Все современные копировальные аппараты, мфу и принтеры Kyocera имеют возможность диагностировать все узлы устройства в режиме запуска и во время работы аппарата. По этому, если во время включения или во время работы произошел сбой, то техника Kyocera сможет сообщить о наличии ошибки.

В большинстве случаев у аппаратов Kyocera код ошибки отображается на дисплее, в остальных случаях тип ошибки зависит от последовательности и количества миганий индикаторов.

Если Ваш копировальный аппарат, МФУ или принтер Kyocera выдал на дисплее некий код, то узнать причину, описание возникновения ошибки, а так же в каком узле аппарата стоит искать проблему, Вы можете в этом разделе выбрав интересующую модель из списка.

Но диагностика не решит проблему сбоя аппарата, для этого лучше обратиться к профессиональным и опытным сервисным специалистам компании Kyomart! Позвоните нам по телефону

8 (343) 288-23-45 или отправьте запрос на электронную почту: sales@kyomart.ru , и мы обязательно свяжемся с Вами в кратчайшие сроки.

| Код ошибки | Описание ошибки | Причина ошибки |

|---|---|---|

| 0030 | FAX control PWB system error Processing with the fax software was disabled due to a hardware problem. |

Defective FAX control PWB. |

| 0060 | Engine PWB type error | Defective engine sub PCB. |

| 0070 | FAX control PWB incompatible detection error Abnormal detection of FAX control PWB incompatibility In the initial communication with the FAX control PWB, any normal communication command is not transmitted. |

Defective FAX software Defective FAX control PWB. |

| 0100 | Backup memory device error | Defective flash memory. |

| 0120 | MAC address data error For data in which the MAC address is invalid. |

Defective main PWB. Defective flash memory. Defective engine PWB. |

| 0130 | Backup memory read/write error (main PWB) | Defective flash memory. Defective main PWB. |

| 0140 | Backup memory data error (main PWB) | Defective flash memory. Defective main PWB. |

| 0150 | Backup memory read/write error (engine PWB) Detecting engine PWB EEPROM communication error. |

Improper installation engine PWB EEPROM. Defective engine PWB. Device damage of EEPROM. |

| 0160 | Backup memory data error (engine PWB) | Defective flash memory. Defective engine PWB. |

| 0170 | Billing counting error A checksum error is detected in the main and engine backup memories for the billing counters. |

Data damage of EEPROM. Defective PWB. |

| 0180 | Machine number mismatch Machine number of main and engine does not match. |

Data damage of EEPROM. |

| 0320 | I/O CPU communication error A communication error is detected 10 times in succession. |

Defective PWB. |

| 0630 | DMA error DMA transmission of image data does not complete within the specified period of time. | Poor contact in the connector terminals. Defective main PWB. |

| 0800 | Image processing error JAM05 is detected twice. |

Defective main PWB. |

| 0830 | FAX control PWB flash program area checksum error A checksum error occurred with the program of the FAX control PWB. |

Defective FAX software. Defective FAX control PWB. |

| 0840 | Faults of RTC The time is judged to go back based on the comparison of the RTC time and the current time or five years or more have passed. |

The battery is disconnected from the main PWB. Defective main PWB. |

| 0870 | FAX control PWB to main PWB high capacity data transfer error High-capacity data transfer between the FAX control PWB and the main PWB of the machine was not normally performed even if the data transfer was retried the specified times. |

Improper installation FAX control PWB. Defective FAX control PWB or main PWB. |

| 0920 | Fax file system error The backup data is not retained for file system abnormality of flash memory of the FAX control PWB. |

Defective FAX control PWB. |

| 1010 | Lift motor error After cassette 1 is inserted, lift sensor does not turn on within 12 s. This error is detected four times successively. |

Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the lift motor. Defective lift motor. Defective engine PWB. |

| 1020 | PF lift motor error (paper feeder) After cassette 2 is inserted, PF lift sensor 1 does not turn on within 12 s. This error is detected four times successively. |

Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF lift motor 1. Defective PF lift motor 1. Defective PF main PWB. |

| 1030 | PF lift motor error (paper feeder) After cassette 3 is inserted, PF lift sensor 2 does not turn on within 12 s. This error is detected four times successively. |

Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF lift motor 2. Defective PF lift motor 2. Defective PF main PWB. |

| 1800 | Paper feeder communication error A communication error is detected 10 times in succession. |

Improper installation paper feeder. Defective connector cable or poor contact in the connector. Defective engine PWB. Defective PF main PWB. |

| 1900 | Paper feeder EEPROM error When writing the data, the write data and the read data is not continuously in agreement 5 times. |

Defective PF main PWB. Device damage of EEPROM. |

| 2000 | Main motor steady-state error Stable OFF is detected for 1 s continuously after main motor stabilized. |

Defective connector cable or poor contact in the connector. Defective drive transmission system of the main motor. Defective main motor. Defective engine PWB. |

| 2010 | Main motor drive error The main motor is not stabilized within 2 s after driving starts. |

Defective connector cable or poor contact in the connector. Defective drive transmission system of the main motor. Defective main motor. Defective engine PWB. |

| 2600 | PF drive motor error (paper feeder) When the PF drive motor is driven, error signal is detected continuously for 1 s. |

Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF drive motor. Defective PF drive motor. Defective PF main PWB. |

| 3100 | ISU home position error The home position is not correct when the power is turned on or at the start of copying using the table. |

Defective connector cable or poor contact in the connector. Defective home position sensor. Defective ISU motor. Defective CCD PWB. Defective engine PWB. |

| 3200 | Exposure lamp error When input value at the time of exposure lamp illumination does not exceed the threshold value between 5 s. |

Defective connector cable or poor contact in the connector. Defective exposure lamp. Defective CCD PWB. Defective main PWB. |

| 3500 | Communication error between scanner and ASIC An error code is detected 3 times in succession. |

Defective connector cable or poor contact in the connector. Defective CCD PWB. Defective main PWB. |

| 3600 | Scanner sequence error | Defective main PWB or engine PWB. |

| 4000 | Polygon motor synchronization error The polygon motor is not stabilized within 10 s after driving starts. |

Defective connector cable or poor contact in the connector. Defective polygon motor. Defective engine PWB. |

| 4010 | Polygon motor steady-state error Stable OFF is detected for 1 s continuously after polygon motor stabilized. |

Defective connector cable or poor contact in the connector. Defective polygon motor. Defective engine PWB. |

| 4100 | BD initialization error BD is not detected within 1 s after polygon motor stabilized. |

Defective connector cable or poor contact in the connector. Defective APC PWB. Defective BD PWB. Defective main PWB. |

| 4700 | VIDEO ASIC device error | Defective connector cable or poor contact in the connector. Defective main PWB or engine PWB. |

| 6000 | Broken fuser heater wire The detected temperature of fuser thermistor does not reach the specified temperature (ready indication temperature) after the fuser heater has been turned on continuously for 60 s in warming up. The fusing temperature at 7 seconds and 20 seconds since fuser temperature control has occurred differs by 43°C/109.4°F or less. |

Defective connector cable or poor contact in the connector. Deformed connector pin. Defective triac. Fuser thermostat triggered. Broken fuser heater wire. Defective engine PWB. |

| 6000 6020 6030 6050 |

Broken fuser heater wire Abnormally high fuser thermistor temperature Broken fuser thermistor wire Abnormally low fuser thermistor temperature |

Deformed connector pin. Defective triac. |

| 6020 | Abnormally high fuser thermistor temperature The fuser thermistor detects a temperature higher than 230°C/446°F continuously for 40 ms. High fuser temperature signal detects a temperature of 255°C/491°F continuously for 40 ms. |

Deformed connector pin. Defective triac. Shorted fuser thermistor. Defective engine PWB. |

| 6030 | Broken fuser thermistor wire A/D value of the fuser thermistor exceeds 251 bit continuously for 7 s during warming up. |

Defective connector cable or poor contact in the connector. Deformed connector pin. Defective triac. Defective fuser thermistor. Defective engine PWB |

| 6050 | Abnormally low fuser thermistor temperature As the stable temperature has reached the second time, the decrease in the fuser thermistor temperature of 60°C/140°F or greater is detected for one second. |

Deformed connector pin. Defective triac. Defective fuser thermistor Defective fuser heater. Defective engine PWB. |

| 6400 | Zero-cross signal error While fuser heater control is performed, the zero-cross signal is not input within 3 s. |

Defective connector cable or poor contact in the connector Defective power source PWB or engine PWB. |

| 7800 | Broken external thermistor wire The thermistor output value is 0.3 V or less. |

Defective connector cable or poor contact in the connector. Defective temperature sensor. |

| 7810 | Short-circuited external thermistor wire The thermistor output value is 3 V or more. |

Defective connector cable or poor contact in the connector. Defective temperature sensor. |

| 7900 | Drum unit EEPROM error No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. |

Defective connector cable or poor contact in the connector. Defective drum unit. |

| 7910 | Developer unit EEPROM error No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. |

Defective connector cable or poor contact in the connector. Defective developer unit. |

| 8030 | Tray upper limit detection problem (document finisher) When the tray elevation motor raises a tray, the ON status of the tray upper limit sensor is detected. |

Defective connector cable or poor contact in the connector. Defective tray upper limit sensor, paper surface sensor 1/2. Defective DF main PWB. |

| 8040 | Belt problem (document finisher) The belt sensor does not turn on/off within specified time of the belt solenoid turning on. |

Defective connector cable or poor contact in the connector. Defective belt sensor. Defective belt solenoid. Defective DF main PWB. |

| 8140 | Tray elevation motor problem (document finisher) The tray low limit sensor or paper surface sensor 1/2 cannot be detected to be on within 10 s since the tray elevation motor is activated. |

Defective connector cable or poor contact in the connector. Defective connector cable or poor contact in the connector. The tray elevation motor malfunctions. Defective tray lower limit sensor, paper surface sensor 1/2. Defective DF main PWB. |

| 8210 | Stapler problem (document finisher) Jam 7012 or 7023 is indicated. |

Defective connector cable of staple or poor contact in the connector. The stapler is blocked with a staple. The stapler is broken Defective DF main PWB. |

| 8320 | Adjustment motor 2 problem (document finisher) The adjustment sensor 2 does not turn on/off within specified time of the adjustment motor 2 turning on. |

Defective connector cable or poor contact in the connector. Defective adjustment sensor 2. Defective adjustment motor 2. Defective DF main PWB. |

| 8330 | Adjustment motor 1 problem (document finisher) The adjustment sensor 1 does not turn on/off within specified time of the adjustment motor 1 turning on. |

Defective connector cable or poor contact in the connector. Defective adjustment sensor 1. Defective adjustment motor 1. |

| 8350 | Roller motor problem (document finisher) The roller sensor does not turn on/off within specified time of the roller motor turning on. |

Defective DF main PWB. Defective connector cable or poor contact in the connector. Defective roller sensor. Defective roller motor. Defective DF main PWB. |

| 8360 | Slide motor problem (document finisher) The slide sensor does not turn on/off within specified time of the slide motor turning on. |

Defective connector cable or poor contact in the connector. Defective slide sensor. Defective slide motor. Defective DF main PWB. |

| 8460 | EEPROM problem (document finisher) Reading from or writing to EEPROM cannot be performed. |

Defective EEPROM or DF main PWB. |

| 8800 | Document finisher communication error A communication error is detected 10 times in succession. |

Defective connector cable or poor contact in the connector Defective DF main PWB. Defective engine PWB. |

| 8830 | Bridge communication error (document finisher) A communication error is detected 10 times in succession. |

Defective connector cable or poor contact in the connector. Defective bridge PWB. Defective engine PWB. |

| 8990 | Document finisher communication error | Defective connector cable or poor contact in the connector. Defective DF main PWB. Defective bridge PWB. |

| 9000 | Document processor communication error A communication error is detected 10 times in succession. |

Defective connector cable or poor contact in the connector. Defective DP main PWB. |

| 9060 | DP EEPROM error Read and write data does not match. Data in the specified area of the backup memory does not match the specified values. | Defective DP main PWB. Device damage of EEPROM. |

| 9500 | BRU communication error | IPU PWB error |

| 9510 | BRU PWB error | IPU PWB error |

| 9520 | BRU PWB data error | IPU PWB error |

| F000 | Main PWB — operation panel PWB communication error | Defective main PWB. Defective operation panel PWB. |

| F010 | Main PWB checksum error | Defective main PWB. |

| F040 | Main PWB — print engine communication error | Defective main PWB. Defective engine PWB. |

| F050 | Print engine ROM checksum error | Defective engine PWB. |

juhay писал(а):К сожалению у нас с Вами немного разный подход к использованию оргтехники. Я — пользователь, Вы — настройщик. Для меня важно в данный момент допечатать, закончить необходимый мне фронт работ, а уже потом — нести аппарат в ремонт. Разумеется я исключаю случаи, когда летят шестерни, переламываются шлейфы, горят платы, замыкают датчики. Механику я чиню сам. Разумеется всё в разумных пределах. Для Вас , на мой взгляд — ортехника — это прежде всего машина, в которую обычному пользователю лучше нос не совать глубже открытия крышки и установки новой тубы с тонером и протирания пыли. А то что заказ (договор, методич руководство, или что нибудь ещё) горит и нужно его распечатать имеено сейчас, потому как дело «на мильон тугриков» об этом Вы не думаете, точнее не заморачиваетесь. Аппарат отказал — неси в ремонт. Сиди и жди без работы 2 дня (в лечшем случае) а потом окажется что там всего лишь нужно было сбросить настройки аппарата на «поумолчанию» — дело 1 минуты. А потеряно 2 дня. Пробег роликов — не менял. Со дня покупки.

Ваша точка зрения примерно ясна. Увы, вы не пользователь: вы юзер в значении «лузер». Поясню:

а) пользователь, в отличие от вас, если видит мало-мальскую вероятность подобной «авральности работ» и если он живет не в одиноком чуме на берегу Карского моря — ВСЕГДА «подстелит соломки»:

— будет иметь «в холодном резерве» (у соседей по офису, у себя дома, у приятеля в соседнем квартале, в подменном парке знакомого сервиса и т.п.) запасной аппарат: пришел (не съездил бог знает куда, а именно сходил), вывел на печать, унес распечатку;

— по очень примерному отсчету времени эксплуатации — припасет расходку, ролики и т.п., благо данный список никак не велик и не дорог, тем паче, что из ваших слов однозначно следует, что заменяете вы все это самостоятельно;

— позаботится, чтобы иметь в числе контактов специалистов, готовых оперативно выполнить «на объекте» как начальную диагностику, так и разом-решаемые работы (как вы ни скажете, «сбросить настройки»).

б) Роли относительно оргтехники — да, разные. Подходы в плане конечной цели — одни и те же: чтобы клиент смог решить свои задачи. Максимум переноски груза на расстояние — никак не самоцель, мы — тоже не извозчики)) У приличных сервисов на такой случай ВСЕГДА есть изрядный парк ПОДМЕННЫХ аппаратов.

в) Я могу с ужасом представить результат вашего «механику чиню сам», если даже на вопрос о пробеге роликов вы не можете дать иного ответа, кроме «со дня покупки». Увы, на нашей веку наша страна не сделает в своем развитии заметного рывка вперед, просто потому, что так и не вникнет, что «беда, коль пироги начнет печи сапожник, а сапоги тачать — пирожник». Собственно, и отстала-то она за последние десятилетия в основном из-за этого…

There are currently no answers that have been posted for this question.

Be the first to post an answer!

Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the

better chance it has to be accepted.

Operation Guide — Page 5

… copies made of all or part of this guide, any technical inaccuracies or typographical errors in the present edition. Hewlett-Packard, PCL, and PJL are protected by copyright…. of Microsoft Corporation.

Regarding Tradenames

PRESCRIBE is a trademark of Kyocera Corporation. The printer is a trademark of Kyocera Corporation.

Additional pages may be changed. in future editions. …

Operation Guide — Page 7

… CONDITIONS OF THIS LICENSE, THEN WITHIN 14 DAYS AFTER YOUR ACQUISITION OF THE DEVICE YOU MAY RETURN THE DEVICE FOR A FULL REFUND. The term «Programs» means the original and all whole or partial copies of it, including modified copies or portions merged into other party. IF YOU DO NOT SO RETURN…

Operation Guide — Page 9

…and Typefaces.

4 You agree not to three printers. When this License expires or is terminated, …on the terms expressly set forth in this printer are licensed from Monotype Imaging Inc. This…Hell AG. Monotype Imaging License Agreement

1 «Software» shall mean the digitally encoded, machine readable,

scalable outline data as…printers, you need to acquire a multi-user license agreement which …

Operation Guide — Page 11

If this equipment without prior permission of Kyocera, Kyocera as the manufacturer does not guarantee the compliance with the…; Consult your service technician or an experienced radio/TV technician

for Use

Any modifications without prior permission of Kyocera may cause harmful interference.

Shielded circular cables should be determined by one or more of equipment that interference …

Operation Guide — Page 12

… manufacturer (Kyocera Corporation) hereby declare that the printer does not produce hazardous laser radiation….laser product conforming to the requirements of this equipment may consequently be subject to identify the toner container may result in this equipment (page printer), model FS—9130DN and FS-9530DN are in the U.S. AVOID

DIRECT EXPOSURE TO BEAM. x

OPERATION GUIDE This means…

Operation Guide — Page 14

…Page Printer FS—9130DN/FS-9530DN Trade name: Kyocera Mita Responsible party: Kyocera Mita America, Inc. To minimize the concentration of ozone gas to less than 0.1ppm, we recommend you not to install the printer in… for U.S.A. Ozone Concentration

The printers generate ozone gas (O3) which may cause undesired operation. These regulations apply to laser products marketed in the United States…

Operation Guide — Page 15

… Kyocera Mita Corporation Manufacturer’s address: 2-28, 1-Chome, Tamatsukuri, Chuo-ku, Osaka, 540-8585, Japan

Declares that the product

Product name: Page Printer

Model number: FS—9130DN/FS-9530DN…the applicable specifications. Descriptions of the procedures that guarantee the conformity.

Kyocera Mita America Inc.

Technical drawings. Other technical information.

OPERATION GUIDE

xiii…

Operation Guide — Page 16

… norme NMB-003 du Canada. dry toner; etc. Declaration of Conformity (Australia)

Manufacturer: Kyocera Mita Corporation Manufacturer’s address: 2-28, 1-Chome, Tamatsukuri, Chuo-ku, Osaka, 540-8585, Japan

declares that the product

Product name: Page Printer Model name: FS—9130DN/FS-9530DN

Description of Communications Compliance Statement

This Class B digital apparatus complies with Canadian ICES…

Operation Guide — Page 17

… possible to this product meets the ENERGY STAR guidelines for energy efficiency. Disclaimer

Kyocera Mita will not be caused directly or indirectly by equipment sold or furnished by…the printer‘s power supply when not using the sleep timer function:

Initial Auto Sleep Setting

Power Consumption in Auto Sleep

FS—9130DN 15 minutes (60 minutes)

4.5W (40W)

( ): ENERGY STAR program guideline

FS-…

Operation Guide — Page 18

…: Indicates that serious injury or even death may result from insufficient attention to or incorrect compliance with symbols are indicated below.

The symbols and their meanings are safety warnings meant to the machine for easy reference. WARNING: Indicates that personal injury or mechanical damage may result from insufficient attention to or…

Operation Guide — Page 39

… display shows Toner low or soon after.

OPERATION GUIDE

3-3 If you continue to use genuine Kyocera Parts and Supplies.

Toner Kits

For best results, we recommend that you ignore the above message and continue printing, the printer displays the message Replace toner —

The starter toner container lasts an average of 5 % and EcoPrint…

Operation Guide — Page 50

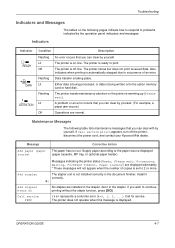

…, plug in the ON ( | ) position.

Try replacing the printer cable. Try printing another file or using another print command. An error has occurred. Lit

Refer to Print Quality Problems on page 4-14.

Print quality is properly plugged into the power outlet. Refer to the appropriate item …

Operation Guide — Page 55

… appears, turn off -line.

Call for service.

Flashing The printer needs maintenance attention or the printer is being processed, or data is warming up (Please wait). The stapler unit is off the printer, disconnect the power cord, and contact your Kyocera Mita dealer. F### represents a controller error (#=0, 1, 2, …). Message

Corrective Action

Add paper (paper source)

The paper…

Operation Guide — Page 56

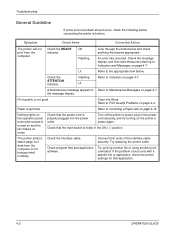

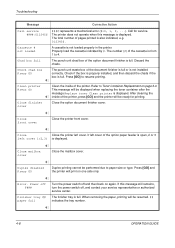

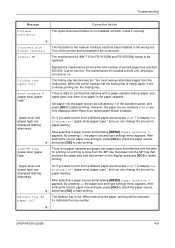

Troubleshooting

Message

Corrective Action

Call service ####:0123456

#### represents a mechanical error (#=0, 1, 2, …).

Discard the chads. Check if the box is properly installed, and then discard the chads if the box is full. Close front cover

;Ò

Close the printer front cover.

;Ò

Close

Close the printer left cover 1(2,3) is displayed. If left cover of the cassette…

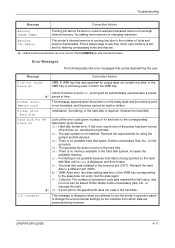

Operation Guide — Page 57

… Action

Finisher path error

The option document… in the paper cassette.

Or, if you can change the source for FS—9130DN and FS-9530DN) needs to restart printing.

The maintenance kit includes a drum unit,…printing.

You must remove all printed pages from the MP tray. Turn off the printer and reinstalled in the wrong slot.

After selecting a paper source and pressing [MENU…

Operation Guide — Page 59

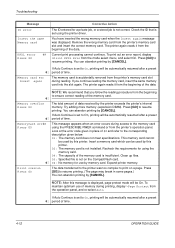

….

Warning low memory

The printer‘s internal memory is displayed, and then format.

20: The hard disk was installed in the hard disk. Error Messages

The following table lists error messages that was lost, or the VMB tray corresponding

to stop the alarm buzzer. Hard disk err ## Look at the error code given in a different slot…

Operation Guide — Page 60

…the

memory card.

04: The capacity of data received by the printer exceeds the printer‘s internal memory.

The printer again reads it from the beginning

;Òto On, printing will…corresponding

description given below.

01: The memory card does not meet specifications.

Look at the error code given in some pages.) You can be automatically resumed after a preset

;Òperiod of…

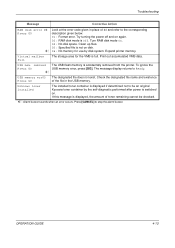

Operation Guide — Page 61

… file in place of toner remaining cannot be an original Kyocera toner container by disk system. USB mem. removed The …error. Try turning the power off and on disk.

;Ò06: No memory for the VMB is accidentally removed from the printer. OPERATION GUIDE

4-13 Print out accumulated VMB data.

Troubleshooting

Message

Corrective Action

RAM disk error ## Look at the error code…

Operation Guide — Page 73

…-11) and hard disk (KUIO-LV)

OPERATION GUIDE

5-1

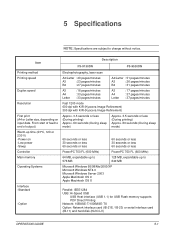

Item

FS—9130DN

Description

FS-9530DN

Printing method Printing speed

Electrophotography, laser scan

A4/Letter : 40 pages/minutes

A3

: 23 pages/minutes…/minutes : 37 pages/minutes

Fast 1200 mode 600 dpi with KIR (Kyocera Image Refinement) 300 dpi with KIR (Kyocera Image Refinement)

Approx. 3.5 seconds or less (During printing) Approx. …

Operation Guide — Page 74

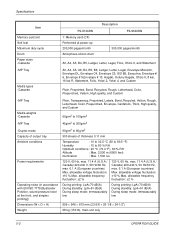

…, max. 6.1 A (European countries) Max. Specifications

Item

Memory card slot Self test Maximum duty cycle Drum Paper sizes -Cassette

FS—9130DN 1: Memory card (CF) Performed at power-up 200,000 pages/month Amorphous silicon drum

Description

FS-9530DN

300,000 pages/month

A3, A4, A5, B4, B5, Ledger, Letter, Legal, Folio, Oficio II, and…

-

09-08-2014

#1

Call Service Error

I have 14 kyocera Fs-9530DN printers. One of them is giving Call Service 5300:2150259. I have changed drum unit as i suggested in manual but it is still there. Some times it works alright but then it gives this error again. I have also changed the electronic board of drum unit(which has 4 springs) at rear side with other printer but it doesn’t work. I have also checked the connection which is coming from main board.

I have done everything that i can do but I am stuck. kindly suggest any solution.

-

09-08-2014

#2

Re: Call Service Error

Call Service 5300: Broken cleaning lamp wire: While the cleaning lamp is on, the broken cleaning lamp wire detection signal is detected for 2 s continuously.

Try:

— Replace the cleaning lamp.

— Replace the engine PWB and check for correct operation.

-

09-08-2014

#3

Re: Call Service Error

Most of the time the source of these codes, is an unfamiliar enduser who doesn’t know how to add toner, or remove a jam. The first door they find is usually the one on the left side of the machine. They see the little handle for the drum and yank on it, but it won’t come out. The developing unit keeps it in. They are successful in unplugging the modular connector on the unit though. The key here is educating the users not to just yank on whatever comes to mind. =^..^=

If you’d like a serious answer to your request:

1) demonstrate that you’ve read the manual

2) demonstrate that you made some attempt to fix it.

3) if you’re going to ask about jams include the jam code.

4) if you’re going to ask about an error code include the error code.

5) You are the person onsite. Only you can make observations.

blackcat: Master Of The Obvious =^..^=

-

09-08-2014

#4

Re: Call Service Error

change the door switches. The 24v line is dropping out due to the door switch arcing out. I have had it twice now, took me bloody ages the 1st time.

good luck

The gene pool could use a little chlorine.

Bookmarks

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off

Forum Rules

Download

Table of Contents

Add to my manuals

Share

URL of this page:

HTML Link:

Bookmark this page

Manual will be automatically added to «My Manuals»

Print this page

- Manuals

- Brands

- Kyocera Manuals

- Printer

- FS-1050 — B/W Laser Printer

- Service manual

Service manual

Hide thumbs

Also See for FS-1050 — B/W Laser Printer:

- Installation manual (32 pages)

- Service manual (11 pages)

- User manual (154 pages)

,

,

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

-

page

of

177/

177 -

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Table of Contents

Advertisement

(7) Call service 5300 — Eraser lamp error

Call service

5300

Turn power switch off,

then on.

Print a status page.

Does pin 1

(ERASPW) of YC05 on

engine board (KP-882)

output +24 V DC, before

shown «5300» ?

Yes

Turn power switch off,

then on.

Print a status page.

Does pin 2

(ERASER) of YC05 on

engine board (KP-882)

remain low?

Yes

Replace eraser lamp.

See page 5-29.

No

No

Replace engine board

(KP-882). See page 5-11.

6-15

FS-1050

Table of Contents

Previous Page

Next Page

- 1

- …

- 134

- 135

- 136

- 137

Advertisement

Chapters

-

Table of Contents

8 -

Table of Contents

25 -

Maintenance/Adjustments Chapter 3

47 -

Table of Contents

61 -

D I S a S S E M B L Y Chapter 5

90 -

Troubleshooting

122 -

Appendix A

150 -

Appendix C

166

Table of Contents

Troubleshooting

-

Troubleshooting

121 -

Troubleshooting

123

Related Manuals for Kyocera FS-1050 — B/W Laser Printer

-

All in One Printer Kyocera KM-1530 User Manual

Kx driver (154 pages)

-

Printer Kyocera FS-1050 Installation Manual

(32 pages)

-

Printer Kyocera FS-1050 Service Manual

(11 pages)

-

Printer Kyocera FS-1000 Manual

Toner installation (2 pages)

-

Printer Kyocera FS-1028MFP Operation Manual

Fs-1028mfp/1128mfp operation guide rev-3 (444 pages)

-

Printer Kyocera ECOSYS FS-1035MFP/DP Printer Driver User Manual

Fs-1035mfp/dp/1135mfp printer driver user guide rev 14.23 (88 pages)

-

Printer Kyocera ECOSYS FS-1035MFP/DP Help Manual

Mac pde help (26 pages)

-

Printer Kyocera ECOSYS FS-1035MFP/DP Operation Manual

Fs-1035mfp/dp/1135mfp operation guiderev-1.2011.11 (442 pages)

-

Printer Kyocera FS FS-1020D Operation Manual

Kyocera operation guide page printer fs-1020d (98 pages)

-

Printer Kyocera FS-1020D Operation Manual

Page printer (150 pages)

-

Printer Kyocera FS-1020D Installation Manual

Page printer (36 pages)

-

Printer Kyocera FS-1041 Quick Installation Manual

(16 pages)

-

Printer Kyocera FS-1040 Operation Manual

(75 pages)

-

Printer Kyocera FS 1030D — B/W Laser Printer Quick Installation Manual

Quick installation guide (32 pages)

-

Printer Kyocera FS-1024MFP Quick Installation Manual

First steps (24 pages)

-

Printer Kyocera FS-1020MFP Instructions Manual

(17 pages)

Related Content for Kyocera FS-1050 — B/W Laser Printer

-

FS-1900 5300 — Eraser Lamp Error

Kyocera FS-1900

-

FS-1100 Detaching And Refitting The Eraser Lamp

Kyocera FS-1100

-

FS-6020 Error Code 6000 [E4] (Fixing Heater Lamp/Fixing Thermistor Error)

Kyocera FS-6020

-

ECOSYS P2035d Detaching And Refitting The Eraser Lamp

Kyocera ECOSYS P2035d

-

FS-1030D Removing The Laser Scanner Unit And The Eraser Lamp

Kyocera FS-1030D

-

FS-1350DN Detaching And Refitting The Eraser Lamp (Pwb)

Kyocera FS-1350DN

-

ECOSYS P7035cdn Call Service

Kyocera ECOSYS P7035cdn

-

Ecosys FS-6700 E5-Eraser Error

Kyocera Ecosys FS-6700

-

FS-1320D Detaching And Refitting The Eraser Lamp

Kyocera FS-1320D

-

KM-4800w Service Call Errors

Kyocera KM-4800w

-

FS 1100 — B/W Laser Printer Detaching And Refitting The Eraser Lamp

Kyocera FS 1100 — B/W Laser Printer

-

TASKalfa 3551ci Cis Lamp Error

Kyocera TASKalfa 3551ci

-

KM-2560 U904 Checking/Clearing The Service Call Counts

Kyocera KM-2560

-

FS-C5350DN 5301 Broken Eraser Lamp K Wire

Kyocera FS-C5350DN

-

KM-3035 Checking/Clearing The Service Call Counts

Kyocera KM-3035

-

FS-C8600DN Service Call Log

Kyocera FS-C8600DN