We have multiple applications developed in Visual Foxpro 8.0 running in a data center on Windows 2008 R2 on VMware. We also have a Citrix farm on the same network where users run yet another VFP 8.0 application in Citrix

sessions. All applications share the same set of data tables located on a file server (also Windows 2008 R2 VM). Virtual hosts are connected by 10Gb LAN (managed switch).

Since <g class=»gr_ gr_88 gr-alert gr_gramm gr_inline_cards gr_run_anim Punctuation only-ins replaceWithoutSep» data-gr-id=»88″ id=»88″>mid-July</g> we started seeing random 1104 «Error

reading file…» errors on multiple different applications on multiple servers. All of them reference different files on the file server.

The problem started mid-July and it frequency gradually increased. Earlier it was most frequent in the afternoons by 3 pm, now it happens from early morning till late afternoon. It affects EDI servers (these run batch jobs

in unattended mode) and Citrix servers and a variety of applications. It occurs when a VFP application (any of them) tries to open a database container file or individual tables most often with USE command but some times executing a SQL Select statement, or

when loading a VFP form that opens tables in DataEnvironment

We caught a moment when the same exact error happened on two different servers running different applications at the same exact moment (up to a second). We also saw two different applications running on the same computer erroring

out at the same moment.

We replaced the file server with a new virtual machine with no relief (we since changed it back to the old file server ).

We disabled the antivirus.

We updated VMware on all hosts to the latest version.

Sysinternals Process Monitor displays «INVALID_NETWORK_RESPONSE» event when the error occurs.

We captured traffic on both the server side and client side when the error occurred and had it analyzed by a network analysis specialist. He observed a peculiar pattern, where client OS starts retrieving the file in question

from the file server AFTER VFP application had thrown an error. It seems that VFP application requests a file from OS, then it either gets an abnormal response or just times out and only after that the OS sends packets requesting the file. Again, this happens

sporadically.

OpLocks and SMB2 have been disabled on all computers both on the server and client side of the equation for many years and everything was running smoothly until now…

Any advice would be greatly appreciated.

-

Edited by

Tuesday, August 22, 2017 9:38 PM

Содержание

- Обнаружена ошибка протокола на клиентском компьютере код 0x1104 сессия будет отключена

- Обнаружена ошибка протокола на клиентском компьютере код 0x1104 сессия будет отключена

- Обнаружена ошибка протокола на клиентском компьютере код 0x1104 сессия будет отключена

- Обнаружена ошибка протокола на клиентском компьютере код 0x1104 сессия будет отключена

- Открываем командную строку из интерфейса Metro UI

- Запуск командной строки из проводника

- Запуск командной строки из диспетчера задач

- Запуск из меню быстрого доступа Win+X

- Повышение привилегий открытого окна командной строки

- Открытие окна команд с правами администратора из файловых менеджеров

- Открытие окна команд с правами администратора из Проводника

- Открытие окна команд с правами администратора из Total Commander

- Открытие окна команд с правами администратора из Far

- Ключи командной строки ELE

- Причины ошибки хранимая на этом компьютере, была изменена

- Как исправить код ошибки удаленного рабочего стола 0x204 на Mac?

- Способ 1. Включите протокол удаленного рабочего стола (на компьютере с Windows)

- Способ 2. Разрешение удаленной удаленной остановки через брандмауэр Windows

- Способ 3: отключение вашего стороннего AV (если применимо)

- Способ 4: удаление стороннего брандмауэра (если применимо)

- Метод 5: Использование приглашения удаленного помощника

- Способ 6: удаление временной папки Remote Dekstop (только для MAC)

- Обнаружена ошибка протокола на клиентском компьютере код 0x1104 сессия будет отключена

Обнаружена ошибка протокола на клиентском компьютере код 0x1104 сессия будет отключена

Сообщения: 28

Благодарности: 1

Доброго времени суток.

Имеется компьютер под управлением Windows 7 Home Premium х64. С него надо подключаться к терминалу Windows Server 2008 R2. При подключении вылетает ошибка: «Обнаружена ошибка протокола на клиентском компьютере (код 0х1104), сессия будет отключена.» При этом подключение к терминалу второго сервера, под управлением Windows Server 2003, проходит нормально. По внутреннему IP-адресу сервера подключение есть.

Сообщения: 28

Благодарности: 1

——-

С точки зрения физики световой меч является психически нездоровым людям

» width=»100%» style=»BORDER-RIGHT: #719bd9 1px solid; BORDER-LEFT: #719bd9 1px solid; BORDER-BOTTOM: #719bd9 1px solid» cellpadding=»6″ cellspacing=»0″ border=»0″> Источник

Обнаружена ошибка протокола на клиентском компьютере код 0x1104 сессия будет отключена

Сообщения: 28

Благодарности: 1

Доброго времени суток.

Имеется компьютер под управлением Windows 7 Home Premium х64. С него надо подключаться к терминалу Windows Server 2008 R2. При подключении вылетает ошибка: «Обнаружена ошибка протокола на клиентском компьютере (код 0х1104), сессия будет отключена.» При этом подключение к терминалу второго сервера, под управлением Windows Server 2003, проходит нормально. По внутреннему IP-адресу сервера подключение есть.

Сообщения: 28

Благодарности: 1

——-

С точки зрения физики световой меч является психически нездоровым людям

» width=»100%» style=»BORDER-RIGHT: #719bd9 1px solid; BORDER-LEFT: #719bd9 1px solid; BORDER-BOTTOM: #719bd9 1px solid» cellpadding=»6″ cellspacing=»0″ border=»0″> Источник

Обнаружена ошибка протокола на клиентском компьютере код 0x1104 сессия будет отключена

Сообщения: 28

Благодарности: 1

Доброго времени суток.

Имеется компьютер под управлением Windows 7 Home Premium х64. С него надо подключаться к терминалу Windows Server 2008 R2. При подключении вылетает ошибка: «Обнаружена ошибка протокола на клиентском компьютере (код 0х1104), сессия будет отключена.» При этом подключение к терминалу второго сервера, под управлением Windows Server 2003, проходит нормально. По внутреннему IP-адресу сервера подключение есть.

Сообщения: 28

Благодарности: 1

——-

С точки зрения физики световой меч является психически нездоровым людям

» width=»100%» style=»BORDER-RIGHT: #719bd9 1px solid; BORDER-LEFT: #719bd9 1px solid; BORDER-BOTTOM: #719bd9 1px solid» cellpadding=»6″ cellspacing=»0″ border=»0″> Источник

Обнаружена ошибка протокола на клиентском компьютере код 0x1104 сессия будет отключена

По непонятным причинам терминальный клиент работающий много лет вдруг, совершенно внезапно, не мог соединиться с терминальным сервером по загадочной причине отсутствия клиентской лицензии. На чешском (я столкнулся с этим у одного из клиентов именно на чешской версии windows) эта ошибка звучит так:

”Vzdálený počítač přerušil spojení z důvodu chyby v licenčním protokolu. Pokuste se připojit ke vzdálenému počítači znovu nebo se obraťte na správce serveru.” На русском:

”Удаленный компьютер отключил сеанс из-за ошибки в протоколе лицензирования. Попытайтесь подключиться к удаленному компьютеру снова или обратитесь к администратору сервера.” На английском:

”The remote computer disconnected the session because of an error in the licensing protocol. Please try connecting to the remote computer again or contact your server administrator.” При этом

ПОМНИТЕ ЧТО РАБОТА С РЕЕСТРОМ МОЖЕТ ПРИВЕСТИ К ОТКАЗУ ОПЕРАЦИОННОЙ СИСТЕМЫ ИЛИ ПРОГРАММ.

Ведите себя в редакторе реестра очень аккуратно и предельно внимательно.

И в заключении привожу немного картинок для тех кто хочет знать, что понял всё верно. Но надписи на скриншотах только на чешском, сбой произошёл именно на машине с чешской версией Windows 7.

В Windows 8 запустить командную строку с помощью прав администратора можно несколькими способами:

Опишем каждый из этих способов открытия командной строки с правами админа в Win8 подробнее.

Открываем командную строку из интерфейса Metro UI

В строке «Поиск» интерфейса Windows 8 Metro UI, нужно набрать “cmd ” (или “ command prompt ”) , в результате в левой панели отобразится найденное приложение. Затем нужно щелкнуть правой кнопкой мыши по появившемуся ярлыку и в нижней части экрана появится строка с дополнительными опциями запуска. Выберите «Запуск от имени администратора» (“Run as administrator”)

Все то же самое можно выполнить, выделив найденное приложение и нажав на клавиатуре комбинацию Ctrl + Shift + Enter .

Запуск командной строки из проводника

Запуск командной строки из диспетчера задач

Запуск из меню быстрого доступа Win+X

Проект получил имя ELE. Восьмикилобайтный экзешник стал для меня панацеей в вопросе эскалации привилегий командной строки.

Повышение привилегий открытого окна командной строки

Открытие окна команд с правами администратора из файловых менеджеров

Открытие окна команд с правами администратора из Проводника

Достаточно интегрировать ELE в контекстное меню папки и фона папки (пустого, свободного от файлов пространства окна Проводника), и вы откроете командую строку от имени администратора в любой локации жесткого диска.

Твик реестра мог бы выглядеть так:

Windows Registry Editor Version 5.00

@=»cmd /c cd /d »%1» & ele /x»

Ну и, соответственно, результат:

Открытие окна команд с правами администратора из Total Commander

Просто перетащите ele. exe на тулбар этого файлового менеджера, и отредактируйте полученную кнопку, удалив путь запуска. Это необходимо, чтобы при запуске ele в качестве рабочей папки использовался путь в активной панели Total Commander.

Нажав на эту кнопку, вы откроете текущую папку в командной строке с правами администратора.

Открытие окна команд с правами администратора из Far

Ключи командной строки ELE

Краткая справка по использованию

Ele программа [параметры]

Запустить программу от имени администратора. Например, Блокнот от имени администратора:

Ele notepad. exe d:text1.txt

Причины ошибки хранимая на этом компьютере, была изменена

В большинстве случаев ошибка удаленный сеанс отключен, так как клиентская лицензия удаленного рабочего стола, хранимая на этом компьютере, была изменена, выскакивает на клиентских операционных системах, по типу Windows 10 или 8.1

Переходим в ветку реестра

И полностью удаляем весь раздел, через правый клик.

Подтверждаем удаление. После чего перезагружаем компьютер.

Как только вы перезагрузились, нажмите WIN+R и введите mstsc /admin, чтобы у вас открылось окно удаленного рабочего стола от имени администратора.

Все можем пытаться подключаться к вашему серверу терминалов.

Если не поможет, то попробуйте создать bat файл и выполнить его, ниже содержимое.

Const HKLM = &H80000002

Const MSLicensingStore = «SoftwareMicrosoftMSLicensingStore»

Set oReg = GetObject(«winmgmts:.rootdefault:StdRegProv»)

RetVal = oReg. EnumKey(HKLM, MSLicensingStore, RegKeys)

If RetVal <> 0 Then

MsgBox(«Не удалось прочитать ветвь реестра » & MSLicensingStore)

WScript. Quit

End If

If IsArray(RegKeys) Then

For Each Key In RegKeys

KeyName = MSLicensingStore & Key

If InStr(1, UCase(KeyName), «LICENSE») > 0 Then

RetVal = oReg. DeleteKey(HKLM, KeyName)

End If

Next

End If

Как исправить код ошибки удаленного рабочего стола 0x204 на Mac?

Некоторые пользователи, которые пытаются подключиться к компьютеру Windows с Mac, Android или другой ОС, получают код ошибки 0x204 при попытке использовать протокол удаленного рабочего стола. Хотя удаленный рабочий стол является надежным инструментом, позволяющим пользователям подключаться к ПК и получать доступ к приложениям, файлам и сетевым ресурсам, иногда все работает не так, как должно.

Одной из наиболее распространенных проблем, которые вызывают код ошибки 0x204, является случай, в котором протокол удаленного рабочего стола не включен на компьютере Windows. В этом случае вы можете решить проблему, включив ее вручную через экран «Свойства системы» и разрешив подключения на сетевом уровне.

Однако это также может быть вызвано вашим брандмауэром (поскольку процесс, используемый удаленным рабочим столом, эксплуатируется многими вредоносными программами). Чтобы решить эту проблему, в этом случае вам необходимо установить правило исключения, отключить защиту в режиме реального времени или вообще удалить сторонний пакет безопасности.

В некоторых случаях проблема может возникнуть из-за некоторых временных файлов, которые хранятся в папке Group Containers. Если этот сценарий применим, вы можете устранить проблему, удалив папку UBF8T346G9.com. microsoft. rdc.

Способ 1. Включите протокол удаленного рабочего стола (на компьютере с Windows)

Одной из наиболее распространенных причин, которые вызывают код ошибки 0x204 при попытке доступа к файлам из ОС Windows с использованием протокола удаленного рабочего стола, является, безусловно, случай, когда функциональность удаленного рабочего стола не включена на экране «Свойства системы».

Это должен быть ваш первый шаг по устранению неполадок, если вы попытались подключиться с использованием протокола удаленного рабочего стола, используя несколько устройств, и все они вызвали одну и ту же проблему.

Вот пошаговое руководство по включению протокола удаленного рабочего стола на компьютере Windows, с которого вы получаете доступ к файлам:

Примечание. Приведенные ниже шаги являются универсальными и должны работать независимо от версии Windows, которую вы используете на хост-компьютере.

Примечание. Когда вам будет предложено UAC (Контроль учетных записей), нажмите Да, чтобы предоставить административные привилегии.

Примечание. Если вы пытаетесь подключиться к компьютеру из другой сети, вам также необходимо снять флажок «Разрешить подключения только с компьютеров, работающих под управлением удаленного рабочего стола с проверкой подлинности на уровне сети».

Если проблема все еще не решена, перейдите к следующему потенциальному решению ниже.

Способ 2. Разрешение удаленной удаленной остановки через брандмауэр Windows

Помните, что по умолчанию брандмауэр Windows не настроен на использование протокола удаленного рабочего стола в белом списке.

Поэтому, если вы хотите использовать удаленный рабочий стол, чтобы сделать ваши файлы доступными для других компьютеров, вам нужно будет изменить настройки безопасности по умолчанию, чтобы разрешить удаленный декстоп и удаленный рабочий стол (Websocket) через меню «Разрешенные приложения» настроек брандмауэра Windows.

Это нужно делать независимо от того, какую версию Windows вы используете.

Важное замечание: Если вы используете сторонний пакет брандмауэра, приведенные ниже шаги не будут применяться. В этом случае вам нужно будет найти конкретные шаги, которые позволят вам внести в белый список протокол удаленного рабочего стола.

Вот краткое руководство о том, как разрешить протоколу удаленного рабочего стола взаимодействовать с другими устройствами в этой сети:

Примечание. Если вас попросит UAC (Контроль учетных записей), нажмите Да, чтобы предоставить административные привилегии.

Если проблема все еще не решена, и вы все еще сталкиваетесь с тем же Кодом ошибки 0x204, перейдите к следующему потенциальному исправлению ниже.

Способ 3: отключение вашего стороннего AV (если применимо)

Как выясняется, во многих случаях пользователи сталкиваются с этой проблемой при использовании сторонних пакетов безопасности. McAfee Internet Security является наиболее распространенным пакетом сторонних производителей, который, как известно, облегчает код ошибки 0x204.

Скорее всего, происходит то, что сторонние AV запускают ложное срабатывание и угрожают порту, используемому протоколом удаленного рабочего стола, как злонамеренная попытка доступа к вашим файлам на расстоянии.

В случае, если этот сценарий применим к вашей текущей ситуации, вы должны быть в состоянии исправить подразумеваемые проблемы, отключив защиту в реальном времени вашего комплекта AV сторонних производителей. Но имейте в виду, что шаги для этого зависят от того, какой AV вы используете.

Но в большинстве случаев вы сможете отключить постоянную защиту (активные щиты) прямо из меню панели задач. Для этого просто щелкните правой кнопкой мыши значок меню на панели задач и найдите параметр, который отключает защиту в режиме реального времени.

Отключение всех щитов Avast

Если вы сделали это безрезультатно или используете сторонний пакет брандмауэров, перейдите к следующему потенциальному исправлению ниже.

Способ 4: удаление стороннего брандмауэра (если применимо)

В случае, если вы используете сторонний брандмауэр, отключение или запрет его работы не будет иметь значения, так как те же наборы безопасности останутся на месте. Если проблема вызвана сторонним брандмауэром, единственный способ исправить это – создать правило белого списка, исключающее удаленный рабочий стол из списка анализируемых процессов.

Но имейте в виду, что шаги этого очень отличаются от инструмента к инструменту.

Если ваш AV не имеет возможности добавлять исключения, единственное реальное исправление – полностью удалить инструмент безопасности и убедиться, что нет оставшихся файлов, которые по-прежнему будут блокировать этот порт.

Если вы хотите выполнить этот метод, вот пошаговое руководство по удалению стороннего брандмауэра:

Если проблема сохраняется, перейдите к следующему потенциальному решению ниже.

Метод 5: Использование приглашения удаленного помощника

Оказывается, некоторые пользователи смогли решить проблему, создав автономное приглашение с помощью утилиты удаленного помощника Windows и открыв его на компьютере, который не может подключиться с помощью протокола удаленного доступа Windows.

Эта операция в конечном итоге обходит каждый потенциально заблокированный порт, который может вызывать проблему с кодом ошибки 0x204, с помощью автономного приглашения.

Вот краткое руководство по созданию приглашения на удаленную помощь:

Примечание. Если вы получите запрос от UAC (Контроль учетных записей), нажмите Да, чтобы предоставить административные привилегии.

Примечание. Вы можете выбрать другой вариант, если вам будет проще (либо прикрепите приглашение с помощью программы электронной почты, либо воспользуйтесь Easy Connect)

Если та же проблема все еще сохраняется, перейдите к следующему потенциальному решению ниже.

Способ 6: удаление временной папки Remote Dekstop (только для MAC)

Если ни один из перечисленных выше методов не сработал, и вы сталкиваетесь только с проблемой OSX, очень вероятно, что временная папка, используемая приложением Mac Remote Desktop, содержит поврежденные файлы, которые не позволяют установить соединение.

Если этот сценарий применим к вашей текущей ситуации, вы можете устранить проблему, удалив временную папку из папки контейнера группы. Вот краткое руководство о том, как это сделать:

Источник

Обнаружена ошибка протокола на клиентском компьютере код 0x1104 сессия будет отключена

Так. Думаю это поможет. Если не понятно, скажи, переведу

This error indicates that RDP is not available to use TCP port 3389l.

Occasionally, RPC provides 3389 to another service and this does not allow

RDP to function. RPC can be isolated and confirmed if you stop the

MSExchangeSA service.

To keep this from happening in the future add the following using regedt32:

(of course, backup the registry keys before making these changes).

Add the following key if not present:

Highlight the following key:

HKEY_LOCAL_MACHINESoftwareMicrosoftRpc

From Edit menu select «Add Key. »

Key Name: Internet

Class:

Add the following values if not prestent:

Highlight the following key:

HKEY_LOCAL_MACHINESoftwareMicrosoftRpcInternet

From Edit menu select «Add Value. »

Value Name: Ports

Data Type: REG_MULTI_SZ

Data: 3389-3389

From Edit menu select «Add Value. »

Value Name: PortsInternetAvailable

Data Type: REG_SZ

Data: N

From Edit menu select «Add Value. »

Value Name: UseInternetPorts

Data Type: REG_SZ

Data: Y

Then reboot the server and try again.

Короче, для начала останови сервиc MSExchangeSA, и попробуй подключитса.

Источник

Adblock

detector

На нашем ресурсе имеется возможность задавать вопросы и делиться собственным опытом по устренению неисправностей связанных с ошибкой C1104. Задав вопрос в течении нескольких дней Вы сможете найти ответ на него.

Принимая во внимание тот факт, что OBD2 ошибки работы двигателя или других электронных систем автомобиля не всегда на прямую указывают на неработающий элемент, и то что разных марках и моделях автомобилей одна и таже ошибка может возникать как следствие неисправности абсолютно разных элементов электронной системы мы создали этот алгоритм помощи и обмена полезной информацией.

Мы надеемся, с Вашей помощью, сформировать причино-следственную связь возникновения той или иной OBD2 ошибки у конкретного автомобиля (марка и модель). Как показал опыт если рассматривать определенную марка-модель автомобиля, то в подавляющем большинстве случаев причина ошибки одна и таже.

Если ошибка указывает на неверные параметры (высокие или низкие значения) какого нибудь из датчиков или анализаторов, то вероятней всего этот элемент исправен, а проблему надо искать так сказать «выше по течению», в элементах работу которых анализирует датчик или зонд.

Если ошибка указывает на постоянно открытый или закрытый клапан, то тут надо подойти к решению вопроса с умом, а не менять бездумно этот элемент. Причин может быть несколько: клапан засорен, клапан заклинил, на клапан приходит неверный сигнал от других неисправных узлов.

Ошибки работы двигателя OBD2 и других систем автомобиля (ELM327) не всегда на прямую указывают на неработающий элемент. Сама по себе ошибка является косвенными данными о неисправности в системе, в некотором смысле подсказкой, и только в редких случаях прямым указанием на неисправный элемент, датчик или деталь. Ошибки (коды ошибок) полученные от прибора, сканера требуют правильной интерпретации информации, дабы не тратить время и деньги на замену работающих элементов автомобиля. Проблема зачастую кроется намного глубже чем кажется на первый взгляд. Это вызвано теми обстоятельствами, что информационные сообщения содержат, как было выше сказано, косвенную информацию о шарушении работы системы.

Вот пару общих примеров. Если ошибка указывает на неверные параметры (высокие или низкие значения) какого нибудь из датчиков или анализаторов, то вероятней всего этот элемент исправен, так как он анализирует (выдает некие параметры или значения), а проблему надо искать так сказать «выше по течению», в элементах работу которых анализирует датчик или зонд.

Если ошибка указывает на постоянно открытый или закрытый клапан, то тут надо подойти к решению вопроса с умом, а не менять бездумно этот элемент. Причин может быть несколько: клапан засорен, клапан заклинил, на клапан приходит неверный сигнал от других неисправных узлов.

Еще один момент который хотелось бы отметить — это специфика той или иной марки и модели. Поэтому узнав ошибку работы двигателя или дрогой системы Вашего автомобиля не спешите делать поспешных решений, а подойдите к вопросу комплексно.

Наш форум создан для всех пользователей, от простых автолюбителей до профессиональных автоэлектриков. По капле от каждого и всем будет полезно.

Содержание

- 0x1104 error remote desktop windows 10

- Произошла ошибка проверки подлинности. Указанная функция не поддерживается

- Ответ

- Отключение NLA для протокола RDP в Windows

- 0x1104 Remote Desktop Windows 7 — remote desktop stopped working, how do I fix it?

- 0x1104 error remote desktop windows 10

- Вопрос

- Все ответы

- To allow Remote Desktop connections through a Windows Firewall

- Ошибка RDP подключения: Указанная функция не поддерживается, ошибка шифрования CredSSP

0x1104 error remote desktop windows 10

Сообщения: 28

Благодарности: 1

Доброго времени суток.

Имеется компьютер под управлением Windows 7 Home Premium х64. С него надо подключаться к терминалу Windows Server 2008 R2. При подключении вылетает ошибка: «Обнаружена ошибка протокола на клиентском компьютере (код 0х1104), сессия будет отключена.» При этом подключение к терминалу второго сервера, под управлением Windows Server 2003, проходит нормально. По внутреннему IP-адресу сервера подключение есть.

Если же вы забыли свой пароль на форуме, то воспользуйтесь данной ссылкой для восстановления пароля.

| Конфигурация компьютера | |

| Материнская плата: Asus P5K-VM | |

| HDD: Seagate Barracuda 7200.10 320GB sATAII | |

| Звук: HDA кодек Realtek ALC883 | |

| CD/DVD: SonyNEC Optiarc AD-7203S | |

| ОС: Windows 7 Ultimate 32-bit | |

» width=»100%» style=»BORDER-RIGHT: #719bd9 1px solid; BORDER-LEFT: #719bd9 1px solid; BORDER-BOTTOM: #719bd9 1px solid» cellpadding=»6″ cellspacing=»0″ border=»0″>

Сообщения: 1

Благодарности: 0

Произошла ошибка проверки подлинности. Указанная функция не поддерживается

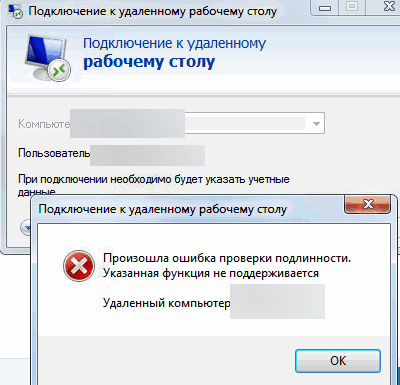

После установки обновления KB4103718 на моем компьютере с Windows 7 я не могу удаленно подключится к серверу c Windows Server 2012 R2 через удаленный рабочий стол RDP. После того, как я указываю адрес RDP сервера в окне клиента mstsc.exe и нажимаю «Подключить», появляется ошибка:

Произошла ошибка проверки подлинности.

Указанная функция не поддерживается.

Удаленный компьютер: computername

После того, как я удалил обновление KB4103718 и перезагрузил компьютер, RDP подключение стало работать нормально. Если я правильно понимаю, это только временное обходное решение, в следующем месяце приедет новый кумулятивный пакет обновлений и ошибка вернется? Можете что-нибудь посоветовать?

Ответ

Вы абсолютно правы в том, что бессмысленно решать проблему удалением обновлений Windows, ведь вы тем самым подвергаете свой компьютер риску эксплуатации различных уязвимостей, которые закрывают патчи в данном обновлении.

В своей проблеме вы не одиноки. Данная ошибка может появится в любой операционной системе Windows или Windows Server (не только Windows 7). У пользователей английской версии Windows 10 при попытке подключится к RDP/RDS серверу аналогичная ошибка выглядит так:

The function requested is not supported.

Remote computer: computername

Ошибка RDP “An authentication error has occurred” может появляться и при попытке запуска RemoteApp приложений.

Почему это происходит? Дело в том, что на вашем компьютере установлены актуальные обновления безопасности (выпущенные после мая 2018 года), в которых исправляется серьёзная уязвимость в протоколе CredSSP (Credential Security Support Provider), использующегося для аутентификации на RDP серверах (CVE-2018-0886) (рекомендую познакомится со статьей Ошибка RDP подключения: CredSSP encryption oracle remediation). При этом на стороне RDP / RDS сервера, к которому вы подключаетесь со своего компьютера, эти обновления не установлены и при этом для RDP доступа включен протокол NLA (Network Level Authentication / Проверку подлинности на уровне сети). Протокол NLA использует механизмы CredSSP для пре-аутентификация пользователей через TLS/SSL или Kerberos. Ваш компьютер из-за новых настроек безопасности, которые выставило установленное у вас обновление, просто блокирует подключение к удаленному компьютеру, который использует уязвимую версию CredSSP.

Что можно сделать для исправления эту ошибки и подключиться к вашему RDP серверу?

- Самый правильный способ решения проблемы – установка последних кумулятивных обновлений безопасности Windows на компьютере / сервере, к которому вы подключаетесь по RDP;

- Временный способ 1 . Можно отключить проверку подлинности на уровне сети (NLA) на стороне RDP сервера (описано ниже);

- Временный способ 2 . Вы можете на стороне клиента разрешить подключение к RDP серверам с небезопасной версией CredSSP, как описано в статье по ссылке выше. Для этого нужно изменить ключ реестра AllowEncryptionOracle (команда REG ADD

HKLMSOFTWAREMicrosoftWindowsCurrentVersionPoliciesSystemCredSSPParameters /v AllowEncryptionOracle /t REG_DWORD /d 2 ) или изменить настройки локальной политики Encryption Oracle Remediation / Исправление уязвимости шифрующего оракула), установив ее значение = Vulnerable / Оставить уязвимость).

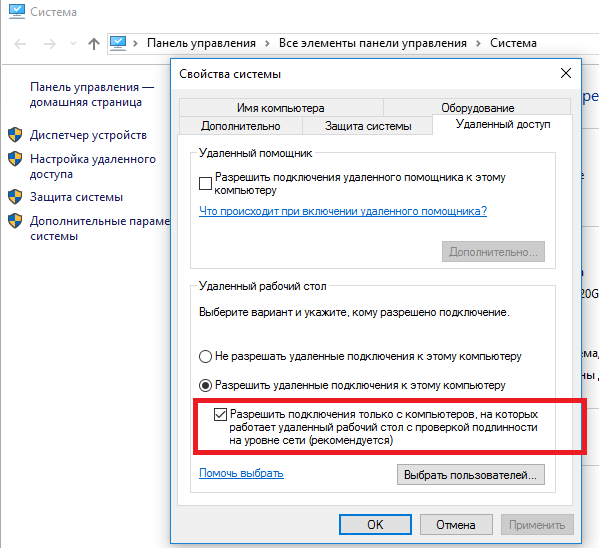

Отключение NLA для протокола RDP в Windows

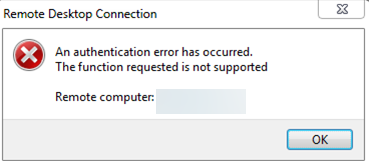

Если на стороне RDP сервера, которому вы подключаетесь, включен NLA, это означает что для преаутентификации RDP пользователя используется CredSPP. Отключить Network Level Authentication можно в свойствах системы на вкладке Удаленный доступ (Remote), сняв галку «Разрешить подключения только с компьютеров, на которых работает удаленный рабочий стол с проверкой подлинности на уровне сети / Allow connection only from computers running Remote Desktop with Network Level Authentication (recommended)» (Windows 10 / Windows 8).

В Windows 7 эта опция называется по-другому. На вкладке Удаленный доступ нужно выбрать опцию «Разрешить подключения от компьютеров с любой версией удаленного рабочего стола (опасный) / Allow connections from computers running any version of Remote Desktop (less secure)».

Также можно отключить проверку подлинности на уровне сети (NLA) с помощью редактора локальной групповой политики — gpedit.msc (в Windows 10 Home редактор политик gpedit.msc можно запустить так) или с помощью консоли управления доменными политиками – GPMC.msc. Для этого перейдите в разделе Конфигурация компьютера –> Административные шаблоны –> Компоненты Windows –> Службы удаленных рабочих столов – Узел сеансов удаленных рабочих столов –> Безопасность (Computer Configuration –> Administrative Templates –> Windows Components –> Remote Desktop Services – Remote Desktop Session Host –> Security), отключите политику Требовать проверку подлинности пользователя для удаленных подключений путем проверки подлинности на уровне сети (Require user authentication for remote connections by using Network Level Authentication).

Также нужно в политике «Требовать использования специального уровня безопасности для удаленных подключений по протоколу RDP» (Require use of specific security layer for remote (RDP) connections) выбрать уровень безопасности (Security Layer) — RDP.

Для применения новых настроек RDP нужно обновить политики (gpupdate /force) или перезагрузить компьютер. После этого вы должны успешно подключиться к удаленному рабочему столу сервера.

0x1104 Remote Desktop Windows 7 — remote desktop stopped working, how do I fix it?

Hi, I realize that there’s another forum post to this effect, which Oberwald locked, where s/he suggests that I should just roll back all the security updates that Microsoft puts out, in order to fix this problem . but does anyone know a way to fix this without the ‘System Restore Point’ methodology?

I’ve tried the registry edits I was able to find (though others might be appreciated), and disabled the Norton firewalls, etc . any other things?

It’s Windows 7 Professional (client) to Windows 7 Ultimate (host).

What was the recent hardware and software change made to the computer before the issue started?

The reason you may be receiving this error might be due to a protocol error of conflicting Visual styles between the computers having Remote Desktop Connection.

On the remote computer you will have to find a compatible visual style that works with RDP in case of a custom style set or conflict.

Please try un checking the option Visual Styles and check if you are able to use the Remote Desktop Connection.

a. Click Start

b. Launch Remote Desktop Connection (RDP)

c. Click on Options on the RDP window

d. Click on the Experience tab

e. Uncheck the Visual Styles option

f. Try starting the RDP process and check if you are able to connect.

You may also refer to the following links,

Why can’t I connect using Remote Desktop Connection?

Hope this helps.

13 people found this reply helpful

Was this reply helpful?

Sorry this didn’t help.

Great! Thanks for your feedback.

How satisfied are you with this reply?

Thanks for your feedback, it helps us improve the site.

0x1104 error remote desktop windows 10

Вопрос

When i try to connect to my other pc through lan it works fine, but through internet from my phone or pc, i get error 1104

port is open, tried switching to a different port. Works through lan.

Все ответы

Please try to launch the RDP via type mstsc /Admin in the Run box, and then make sure the configuration is below:

Meanwhile, disable all of your security software include firewall. It might be because Firewall block the RDP port.

To allow Remote Desktop connections through a Windows Firewall

If you’re having trouble connecting, Remote Desktop connections might be getting blocked by the firewall. Here’s how to change that setting on a Windows PC. If you’re using another firewall, make sure the port for Remote Desktop (usually 3389) is open.

- On the remote computer, click Start and select Control Panel .

- Click System and Security.

- Click Allow a program through Windows Firewall under Windows Firewall.

- Click Change settings and then check the box next to Remote Desktop .

- Click OK to save the changes.

Ошибка RDP подключения: Указанная функция не поддерживается, ошибка шифрования CredSSP

После установки последних обновлений безопасности, вышедших 8 мая 2018 года, на Windows 10 и 7, пользователи стали жаловаться, что при попытке подключится к RemoteApp на RDS серверах под Windows Server 2016 / 2012 R2 / 2008 R2, или удаленным рабочим столам других пользователей по протоколу RDP (на Win 10/8/7), появляется ошибка:

Remote Desktop connection

An authentication error has occurred.

The function is not supported.

Remote Computer: hostname

This could be due to CredSSP encryption oracle remediation.

Подключение к удаленному рабочему столу

Произошла ошибка при проверке подлинности.

Указанная функция не поддерживается.

Причиной ошибки может быть исправление шифрования CredSSP.

Данная ошибка связана с тем, что на Windows Server или обычных десктопных версиях Windows, к котором вы пытаетесь подключится по RDP, с марта 2018 года не устанавливались обновления безопасности. Дело в том, что еще в марте 2018 Microsoft выпустила обновление, закрывающее возможность удаленного выполнения кода с помощью уязвимости в протоколе CredSSP (бюллетень CVE-2018-0886). В мае 2018 было опубликовано дополнительное обновление, в котором по-умолчанию клиентам запрещается подключаться к удаленным RDP серверам с уязвимой (непропатченной) версией протокола CredSSP.

Таким образом, если вы не устанавливали накопительные обновления безопасности на RDS серверах Windows с марта этого года, а клиенты (Win 10 / 8 / 7) установили майские обновления, то на них при попытке подключится к RDS серверам с непропатченной версией CredSSP будет появляется ошибка о невозможности подключения: This could be due to CredSSP encryption oracle remediation.

Ошибка RDP клиента появляется после установки следующих обновлений безопасности:

- Windows 7 / Windows Server 2008 R2 — KB4103718

- Windows 8.1 / Windows Server 2012 R2 — KB4103725

- Windows Server 2016 — KB4103723

- Windows 10 1803 — KB4103721

- Windows 10 1709 — KB4103727

- Windows 10 1703 — KB4103731

- Windows 10 1609 — KB4103723

Для восстановления удаленного подключения к рабочему столу можно удалить указанное обновление (но это не рекомендуется и делать этого не стоит, есть более правильное решение).

Для решения проблемы нужно временно на компьютере, с которого вы подключаетесь по RDP, убрать данное уведомление безопасности, блокирующее подключение.

Это можно сделать через редактор локальных групповых политик. Для этого:

- Запустите редактор локальных GPO: gpedit.msc ;

В том случае, если у вас отсутствует редактор локальных GPO (например, в Home редакциях Windows), вы можете внести изменение, разрешающее RDP подключение к серверам с непропатченной версия CredSSP, напрямую в реестр с помощью команды:

REG ADD HKLMSOFTWAREMicrosoftWindowsCurrentVersionPoliciesSystemCredSSPParameters /v AllowEncryptionOracle /t REG_DWORD /d 2

Можно внести изменения сразу на множестве компьютеров в AD с помощью доменной GPO или такого PowerShell скрипта (список компьютеров в домене можно получить с помощью командлета Get-ADComputer ):

Import-Module ActiveDirectory

$PSs = (Get-ADComputer -Filter *).DNSHostName

Foreach ($computer in $PCs) <

Invoke-Command -ComputerName $computer -ScriptBlock <

REG ADD HKLMSOFTWAREMicrosoftWindowsCurrentVersionPoliciesSystemCredSSPParameters /v AllowEncryptionOracle /t REG_DWORD /d 2

>

>

После успешного подключения к удаленному RDP серверу (компьютеру) нужно установить на нем отсутствующие обновления безопасности через службу Windows Update (проверьте, что служба включена) или вручную. Ниже представлены прямые ссылки на обновления для Windows Server, которые обязательно нужно установить:

- Windows Server 2012 R2 / Windows 8: KB4103715

- Windows Server 2008 R2 / Windows 7: KB4103712

- Windows Server 2016 / Windows 10 1607 = KB4103723

После установки обновлений и перезагрузки сервера, не забудьте отключить политику на клиентах (либо выставить ее на Force Updated Clients), или вернуть значение 0 у ключа реестра AllowEncryptionOracle. В этом случае, ваш компьютер не будет подвержен риску подключения к незащищенным хостам с CredSSP и эксплуатации уязвимости.

REG ADD HKLMSOFTWAREMicrosoftWindowsCurrentVersionPoliciesSystemCredSSPParameters /v AllowEncryptionOracle /t REG_DWORD /d 0

Adblock

detector

Code

Display

1101

Error: Host name

1102

Error: User/Password

1104

Error: No Recipient address The destination address is not

1105

Error: Not support protocol

1106

Error: No Sender Info

2101

Error: Can not connect

2102

Error: Can not connect with

timeout

2103

Error: Response wait with

timeout

2201

Error: Network transfer

2202

Error: Network transfer with

timeout

2203

Error: Response wait with

timeout

2204

Error: E-Mail Size limit

3101

Error: Server response

3201

Error: Not Found Authenti-

cation Mechanism

9181

Error: Page max count over

Causes

SMTP sever name is not set.

Error SMTP server name.

User ID for the authentication

is not entered or entered

wrongly.

Wrong authentication pass-

word is entered.

specified.

SMTP Protocol is set to OFF.

Sender address is not enter

Select [Other authenticate]

when authenticating POP

before SMTP.

The specified server is not

SMTP server.

Network is not connected.

The server is unable to com-

municate.

The server is unable to com-

municate.

Error occurs on the network.

Error occurs on the network.

Response is not returned

from the server above speci-

fied time.

The size of E-mail exceeds its

limit.

The server is error status.

Server setting is not authenti-

cated normally.

Unsupported SMTP Authenti-

cation Mechanism is found.

The number of pages of a

send file exceeded 999

pages.

Remarks

Check procedures/corrective measures

Register [SMTP Server Name] in

[Advanced]-[SMTP] -[General] in

COMMAND CENTER.

Enter the correct user ID/password for

authentication at [Advance] in COMMAND

CENTER.

Enter the password of [Login User Name] of

the [POP3] page or the [SMTP] page cor-

rectly.

Specify the destination address.

Check ON [SMTP] in [Advanced]-[SMTP] —

[General] in COMMAND CENTER.

Enter the correct [Sender Address] in

[Advanced]-[SMTP] -[General] in

COMMAND CENTER.

Select valid POP3 user other than [Other].

Enter the correct [SMTP Server Name] in

[Advanced]-[SMTP] -[General] in

COMMAND CENTER.

Check if the server is operating properly.

Check the network connection (cable. net-

work condition within LAN, etc.).

Check if the server is operating properly.

Check if the server is operating properly.

Check the network connection (cable. net-

work condition within LAN, etc.).

Check the network connection (cable. net-

work condition within LAN, etc.).

Check the network connection (cable. net-

work condition within LAN, etc.).

Change the [E-mail Size Limit] in

[Advanced]-[SMTP] -[General]-[E-mail Set-

ting] in COMMAND CENTER.

Check if the server is working properly.

Check the settings for client/server authenti-

cation.

Check the settings for client/server Authenti-

cation Mechanism.

Set the number of pages as 999 or less.

2JN

1-4-33

Kyocera. 1102 ошибка

Перевод описания ошибки из сервисного руководства:

1102. Подсоединение к компьютеру не удалось:

- Подтвердите имя пользователя и пароль.

- Проверьте правильность параметров сети, к которой подключено устройство.

- Проверьте компьютер, если папка правильно размещена.

1102 ошибка может возникать при:

- Передаче через SMB‐сервер. Проверьте параметры настройки SMB:

- имя пользователя и пароль при входе;

Примечание: Если отправитель является пользователем домена, укажите имя домена.

- имя хоста;

- путь.

- Передаче электронного письма. Проверьте следующие настройки в COMMAND CENTER:

- имя пользователя и пароль для сервера SMTP;

- имя пользователя и пароль для сервера POP3.

- Передаче через FTP‐сервер. Проверьте параметры настройки FTP‐сервера:

- имя пользователя и пароль при входе;

Примечание: Если отправитель является пользователем домена, укажите имя домена.

- путь;

- право доступа получателя к папке.

Распространённые ошибки настройки: скорее всего, вы ввели короткий логин для доступа к папке вместо полного. Полный логин содержит имя домена (для доменной учётной записи), например: DOMAINUserLogin. (Для локального пользователя — просто UserLogin.) Если это условие выполнено, но ошибка появляется, проверьте настройки сетевого экрана (в качестве быстрой проверки (не рекомендуется) можно временно его полностью отключить). Также проверьте путь к папке сканирования (он должен быть максимально коротким (не более двух слешей).

Причины сбоев и ошибок:

- Постоянная или временная недоступность настроенного сетевого ресурса.

- Ограничение на допустимое количество символов в имени компьютера, имени пользователя и пароле — не более 64. Путь к сетевой папке не должен содержать более 128 символов.

- Ошибка 1102 может возникать при использовании короткого логина вместо полного («имя домена имя пользователя (без кавычек и пробелов около косой черты).

- Неверный путь к сетевой папке. Например, указан локальный путь, а не сетевой.

- Если все сохраненные значения параметров верны, а при попытке сканирования возникает ошибка, проверьте настройки сетевого экрана (firewall’а — ‘брандмауэра’), возможно, что в сетевых правилах существует запись с более высоким приоритетом, блокирующая порт.

Настройка компьютера:

- Проверьте сетевое полное имя компьютера (хоста), домен и имя пользователя и запишите значения. Пользователи Windows в командной строке могут набрать net config workstation либо получить нужные значения через «Свойства системы.

- Создайте сетевую папку и настройте права доступа в ней. В общей папке можно создать подпапку в качестве расположения для передачи данных. В этом случае в поле «Путь нужно ввести «Имя общей папки Имя подпапки (без кавычек и пробелов около косой черты).

- Включите общий доступ для файлов и принтеров и (если необходимо) настройте правило для входящих подключений: 139 порт по протоколу TCP. 139 — порт по умолчанию, но он может быть изменен (см. Руководство пользователя).

Настройка МФУ:

-

- Убедитесь, что в COMMAND CENTER включены протоколы SMB и FTP (подробная информация изложена в руководстве пользователя, в том числе правило ввода символов).

- Положите оригинал на стекло, нажмите клавишу «Отправить.

- Выберите направление передачи: папка SMB или папка FTP.

- Введите имя компьютера.

- Введите имя папки, заданное в параметрах общего доступа.

- Введите имя и пароль пользователя, которые используются для входа в компьютер с папкой общего доступа.

- В случае удачной проверки нажмите «Подтвердить адресат и клавишу «Старт.

Примечание: При внесении неправильных данных могут возникать ошибки с кодами 1102, 1103 и 3101 при проблемах с FTP‐сервером.

Kyocera. Ошибка 1103

Может быть при сканировании может появиться при:

- Передаче через SMB‐сервер. Проверьте параметры настройки SMB:

- имя пользователя и пароль при входе;

Примечание: Если отправитель является пользователем домена, укажите имя домена.

- путь;

- право доступа получателя к папке.

- Передаче через FTP‐сервер. Проверьте параметры настройки FTP‐сервера:

- путь;

- право доступа получателя к папке.

Ошибка 1105 Kyocera

может быть при:

- Передаче через SMB‐сервер. Проверьте следующие настройки в COMMAND CENTER:

- задайте значение «Вкл. для настроек SMB‐сервера.

- Передаче электронного письма. Проверьте следующие настройки в COMMAND CENTER:

- задайте значение «Вкл. для настроек SMTP‐сервера.

- Передаче через FTP‐сервер. Проверьте следующие настройки в COMMAND CENTER:

- задайте значение «Вкл. для настроек FTP‐сервера.

Below is a long list of Kyocera error codes. Some Kyocera printers can be reset by turning the machine power switch off and back on while some others activate “partial operation control” disabling the defective part/area of the machine (paper feed cassette, stapler, document processor etc). If a specific unit is not working, perform U906 after taking measures against the cause of trouble to reactivate the unit.

Error Code

Description

C0030

Fax PWB Problem. Processing with fax software is disabled due to software or hardware issues.

C0060

Main PWB Type Mismatch Error.

C0070

Fax PWB Incompatability Detection Problem. Fax software is not compatible with main PWB software.

C0130

Main PWB EEPROM Backup Memory Device Problem. EEPROM can not be written or read.

C0140

Main PWB EEPROM Backup Memory Data Problem. Abnormal reading data from EEPROM.

C0150

Engine PWB EEPROM Backup Memory Device Problem. EEPROM cannot be written or read.

C0160

Engine PWB EEPROM Backup Memory Data Problem. Abnormal reading data from EEPROM. Read & write data do not match five times consecutively.

C0170

Copy Counts Problem. A checksum error is detected in the main and engine backup memories for copy counters.

C0180

Machine Number Mismatch Error. Machine number does not match on main and engine PWBs

C0600

Main PWB DIMM Installed Incorrectly.

C0610

Main PWB DIMM error

C0630

DMA transmission of compressed, decompressed, rotated, relocated, or blanked-out image data does not complete within a specified period of time.

C0640

Hard Disk Drive cannot be accessed

C0700

Optional CF backup is not suitable.

C0800

Image processing problem. JAM05 is detected twice.

C0830

Fax Flash ROM program area checksum error

C0870

Fax PWB to Main PWB high capacity data transfer problem.

C0880

Fax PWB program archive problem.

C0920

Fax backup data is not retained.

C1010

Cassette #1 Lift Motor error. Exceeds 12 seconds of operation or 500ms of overcurrent.

C1020

Cassette #2 Lift Motor error. Exceeds 12 seconds of operation or 500ms of overcurrent.

C1030

PF-700 optional cassette #3 lift motor error.

C1040

PF-700 optional cassette #4 lift motor error.

C1100

PF-750 (Left) Lift Motor 1 error. Exceeds 1 second overcurrent.

C1110

PF-750 (Right) Lift Motor 2 error. Exceeds 1 second overcurrent.

C1120

PF-750 (Left) Lift Motor 1 position problem. PF switch 2 remains off after 30 seconds of motor operation.

C1130

PF-750 (Right) Lift Motor 2 position problem. PF switch 1 remains off after 30 seconds of motor operation.

C1800

PF-700/PF-750 Communication Problem.

C1900

PF-700 EEPROM error. Write data & Read data are not in agreement three times consecutively.

C2000

Drive Motor Problem. Stable Off is detected exceeding 1 sec after motor stability. Stabilization is not detected with 6 sec of activation.

C2250

Main Charge Cleaner Motor error. Lock error is detected three times in a row during cleaner motor operation.

C2500

Paper Feed Motor error. Stable Off is detected exceeding 1 sec after motor stability. Stabilization is not detected within 6 seconds of activation.

C2600

PF-700 Drive Motor error. Lock signal exceeds 500ms.

C2600

PF-750 Paper Conveying Motor error. Lock signal exceeds 450ms.

C3100

Scanner Carriage Problem. Scanner home position is not detected at initialization or start of copying from contact glass.

C3200

Exposure Lamp Problem. Exposure lamp does not reach the input value threshold within 5 sec of commencing reading.

C3210

Exposure Lamp Problem. Exposure lamp does not exceed the input threshold value within 5 sec of commencing reading.

C3300

CCD AGC Problem. After AGC correct input is not obtained at the CCD.

C3310

CIS AGC Problem. After AGC correct input is not obtained at the CIS.

C3500

Communication Error Between Scanner and SHD.

C3900

Scanner PWB Backup Memory Read/Write Problem. Read & Write data does not match.

C3910

Scanner PWB Backup Memory Data Problem. Data in a specified area of the backup memory does not match the specified values.

C4000

Polygon Motor Synchronization Problem. Polygon motor does not stabilize speed within 20 sec of activation.

C4010

Polygon Motor Steady-State Problem. Stable Off is detected for 20 sec continuously after polygon motor stabilization.

C4200

BD Steady-State Problem. ASIC detects a Beam Detect error A for 2 sec after polygon motor stabilization.

C5300

Cleaning Lamp Broken Wire. While the cleaning lamp is On, the broken wire detection signal is detected for 2 sec continuously.

C6000

Fuser Heater Break. Thermistor1 detected less than 70C/158F for 10 sec during warmup & ready. Thermistor2 detected less than 40C/104F for 10 sec during warmup & ready. Temp at thermistor 1or 2 does not rise by at least 1C/1.8F within 5 sec.

C6020

Abnormally High Thermistor Temperature. Thermistor 1 or 2 is detected 250C/482F for 40ms or more.

C6030

Fixing Thermistor Break Error. Thermistor break signal is detected for 1 sec.

C6050

Abnormally Low Thermistor Temperature. Thermistor 1 is detected 80C/176F or less for 1 sec continuously during copying.

C6400

Zero-Cross Signal Error. While fuser heater On/Off control is performed, the zero-cross signal is not input within 3 sec.

C6410

Fuser Unit Connection Insertion Problem. Absence of fuser unit is detected.

C6420

Fuser Unit Fuse Cut Problem. The fuse has been cut 33 sec after the fuse cut signal is turned on.

C7300

Toner Container Problem. Toner level is not detected when toner empty is detected.

C7400

Developing Unit Connection Insertion Problem. Absence of the developing unit is detected.

C7410

Drum Unit Connection Insertion Problem. Absence of the drum unit is detected.

C7800

Broken External Thermistor Wire. Thermistor on the environmental sensor outputs 4.5v or more.

C7810

Short-Circuited External Thermistor. Thermistor input value is 0.5v or less.

C7900

Drum EEPROM Error. Reading or writing to the EEPROM cannot be performed.

C7910

Developing EEPROM Error. Reading or writing to the EEPROM cannot be performed.

C8020

DF-710 Punch Motor Problem. Punch motor lock signal is detected for 500ms or more during activation.

C8030

DF-730 Tray Upper Limit Detection Problem. When tray elevation motor raises a tray, the upper limit switch detects On condition.

C8050

DF-710 Paper Conveying Belt Motor 1 Error. Paper conveying belt home position sensor 1 does not turn Off within 1.5 sec. Paper conveying belt home position sensor 1 does not turn On within 2.5 sec. Jam 88.

C8060

DF-710 Paper Conveying Belt Motor 2 Error. Paper conveying belt home position sensor 2 does not turn Off within 1.5 sec. Paper conveying belt home position sensor 2 does not turn On within 2.5 sec.

C8070

DF-710 Internal Tray Communication Error. The connection is detected, but communication is not possible with the internal tray.

C8140

DF-710 Main Tray Problem. Main tray is not detected in not detected by main tray top limit detection sensor or main tray capacity detection sensor within 20 sec of ascending. Main tray upper limit detection sensor or main tray load detection sensor is not detected as Off within 20 sec of main tray descending. Main tray lower limit detection sensor is not detected as On within 20 sec of main tray descending. Main tray upper limit detection sensor or main tray load detection sensor remain on for 2 sec or more during main tray ascent.

C8140

DF-730 Tray Elevation Motor Problem. Tray lower limit sensor or surface view sensor cannot be detected within 10 sec.

C8170

DF-710 Side Registration Motor 1 Problem. During initial rotations home position is not detected within 3 sec. Jam 88.

C8170

DF-720 Front Side Registration Motor Problem. During initial rotations home position is not detected within 106 pulses. When the front side home position sensor is turned off during initialization, the sensor did not turn on within 3 sec.

C8170

DF-730 Adjustment Motor Problem. Adjustment motor home position motor is not detected within a specific time during activation.

C8180

DF-710 Side Registration Motor 2 Problem. During initial rotations home position is not detected within 3 sec. Jam 88.

C8180

DF-720 Rear Side Registration Motor Problem. During initial rotations home position is not detected within 106 pulses. When the rear side home position sensor is turned off during initialization, the sensor did not turn on within 3 sec.

C8190

DF-720 Trailing Edge Registration Motor Problem. During initial rotations home position is not detected within 106 pulses. When the trailing edge home position sensor is turned off during initialization, the sensor did not turn on within 3 sec.

C8210

DF-710 Stapler Moving Motor 1 Error. During initial rotations home position is not detected within 1.5 sec.

C8210

DF-720 Finisher Stapler Problem. Stapler home position sensor does not change state from non-detect to detect within 200ms of forward (CCW) rotation. During initial rotations stapler home position detection does not change state from non-detect to detect within 600ms of reverse (CW) rotation.

C8210

DF-730 Stapler Problem. Home position is not detected within a specific time of activation.

C8220

DF-710 Stapler Moving Motor 2 Error. During initial rotations home position is not detected within 3.5 sec.

C8230

DF-710 Stapler Motor Problem. Jam 82 is indicated.

C8300

BF-710 Centerfold Unit Communiation Error. Although the connection is detected, communication is not possible with the centerfold unit.

C8310

BF-710 Centerfold Side Registration Motor 1 Problem. During initial rotations home position is not detected within 1000ms.

C8320

BF-710 Centerfold Paper Conveying Belt Motor Problem. During initial rotations home position is not detected within 2500ms.

C8330

BF-710 Blade Motor Problem. During initial rotations home position is not detected within 1500ms.

C8340

BF-710 Centerfold Staple Motor Problem. Jam 89.

C8350

BF-710 Centerfold Side Registration Motor 2 Problem. During initial rotations home position is not detected within 1000ms.

C8360

BF-710 Centerfold Main Motor Problem. The motor lock signal is detected for more than 1000ms during activation.

C8440

DF-730 Sensor Adjusting Problem. The paper entry sensor cannot be adjusted within the specified range.

C8460

DF-730 EEPROM Problem. Reading to or writing from EEPROM cannot be performed.

C8500

MT-710 Communication Error. The connection is detected, but communication is not possible with the mailbox.

C8510

MT-710 Drive Motor Problem. The motor lock signal is detected for more than 500ms during activation.

C8800

DF-710 Communication Problem. No communication: there is no reply after (5) tries. Abnormal communication: a parity or checksum error is detected (5) times in succession.

C8900

DF-710 Backup Memory Data Problem. Read and write data does not match.

C8910

PH-5A Backup Memory Data Problem. Read and write data does not match.

C8920

MT-710 Backup Memory Data Problem. Read and write data does not match.

C8930

BF-710 Backup Memory Data Problem. Read and write data does not match.

C9000

DP-700 Communication Problem. A communication error is detected.

C9040

DP-700 Lift Motor Ascent Error. The DP lift upper limit switch is not detected within 10000 pulses. After a one time retry, the DP lift upper limit switch could not be turned On.

C9050

DP-700 Lift Motor Descent Error. The DP lift lower limit switch is not detected within 10000 pulses. After a one time retry, the DP lift lower limit switch could not be turned On.

C9060

DP-700 EEPROM Error. Read and write data does not match. Data in the specified area of the backup memory does not match the specified values.

C9070

DP-700 Communication Error between the DP and SHD. A communication error is detected.

C9080

DP-700 Communication Error between the DP and CIS. Reading cannot be performed correctly.

CF000

Operation Panel PWB Communication Error/System Error. Unknown error. Communication error between panel and main controller. (If CF620 occurred and is left, CF000 also occurred because of timeout control.

CF010

Main PWB Checksum Error/System Error. Communication error between panel and main controller.

CF020

Memory Checksum Error/Operation System Error.

CF030

Main PWB System Error.

CF040

Engine PWB Communication Error.

CF041

Scanner PWB Communication Error.

CF050

Engine ROM Checksum Error.

CF060

Engine RAM Error.

CF070

Flash ROM Error. Defective flash ROM (which?).

CF080

Flash ROM Error (during download). Defective flash ROM (which?).

CF090

Fax System M Communication Error.

CF14F

Power Source Secondary Side Error/Operation System Error. The operation decomes unstable after recovering the power supply fail (brownout or power drop). Wall voltage is unstable or the main power supply switch was turned OFF/ON within 1 sec.

CF256

Fax System M IOBL error or KUIOLIB error. Poor contact at the fax card card due to mis-installation.

CF257

Fax System M IOBL error or KUIOLIB error. Poor contact at the fax card card due to mis-installation.

CF26F

Print System Other Errors. Bug of v.2.03B has been fixed by v. 2.04A (Booklet > Booklet Print).

CF3xx

Undefined.

CF423

Fax System M Error. Wrong data or value detected when the following function is used. Or poor contact at fax card due to mis-installation.

CF423

Fax System M Error. The IF error detects during system authentication from ACT_Account_Manager. Or poor contact at fax card due to mis-installation.

CF433 CF434 CF437 CF43F CF441 CF444 CF445 CF451

HDD Image Process Error. Destruction of stored jobs on the HDD. It may occur when selecting the keys for calling stored copy or scanner job from a custom box.

CF45F CF453 CF454 CF45F CF460 CF463 CF46F CF470

HDD Image Process Error. Destruction of stored jobs on the HDD. It may occur when selecting the keys for calling stored copy or scanner job from a custom box.

CF473 CF47F CF484 CF487 CF48F CF490 CF493 CF494

HDD Image Process Error. Destruction of stored jobs on the HDD. It may occur when selecting the keys for calling stored copy or scanner job from a custom box.

CF5xx

Undefined.

CF610

System Start Error.

CF620

System Error. Error acquiring the event data. Panel detects CF000 as same error.

CF620

System Error. Error acquiring the event data. Panel detects CF000 as same error. Unable to Load Files To CF Card.

CF7D7

Readout Error of SSL (authentication data).

CFAxx

HDD Error.

CFB2C CFB30 CFB31

Panel Error. NetFont error. Communication error between panel and main controller during initialization or rejection of communication by controller during initialization. Blue Screen of Death.

CFB30

Incompatible Level Of Firmware on Main EEPROM.

CFB31

Corrupt Firmware on Main EEPROM.

CFB32

Panel Error. Timeout request for start up command. Start command hasn’t been received. Possible destruction of system file in HDD. Cannot enter maintenance mode. Blue Screen of Death.

CFB33

Panel Error. Detects disconnection with controller. Possible overdrive of control board or destruction of system file in HDD. Cannot enter maintenance mode. Blue Screen of Death.

F000

Operation Panel PWB Communication Error.

F010

Main PWB Checksum Error.

F020

Memory Checksum Error.

F030

Main PWB System Error.

F040

Engine PWB Communication Error.

F041

Scanner PWB Communication Error.

F050

Engine ROM Checksum Error.

F060

Engine RAM Error.

F070

Flash ROM Error.

F080

Flash ROM Error (during download).

F090

Fax Control PWB Communication Error.

F14F

Power Source PWB Second Side Error.

E00000 or U00000

Fax Communication Error: No response or line busy after the set number of redials.

E00100 or U00100

Fax Communication Error: Transmission was interruped by a press of the Stop/Clear key.

E00200 or U00200

Fax Communication Error: Reception was interrupted by a press of the Stop/Clear key.

E00300 or U00300

Fax Communication Error: Recording paper on the destination unit has run out during reception.

E00420 or U00420

Fax Communication Error: A relay request was received from the host center but interrupted because of a mismatch in permit ID or telephone number.

E00421 or U00421

Fax Communication Error: Subaddress-based relay reception was interrupted because of a mismatch in the specified subaddress relay box number.

E00430 or U00430

Fax Communication Error: Polling request (confidential or reverse polling) was received but interrupted because of a mismatch in the permit number.

E00430 or U00430

Fax Communication Error: Subaddress-based bulletin board transmission was interrupted because of a mismatch in the permit ID of the transmitting unit.

E00431 or U00431

Fax Communication Error: Confidential polling transmission was interrupted because the specified confidential box number was not registered.

E00431 or U00431

Fax Communication Error: A subaddress-based bulletin board transmission was interrupted because the specified subaddress confidential box was not registered.

E00432 or U00432

Fax Communication Error: Confidential polling transmission was interrupted because of a mismatch in the confidential box ID number.

E00432 or U00432

Fax Communication Error: A subaddress-based bulletin board transmission was interrupted because of a mismatch in the subaddress confidential box number.

E00433 or U00433

Fax Communication Error: Confidential polling request was received but data was not present in the confidential box.

E00433 or U00433

Fax Communication Error: Subaddress-based bulletin board transmission request was received but data was not present in the subaddress confidential box.

E00434 or U00434

Fax Communication Error: Confidential polling request was received but interrupted because the specified confidential box number was intended for encryption.

E00435 or U00435

Fax Communication Error: Confidential polling request was received but interrupted because the specified confidential box was being accessed.

E00435 or U00435

Fax Communication Error: Subaddress-based bulletin board transmission request was received but interrupted because the specific subaddress confidential box was being accessed.

E00440 or U00440

Fax Communication Error: Confidential reception was interrupted because the specified confidential box number was not registered.

E00440 or U00440

Fax Communication Error: Subaddress-based confidential reception or subaddress-based relay reception was interrupted because the specific subaddress box was not registered.

E00440 or U00440

Fax Communication Error: Subaddress-based confidential reception or subaddress-based relay command reception was interrupted because the specific subaddress box number was being accessed.

E00441 or U00441

Fax Communication Error: Confidential reception was interrupted because the specified confidential box number was intended for encryption.

E00450 or U00450

Fax Communication Error: The destination transmitter disconnected because the permit IDs did not agree while the destination transitter is in password-check transmission or restricted transmission.

E00460 or U00460

Fax Communication Error: Encrypted reception was interrupted because the specified encryption box number was not registered.

E00460 or U00460

Fax Communication Error: Ecrypted reception request was received but interrupted because the specified encryption box was being accessed.

E00462 or U00462

Fax Communication Error: Ecryption reception was interrupted because the encryption key for the specified encryption box was not registered.

E00500 or U00500

Fax Communication Error: Multiple communication was interrupted and the call was not made on destination units after interruption.

E00600 or U00600

Fax Communication Error: The document processor cover is open.

E00601 or U00601

Fax Communication Error: Document jam or the document length exceeds the maximum.

E00602 or U00602

Fax Communication Error: Image scanning section problem

E00603 or U00603

Fax Communication Error: No document feed.

E00604 or U00604

Fax Communication Error: Document length exceeded the limit of the bitmap memory capacity.

E00610 or U00610

Fax Communication Error: Recording section cover open.

E00611 or U00611

Fax Communication Error: Recording paper jam.

E00613 or U00613

Fax Communication Error: Image writing section problem.

E00614 or U00614

Fax Communication Error: Nearly empty of recording paper.

E00615 or U00615

Fax Communication Error: Empty of recording paper.

E00620 or U00620

Fax Communication Error: Copier fixing unit problem.

E00622 or U00622

Fax Communication Error: Copier drive motor problem.

E00655 or U00655

Fax Communication Error: CTS was not activated after RTS due to a modem error.

E00656 or U00656

Fax Communication Error: Data was not transmitted after CTS was activated due to a modem error.

E00670 or U00670

Fax Communication Error: Power was cut off during communication.

E00677 or U00677

Fax Communication Error: There was no file to transmit in the memory transmission mode.

E00690 or U00690

Fax Communication Error: System error.

E00700 or U00700

Fax Communication Error: Communication was interrupted because of a problem in the destination unit.

E00800 or U00800

Fax Communication Error: A page transmission error occurred in G3 mode, because of reception of a RTN or PIN signal.

E00810 or U00810

Fax Communication Error: A page transmission error re-occurred in G3 mode after retry of transmission in ECM mode.

E00900 or U00900

Fax Communication Error: A page reception error occurred in G3 mode. An RTN or PIN signal was transmitted because of a page reception error.

E00910 or U00910

Fax Communication Error: A page reception error occurred in G3 mode. A page reception error remained after retry of transmission in ECM mode.

E01000 or U01000

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. An FTT signal was received for a set number of times after TCF signal transmissions at 2400bps.

E01000 or U01000

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. An RTN signal was received in response to a Q signal (excluding EOP) after transmission at 2400bps.

E01001 or U01001

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. The function of the unit differs from that indicated by a DIS signal.

E01010 or U01010

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of a DNL (MPS or EOM) signal, and the preset number of command retransfers was exceeded (between units of our make).

E01011 or U01011

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of a DCS, TCF signal, and the preset number of command retransfers was exceeded.

E01012 or U01012

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of an NSS1, NSS2 (TCF) signal, and the preset number of command retransfers was exceeded (between units of our make).

E01013 or U01013

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of an NSS3, TCF signal, and the preset number of command retransfers was exceeded (between units of our make).

E01014 or U01014

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of an MPS signal, and the preset number of command retransfers was exceeded.

E01015 or U01015

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of an EOM signal, and the preset number of command retransfers was exceeded.

E01016 or U01016

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. An MCF signal was received but no DIS signal was received after transmission of an EOM signal, and T1 timeout was detected.

E01017 or U01017

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of an EOP signal, and the preset number of command retransfers was exceeded.

E01018 or U01018

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of a PRI-EOP signal, and the preset number of command retransfers was exceeded.

E01019 or U01019

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of a CNC signal, and the preset number of command retransfers was exceeded (between units of our make).

E01020 or U01020

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of a CTC signal, and the preset number of command retransfers was exceeded (ECM).

E01021 or U01021

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of an EOR.Q signal, and the preset number of command retransfers was exceeded (ECM).

E01022 or U01022

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of a RR signal, and the preset number of command retransfers was exceeded (ECM).

E01023 or U01023

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of a PS.NULL signal, and the preset number of command retransfers was exceeded (ECM).

E01024 or U01024

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of a PPS.MPS signal, and the preset number of command retransfers was exceeded (ECM).

E01025 or U01025

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of a PPS.EOM signal, and the preset number of command retransfers was exceeded (ECM).

E01026 or U01026

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of a PPS.EOP signal, and the preset number of command retransfers was exceeded (ECM).

E01027 or U01027

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. No relevant signal was received after transmission of a PPS.PRI-EOP signal, and the preset number of command retransfers was exceeded (ECM).

E01028 or U01028

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. T5 timeout was detected during ECM Transmission (ECM).

E01040 or U01040

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN or other inappropriate signal was received during standby for DIS signal reception.

E01041 or U01041

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of a DNL (MPS or EOM) signal (between units of our make).

E01042 or U01042

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of a DCS, TCF signal.

E01043 or U01043

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of an NSS1, NSS2 (TCF) signal (between units of our make).

E01044 or U01044

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of an NSS3, TCF signal (between units of our make).

E01045 or U01045

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN or other inappropriate signal was received after transmission of an MPS signal.

E01046 or U01046

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN or other inappropriate signal was received after transmission of an EOM signal.

E01047 or U01047

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN or other inappropriate signal was received after transmission of an EOP signal.

E01048 or U01048

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of a PRI-EOP signal.

E01049 or U01049

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of a CNC signal (between units of our make).

E01050 or U01050

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of a CTC signal (ECM).

E01051 or U01051

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of an EOR.Q signal (ECM).

E01052 or U01052

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of an RR signal (ECM).

E01053 or U01053

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of a PPS.NULL signal (ECM).

E01054 or U01054

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of a PPS.MPS signal (ECM).

E01055 or U01055

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of a PPS.EOM signal (ECM).

E01056 or U01056

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of a PPS.EOP signal (ECM).

E01057 or U01057

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. A DCN signal was received after transmission of a PPS.PRI-EOP signal (ECM).

E01070 or U01070

Fax Communication Error: Transmission in G3 mode was interrupted by a signal error. Polarity reversal was detected during handshake.

E01071 or U01071