Jungheinrich System Error Codes list.pdf

Adobe Acrobat Document

168.2 KB

Jungheinrich Fault Codes.pdf

Adobe Acrobat Document

720.8 KB

Jungheinrich Error Codes List PDF.pdf

Adobe Acrobat Document

191.8 KB

Jungheinrich EJC112 & E1202 Event Messag

Adobe Acrobat Document

582.8 KB

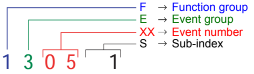

Event Messages

Z This display units shows a four-digit event message for every

event. Trucks that only use one luminous display (e.g. LED) show

the event through a flashing code (see «Display System”).

Each event message is also stored in the master logbook. The

master logbook describes the event in more detail through the sub

index behind the event message (FEXX).

Event numbering display

F E XX S

F Function group; E Event group

XX Event number S Sub index

The first two characters “F, E” refer to the category. The middle

two digits “XX” refer to the event. From these two digits the range:

• 1 to 50 describes standard events (uniform basic events)

which can occur in any function group.

• 51 to 99 describes specific events.

The event is described in further detail through the last characters

“S” (single digit / multi-digit).

This process ensures that a unique number is assigned to each

event. Example:

0 Fault reset or

no fault

1 General fault / additional functions

Example:

Logic error, e.g. both directions selected simultaneously

2 Current

(input interface, device-internal, output interface)

3 Voltage

(input interface, device-internal, output interface)

4 Temperature

5 Hardware

Example: Output transformer short circuit, EEPROM not

responding, …

6 Software

(internal software, application software, data record /

parameters)

Example: EEPROM data error

7 Additional modules

8 CAN monitoring

9 External fault

Example: ISM

Jungheinrich EJE 116:

error code e1504

Hello,

Can some one tell me what the error code e1504 means?

kind regards,

Martin

Showing items 1 — 11 of 11 results.

Sort messages by:

on 2016 and newer ere machines there is a factory fault with brake and motor temp sensor electrical instalation, wires brakes inside connectors due to poor strain relife.

solution is to cut the connector, replace it with new one and leave it without zip ties just floating in free air.

I have same error on Ere 225 , when i tried to diagnose with UMS 100 for jungheinrich it said to check three key switch inputs and wires and if ok ,then replace controller.

same code i had trouble is was giving the control unit , contactors and breake pad was almost gone, it didtn have break.

Most controllers switch using a basic open collector circuit. An internal transistor is switched on by applying a forward biasing signal to the base emitter circuit. When the transistor base is forward biased the transistor is switched on allowing current to flow from the collector across the junction to the emitter and to ground or battery negative, usually through a current limiting resistor.

Now as the transistor is switching an inductive load it will experience high back emf which depending on the loads inductance and speed of switching can destroy the transistor (e=-Ldi/dt) hence a freewheel diode is placed in parallel to the inductive load to prevent the transistor seeing this high voltage. The most common failure mode is for the diode to fail which in turn causes the transistor to fail.

So identify the switching transistor on the board, test and if faulty replace it AND the freewheel diode, otherwise it WILL fail again

well you can always try what is suggested by little forker and put the brake unit on another machine and see if it works.

Or you can apply signal voltage to it and usually you can hear it clicking in (actuating) for releasing.

when you removed the cover did you notice anything about the standoff’s where the power cables hook to it? they should be fixed in a solid position, not loose. If any of them are loose then the controller will have to he replaced.

Do you have another truck that you could try the brake unit on?

I have never had a faulty controller give out this fault code before

I removed the cover off the controler.

all the connectors inside the controler are ok.

There’s nothing inside what looks bad.

i think the best option is replace the controler but thats verry expensive…….

thanks for the support sofar

yes

no load you will have a + volt signal

when load you will see 0v

pretty much any control these days uses negative switching so generally you will see a + voltage when no load.

reading these codes are not like most codes

they are broken down into segments

E designates it as an event code

1 designates the function group which is ‘travel’

5 designates the event group which is ‘hardware’

04 designates the event number which is an output error in phase of V and W phase of transformer.

manual recommends replacement of controller.

now in some cases you can remove the cover of the controller and access the internal circuit boards and there should be ribbon cables connecting them together, i have seen these vibrate loose and cause errors such as this. Caterpillars fix was to clean, reinsert the connectors and apply silicone sealer to hold them in place.

Also i have seen tech’s overtorque the cables and actually break the standoff loose from the heatsink inside the controller, if this is the case there is no fix for this and the controller has to be replaced.

good luck, hope this helps

When i measure the ouput without the brake it gaves 13,5 volt

when i connect the brake i measure 0,2 volt

is that right?

Check the brake connection under load. connection may seem okay but fails on start up. The brake is controlled from the micropulse but unlikely for it to be throwing up this code

i checked the brake and it works ok

also the wires to the brakes are good

do you have other sugestions?

Check the connection to the magnetic brake on the drive motor, if that is okay them check the brake itself

Having trouble using the Discussion Forums? Contact us for help.

Forkliftaction.com accepts no responsibility for forum content and requires forum participants to adhere to the rules. Click here for more information.

Jungheinrich System Error Codes list.pdf

Adobe Acrobat Document

168.2 KB

Jungheinrich Fault Codes.pdf

Adobe Acrobat Document

720.8 KB

Jungheinrich Error Codes List PDF.pdf

Adobe Acrobat Document

191.8 KB

Jungheinrich EJC112 & E1202 Event Messag

Adobe Acrobat Document

582.8 KB

Event Messages

Z This display units shows a four-digit event message for every

event. Trucks that only use one luminous display (e.g. LED) show

the event through a flashing code (see «Display System”).

Each event message is also stored in the master logbook. The

master logbook describes the event in more detail through the sub

index behind the event message (FEXX).

Event numbering display

F E XX S

F Function group; E Event group

XX Event number S Sub index

The first two characters “F, E” refer to the category. The middle

two digits “XX” refer to the event. From these two digits the range:

• 1 to 50 describes standard events (uniform basic events)

which can occur in any function group.

• 51 to 99 describes specific events.

The event is described in further detail through the last characters

“S” (single digit / multi-digit).

This process ensures that a unique number is assigned to each

event. Example:

0 Fault reset or

no fault

1 General fault / additional functions

Example:

Logic error, e.g. both directions selected simultaneously

2 Current

(input interface, device-internal, output interface)

3 Voltage

(input interface, device-internal, output interface)

4 Temperature

5 Hardware

Example: Output transformer short circuit, EEPROM not

responding, …

6 Software

(internal software, application software, data record /

parameters)

Example: EEPROM data error

7 Additional modules

8 CAN monitoring

9 External fault

Example: ISM

6.4

Fault

Truck

does not

move

Load

cannot be

lifted

Z

If the fault could not be eliminated after performing the «Remedial actions» contact the

customer service of the manufacturer since all follow-up troubleshooting can only be

performed by specially trained and qualified service staff.

E 22

Possible cause

– Battery connector not con-

nected.

– Key switch in position «0».

– Incorrect CANCODE code

– Battery exhausted.

– Fuse defective.

– Truck is being charged

– Battery capacity below

20 / 40%

– Truck not operative.

– Hydraulic oil level too low.

– Fuse defective.

Remedial action

– Check the battery connector and

connect if necessary.

Set the key switch to position «I»

– Verify code

– Check the charging condition of the

battery and recharge if necessary

– Check fuses F1 and 1F1

– Interrupt charging process

– Charging the battery

– Perform all remedial actions listed

under the fault «Truck does not

move».

– Check the hydraulic oil level

– Check fuse 2F1

Powerful thanks to maintenance-free 3-phase AC drive motor

Compact due to extremely short chassis length

Outstanding driving stability

Multi-shift operation facilitated by sideways battery exit (optional)

EJE 116/118/120

Electric pedestrian pallet truck (1,600/1,800/2,000 kg)

The EJE Series 1 pallet trucks are a particularly economic means of loading and offloading HGVs as well as transporting pallets over short distances. The main advantage: Due to its short chassis length (L2) of just 494 mm (short version), the EJE can be manoeuvred in very restricted spaces.

The innovative 3-phase AC drive motor is another advantage. Its optimised efficiency ensures high speed and powerful acceleration – ideal for fast, efficient product throughput. In addition to its speed, it also offers long operating times: Batteries up to 250 Ah in com-

bination with excellent energy management ensure long operating times. For operations lasting more than 1 shift, the battery can be removed laterally for quick battery replacement (optional for EJE 118/120).

The low-mounted long tiller ensures safe operation. They maintain the adequate distance between the operator and the truck. Especially when cornering, the EJE 116 — 120 never gets too close to the operator. If space is at a premium, the crawl speed button makes travelling safe with the tiller in the upright position. A touch of the button is sufficient: The

brake is released and activation of the travel switch automatically reduces the speed of travel. Particularly in confined spaces, the low battery height has its advantages. It provides even the shortest of operators with optimum visibility of the fork tips.

The re-designed multi-functional tiller arm is full of innovations: Sealed sensor system (IP 65) for maximum breakdown protection, rocker switches with contactless electronics for precise operation in any tiller position, ergonomically arranged switches.

EJE 116/118/120

|

l |

|

|

x |

|

|

c |

|

|

h14 |

Q |

|

max. |

|

|

h14 |

|

|

min. |

|

|

150 |

s |

|

m2 |

|

|

y |

|

|

l2 |

|

|

l1 |

|

|

(l6) |

|

|

e |

|

b10 |

b11 |

b5 |

(b12) |

|

b1 |

|||

|

Wa |

|||

|

a/2 |

a/2 |

||

|

Ast |

I = Travel range; II = Crawl speed range

- 0915.2 — Industrial truck not ready for operation — battery door opened.

- 0938.1 — Battery discharged (0%).

- 1901.1 — Drive pedal activated during startup.

- 1904.1 — No travel direction present with drive pedal activated.

- 1908.1 — Seat belt or belt lock not closed when the pedal is pressed.

- 1909.1 — Activation of drive pedal when the parking brake is not released.

- 1917.1 — Drive pedal and brake pedal both activated at the same time.

- 1918.1 — Industrial truck ready for operation, but cab door opened.

- 2908.1 — Seat belt or belt lock not closed when hydraulic function is activated.

- 2937.3 — Simulatneous activiation of several hydraulic functions that can only be operated as individual functions.

- 2951.1 — Hydraulic function activated during startup.

- 5409.1 — Battery temperature too high

- 5393.1 — Battery cell faulty

Some JUNGHEINRICH Forklift Trucks Error Codes

Sub-division of function group F

0 Dystem: Overlappingfunction that cannot be assigned to any other function group

1 Travel

2 Hydraulics (load handling)

3 Steering and travel

4 Displays / controls, interface

5 Charger (either on-board or external charger)

6 Reserved

7 Reserved

8 Reserved

9 Special Functions

Sub-division of event group E

0 Fault reset or no fault

1 General fault /additional functions

2 Current

3 Voltage

4 Temperature

5 Hardware

6 Software

7 CAN motitoring

8 External fault

5

The operator keyboard is composed of 10 nume-

ric keys, a Set key and an o-key.

Activation of the travel programs by means of

switches 1,2,3 is indicated by green LEDs.

The o-key indicates operating conditions by a

red/green LED.

It has the following functions:

– Code lock function (setting the truck into oper-

ation).

– Selecting the travel program.

– Setting the travel and battery parameters, only

in conjunction with the indicator instrument

(CANDIS (o)).

The o-key has top priority and reset the truck

from any condition to the basic condition without modifying any settings.

5.1

Code lock

After entering the correct code, the truck is ready for operation. It is possible to assign

an individual code to every truck, operator or even operator group.

Z

When delivered from the factory, the operator code (factory setting 2-5-8-0) is indicat-

ed on a removable sticker.

M

Change the master and operator codes when setting the truck into operation for the

first time! (refer to section 5.4).

E 10

1

2

3

4

5

6

7

8

9

0

Set