-

Page 1: Service Manual

FS-1120D FS-1320D SERVICE MANUAL Published in June 2010 842LZ112 2LZSM062 Rev. 2…

- Page 2

CAUTION RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS. It may be illegal to dispose of this battery into the municipal waste stream. Check with your local solid waste officials for details in your area for proper disposal. ATTENTION IL Y A UN RISQUE D’EXPLOSION SI LA BATTERIE EST REMPLACEE PAR UN MODELE DE TYPE INCORRECT. -

Page 3: Revision History

Revision history Revision Date Replaced pages Remarks March 4, 2010 1-1-2, 1-2-1 June 4, 2010 1-1-1, 1-3-1, 1-3-11, 1-3-12…

- Page 4

This page is intentionally left blank. -

Page 5: Safety Precautions

Safety precautions This booklet provides safety warnings and precautions for our service personnel to ensure the safety of their customers, their machines as well as themselves during maintenance activities. Service personnel are advised to read this booklet carefully to familiarize themselves with the warnings and precautions described here before engaging in maintenance activities.

- Page 6

Safety warnings and precautions Various symbols are used to protect our service personnel and customers from physical danger and to prevent damage to their property. These symbols are described below: DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect compliance with warning messages using this symbol. -

Page 7: Installation Precautions

1. Installation Precautions WARNING • Do not use a power supply with a voltage other than that specified. Avoid multiple connections to one outlet: they may cause fire or electric shock. When using an extension cable, always check that it is adequate for the rated current…………………. •…

-

Page 8: Specifications 1

2. Precautions for Maintenance WARNING • Always remove the power plug from the wall outlet before starting machine disassembly….• Always follow the procedures for maintenance described in the service manual and other related brochures……………………….• Under no circumstances attempt to bypass or disable safety features including safety mechanisms and protective circuits.

- Page 9

• Do not remove the ozone filter, if any, from the copier except for routine replacement……. • Do not pull on the AC power cord or connector wires on high-voltage components when removing them; always hold the plug itself………………….•… - Page 10

This page is intentionally left blank. -

Page 11: Table Of Contents

(1) Precautions ……………………….1-5-1 (2) Drum…………………………1-5-1 (3) Toner container ……………………..1-5-1 (4) How to tell a genuine Kyocera Mita toner container…………….1-5-2 1-5-2 Outer covers ……………………….1-5-3 (1) Detaching and refitting the top cover………………..1-5-3 (2) Detaching and refitting the right and left covers …………….1-5-4 1-5-3 Paper feed section ……………………..1-5-6…

- Page 12

2LY/2LZ 1-5-6 Transfer/separation section ……………………1-5-14 (1) Detaching and refitting the transfer roller ………………1-5-14 1-5-7 Fuser section ……………………….1-5-16 (1) Detaching and refitting the fuser unit………………..1-5-16 (2) Switching the fuser pressure ………………….1-5-18 1-5-8 PWBs …………………………1-5-19 (1) Detaching and refitting the control PWB ………………1-5-19 (2) Detaching and refitting the power source PWB…………….1-5-22 (3) Detaching and refitting the operation panel PWB …………….1-5-24 (4) Detaching and refitting the high voltage PWB……………..1-5-25… -

Page 13: Specifications

2LY/2LZ-2 1-1 Specifications 1-1-1 Specifications Type ……….Desktop Printing method……. Electrophotography, laser scan Paper weight……..Cassette: 60 to 120 g/m (Duplex: 60 to 105 g/m MP tray: 60 to 220 g/m Paper type ……..Cassette: Plain, Preprinted, Bond, Recycled, Rough, Letterhead, Color (Colour), Prepunched, High quality, Custom 1 to 8 MP tray: Plain, Transparency, Preprinted, Labels, Bond, Recycled, Rough, Vellum,…

- Page 14

2LY/2LZ-1 ° ° Operating environment ….Temperature: 10 to 32.5 C/50 to 90.5 Humidity: 15 to 80% Altitude: 2,500 m/8,202 ft maximum Brightness: 1,500 lux maximum Controller ……..PowerPC 405F5/360 MHz Supported OS ……… Microsoft Windows 2000/XP/Vista/7, Windows Server 2003/2008, Mac OS X 10.x Interface………. -

Page 15: Parts Names

2LY/2LZ 1-1-2 Parts names (1) Overall Figure 1-1-1 Top cover MP tray Paper stopper Sub tray Top tray 10. Optional interface slot cover Operation panel 11. USB interface connector Right side cover 12. Rear cover Cassette 13. Power cord connector Front cover 14.

- Page 16

2LY/2LZ (2) Operation panel Figure 1-1-2 Ready indicator Attention indicator Toner indicator Data indicator Paper indicator Jam indicator Cancel key GO key 1-1-4… -

Page 17: Machine Cross Section

2LY/2LZ 1-1-3 Machine cross section Light path Paper path Paper path (option) Figure 1-1-3 Cassette Laser scanner unit MP tray Transfer/separation section Paper feed/conveying section 10. Fuser section Toner container 11. Exit section Developing unit 12. Top tray Main charger unit 13.

- Page 18

2LY/2LZ This page is intentionally left blank. 1-1-6… -

Page 19: Installation Environment

2LY/2LZ-1 1-2 Installation 1-2-1 Installation environment ° ° Temperature: 10 to 32.5 C/50 to 90.5 Humidity: 15 to 80%RH Power supply: 120 V AC, 8.0 A 220 — 240 V AC, 4.2 A ± ± Power source frequency: 50 Hz 0.3%/60 Hz 0.3% Installation location…

-

Page 20: Unpacking

2LY/2LZ 1-2-2 Unpacking 220 — 240 V AC model 120 V AC model Figure 1-2-2 Printer 11. Power cord Outer case 12. Pad Bottom pad L 13. Plastic bag Bottom pad R 14. Installation guide Machine cover 15. Panel GFIS sheet Top pad L 16.

-

Page 21: Removing The Tapes

2LY/2LZ (1) Removing the tapes Procedure 1. Remove three tapes. Tape Tape Tape Figure 1-2-3 1-2-3…

-

Page 22: Installing The Expanded Memory (Option)

2LY/2LZ 1-2-3 Installing the expanded memory (option) Procedure 1. Turn off printer power switch. Caution: Do not insert or remove expanded memory while printer power is on. Doing so may cause damage to the printer and the expanded memory. 2. Remove the right side cover. 3.

-

Page 23: Installing The Memory Card (Option)

2LY/2LZ 1-2-4 Installing the memory card (option) Procedure 1. Turn off printer power switch. Caution: Do not insert or remove memory card while printer power is on. Doing so may cause damage to the printer and the memory card. 2. Open the rear cover. Rear cover Figure 1-2-6 3.

-

Page 24: Installing The Network Interface Card (Option)

2LY/2LZ 1-2-5 Installing the network interface card (option) Procedure 1. Turn off printer power switch. Caution: Do not insert or remove network interface card while printer power is on. Doing so may cause damage to the printer and the network interface card. 2.

-

Page 25: Maintenance Mode

2LY/2LZ-2 1-3 Maintenance Mode 1-3-1 Maintenance mode The product incorporates several service modes which are activated by using the keys on the operation panel or by com- manding from a PC. (1) Executing a service mode Printing a status page for service purpose……..See page 1-3-2. Printing an event log (EVENT LOG) ……….

-

Page 26: Service Status Page

2LY/2LZ Service items Description Printing a status page Description for service purpose Prints a status page for service purpose. The status page includes various printing settings and service cumulative. Purpose To acquire the current printing environmental parameters and cumulative information. Procedure 1.

- Page 27

2LY/2LZ Service items Description Detail of service information Service information Total page 9690 [XXXXXXXX][XXXXXXXX][01/00] /t/U00/F00/N00 (6) (7) (8) /0020/0020/1061/0811/ (10) (11) (12) (13) /0000/0000/ /00/300/81/31/81/31/ (14)(15)(16)(17)(18)(19) (20) A:1234567890123456 (21) /02870284/03028003/83030286/86000086/02000000/02020202/02020202/ (22) /03030303/03030303/03030303/03030303/03000000/03030303/03030303/ SPD1:0203040508090A0B0C0D0F101112131415161718191A1B1C1D1E1F202122235E (23) (24) /00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/ /00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/ /00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/ /00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/ /00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/ /00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/ /00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/ /00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/… - Page 28

1 = 0: Overseas, 1: Domestic (Japan) [First byte/Second byte bit 2, 3 (Not used) (displayed in OEM model bit 4 = 0: Kyocera, 1: OEM only)] bit 5 = 0: For Europe, 1: For US bit 6 = 0: Non MICR mode, 1: MICR mode… - Page 29

2LY/2LZ Service items Description Items Description (20) Fixed asset number (Maximum 16 characters) (21) Paper type attributes Paper type setting value from 1 to 28 (fuser, weight, duplex) (unused paper type are always 0x00.) (22) Paper type attributes Paper type setting value from 1 to 28 (density) (unused paper type are always 0x00.) (23) Memory SPD information (slot… - Page 30

2LY/2LZ Service items Description Printing an event log Description (EVENT LOG) Prints a history list of occurrences of paper jam, self-diagnostics, toner replacements, etc. Purpose To allow machine malfunction analysis based on the frequency of paper misfeeds, self diag- nostic errors and replacements. Procedure 1. -

Page 31: Event Log

2LY/2LZ Service items Description EVENT LOG [EB20MA001/2LZ_1000.001.019] [40.00SFLB] [01] Firmware version: 2LZ_30000.001.024 Released: 20/January/2010 Printed page(s) 12345 Paper Jam Log Service Call Log Count. Event Count. Service Code 9993 10.48.01.08.01.01 11234 01.6000 10000 01.6000 9992 10.48.01.08.01.01 9999 01.6000 9991 10.48.01.08.01.01 9998 01.6000 9990…

- Page 32

[First byte/Second byte (dis- bit 2, 3 (Not used) played in OEM mode only)] bit 4 = 0: Kyocera, 1: OEM bit 5 = 0: For Europe, 1: For US bit 6 = 0: Non MICR mode, 1: MICR mode… - Page 33

2LY/2LZ Service items Description Items Description Paper Jam (a) Cause of paper jam cont. 10: Paper does not arrive at the registration sensor. (MP tray) [42] 10: Paper does not arrive at the registration sensor. (Cassette 1) [31] 10: Paper does not arrive at the registration sensor. (Cassette 2) [31] 10: Paper does not arrive at the registration sensor. - Page 34

2LY/2LZ Service items Description Items Description (c) Detail of paper source (Hexadecimal) Paper Jam Log cont. 00: MP tray 01: Cassette 1 (printer) 02: Cassette 2 (paper feeder 1) 03: Cassette 3 (paper feeder 2) 07: Duplex (d) Detail of paper size (Hexadecimal) 00: (Undefined) 09: B5R 20: Reply-paid postcard… - Page 35

2LY/2LZ-2 Service items Description Items Description (11) Unknown Toner Count. Item Remembers 1 to 5 of occur- The total page count at Unknown toner log code rence of unknown toner the time of the “Toner (1 byte, 2 categories) NOTE: detection. - Page 36

2LY/2LZ-2 Service items Description [REPLACE MAINTE- Description NANCE KIT] message [REPLACE MAINTENANCE KIT] message sheet is printed at the 1st power-up after the sheet page count exceeding 100,000 pages. Procedure Replace the maintenance kit. 30/32 ppm model (A4/Letter) Maintenance kit MK-162 (for 120 V specifications) Maintenance kit MK-160 (for 230 V specifications) Maintenance kit MK-164 (for 240 V specifications) 35/37 ppm model (A4/Letter) -

Page 37: Paper Misfeed Detection

2LY/2LZ 1-4 Troubleshooting 1-4-1 Paper misfeed detection (1) Paper misfeed indication If paper jams in the paper conveying system, or no paper sheets are fed at all, the printer automatically goes offline, and the jam indicator will flash rapidly. Status Monitor or COMMAND CENTER can indicate the location of the paper jam (the component where the paper jam has occurred).

-

Page 38: Paper Misfeed Detection Condition

2LY/2LZ (2) Paper misfeed detection condition Printer Peper feeder 1 (Option) (1) Registration sensor (2) Paper sensor (3) MP paper sensor (4) Paper exit sensor (5) PF paper sensor (6) PF paper feed sensor Peper feeder 2 (Option) Figure 1-4-2 1-4-2…

-

Page 39: Self-Diagnostic Function

2LY/2LZ 1-4-2 Self-diagnostic function (1) Self-diagnostic function The printer is equipped with self-diagnostic function which automatically halts the printer when an error is detected. The four indicators (Jam, Paper, Attention, Toner) are simultaneously lit, then indicate a specific error by the combination of the four indicators.

-

Page 40: Self Diagnostic Codes Indication

2LY/2LZ (2) Self diagnostic codes indication Sequence of display Indicates the occurrence of a self diagnostics error. 1.6 s 1.6 s 0.8 s 0.8 s Example of self-diagnostic code: 2610 (Refer to the following code conversion table) 0.8 s 0.8 s 0.8 s Indication example Lit (Green)

-

Page 41: Self Diagnostic Codes

2LY/2LZ (3) Self diagnostic codes Remarks Code Contents Causes Check procedures/corrective measures 0150 Control PWB EEPROM error Improper installation Check the installation of the EEPROM Detecting control PWB EEPROM control PWB EEPROM (U300) and remedy if necessary (See page (U300) communication error. (U300).

- Page 42

2LY/2LZ Remarks Code Contents Causes Check procedures/corrective measures 2610 PF paper feed motor error (Paper Defective harness Reinsert the connector. Also check for conti- feeder 1) between PF paper nuity within the connector harness. If none, The PF paper feed motor of paper feed motor and PF remedy or replace the harness (Refer to the feeder 1 ready input is not given for 2… - Page 43

2LY/2LZ Remarks Code Contents Causes Check procedures/corrective measures 6000 Broken fuser heater lamp wire Poor contact in the Reinsert the connector (See page 1-5-16). The fuser temperature does not rise fuser thermistor con- after the fuser heater lamp has been nector terminals. - Page 44

2LY/2LZ Remarks Code Contents Causes Check procedures/corrective measures 7990 Waste toner full Waste toner reservoir Turn the main power switch off/on to restart The waste toner sensor has detected (drum unit) is full. the printer. If the error is not resolved, that the waste toner reservoir (drum replace the drum unit (See page 1-5-12). -

Page 45: Image Formation Problems

2LY/2LZ 1-4-3 Image formation problems (1)Completely blank (2)All-black printout. (3)Dropouts. (4)Black dots. (5)Black horizontal printout. streaks. See page 1-4-10 See page 1-4-10 See page 1-4-11 See page 1-4-11 See page 1-4-11 (6)Black vertical (7)Unsharpness. (8)Gray background. (9)Dirt on the top (10)Undulated print- streaks.

-

Page 46: All-Black Printout

2LY/2LZ (1) Completely blank printout. Print example Causes Check procedures/corrective measures Defective drum unit or developing Open the top cover and check that the drum unit and develop- unit. ing unit are correctly seated. Investigate that the terminals between the main charger unit and the drum unit are not in loose contact (See page 1-5-12 and 1-5-11).

-

Page 47: Dropouts

2LY/2LZ (3) Dropouts. Print example Causes Check procedures/corrective measures Defective developing roller (develop- If the defects occur at regular intervals of 62.8 mm/2 » (See ing unit). page 2-4-2), the problem may be the damaged developing roller (in the developing unit). Replace the developing unit (See page 1-5-11).

-

Page 48: Black Vertical Streaks

2LY/2LZ (6) Black vertical streaks. Print example Causes Check procedures/corrective measures Adhesion of oxide to main charger Remove the drum unit (See page 1-5-12). Slide the charger wire. cleaner (green) left and right 2 or 3 times to clean the charger wire, then return it to its original position (CLEANER HOME POSITION).

-

Page 49: Dirt On The Top Edge Or Back Of The Paper

2LY/2LZ (9) Dirt on the top edge or back of the paper. Print example Causes Check procedures/corrective measures Toner contamination in various parts. Dirty edges and back of the paper can be caused by toner accumulated on such parts as the paper chute guide, paper conveying paths, the bottom of the drum and developing unit, and the fuser unit inlet.

-

Page 50: Electric Problems

2LY/2LZ 1-4-4 Electric problems Problem Causes Check procedures/corrective measures No electricity at the power Measure the input voltage. The machine does outlet. not operate when the The power cord is not Check the contact between the power plug and the outlet. power switch is plugged in properly.

- Page 51

2LY/2LZ Problem Causes Check procedures/corrective measures Broken developing clutch Check for continuity across the coil. If none, replace the develop- Developing clutch coil. ing clutch. does not operate. Defective harness between Reinsert the connector. Also check for continuity within the con- developing clutch and con- nector harness. -

Page 52: Mechanical Problems

2LY/2LZ 1-4-5 Mechanical problems Problem Causes/check procedures Corrective measures Check if the surfaces of the paper feed roller Clean with isopropyl alcohol. No primary paper feed. is dirty with paper powder. Check if the paper feed roller is deformed. Check visually and replace any deformed paper feed roller (assembly) (See page 1-5- Defective paper feed clutch installation.

-

Page 53: Assembly And Disassembly

2LY/2LZ 1-5 Assembly and Disassembly 1-5-1 Precautions for assembly and disassembly (1) Precautions Be sure to turn the power switch off and disconnect the power plug before starting disassembly. When handling PWBs, do not touch connectors with bare hands or damage the PWB. Do not touch any PWB containing ICs with bare hands or any object prone to static charge.

-

Page 54: How To Tell A Genuine Kyocera Mita Toner Container

A black-colored band when seen through the left side window A shiny or gold-colored band when seen through the right side window The above will reveal that the toner container is a genuine Kyocera Mita branded toner container, otherwise, it is a coun- terfeit.

-

Page 55: Outer Covers

2LY/2LZ 1-5-2 Outer covers (1) Detaching and refitting the top cover Procedure 1. Open the top cover. 2. Remove two screws. Top cover Screw Screw Figure 1-5-3 3. Extract the boss from the hole. 4. Unhook the A hook. Top cover 5.

-

Page 56: Detaching And Refitting The Right And Left Covers

2LY/2LZ (2) Detaching and refitting the right and left covers Procedure 1. Remove the top cover (See page 1-5-3). 2. Remove the cassette (See page 1-5-6). 3. Open the front cover. 4. Unhook seven hooks and then remove the right cover. Hooks Right cover Figure 1-5-5…

- Page 57

2LY/2LZ 5. Unhook seven hooks and then remove the left cover. Left cover Hooks Figure 1-5-6 1-5-5… -

Page 58: Paper Feed Section

2LY/2LZ 1-5-3 Paper feed section (1) Detaching and refitting the paper feed assembly (paper feed roller and pickup roller) Procedure 1. Remove the cassette. Cassette Figure 1-5-7 2. Slide the feed shaft. 3. While pressing the lever and then remove the paper feed roller assembly.

- Page 59

2LY/2LZ 4. Check or replace the paper feed assembly and refit all the removed parts. Paper feed roller Feed shaft assembly When refitting the paper feed roller assem- bly, be sure to align the paper feed roller pivot with the slotted hole on the feed shaft. Paper feed roller assembly Feed shaft… -

Page 60: Detaching And Refitting The Retard Roller Assembly

2LY/2LZ (2) Detaching and refitting the retard roller assembly Procedure 1. Remove the cassette (See page 1-5-6). Retard guide 2. Push the bottom plate down until it locks. Hook 3. Unhook two hooks and then remove the retard guide. Hook Cassestte Bottom plate Cassette…

- Page 61

2LY/2LZ 5. Check or replace the retard roller assembly and refit all the removed parts. Retard roller Caution: Before refitting the retard roller assembly assembly, firmly install the spring onto the projection of the retard roller assembly. Projection Spring Figure 1-5-12 1-5-9… -

Page 62: Detaching And Refitting The Mp Paper Feed Roller

2LY/2LZ (3) Detaching and refitting the MP paper feed roller Procedure 1. Open the front cover. 2. Pull the MP feed holder (lever) down (1). 3. Slide the MP feed holder (2). 4. Remove the MP paper feed roller (3). MP paper feed roller Front cover MP paper feed roller…

-

Page 63: Developing Section

2LY/2LZ 1-5-4 Developing section (1) Detaching and refitting the developing unit Procedure 1. Open the top cover. Top cover 2. Open the front cover. 3. Remove the developing unit (with toner con- tainer). 4. Check or replace the developing unit and refit all the removed parts.

-

Page 64: Drum Section

2LY/2LZ 1-5-5 Drum section (1) Detaching and refitting the drum unit Procedure 1. Remove the developing unit (See page 1-5- 11). 2. Remove the drum unit. 3. Check or replace the drum unit and refit all the removed parts. Drum unit Figure 1-5-16 1-5-12…

-

Page 65: Detaching And Refitting The Main Charger Unit

2LY/2LZ (2) Detaching and refitting the main charger unit Procedure 1. Remove the drum unit (See page 1-5-12). 2. Remove the tape. 3. While pushing on the main plate (1), slide the main charger unit (2). Tape Main charger unit Drum unit Main charger unit Main plate…

-

Page 66: Transfer/Separation Section

2LY/2LZ 1-5-6 Transfer/separation section (1) Detaching and refitting the transfer roller Procedure 1. Remove the developing unit (See page 1-5- 11). 2. Remove the drum unit (See page 1-5-12). 3. Slide the paper chute guide and unhook the hooks. 4. Remove the paper chute guide. Paper chute guide Paper chute guide Hook…

- Page 67

2LY/2LZ 5. Remove the transfer roller’s shaft from the Shaft both transfer bushes. 6. Remove the gear Z16 from the transfer roller. Transfer roller Shaft Transfer roller Transfer roller Transfer roller Gear Z16 Figure 1-5-20 7. Check or replace the transfer roller and refit all the removed parts. -

Page 68: Fuser Section

2LY/2LZ 1-5-7 Fuser section (1) Detaching and refitting the fuser unit Procedure 1. Remove the outer covers (See page 1-5-3). 2. Remove two connectors. 3. Release the wires form wire clamps. Wires Wire clamps Connector (Fuser heater lamp) Connector (Fuser thermistor) Figure 1-5-22 4.

- Page 69

2LY/2LZ 5. Remove the rear cover. Rear cover Figure 1-5-24 6. Remove two screws and then remove the fuser unit. 7. Check or replace the fuser unit and refit all the removed parts. Fuser unit Screw Screw Figure 1-5-25 1-5-17… -

Page 70: Switching The Fuser Pressure

2LY/2LZ (2) Switching the fuser pressure The fuser pressure may be decreased to suppress the print quality problems such as paper creases and curls. It must be cautioned that decreasing the fuser pressure could cause loose toner fusing. Procedure 1. Remove the cassette (See page 1-5-6). 2.

-

Page 71: Pwbs

2LY/2LZ 1-5-8 PWBs (1) Detaching and refitting the control PWB Procedure 1. Remove the right cover (See page 1-5-4). 2. Remove fourteen connectors form the con- trol PWB. 3. Release the wires from the wire clamps. Control PWB Wire clamps Connectors (Thirteen) Connector…

- Page 72

2LY/2LZ 4. Remove five screws. 5. Remove three connectors form the control PWB. Connectors (Three) 6. Unhook the hook and then remove the con- trol PWB assembly. Control PWB Hook Screw Screws Screws Control PWB assembly Figure 1-5-28 1-5-20… - Page 73

2LY/2LZ 7. Remove five screws and then remove the control PWB. Screw 8. Check or replace the control PWB and refit all the removed parts. Screw To replace the control PWB, remove the Screw EEPROM (U300) from the old control PWB and mount it to the new control PWB. -

Page 74: Detaching And Refitting The Power Source Pwb

2LY/2LZ (2) Detaching and refitting the power source PWB Procedure 1. Remove the top cover (See page 1-5-3). 2. Remove the left cover (See page 1-5-4). 3. Remove four connectors. Connector Connector Connector Connector (YC104) Figure 1-5-30 4. Remove four P tight screws, two screws and ground terminal.

- Page 75

2LY/2LZ 6. Remove four screws and then remove the Screws power source plate from the power source PWB. 7. Check or replace the power source PWB and refit all the removed parts. Caution: The power source film must be installed in the specified position. Screws Power source PWB Power source film… -

Page 76: Detaching And Refitting The Operation Panel Pwb

2LY/2LZ (3) Detaching and refitting the operation panel PWB Procedure 1. Remove the top cover (See page 1-5-3). 2. Remove two screws and then remove the Screw panel cover. 3. Remove the operation panel PWB. 4. Remove the connector. Panel cover 5.

-

Page 77: Detaching And Refitting The High Voltage Pwb

2LY/2LZ (4) Detaching and refitting the high voltage PWB Procedure 1. Remove the developing unit (See page 1-5- 11). 2. Remove the drum unit (See page 1-5-12). 3. Remove the cassette (See page 1-5-6). Stop ring 4. Remove the outer covers (See page 1-5-3). 5.

- Page 78

2LY/2LZ 11. Remove four screws. 12. Unhook three hooks and then remove the lower base cover. Lower base cover Hook Hook Hook Screws Screws Lower base cover Figure 1-5-36 1-5-26… - Page 79

2LY/2LZ 13. Remove the spring. 14. Remove the cassette pin. Cassette pin Spring Figure 1-5-37 15. Remove two connectors and then remove the high voltage PWB. 16. Remove the cassette pin holder from the high voltage PWB. Cassette pin holder High voltage High voltage PWB YC202… - Page 80

2LY/2LZ 17. Check or replace the high voltage PWB and refit all the removed parts. When refitting the high voltage PWB, be High voltage PWB careful about following points. • Position the ground plate so that it is atop the high voltage PWB. Ground plate •… -

Page 81: Others

2LY/2LZ 1-5-9 Others (1) Detaching and refitting the main motor Procedure 1. Remove the right cover (See page 1-5-4). 2. Remove the connector. Connector Figure 1-5-40 3. Remove the M3 screw and two M4 screws. 4. Remove the main motor. 5.

-

Page 82: Detaching And Refitting The Laser Scanner Unit

2LY/2LZ (2) Detaching and refitting the laser scanner unit Procedure 1. Remove the right cover (See page 1-5-4). 2. Remove the connector from the control PWB. 3. Release the wire clamp. 4. Draw in the connector inside. Connector Control PWB Clamp Connector Figure 1-5-42…

- Page 83

2LY/2LZ 5. Remove four screws and then remove the laser scanner unit. 6. Check or replace the laser scanner unit and refit all the removed parts. Screws Screws Laser scanner unit Figure 1-5-43 1-5-31… -

Page 84: Detaching And Refitting The Eraser Lamp

2LY/2LZ (3) Detaching and refitting the eraser lamp Procedure 1. Remove the laser scanner unit (See page 1- 5-30). 2. Remove the connector. 3. Remove the eraser lamp. 4. Check or replace the eraser lamp and refit all the removed parts. Eraser lamp Connector Figure 1-5-44…

-

Page 85: Direction Of Installing The Left And Right Cooling Fan Motors

2LY/2LZ (4) Direction of installing the left and right cooling fan motors When detaching or refitting the left and/or right cooling fan motors, be careful of the airflow direction (intake or exhaust). Right cooling Left cooling fan motor fan motor Intake Exhaust Figure 1-5-45…

- Page 86

2LY/2LZ This page is intentionally left blank. 1-5-34… -

Page 87: Firmware

2LY/2LZ 1-6 Firmware 1-6-1 Downloading firmware Firmware files are named after the following codes: Firmware file name example Compression Software ID S 2 L Z _ 1 0 0 0 0 0 1 0 2 1 . c m p Product code Pause (period) 2LY: 30/32 ppm model (A4/Letter)

-

Page 88: Downloading The Firmware From The Memory Card

2LY/2LZ (1) Downloading the firmware from the memory card To download data written in a memory card (CompactFlash) to the printer, proceed as explained in this section. CAUTION Downloading firmware takes several minutes. Do not turn power off during downloading. If downloading is interrupted by an accidental power failure, etc., the control PWB may have to be replaced.

- Page 89

2LY/2LZ 5. Turn printer power on. The printer starts and finishes downloading automatically. Sequence of display Indication example Off (Amber) Downloading start Lit (Green) Lit (Amber) 4.8 s Off (Amber) Supervisor Off (Green) mode Lit (Amber) 4.8 s (Repeat) Receiving data *: 0.8 s (Repeat) - Page 90

2LY/2LZ 6. Confirm that downloading was finished nor- mally (See previous page). 7. Turn power off. 8. Remove the memory card. 9. Secure the optional interface slot cover by using two screws. Memory card slot 10. Close the rear cover. 11. -

Page 91: Paper Feed/Conveying Section

2LY/2LZ 2-1 Mechanical Construction 2-1-1 Paper feed/conveying section Paper feed/conveying section consists of the paper feed unit that feeds paper from the cassette and the MP tray paper feed unit that feeds paper from the MP tray, and the paper conveying section that conveys the fed paper to the transfer/ separation section.

-

Page 92: Mp Tray Paper Feed Section

2LY/2LZ (2) MP tray paper feed section Figure 2-1-3 MP tray paper feed section MP paper feed roller MPF frame MPF separation pad MPF guide R/L MPF separator (10) MPF base MPF bottom plate (11) MPF middle tray MPF friction pad (12) MPF upper tray MP paper sensor (13) MPF turn guide…

-

Page 93: Paper Conveying Section

2LY/2LZ (3) Paper conveying section Figure 2-1-5 Paper conveying section Lower registration roller Upper registration roller Registration sensor Actuator (registration sensor) Feed pulley Control PWB MMOTRDYN YC305-3 MOTCLK YC305-4 Main motor REMOTEN YC305-5 REGDRN Registration YC308-2 clutch High voltage PWB Registration REGN sensor…

-

Page 94: Drum Section

2LY/2LZ 2-1-2 Drum section (1) Drum section The durable layer of organic photoconductor (OPC) is coated over the aluminum cylinder base. The OPC tend to reduce its own electrical conductance when exposed to light. After a cyclic process of charging, exposure, and development, the electrostatic image is constituted over the OPC layer.

-

Page 95: Main Charger Unit

2LY/2LZ (2) Main charger unit As the drum rotates in a “clean (neutral)” state, its photoconductive layer is given a uniform, positive (+) corona charge dis- persed by the main charger wire. Due to high-voltage scorotron charging, the charging wire can get contaminated by oxi- dization after a long run.

-

Page 96: Expose Section

2LY/2LZ 2-1-3 Expose section (1) Laser scanner unit The charged surface of the drum is then scanned by the laser beam from the laser scanner unit. The laser beam (780 nm wavelength) beam is dispersed as the polygon motor revolves to reflect the laser beam over the drum.

- Page 97

2LY/2LZ Figure 2-1-11 Laser scanner unit Polygon motor (mirror) Laser diode (APC PWB) Collimator lens Cylindrical lens F-θ lens F-θ lens PD mirror SOS lens Pin photo diode sensor (PD PWB) (10) LSU mirror 2-1-7… -

Page 98: Developing Section

2LY/2LZ 2-1-4 Developing section The latent image constituted on the drum is developed into a visible image. The developing roller contains a 3-pole (S-NS) magnet roller and an aluminum cylinder rotating around the magnet roller. Toner attracts to the magnet sleeve since it is powdery ink made of black resin bound to iron particles.

-

Page 99: Transfer/Separation Section

2LY/2LZ 2-1-5 Transfer/separation section The transfer/separation section consists of the transfer roller, discharger brush and paper chute guide. A high voltage gen- erated by the high voltage PWB is applied to the transfer roller for transfer charging. Paper after transfer is separated from the drum.

-

Page 100: Cleaning Section

2LY/2LZ 2-1-6 Cleaning section After the transferring process, the drum needs to be physically cleaned of toner which is residual after the development process. The cleaning blade is constantly pressed against the drum and scrapes the residual toner off to the sweep roller. The waste toner is collected at the output end of the sweep roller and sent back to the toner container, into the waste toner reservoir.

-

Page 101: Fuser Section

2LY/2LZ 2-1-7 Fuser section The toner on the paper is molten and pressed into the paper as it passes between the heat roller and the press roller in the fuser unit. The heat roller has a heater lamp inside which continuously turns on and off by the fuser thermistor to maintain the constant temperature onto the heat roller surface.

- Page 102

2LY/2LZ Fuser unit High Power Control PWB voltage source PWB Fuser thermal cutout HEATN YC103-6 YC311-5 YC102-1 SLEEP YC103-7 YC311-6 ZCROSS YC102-3 YC103-8 YC311-3 Fuser heater lamp Fuser thermistor THERM YC311-16 Figure 2-1-19 Fuser section block diagram 2-1-12… -

Page 103: Paper Exit Section

2LY/2LZ 2-1-8 Paper exit section The paper exit section transports the paper which passed the fuser unit towards the top tray. The paper which passed through the fuser unit turns on the actuator (exit sensor) in the fuser unit, and is led by the guide comprised of the rear cover, frame and the FD cover guide, finally reaching the upper FD roller.

- Page 104

2LY/2LZ Fuser unit Control PWB EXITN YC307-3 Exit sensor Figure 2-1-21 Paper exit section block diagram 2-1-14… -

Page 105: Duplex/Conveying Section

2LY/2LZ 2-1-9 Duplex/conveying section The duplex/conveying section consists of conveying path which sends the paper sent from the exit section to the paper feed/conveying section when duplex printing. Figure 2-1-22 Duplex/conveying section DU cover B DU holder Middle pulley B DU roller DU cover A Lower base cover…

- Page 106

2LY/2LZ This page is intentionally left blank. 2-1-16… -

Page 107: Electrical Parts Layout

2LY/2LZ 2-2 Electrical Parts Layout 2-2-1 Electrical parts layout (1) PWBs Machine left Machine inside Machine right Figure 2-2-1 PWBs Control PWB ……….Main controller: Controls the software such as the print data processing and provides the interface with computers. Engine: Controls printer hardware such as high voltage/bias output con- trol, paper conveying system control, and fuser temperature control, etc.

-

Page 108: Switches And Sensors

2LY/2LZ (2) Switches and sensors Machine left Machine inside Machine right Figure 2-2-2 Switches and sensors Power switch……….Turns ON/OFF the AC power source. Interlock switch ……….Shuts off 24 V DC power line when the top cover is opened. Cassette switch……….

-

Page 109: Other Electrical Components

2LY/2LZ (3) Other electrical components Machine left Machine inside Machine right Figure 2-2-3 Other electrical components Main motor …………Drives the paper feed/conveying section and fuser unit. Polygon motor……….. Drives the polygon mirror. Right cooling fan motor ……..Cools the interior of machine. Left cooling fan motor ……..

- Page 110

2LY/2LZ This page is intentionally left blank. 2-2-4… -

Page 111: Power Source Pwb

2LY/2LZ 2-3 Operation of the PWBs 2-3-1 Power source PWB Power source PWB Left +24V1 cooling fan motor ZCROSS Zero cross signal circuit Power switch SLEEP AC input Switching +5V1 regulator circuit +24V2 Fuser heater Interlock lamp control switch HEATN circuit +3.3V1 THERM…

- Page 112

2LY/2LZ YC104 YC105 YC102 YC103 YC101 Figure 2-3-2 Power source PWB silk-screen diagram Connector Pin No. Signal Voltage Description YC101 LIVE 120 V AC AC power input Connected 220 — 240 V AC to the AC NEUTRAL 120 V AC AC power input inlet 220 — 240 V AC… -

Page 113: Feeder

2LY/2LZ 2-3-2 Control PWB Control PWB Engine Main controller Laser scanner unit I/F Duplex solenoid Registration clutch Operation MP paper feed panel PWB I/F solenoid Paper feed clutch USB I/F +3.3 V Developing clutch Memory card I/F Paper feed sensor Engine I/F MP paper feed KUIO I/F…

- Page 114

2LY/2LZ YC316 YC317 YC307 U300 Figure 2-3-4 Control PWB silk-screen diagram 2-3-4… - Page 115

2LY/2LZ Connector Pin No. Signal Voltage Description LED1 3.3/0 V DC Paper indicator display: On/Off Connected LED2 3.3/0 V DC Jam indicator display: On/Off to the opera- Analog Cancel key/GO key: On/Off tion panel SGND Ground LED3 3.3/0 V DC Ready indicator display: On/Off LED4 3.3/0 V DC… - Page 116

2LY/2LZ Connector Pin No. Signal Voltage Description YC311 +24V1 24 V DC 24 V DC power source Connected +3.3V2 3.3 V DC 3.3 V DC power source to the high ZCROSS 0/3.3 V DC (pulse) Zero cross signal voltage 0/24 V DC Left cooling fan motor: On/Off HEATN 0/3.3 V DC… - Page 117

2LY/2LZ Connector Pin No. Signal Voltage Description YC318 +24V3 24 V DC 24 V DC power source Connected PGND Ground to the PFSI 0/3.3 V DC (pulse) Serial communication data input signal optional PFSO 0/3.3 V DC (pulse) Serial communication data output signal paper feeder PFSEL 0/3.3 V DC… - Page 118

2LY/2LZ This page is intentionally left blank. 2-3-8… -

Page 119: Appendixes

2LY/2LZ 2-4 Appendixes 2-4-1 Appendixes (1) Wiring diagraml LED1 LED2 SGND LED3 LED4 LED5 LED6 +3.3V1 PFSEL PFSO PFSI PGND +24V3 connector +3.3V1 PFSEL slot DIMM Expanded slot card Memory PFSO PFSI PGND DUDR2 +24V3 COMMON DUDR1 SGND TNFULL +3.3V1 DLPDRN SGND +24V3…

-

Page 120: Repetitive Defects Gauge

2LY/2LZ (2) Repetitive defects gauge First occurrence of defect [24.99 mm/1″] Upper registration roller [37.68 mm/1 «] Lower registration roller [45.216 mm/1 «] Transfer roller [62.8 mm/2 «] Developing roller (developing unit) [73.162 mm/2 «] Heat roller (fuser unit) [78.5 mm/3 «] Press roller (fuser unit) 1/16 [94 mm/3…

-

Page 121: Self Diagnostic Codes Indication (Animation)

2LY/2LZ (3) Self diagnostic codes indication (Animation) Click the icon to play the animation of the indicator combinations. Right-click an indicator, then select Playback and Play to play the animation repeatedly. To play the animation, you have to install Adobe Flash Player and Adobe Reader (Version 6.01 or more) to your PC. If the animation is not displayed, you should get the latest version from Adobe site (http://www.adobe.com/downloads/).

- Page 122

2LY/2LZ Indication Contents Broken fuser thermistor wire Zero cross signal error Control PWB checksum error Control PWB RAM checksum error Control PWB general failure Control PWB engine communication error Control PWB engine checksum error Control PWB video data control error 2-4-4… -

Page 123: Maintenance Parts List

2LY/2LZ (4) Maintenance parts list 30/32 ppm model (A4/Letter) Maintenance part name Alternative part Part No. Name used in service manual Name used in parts list Maintenance kit (120 V specifications) MK-162/MAINTENANCE KIT 1702LY7US0 072LY7US DK-150 DV-162(U) Maintenance kit (230 V specifications) MK-160/MAINTENANCE KIT 1702LY8NL0 072LY8NL…

- Page 124

2LY/2LZ This page is intentionally left blank. 2-4-6…

Все современные копировальные аппараты, мфу и принтеры Kyocera имеют возможность диагностировать все узлы устройства в режиме запуска и во время работы аппарата. По этому, если во время включения или во время работы произошел сбой, то техника Kyocera сможет сообщить о наличии ошибки.

В большинстве случаев у аппаратов Kyocera код ошибки отображается на дисплее, в остальных случаях тип ошибки зависит от последовательности и количества миганий индикаторов.

Если Ваш копировальный аппарат, МФУ или принтер Kyocera выдал на дисплее некий код, то узнать причину, описание возникновения ошибки, а так же в каком узле аппарата стоит искать проблему, Вы можете в этом разделе выбрав интересующую модель из списка.

Но диагностика не решит проблему сбоя аппарата, для этого лучше обратиться к профессиональным и опытным сервисным специалистам компании Kyomart! Позвоните нам по телефону

8 (343) 288-23-45 или отправьте запрос на электронную почту: sales@kyomart.ru , и мы обязательно свяжемся с Вами в кратчайшие сроки.

| Код ошибки | Описание ошибки | Причина ошибки |

|---|---|---|

| 0030 | FAX PWB system error Processing with the fax software was disabled due to a hardware problem. |

Defective FAX PWB. |

| 0100 | Backup memory device error | Defective flash memory. Defective main PWB. |

| 0120 | MAC address data error For data in which the MAC address is invalid. |

Defective flash memory. Defective engine PWB. |

| 0190 | Backup memory error (engine) Unable to read the main PWB IC. |

Defective flash memory. Defective main PWB. |

| 2000 | Main motor error The main motor ready input is not given for 2 s during the main motor is ON. |

Defective harness between main motor (CN1) and control PWB (YC17), or improper connector insertion. Defective drive transmission system of the main motor. Defective main motor. Defective control PWB. |

| 3100 | ISU home position error | Defective FFC between CCD PWB (YC1) and control PWB (YC8). Defective FFC between control PWB (YC6) and scanner PWB (YC103), or improper FFC insertion. Defective home position sensor. Defective harness between ISU motor and scanner PWB (YC104), or improper connector insertion. Defective ISU motor. |

| 3200 | Exposure lamp error The exposure lamp is not turned on. |

Defective FFC between scanner PWB (YC103) and control PWB (YC6), or improper FFC insertion. Defective FFC between CCD PWB (YC1) and control PWB (YC8). Defective harness between CCD PWB (YC3) and inverter PWB (YC101), or improper connector insertion. Defective harness between inverter PWB (YC102) and exposure lamp, or improper connector insertion. Defective exposure lamp. Defective inverter PWB. Defective control PWB. |

| 3300 | AGC error After AGC, correct input is not obtained at CCD. |

Defective FFC between CCD PWB (YC1) and control PWB (YC8). Defective exposure lamp. Defective CCD PWB. Defective control PWB. |

| 3500 | CPU — ASIC (CCD PWB) communication error An error code is detected. |

Defective FFC between CCD PWB (YC1) and control PWB (YC8). Defective CCD PWB. Defective control PWB. |

| 4000 | Polygon motor (laser scanner unit) error The polygon motor ready input is not given for 6 s during the polygon motor is ON. |

Defective harness between polygon motor and control PWB (YC10), or improper connector insertion. Defective laser scanner unit. Defective control PWB. |

| 4200 | BD error (laser scanner unit) error | BD sensor does not detect laser beam due to condensation on the polygon mirror. Defective laser scanner unit. Defective control PWB. |

| 6000 | Broken fuser heater lamp wire The fuser temperature does not rise after the fuser heater lamp has been turned on. |

Poor contact in the fuser thermistor connector terminals. Poor contact in the fuser heater lamp connector terminals. Fuser thermistor installed incorrectly. Fuser thermal cutout triggered. Fuser heater lamp installed incorrectly. Broken fuser heater lamp wire. |

| 6020 | Abnormally high fuser thermistor temperature Fuser thermistor detects abnormally temperature. |

Shorted fuser thermistor. Defective control PWB. |

| 6030 | Broken fuser thermistor wire Input from fuser thermistor is 0 (A/D value). |

Poor contact in the fuser thermistor connector terminals. Broken fuser thermistor wire. Fuser thermistor installed incorrectly. Fuser thermal cutout triggered. Fuser heater lamp installed incorrectly. Broken fuser heater lamp wire. |

| 6400 | Zero cross signal error The zero cross signal does not reach the control PWB for specified time. |

Defective harness between high voltage PWB (YC202) and control PWB (YC23), or improper connector insertion. Defective connection between power source PWB (YC103) and high voltage PWB (YC201). Defective power source PWB. Defective control PWB. |

| F000 | Communication Error between Main PCB and Panel PCB Communication failure during the start-up or operation. * : Only 3 in 1 25/26 ppm model, 4 in 1 20/21, 25/26 ppm model |

Defective main PWB. Defective operation PWB. |

| F020 | Control PWB RAM checksum error | Defective main memory (RAM) on the control PWB. Defective expanded memory (DIMM). |

| F040 | Control PWB engine communication error A communication error is detected. |

Defective control PWB. |

| F050 | Control PWB engine checksum error | Some error may have occurred when downloading the firmware of the control PWB. Defective control PWB. |

2LY/2LZ

(2) Self diagnostic codes indication

1.6 s

Repeat

Code conversion table

Code

1

Indicator

Code

6

Indicator

Self diagnostic codes indication (Animation). See page 2-4-3.

1-4-4

Sequence of display

1.6 s

0.8 s

0.8 s

0.8 s

0.8 s

0.8 s

0.8 s

2

7

Indicates the

occurrence of a self

diagnostics error.

2

Example of self-diagnostic code: 2610

(Refer to the following code conversion table)

1

0

Off (Amber)

Lit (Amber)

3

4

8

9

Figure 1-4-4

Indication example

Lit (Green)

Lit (Amber)

Off (Amber)

Off (Green)

5

0

F

Порой бывает трудно понять, почему «не работает принтер». На самом деле при любой ошибке принтер выдает код. Здесь я выкладываю коды ошибок на отличные МФУ Kyocera, которые мы используем при работе.

Коды ошибок Kyocera FS-1020MFP, 1025MFP, 1120MFP, 1125MFP, 1220MFP, 1320MFP, 1325MFP

If the part causing the problem was not supplied, use the unit including the part for replacement.

Release is performed by power supply OFF/ON.

| Код ошибки | Неполадки | Причина | Устранение |

| 0030 | FAX Board System Error Cannot communicate with the modem when activated. *: 4 in 1 model only | Defective FAX control PWB. | Replace the fax control PWB and check for correct operation |

| 0100 | Backup memory read/write error(NOR) Flash returns an abnormal status. | Defective flash memory. | Replace the main PWB and check for correct operation |

| Defective main PWB. | Replace the main PWB and check for correct operation | ||

| 0120 | MAC address data error For data in which the MAC address is invalid. | Defective flash memory. | Replace the main PWB and check for correct operation |

| 0190 | Backup memory error (engine)Unable to read the main PWB IC. | Defective flash memory. | Replace the main PWB and check for correct operation |

| Defective main PWB. | Replace the main PWB and check for correct operation | ||

| 0630 | Scan DMA error Unable to transfer DMA. | Defective main PWB. | Replace the main PWB and check for correct operation |

| 2000 | Main motor error Pulse is not detected after 1000msec. Motor won’t stabilize after 300msec. | Defective connector cable or poor contact in the connector. | Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable, main motor and Relay PWB (YC4) Relay PWB and main PWB (YC14). |

| Defective drive transmission system of motor. | Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any. | ||

| Defective motor. | Replace the main motor. | ||

| Defective main PWB. | Replace the main PWB and check for correct operation | ||

| 3100 | Scanner Carriage Error The HP sensor won’t be opened when it is driven in the scan direction for 37.44 mm (*1) at the initial scanning when the HP sensor is cut off. The HP sensor won’t be cut off when it is driven in the return direction for 320.44mm (*2) at the initial scanning when the HP sensor is open. | Defective connector cable or poor contact in the connector. | Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Home position sensor and OPWB Scanner motor and main PWB (YC18) |

| Defective home position sensor. | Replace the home position sensor. | ||

| Defective scanner motor. | Replace the scanner motor. | ||

| Defective main PWB. | Replace the main PWB and check for correct operation | ||

| 3300 | AGC Error The resultant AGC fell outside the range of allowance. | Defective connector cable or poor contact in the connector. | Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. CIS sensor and main PWB (YC8) |

| CIS sensor. | Replace the CIS sensor. | ||

| Defective main PWB. | Replace the main PWB and check for correct operation | ||

| 3500 | Scan ASIC Error The scan ASIC has been inoperative. | Defective main PWB. | Replace the main PWB and check for correct operation |

| 4000 | Polygon motor synchronize errorPolygon motor is not stabilized within 15 s since the | Defective connector cable or poor contact in the connector. | Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Polygon motor and main PWB (YC17) |

| motor is activated. After polygon motor is stabilized, the ready signal is not detected for 7 s continuously. | Defective polygon motor. | Replace the laser scanner unit | |

| Defective main PWB. | Replace the main PWB and check for correct operation | ||

| 4200 | BD stability error The BD signal is not detected for 1000 ms after processing the compulsion lighting. At the interrupt in VSYNC, the | Defective connector cable or poor contact in the connector. | Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Laser scanner unit (YC1) and main PWB (YC5) |

| BD error is detected continuously for 10 times in 400 ms intervals. | Defective APC PWB. | Replace the laser scanner unit | |

| Defective main PWB. | Replace the main PWB and check for correct operation | ||

| 6000 | Broken fuser heater The temperature does not reach 100° C/212 °F after the fuser heater lamp has been turned on continuously for 30 s | Defective connector cable or poor contact in the connector. | Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. fuser heater lamp and Power source PWB (YC102). |

| At the time of 20 degrees or less from specified temperature, the fuser temperature does not rise by 2 degrees or | Fuser thermostat triggered. | Replace the fuser unit | |

| Defective fuser heater. | Replace the fuser unit | ||

| more after the fuser heater lamp has been turned on continuously for 8 s. (during ready or during print) | Defective main PWB. | Replace the main PWB and check for correct operation | |

| 6020 | Abnormally high fuser thermistor temperature Fuser thermistor detects a temperature higher than 210°C/410°F for 3 s | Deformed connector pin. | If the l/F connector pins of the fuser unit and the main unit are deformed owing to foreign matters, such as paper dusts, replace the connectors or the units including the connectors. |

| Shorted fuser thermistor. | Replace the fuser unit | ||

| Defective power source PWB. | Replace the power source PWB | ||

| Defective main PWB. | Replace the main PWB and check for correct operation | ||

| 6030 | Broken fuser thermistor wireAverage input AD given by the thermistor is less than 2 for 300msec. | Defective connector cable or poor contact in the connector. | Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser unit and main PWB (YC15) |

| Broken fuser thermistor wire. | Replace the fuser unit | ||

| Fuser thermostat triggered. | Replace the fuser unit | ||

| Defective main PWB. | Replace the main PWB and check for correct operation | ||

| 6400 | Fixing control zero cross signal error The ZCROSS signal does not reach the main PWB for more than 2 s. | Defective connector cable or poor contact in the connector. | Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Power source PWB (YC103) and main PWB (YC12) |

| Defective power source PWB. | Replace the power source PWB | ||

| Defective main PWB. | Replace the main PWB and check for correct operation | ||

| F000 | Communication Error between Main PCB and Panel PCBCommunication failure during the start-up or operation. *: Only 3 in 1 25/26ppm model, 4 in 1 20/21, 25/26 ppm model | Defective main PWB. | Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB |

| Defective operation PWB. | Replace the operation PWB and check for correct operation. | ||

| F020 | RAM R/W error The average AD value of the sensor input is smaller than 2 during SLP_RLY is off and 300 ms. | Defective main PWB. | Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB |

| F040 | Communication Error between Main PCB and Engine PCBCommunication is failed between the controller and the engine. | Defective main PWB. | Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB |

| F05D | No Engine Main Program Engine program failure. | Defective engine software. | Install the engine software. |

| Defective main PWB. | Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB | ||

| E-0001 | 0001 Установлен неоригинальный картридж с тонером |

Производитель не несет ответственности за повреждения, вызванные использованием неоригинального тонера. Рекомендуется использовать только оригинальные картриджи с тонером. Если вы хотите использовать картридж с тонером, установленный на данный момент, одновременно нажмите Клавиша выбора режима и [Стоп/Сброс] и удерживайте не менее 3 секунд. |

|

| E-0002 | Возникла ошибка: Региональные спецификации установленного картриджа с тонером не соответствуют спецификациям аппарата. |

Установите картридж с тонером, соответствующий спецификациям. |

|

| E-0003 | Память переполнена. Сканирование невозможно из-за нехватки памяти сканера. |

Доступны только отсканированные страницы. Нажмите [Стоп/Сброс], после чего задание будет отменено. Код ошибки E-0001 Отображается в виде повторяющихся двузначных сегментов (E-, 00 и 01). |

|

| E-0007 | Добавьте тонер | В картридже закончился тонер | Установите новый картридж с тонером |

| E-0008 | Открыта крышка | Открыта задняя или передняя крышка | Закройте крышки |

| E-0009 | Лоток переполнен | Внутренний лоток заполнен бумагой | Аппарат приостанавливается после печати 100 листов. Извлеките бумагу из внутреннего лотка и нажмите [ Старт ] для возобновления печати |

| E-0012 | Переполнение памяти | Невозможно продолжение задания из-за нехватки памяти | Измените разрешение печати с «Fast1200» (Быстрая 1200) на 600 т/д. Смотрите (Руководство пользователя) |

| E-0014 | Добавьте бумагу | Формат бумаги во входном лотке отличается от настройки драйвера принтера или KYOCERA Client Tool | Загрузите в лоток бумагу подходящего формата |

| E-0015 | Не подсоединено | USB-кабель не подключен | Нажмите Стоп/Сброс. Подключите USB-кабель |

| Сетевой кабель не подключен | Нажмите Стоп/Сброс. Подключите сетевой кабель | ||

| Выключено питание аппарата | Нажмите Стоп/Сброс. Включите питание | ||

| Не удается найти соответствующий драйвер | Установите соответствующий драйвер | ||

| E-0018 | Ошибка | Указанного файла нет в ящике печати | Нажмите Стоп/Сброс |

| E-0019 | Ошибка | Аппарат не может выполнить данную программу, потому что в ней зарегистрирован неиспользуемый формат оригинала | Нажмите Стоп/Сброс и измените настройки программы |

| J-0511 | Застревание бумаги | Застревание бумаги под задней крышкой | Извлеките застрявшую бумагу. Как -см. инструкцию пользователя. |

Ошибка, код ошибки: E-0001, E-0002, E-0003, E-0007, E-0008, E-0009, E-0012, E-0014, E-0015, E-0018, E-0019, J-0511, C-0030, C-0100, C-0120, C-0190, C-0630, C-2000, C-3100, C-3300, C-3500, C-4000, C-4200, C-6000, C-6020, C-6030, C-6400, C-F000, C-F020, C-F040, C-F05D Kyocera FS-1020MFP, 1025MFP, 1120MFP, 1125MFP, 1220MFP, 1320MFP, 1325MFP

Взято отсюда:

Коды ошибок Kyocera FS-1020MFP, 1025MFP, 1120MFP, 1125MFP, 1220MFP, 1320MFP, 1325MFP.

Отблагдарить автора статьи также можно переводом, +100 вам в карму!

Японская компания Kyocera производит высококачественные лазерные принтеры и МФУ для офисной печати. Их продукция одна из самых востребованных на сегодняшний день. Ведь печатающие устройства Kyocera характеризуются высокой надежностью, износостойкостью и большим сроком эксплуатации. Однако даже их изделия не являются вечными. Со временем принтеры Kyocera начинают сбоить.

К счастью, оргтехника Kyocera оснащена системой самодиагностики (так же, как и струйные принтеры Canon). Поэтому, в случае возникновения проблемы, устройство самостоятельно выявит уязвимое место и сообщит Вам об этом миганием соответствующего индикатора на панели управления либо кодом ошибки, выведенным на дисплей принтера.

Если Вы не являетесь мастером по обслуживанию принтеров и МФУ Kyocera, то, чтобы понять, о чем сообщает печатающее устройство, Вам потребуется расшифровать указанный им код. Для этого мы добавили в статью таблицу кодов ошибок лазерных принтеров Kyocera серии FS и не только.

Коды ошибок принтеров и МФУ Kyocera, которые можно исправить самостоятельно

|

Код ошибки |

Значение ошибки |

Решение проблемы |

|

E-0001 (E1) |

Поврежден чип картриджа либо установлен неоригинальный картридж. |

Замените установленный картридж оригинальной версией изделия. Если хотите сэкономить, тогда купите и установите новый чип на картридж или перепрошейте принтер Kyocera. Однако предварительно не помешает попробовать сбросить ошибку соответствующей комбинацией клавиш (как это сделать, читайте в статье «Сброс ошибки установки неоригинального картриджа в принтерах Kyocera»). |

|

E-0002 (E2) |

Регион использования картриджа и принтера не совпадают. |

Замените чип или прошейте принтер Kyocera. |

|

E-0003 (E3) |

Заполнена память принтера или МФУ Kyocera. |

Отпечатайте ранее отсканированные листы или очистите очередь печати нажатием кнопки Стоп/Сброс (ранее отсканированные листы также удалятся из памяти принтера, даже если они еще не были распечатаны). |

|

E-0007 (E7) |

Тонер-картридж Kyocera израсходовал ресурс красящего вещества. |

Замените или заправьте картридж Kyocera (если используете совместимый или перезаправленный расходник, то после установки его в принтер не забудьте сбросить ошибку зажатием на 3-5 секунды кнопок [Ок] и [Сброс/Стоп]). |

|

E-0008 (E8) |

Открыта крышка принтера либо не работает датчик закрытия крышек устройства. |

Откройте и еще раз закройте переднюю и заднюю крышку принтера. Во время закрытия Вы должны услышать характерный щелчок. Если не помогло, то причина в неисправности датчика. |

|

E-0009 (E9) |

Лоток приема бумаги полон. |

Уберите все отпечатанные листы бумаги из выходящего лотка. Чтобы возобновить печать, нажмите кнопку [Старт]. |

|

E-0012 (E12) |

Ошибка памяти принтера Kyocera. |

Попробуйте уменьшить разрешение печати. Скорее всего, формат создаваемого отпечатка не соответствует возможностям принтера. |

|

E-0014 (E14) |

Установлен неверный формат бумаги (неподдерживаемый принтером Kyocera). |

Поменяйте бумагу на поддерживаемую принтером либо смените ее формат в настройках печати. Попробуйте обновить программное обеспечение. Возможно, это расширит поддерживаемые принтером Kyocera форматы. |

|

E-0015 (E15) |

Устройство не подключено к электрической сети либо на компьютере нет (не работает) драйвера принтера Kyocera. |

Проверьте подключение печатающего аппарата к электрической сети, а также целостность кабеля. Если ошибка не исчезает, скачайте драйвер принтера Kyocera и установите его на компьютер. |

|

E-0017 (E17) |

Ошибка передачи данных. |

Проверьте подключение принтера к компьютеру. Кабель не должен быть длиннее 5 метров, а также обязан поддерживать стандарт USB 2.0. Кроме того, переустановите драйвер принтера и утилиту Kyocera Client Tool. |

|

E-0018 (E18) |

Очередь печати заполнена. |

Очистите очередь печати нажатием кнопки [Сброс] либо через драйвер принтера. |

|

E-0019 (E19) |

Неверный формат печати. |

Отмените печать нажатием кнопки [Стоп/Сброс]. Выберите в настройках принтера соответствующий режим печати, а также установите в лоток поддерживаемый принтером формат бумаги. |

|

J-0000 (jam0000) |

Замятие бумаги за задней крышкой. |

Откройте крышку и извлеките бумагу. Проверьте надежность крепления бумаги в лотке, а также принтер на наличие посторонних предметов. Еще причина может быть в пружине выходного флажка. Если она растянулась, то может плохо работать фиксатор. Также проблема может быть из-за печки, сделайте ее ревизию, переборку и смазку. |

|

J-0501 (jam0501) |

Бумага застряла в принтере Kyocera |

Извлеките замятую бумагу. Проверьте надежность установки бумаги во входной лоток. Проверьте целостность роликов протяжки бумаги, а также принтер на наличие посторонних предметов. Если не помогло, стоит внимательно осмотреть ребра на направляющей пластине. На них могут образоваться сколы, трещины и заусенцы. Их можно слегка подчистить наждачной бумагой (нулевкой). |

|

J-0511 (jam0511) |

Принтер Kyocera замял бумагу. |

Извлеките замятую бумагу и повторите печать. Если проблема не исчезла, несите принтер в сервис. Скорее всего, изношен ролик протяжки бумаги. |

|

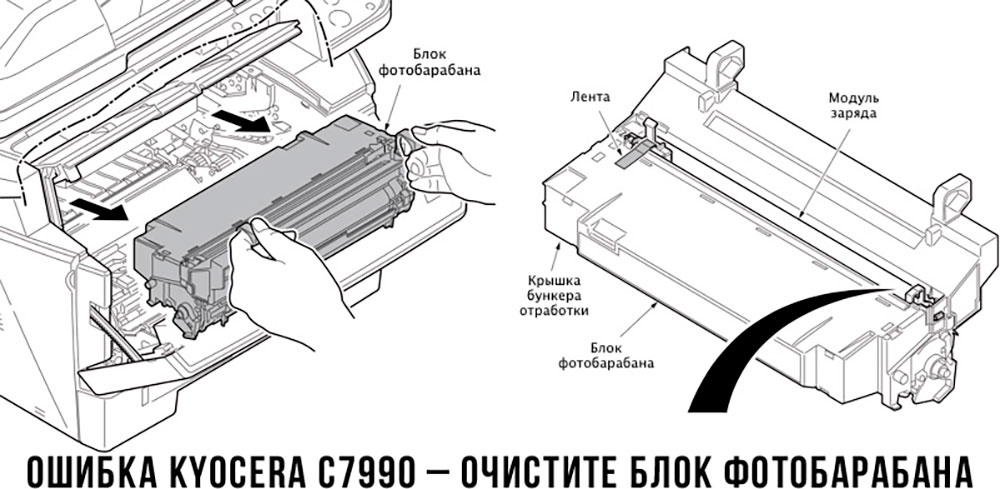

C7990 |

Бункер драм-картриджа (блока фотобарабана) заполнен отработанным тонером либо неисправен счетчик отработки красящего вещества. Еще проблема может быть в главной плате PWB. |

Осуществите чистку драм-картриджа (блока фотобарабана). Если проблема в датчике или плате, то нужно отнести принтер в СЦ на диагностику. |

|

F248 |

Ошибка обработки отпечатываемого материала. |

Перезагрузите принтер. Уберите неподдерживаемые спецсимволы из отпечатка. Обновите ПО принтера Kyocera. Смените режим работы принтера с PDL на GDI (Пуск -> Принтеры -> Свойства -> Параметры устройства). |

|

PF |

Отсутствует бумага в лотке подачи. |

Загрузите листы бумаги во входной лоток. Если принтер по-прежнему не печатает, значит нужно искать проблему в чем-то другом. |

|

1101 |

Ошибка сканирования через сеть из-за неправильного имени SMTP сервера. |

Пропишите DNS-адреса помимо прочих настроек печати по сети. |

|

1102 |

Некорректная настройка сканера для работы через сеть |

Зайдите в Web-панель управления принтером (нужно в адресную строку браузера ввести iP принтера Kyocera). Далее в зависимости от модели введите логин и пароль (Admin/Admin или просто admin00 без логина). Далее следуйте инструкции:

Логин и пароль нужны обязательно, если их нет, то следует создать. |

|

2101 |

Ошибка передачи данных при сканировании через сеть. |

Правильно настройте параметры (как для ошибки 1102), только предварительно отключите на ПК антивирус и брандмауэр. |

Если Вы испытали все способы, но не смогли убрать ошибку, то следует нести печатающее устройство в сервисный центр. Кроме того, есть ряд ошибок (высвечиваемых на дисплее принтера), которые нельзя устранить в домашних условиях. Соответствующие коды ошибок принтеров Kyocera представляем в очередной таблице.

Коды ошибок принтеров и МФУ Kyocera, которые нужно устранять в сервисном центре

|

Код ошибки |

Значение ошибки |

Решение проблемы |

|

0030 |

Неисправность платы управления факсом принтера. |

Замена платы. |

|

0100 |

Неисправность платы управления или флеш-памяти принтера. |

Замена платы. |

|

0120 |

Ошибка чтения mac-адреса из-за неисправности флеш-памяти принтера. |

Замена платы. |

|

0190 |

Неисправность платы управления или флеш-памяти принтера. |

Замена платы. |

|

0630 |

Неисправность платы управления принтера. |

Замена платы. |

|

1020 |

Неисправность мотора, привода или отсутствие контакта. |

Разборка принтера и замена изношенных частей. Проверка надежности подключений, замена разорванных (прогоревших) кабелей. Ремонт или замена привода мотора. |

|

1040 |

Неисправность мотора, привода или отсутствие контакта. |

Разборка принтера и замена изношенных частей. Проверка надежности подключений, замена разорванных (прогоревших) кабелей. Ремонт или замена привода мотора. |

|

2000 |

Неисправность главной платы управления, соединительного кабеля или привода принтера. |

Проверить ремни, шестерни и ролики привода. Смазать или заменить, если есть дефекты. Заменить привод или главную плату. |

|

3100 (C3100) |

Неисправность главной платы, привода сканера, датчика положения или нарушение целостности соединений. |

Проверить наличие разрывов и отсутствия контакта. Смазать или заменить изношенные элементы привода. Заменить привод, главную плату, датчик или соединительный кабель. Если Вам повезло, то возможно забыли отключить фиксатор блока сканера. |

|

3101 |

Сетевой кабель не подсоединен, или нарушена работа концентратора. Еще может быть из-за наличия вирусов в системе или неправильно заданным параметрам сервера SMTP. |

Проверить соединения, правильно настроить параметры сети. |

|

3300 |

Неисправность главной платы, датчика CIS или соединительного кабеля. |

Проверить контакты, заменить плату или датчик. |

|

3500 |

Неисправность главной платы или нарушение соединения контактов. |

Проверить контакты, заменить плату. |

|

4000 (C4000) |

Неисправность главной платы, привода сканера или нарушение соединений. Однако чаще всего ошибка лазера. |

Проверить контакты, заменить плату или привод блока сканера. Почистить лазер, смазать ось полигон-мотора, либо полностью заменить блок лазера. |

|

4200 |

Неисправность главной платы, блока сканера или датчика BD. |

Отключить питание принтера на 30 минут. Если не помогло, то следует заменить привод сканера или главную плату принтера. |

|

6000 (С6000) |

Неисправность главной платы, термостата, печки или нарушение соединения контактов. |

Проверить и поправить контакты. Заменить фьюзер. Ремонт или замена печки, термодатчика, термопредохранителя и т.д. |

|

6020 |

Сгорание термистора или главной платы. |

Замена термистора или главной платы. |

|

6030 |

Неисправность главной платы, термостата или термистора. Возможно, причина в отсутствии контакта. |

Проверить соединения. Заменить плату, термостат или термистор. |

|

6400 |

Неисправность главной платы, отсутствие питания или контакта. |

Заменить плату или источник питания. |

|

F000 |

Неисправность главной платы или отсутствие контакта. |

Проверить соединение ремня безопасности. Заменить ремень или плату управления. |

|

F020 |

Неисправность элементов памяти принтера. |

Перезагрузить принтер. Если ошибка не устранилась – заменить плату управления. |

|

F040 |

Неисправность главной платы принтера. |

Перезагрузить принтер. Если ошибка не устранилась – заменить плату управления. |

|

F05D |

Неисправность главной платы. Сбой программного оборудования привода. Проблемы с прошивкой принтера Kyocera. |

Перезагрузить принтер. Если ошибка не устранилась – заменить плату управления. Перепрошить принтер Kyocera. |

|

F245 F246 F247 F375 |

Принтер Kyocera заблокирован из-за проблемы, вызванной отказом источника питания. |

Нужно перепрошить принтер специальной сервисной микропрограммой. |

Обратите внимание: Если у печатающего устройства нет дисплея, то определить проблему можно по светодиодным индикаторам, встроенным в панель управления принтером. Например, у Kyocera Ecosys P2135D нужно сосчитать количество миганий индикаторов красного цвета и таким образом определить число, указывающее на ту или иную ошибку. В свою очередь, у модели Kyocera FS-1040 все зависит от темпа мигания светодиода с надписью «Внимание!» («Attention!»):

- Мигает медленно – указывает на отсутствие бумаги в лотке или тонера в картридже.

- Мигает быстро – оповещает о проблеме с памятью устройства, переполненном лотке или замятии бумаги, а также об использовании неоригинальных расходных материалов.

- Горит постоянно – говорит о проблемах с картриджем или фотобарабаном либо указывает на открытые крышки принтера.

Чтобы потребитель мог наверняка определить проблему, рекомендуем использовать утилиту Kyocera Client Tool, которая идет в комплекте с драйверами принтера.

Ваше Имя:

Ваш вопрос:

Внимание: HTML не поддерживается! Используйте обычный текст.

Оценка:

Плохо

Хорошо

Введите код, указанный на картинке: