will unliely be correct still!

ALARM 2 – EXEC_ALARM_SOFT_LIMIT

Soft Limit Error, Either you or a Gcode file tried to send some axis past further than you have suggested it can in your $130, $131 ,$132 parameters

ALARM 3 – EXEC_ALARM_ABORT_CYCLE

The Estop was hit! Same as a hard limit, just a different button – look at details above for Alarm 1

ALARM 4 – EXEC_ALARM_PROBE_FAIL_INITIAL

Grbl was expecting your probe to be in a state other than that it is before starting a probing cycle – ie your tool is already touching the probe or similar

ALARM 5 – EXEC_ALARM_PROBE_FAIL_CONTACT

Z axis was sent down as far as it dared (instructed) and did not hit a switch. Instead of digging to china it assumes you forgot to put an aligator clip on or that something else is wrong and so stops.

ALARM 6 – EXEC_ALARM_HOMING_FAIL_RESET

Reset was issued during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment if your estop button is connected to the Abort pin and not to the reset pin that is

ALARM 7 – EXEC_ALARM_HOMING_FAIL_DOOR

Safety door was opened during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment

ALARM 8 – EXEC_ALARM_HOMING_FAIL_PULLOFF

Grbl tries to pull back of a switch and hit it a second time (slowly) during a homing cycle. Your Homing Pulloff value was not sufficient to enable the axis to move far enough away from the switch. Increase $27 to maybe 3 or 5mm – $27=5.000

ALARM 9 – EXEC_ALARM_HOMING_FAIL_APPROACH

When homing, grbl will not travel further than the values in parameters $130, $131 ,$132 while trying to locate a limit switch. So even if your soft limits are off, make sure these values are correct or larger than your machine. Homing fail. Could not find limit switch within search distance. Defined as 1.5 * max_travel on search and 5 * pulloff on locate phases.”

Hold 0 – Hold complete. Ready to resume

Hold 1 – Hold in-progress. Reset will throw an alarm

Door 0 – Door closed. Ready to resume.

Door 1 – Machine stopped. Door still ajar. Can’t resume until closed.

Door 2 – Door opened. Hold (or parking retract) in-progress. Reset will throw an alarm.

Door 3 – Door closed and resuming. Restoring from park, if applicable. Reset will throw an alarm.

Alex1969

- Регистрация

- 27.03.2019

- Сообщения

- 24

- Реакции

- 10

- Баллы

- 23

- Город

-

Минск

- Имя

-

Александр

-

#1

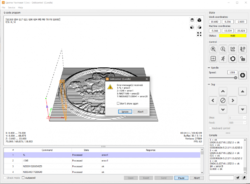

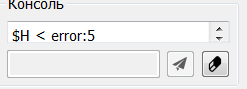

Здравствуйте. Пока с Китая идет новый лазер, решил освоить данную программу. Но вот незадача, стали появляться ошибки. Описание их найти не могу. Первое, при запуске кода на выполнение выскакивает такое окно как в приложенном файле. После нажатия Ignore, процесс идет нормально. Далее, не пойму что с кнопками управления. Выставляю нулевые позиции кнопками, потом смещаю позицию гравера и при нажатии кнопки «Домой» опять вылазит ошибка — $H < error:5 S1000 < ok. Помогите, пожалуйста разобраться в данном вопросе.

-

kontrol.png

394 KB

· Просмотры: 313

Андрей

- Регистрация

- 08.05.2018

- Сообщения

- 8 416

- Реакции

- 8 151

- Баллы

- 350

- Адрес

-

Россия

- Веб-сайт

- www.cnc3018.ru

- Город

-

Санкт-Петербург

- Станок

-

CNC3018

- Плата

-

3.2

- Прошивка

-

1.1f

-

#2

Alex1969, скажите, а Вы в чем создаете УП ?

Какой постпроцессор используете?

Alex1969

- Регистрация

- 27.03.2019

- Сообщения

- 24

- Реакции

- 10

- Баллы

- 23

- Город

-

Минск

- Имя

-

Александр

-

#3

Использую Autodesk ArtCAM Premium 2018. Вчера сделал одно изображение, все получилось. И черновая и пробные на одном и том же рисунке 3 чистовых разными фрезами. А сегодня… 3 фрезы сломал. Один раз воспользовался кнопкой Z-probe и не нашел чем аварийно остановить… И после этого станок пытался рыть глубже уровня который я ему указал… Пока не отключил от компьютера. Больше ничем не пользовался. Просто не могу найти какого-либо мануала в одном месте и о том как готовить коды, назначение кнопок программы, настройка ее и ошибки как распознать.

Андрей

- Регистрация

- 08.05.2018

- Сообщения

- 8 416

- Реакции

- 8 151

- Баллы

- 350

- Адрес

-

Россия

- Веб-сайт

- www.cnc3018.ru

- Город

-

Санкт-Петербург

- Станок

-

CNC3018

- Плата

-

3.2

- Прошивка

-

1.1f

-

#4

Alex1969, здрасьте!!! Приехали!

У нас в ресурсах полно документации по поводу АртКама

А еще если использовать наш постпроцессор (тоже в ресурсах есть)

То ошибок таких не будет.

Добавьте себе вот этот

ПОСТПРОЦЕССОР >>

Вот Вам ИНСТРУКЦИЯ НА РУССКОМ ЯЗЫКЕ >>

Alex1969

- Регистрация

- 27.03.2019

- Сообщения

- 24

- Реакции

- 10

- Баллы

- 23

- Город

-

Минск

- Имя

-

Александр

-

#5

Спасибо большое. Многое можно узнать пообщавшись с умными людьми. Попробовал так проделать как описано в первой ссылке программа ArtCam выдала ошибку.

Ваши сообщения автоматически объединены: 16.04.2019

Инструкцию я имел в виду к grblControl…

-

Error.png

562.7 KB

· Просмотры: 306

Alex1969

- Регистрация

- 27.03.2019

- Сообщения

- 24

- Реакции

- 10

- Баллы

- 23

- Город

-

Минск

- Имя

-

Александр

-

#6

И как теперь быть? Получается данный постпроцессор не принимает ArtCam?

Андрей

- Регистрация

- 08.05.2018

- Сообщения

- 8 416

- Реакции

- 8 151

- Баллы

- 350

- Адрес

-

Россия

- Веб-сайт

- www.cnc3018.ru

- Город

-

Санкт-Петербург

- Станок

-

CNC3018

- Плата

-

3.2

- Прошивка

-

1.1f

-

#7

Инструкцию я имел в виду к grblControl…

Простите, но что там инструктировать ? Там две с половиной кнопки.

Ну может как-нибудь кто-то сделает инструкцию, но я смысла большого не вижу.

И как теперь быть? Получается данный постпроцессор не принимает ArtCam?

Вы про какой постпроцессор говорите?

Я не вижу на Вашем скриншоте что там не так

И у нас работает постпроцессор нормально.

Можно пояснить что не работает и главное что делали и чего не делали?

number1

- Регистрация

- 29.12.2018

- Сообщения

- 115

- Реакции

- 163

- Баллы

- 63

- Имя

-

CNC 3018 Pro

- Плата

-

WP 3.2A

- Прошивка

-

Grbl 1.1f

-

#8

Alex1969, уважаемый, для начала необходимо разархивировать Custom_mm.zip

Alex1969

- Регистрация

- 27.03.2019

- Сообщения

- 24

- Реакции

- 10

- Баллы

- 23

- Город

-

Минск

- Имя

-

Александр

-

17.04.2019

-

Последнее редактирование: 17.04.2019

-

#9

Последнее редактирование: 17.04.2019

Я по ссылке прочел фразу: «У данного файла переименуйте расширение в формат .con и скопируйте его по пути:

Program FilesArtCAM 2012postp»

Так и выполнил. Про разархивацию ни слова. Я думал просто форум не позволяет выкладывать файлы с подобными расширениями. Хорошо, попробую.

Простите, но что там инструктировать ? Там две с половиной кнопки.

Ну может как-нибудь кто-то сделает инструкцию, но я смысла большого не вижу.

Да, но просто у меня они не работают адекватно, кроме обнуления позиции. Не работает, например, кнопка «Домой» и некоторые другие. Я не знаю почему, вот и хотел разобраться.

Ваши сообщения автоматически объединены: 17.04.2019

В общем там нужно заменить фразу «У данного файла переименуйте расширение в формат » в «Распакуйте данный архив и полученный файл…». Все получилось. Спасибо!

Вопрос по кнопкам с изображением человечка, домика, ресет и унлок. Смысл понимаю, но ничего не происходит при их нажатии.

Дым506

- Регистрация

- 16.12.2019

- Сообщения

- 112

- Реакции

- 62

- Баллы

- 48

- Город

-

Россия

-

16.12.2019

-

Последнее редактирование: 16.12.2019

-

#10

Последнее редактирование: 16.12.2019

$H<ERROR:5 тоже такая ошибка

вот , постпроцессор исправит ?

Ваши сообщения автоматически объединены: 16.12.2019

установил постпроцессор не помогло , нажимаю кнопку дом и опять таже ошибка

-

Снимок.PNG

2.7 KB

· Просмотры: 140

extrimus

- Регистрация

- 29.03.2019

- Сообщения

- 5 902

- Реакции

- 5 250

- Баллы

- 250

- Возраст

- 56

- Адрес

-

Россия

- Город

-

Иваново

- Имя

-

Андрей

- Плата

-

Woodpecker 3.2

- Прошивка

-

GBRL 1.1f

-

16.12.2019

-

Последнее редактирование: 16.12.2019

-

#11

Последнее редактирование: 16.12.2019

$H<ERROR:5 тоже такая ошибка

вот , постпроцессор исправит ?

Ваши сообщения автоматически объединены: 16.12.2019

установил постпроцессор не помогло , нажимаю кнопку дом и опять таже ошибка

Постпроцессор в поиске дома никакой роли не играет. Концевики-то у вас стоят? Параметр $22 активирован?

Дым506

- Регистрация

- 16.12.2019

- Сообщения

- 112

- Реакции

- 62

- Баллы

- 48

- Город

-

Россия

-

#12

концевиков нет , $22=0 ,

Ваши сообщения автоматически объединены: 16.12.2019

вообще для чего эта кнопка дом , извените конечно я есчо в чпу совсем балбес

extrimus

- Регистрация

- 29.03.2019

- Сообщения

- 5 902

- Реакции

- 5 250

- Баллы

- 250

- Возраст

- 56

- Адрес

-

Россия

- Город

-

Иваново

- Имя

-

Андрей

- Плата

-

Woodpecker 3.2

- Прошивка

-

GBRL 1.1f

-

#13

Ну и что вы тогда хотите? Поиск дома работает только при наличии концевиков.

extrimus

- Регистрация

- 29.03.2019

- Сообщения

- 5 902

- Реакции

- 5 250

- Баллы

- 250

- Возраст

- 56

- Адрес

-

Россия

- Город

-

Иваново

- Имя

-

Андрей

- Плата

-

Woodpecker 3.2

- Прошивка

-

GBRL 1.1f

-

#14

вообще для чего эта кнопка дом , извените конечно я есчо в чпу совсем балбес

Чтоб станок «знал» свои начальные координаты.

Вам бы, прежде чем включать станок, азы для начала изучить: https://cnc3018.ru/ewr-carta/

denbar

- Регистрация

- 29.02.2020

- Сообщения

- 28

- Реакции

- 10

- Баллы

- 23

- Город

-

Волгоград

- Имя

-

Денис

-

#15

Кто подскажет что за ошибка error 1 , а после сразу error 22

Grbl 1.1f

ERRORs

ERROR 0 – STATUS_OK All Good, This is an error code suggesting that there is NO error

ERROR 1 – STATUS_EXPECTED_COMMAND_LETTER Gcodes should start with a Letter, what ever was just sent to GRBL did not

ERROR 2 – STATUS_BAD_NUMBER_FORMAT The number part of the Gcode was invalid

ERROR 3 – STATUS_INVALID_STATEMENT Usualy a bad GRBL Specific $ instruction

ERROR 4 – STATUS_NEGATIVE_VALUE Negative value received for an expected positive value.

ERROR 5 – STATUS_SETTING_DISABLED A call to a disabled function was issued – EG you issued $H for homing but your $20 (homing enable) parameter is set to 0 (off)

ERROR 6 – STATUS_SETTING_STEP_PULSE_MIN Your $0 (step pulse time) is to short, set it back to its default value, $0=10

ERROR 7 – STATUS_SETTING_READ_FAIL Corrupt EEPROM values, you will need to reconfigure all your $ values as they have been reset to default – this time once you have worked them all out, make a copy! This is a rare error.

ERROR 8 – STATUS_IDLE_ERROR You have issued a command only allowed when the machine active state is Idle. Example you sent $$ while the Active state was run (job was in progress)

ERROR 9 – STATUS_SYSTEM_GC_LOCK machine is locked in error of some sort, and you tried to issue a movement command. Did you forget to $X the machine? Or is it sitting on a Limit Switch?

ERROR 10 – STATUS_SOFT_LIMIT_ERROR You will see this if you try to enable soft limits without also enabling homing cycle. Soft limits cannot work unless you first home the machine so it knows where it is!

ERROR 11 – STATUS_OVERFLOW GRBL has a max number of charactors it will accept in one command, it received on that was too long – often happens when CAM software puts long comments in file

ERROR 12 – STATUS_MAX_STEP_RATE_EXCEEDED You tried to set a Step rate that was too high, look at your $110, $111,$112 values! ERROR 13 – STATUS_CHECK_DOOR You have the safety door funtion turned on and it is showing not closed…close it

ERROR 14 – STATUS_LINE_LENGTH_EXCEEDED You should not see this error and if you do you should know what it means!

ERROR 15 – STATUS_TRAVEL_EXCEEDED You have got soft limits turned on and configured, and the job your trying to run is larger than you have told grbl that your machine actualy is. Either fix your soft limit values and if they are correct, look at why your cam setup is trying to use more space than you actually have.

ERROR 16 – STATUS_INVALID_JOG_COMMAND Jogging command issued was not valid, possibly forgot the =… part

ERROR 17 – STATUS_SETTING_DISABLED_LASER Probrably happened when you turned on $32 wthout enableing PWM – We don’t know a lot about this error – email us if you work it out and we can add it to this list

ERROR 20 – STATUS_GCODE_UNSUPPORTED_COMMAND Unsupported or invalid g-code command found in block.

ERROR 21 – STATUS_GCODE_MODAL_GROUP_VIOLATION Read: http://linuxcnc.org/docs/html/gcode/overview.html#_modal_groups

ERROR 22 – STATUS_GCODE_UNDEFINED_FEED_RATE You cannot issue a movement if no feed rate has been set – so issue something like F1000 (feed at 1000mm/min) before sending a movement command. You will likely only see this error when bashing stuff into the command prompt and not when using a gui

ERROR 23 – STATUS_GCODE_COMMAND_VALUE_NOT_INTEGER Look into the command you sent, did it include a non integer value?

ERROR 24 – STATUS_GCODE_AXIS_COMMAND_CONFLICT Two G-code commands that both require the use of the XYZ axis words were detected in the block.

ERROR 25 – STATUS_GCODE_WORD_REPEATED A G-code word was repeated in the block.

ERROR 26 – STATUS_GCODE_NO_AXIS_WORDS A G-code command implicitly or explicitly requires XYZ axis words in the block, but none were detected.

ERROR 27 – STATUS_GCODE_INVALID_LINE_NUMBER N line number value is not within the valid range of 1 – 9,999,999 – why not turn off line numbers in your CAM software

ERROR 28 – STATUS_GCODE_VALUE_WORD_MISSING A G-code command was sent, but is missing some required P or L value words in the line.

ERROR 29 – STATUS_GCODE_UNSUPPORTED_COORD_SYS Grbl supports six work coordinate systems G54-G59. G59.1, G59.2, and G59.3 are not supported.

ERROR 30 – STATUS_GCODE_G53_INVALID_MOTION_MODE The G53 G-code command requires either a G0 seek or G1 feed motion mode to be active. A different motion was active.

ERROR 31 – STATUS_GCODE_AXIS_WORDS_EXIST There are unused axis words in the block and G80 motion mode cancel is active.

ERROR 32 – STATUS_GCODE_NO_AXIS_WORDS_IN_PLANE A G2 or G3 arc was commanded but there are no XYZ axis words in the selected plane to trace the arc.

ERROR 33 – STATUS_GCODE_INVALID_TARGET The motion command has an invalid target. G2, G3, and G38.2 generates this error, if the arc is impossible to generate or if the probe target is the current position.

ERROR 34 – STATUS_GCODE_ARC_RADIUS_ERROR A G2 or G3 arc, traced with the radius definition, had a mathematical error when computing the arc geometry. Try either breaking up the arc into semi-circles or quadrants, or redefine them with the arc offset definition.

ERROR 35 – STATUS_GCODE_NO_OFFSETS_IN_PLANE A G2 or G3 arc, traced with the offset definition, is missing the IJK offset word in the selected plane to trace the arc.

ERROR 36 – STATUS_GCODE_UNUSED_WORDS There are unused, leftover G-code words that aren’t used by any command in the block.

ERROR 37 – STATUS_GCODE_G43_DYNAMIC_AXIS_ERROR The G43.1 dynamic tool length offset command cannot apply an offset to an axis other than its configured axis. The Grbl default axis is the Z-axis.

ERROR 38 – STATUS_GCODE_MAX_VALUE_EXCEEDED You sent a number higher than expected, maybe for a tool change you tried to select tool 50000 or something?

ALARMs

ALARM 1 – EXEC_ALARM_HARD_LIMIT Hard Limit Error, A limit switch was triggered, this always results in the end of your job. The only time a limit switch should be hit is during a homing cycle, at any other time it will stop the system. Either your machine went to far in one direction and hit a switch or you have electrical noise getting into your limit switch wiring. Do not restart your jhob without rehoming or resetting / confirming the machines position, it will unliely be correct still!

ALARM 2 – EXEC_ALARM_SOFT_LIMIT Soft Limit Error, Either you or a Gcode file tried to send some axis past further than you have suggested it can in your $130, $131 ,$132 parameters

ALARM 3 – EXEC_ALARM_ABORT_CYCLE The Estop was hit! Same as a hard limit, just a different button – look at details above for Alarm 1

ALARM 4 – EXEC_ALARM_PROBE_FAIL_INITIAL Grbl was expecting your probe to be in a state other than that it is before starting a probing cycle – ie your tool is already touching the probe or similar

ALARM 5 – EXEC_ALARM_PROBE_FAIL_CONTACT Z axis was sent down as far as it dared (instructed) and did not hit a switch. Instead of digging to china it assumes you forgot to put an aligator clip on or that something else is wrong and so stops.

ALARM 6 – EXEC_ALARM_HOMING_FAIL_RESET Reset was issued during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment if your estop button is connected to the Abort pin and not to the reset pin that is

ALARM 7 – EXEC_ALARM_HOMING_FAIL_DOOR Safety door was opened during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment

ALARM 8 – EXEC_ALARM_HOMING_FAIL_PULLOFF Grbl tries to pull back of a switch and hit it a second time (slowly) during a homing cycle. Your Homing Pulloff value was not sufficient to enable the axis to move far enough away from the switch. Increase $27 to maybe 3 or 5mm – $27=5.000

ALARM 9 – EXEC_ALARM_HOMING_FAIL_APPROACH When homing, grbl will not travel further than the values in parameters $130, $131 ,$132 while trying to locate a limit switch. So even if your soft limits are off, make sure these values are correct or larger than your machine. Homing fail. Could not find limit switch within search distance. Defined as 1.5 * max_travel on search and 5 * pulloff on locate phases.

Etc.

HOLD 0 – HOLD COMPLETE. READY TO RESUME

HOLD 1 – HOLD IN-PROGRESS. RESET WILL THROW AN ALARM

DOOR 0 – DOOR CLOSED. READY TO RESUME.

DOOR 1 – MACHINE STOPPED. DOOR STILL AJAR. CAN’T RESUME UNTIL CLOSED.

DOOR 2 – DOOR OPENED. HOLD (OR PARKING RETRACT) IN-PROGRESS. RESET WILL THROW AN ALARM.

Permalink

Cannot retrieve contributors at this time

This file contains bidirectional Unicode text that may be interpreted or compiled differently than what appears below. To review, open the file in an editor that reveals hidden Unicode characters.

Learn more about bidirectional Unicode characters

| Error Code in v1.1+ | Error Message in v1.0- | Error Description | |

|---|---|---|---|

| 1 | Expected command letter | G-code words consist of a letter and a value. Letter was not found. | |

| 2 | Bad number format | Missing the expected G-code word value or numeric value format is not valid. | |

| 3 | Invalid statement | Grbl ‘$’ system command was not recognized or supported. | |

| 4 | Value < 0 | Negative value received for an expected positive value. | |

| 5 | Setting disabled | Homing cycle failure. Homing is not enabled via settings. | |

| 6 | Value < 3 usec | Minimum step pulse time must be greater than 3usec. | |

| 7 | EEPROM read fail. Using defaults | An EEPROM read failed. Auto-restoring affected EEPROM to default values. | |

| 8 | Not idle | Grbl ‘$’ command cannot be used unless Grbl is IDLE. Ensures smooth operation during a job. | |

| 9 | G-code lock | G-code commands are locked out during alarm or jog state. | |

| 10 | Homing not enabled | Soft limits cannot be enabled without homing also enabled. | |

| 11 | Line overflow | Max characters per line exceeded. Received command line was not executed. | |

| 12 | Step rate > 30kHz | Grbl ‘$’ setting value cause the step rate to exceed the maximum supported. | |

| 13 | Check Door | Safety door detected as opened and door state initiated. | |

| 14 | Line length exceeded | Build info or startup line exceeded EEPROM line length limit. Line not stored. | |

| 15 | Travel exceeded | Jog target exceeds machine travel. Jog command has been ignored. | |

| 16 | Invalid jog command | Jog command has no ‘=’ or contains prohibited g-code. | |

| 17 | Setting disabled | Laser mode requires PWM output. | |

| 20 | Unsupported command | Unsupported or invalid g-code command found in block. | |

| 21 | Modal group violation | More than one g-code command from same modal group found in block. | |

| 22 | Undefined feed rate | Feed rate has not yet been set or is undefined. | |

| 23 | Invalid gcode ID:23 | G-code command in block requires an integer value. | |

| 24 | Invalid gcode ID:24 | More than one g-code command that requires axis words found in block. | |

| 25 | Invalid gcode ID:25 | Repeated g-code word found in block. | |

| 26 | Invalid gcode ID:26 | No axis words found in block for g-code command or current modal state which requires them. | |

| 27 | Invalid gcode ID:27 | Line number value is invalid. | |

| 28 | Invalid gcode ID:28 | G-code command is missing a required value word. | |

| 29 | Invalid gcode ID:29 | G59.x work coordinate systems are not supported. | |

| 30 | Invalid gcode ID:30 | G53 only allowed with G0 and G1 motion modes. | |

| 31 | Invalid gcode ID:31 | Axis words found in block when no command or current modal state uses them. | |

| 32 | Invalid gcode ID:32 | G2 and G3 arcs require at least one in-plane axis word. | |

| 33 | Invalid gcode ID:33 | Motion command target is invalid. | |

| 34 | Invalid gcode ID:34 | Arc radius value is invalid. | |

| 35 | Invalid gcode ID:35 | G2 and G3 arcs require at least one in-plane offset word. | |

| 36 | Invalid gcode ID:36 | Unused value words found in block. | |

| 37 | Invalid gcode ID:37 | G43.1 dynamic tool length offset is not assigned to configured tool length axis. | |

| 38 | Invalid gcode ID:38 | Tool number greater than max supported value. |

ERROR LIST

“error:1” : _(“G-code words consist of a letter and a value. Letter was not found.”),

“error:2” : _(“Numeric value format is not valid or missing an expected value.”),

“error:3” : _(“Grbl ‘$’ system command was not recognized or supported.”),

“error:4” : _(“Negative value received for an expected positive value.”),

“error:5” : _(“Homing cycle is not enabled via settings.”),

“error:6” : _(“Minimum step pulse time must be greater than 3usec”),

“error:7” : _(“EEPROM read failed. Reset and restored to default values.”),

“error:8” : _(“Grbl ‘$’ command cannot be used unless Grbl is IDLE. Ensures smooth operation during a job.”),

“error:9” : _(“G-code locked out during alarm or jog state”),

“error:10” : _(“Soft limits cannot be enabled without homing also enabled.”),

“error:11” : _(“Max characters per line exceeded. Line was not processed and executed.”),

“error:12” : _(“(Compile Option) Grbl ‘$’ setting value exceeds the maximum step rate supported.”),

“error:13” : _(“Safety door detected as opened and door state initiated.”),

“error:14” : _(“(Grbl-Mega Only) Build info or startup line exceeded EEPROM line length limit.”),

“error:15” : _(“Jog target exceeds machine travel. Command ignored.”),

“error:16” : _(“Jog command with no ‘=’ or contains prohibited g-code.”),

“error:20” : _(“Unsupported or invalid g-code command found in block.”),

“error:21” : _(“More than one g-code command from same modal group found in block.”),

“error:22” : _(“Feed rate has not yet been set or is undefined.”),

“error:23” : _(“G-code command in block requires an integer value.”),

“error:24” : _(“Two G-code commands that both require the use of the XYZ axis words were detected in the block.”),

“error:25” : _(“A G-code word was repeated in the block.”),

“error:26” : _(“A G-code command implicitly or explicitly requires XYZ axis words in the block, but none were detected.”),

“error:27” : _(“N line number value is not within the valid range of 1 – 9,999,999.”),

“error:28” : _(“A G-code command was sent, but is missing some required P or L value words in the line.”),

“error:29” : _(“Grbl supports six work coordinate systems G54-G59. G59.1, G59.2, and G59.3 are not supported.”),

“error:30” : _(“The G53 G-code command requires either a G0 seek or G1 feed motion mode to be active. A different motion was active.”),

“error:31” : _(“There are unused axis words in the block and G80 motion mode cancel is active.”),

“error:32” : _(“A G2 or G3 arc was commanded but there are no XYZ axis words in the selected plane to trace the arc.”),

“error:33” : _(“The motion command has an invalid target. G2, G3, and G38.2 generates this error, if the arc is impossible to generate or if the probe target is the current position.”),

“error:34” : _(“A G2 or G3 arc, traced with the radius definition, had a mathematical error when computing the arc geometry. Try either breaking up the arc into semi-circles or quadrants, or redefine them with the arc offset definition.”),

“error:35” : _(“A G2 or G3 arc, traced with the offset definition, is missing the IJK offset word in the selected plane to trace the arc.”),

“error:36” : _(“There are unused, leftover G-code words that aren’t used by any command in the block.”),

“error:37” : _(“The G43.1 dynamic tool length offset command cannot apply an offset to an axis other than its configured axis. The Grbl default axis is the Z-axis.”),

“error:38” : _(“An invalid tool number sent to the parser”),

“ALARM:1” : _(“Hard limit triggered. Machine position is likely lost due to sudden and immediate halt. Re-homing is highly recommended.”),

“ALARM:2” : _(“G-code motion target exceeds machine travel. Machine position safely retained. Alarm may be unlocked.”),

“ALARM:3” : _(“Reset while in motion. Grbl cannot guarantee position. Lost steps are likely. Re-homing is highly recommended.”),

“ALARM:4” : _(“Probe fail. The probe is not in the expected initial state before starting probe cycle, where G38.2 and G38.3 is not triggered and G38.4 and G38.5 is triggered.”),

“ALARM:5” : _(“Probe fail. Probe did not contact the workpiece within the programmed travel for G38.2 and G38.4.”),

“ALARM:6” : _(“Homing fail. Reset during active homing cycle.”),

“ALARM:7” : _(“Homing fail. Safety door was opened during active homing cycle.”),

“ALARM:8” : _(“Homing fail. Cycle failed to clear limit switch when pulling off. Try increasing pull-off setting or check wiring.”),

“ALARM:9” : _(“Homing fail. Could not find limit switch within search distance. Defined as 1.5 * max_travel on search and 5 * pulloff on locate phases.”),

“Hold:0” : _(“Hold complete. Ready to resume.”),

“Hold:1” : _(“Hold in-progress. Reset will throw an alarm.”),

“Door:0” : _(“Door closed. Ready to resume.”),

“Door:1” : _(“Machine stopped. Door still ajar. Can’t resume until closed.”),

“Door:2” : _(“Door opened. Hold (or parking retract) in-progress. Reset will throw an alarm.”),

“Door:3” : _(“Door closed and resuming. Restoring from park, if applicable. Reset will throw an alarm.”),