Если при работе с копировальном аппаратом у вас возникли проблемы, и система выдает код ошибки, вы можете идентифицировать ее с помощью данной таблицы.

Коды ошибок Kyocera-Mita указаны для более поздних моделей копиров. Если вы являетесь владельцем более ранней модели, необходимо к трехзначному коду ошибки прибавить знак «0».

Общие ошибки

| Код ошибки | Описание |

|---|---|

| 0030 | Fax control PWB system problem |

| 0070 | Fax control PWB incompatibility detection problem |

| 0100 | Backup memory read/write problem (main board) |

| 0110 | Backup memory data problem (main board) |

| 0120 | Drum EEPROM read/write problem (для 2550) |

| 0130 | Backup memory read/write problem (main PCB EEPROM) (для 1650/2050/2550) |

| 0140 | Backup memory data problem (main PCB EEPROM) (для 1650/2050/2550) |

| 0150 | Backup memory read/write problem (engine board) |

| 0160 | Backup memory data problem (engine board) |

| 0170 | Accounting count problem |

| 0180 | Machine number mismatch |

| 0210 | Communication problem between the main board and engine board (для KM-1500/1620/2020/1635/2035/1650/2050/2550/6030/8030, FS-1018/1118) |

| Communication problem between the main board and operation board (для KM-1525/1530/2030/2530/3530/6230/4530/5530/6330/7530) | |

| 0240 | Printer board PWB communication problem |

| 0250 | Scanner network board communication problem |

| 0280 | Communication problem between the fax control PWB and main PWB |

| 0320 | Side deck communication problem |

| 0340 | Finisher communication problem |

| 0410 | Optional DP communication problem |

| 0420 | Optional first paper feeder communication problem |

| Large paper deck /paper feed desk communication problem /Side deck communication problem | |

| 0440 | Finisher communication problem |

| 0450 | Mailbox communication problem |

| 0470 | Switchback unit communication problem |

| 0500 | Optional second paper feeder communication problem |

| 0510 | Optional third paper feeder communication problem |

| 0600 | DIMM problem (для 2530/3530) |

| 0610 | Bitmap (DIMM) problem |

| 0620 | Memory input interface problem |

| 0630 | DMA problem |

| 0640 | Hard disk drive problem |

| 0800 | Image processing problem (JAM05 is detected twice) |

| 0820 | Fax control PCB CG ROM checksum error |

| 0830 | Flash ROM program area checksum error |

| 0860 | Fax control PCB software switch checksum error |

| 0870 | Fax control PWB to main PWB high capacity data transfer problem |

| 0880 | Fax control PWB program archive problem |

| 0890 | Fax control PCB CG font archive problem |

| 0900 | Fax software incompatibility detection problem |

| 0920 | Fax file system error |

| 0960 | Developer EEPROM read/write problem (для 2550/6030/8030) |

| 1000 | Exposure lamp problem |

| 1010 | Lift motor 1 error |

| 1020 | Lift motor 2 error |

| 1030 | Lift motor 3 error |

| 1040 | Lift motor 4 error |

| 1100 | Paper deck motor 1 problem [Drawer 3] |

| 1110 | Paper deck motor 2 problem [Drawer 4] |

| 1120 | Deck right lift position problem |

| 1130 | Deck left lift position problem |

| 1140 | Side deck lift motor (going up) problem |

| 1150 | Side deck lift motor (going down) problem |

| 1160 | Large paper deck (paper feed desk) sequence problem |

| 1170 | Large paper deck (paper feed desk) incorrect type problem |

| 2000 | Main motor problem |

| Image forming motor problem (для 6230/4530/5530/6330/7530) | |

| 2500 | Paper feed motor problem |

| 2550 | Paper conveying motor problem (для 4530/5530) |

| 2600 | Deck conveying motor /desk drive motor problem |

| 2640 | Side deck drive motor problem |

| 3100 | Scanner carriage problem |

| 3200 | Exposure lamp problem |

| 3300 | Optical system (AGC) problem |

| 4000 | Polygon motor synchronization problem |

| 4010 | Polygon motor steady-state problem |

| 4100 | BD initialization (A) problem |

| 4110 | BD initialization (B) problem |

| 4200 | BD steady-state problem |

| 5100 | Main charger problem |

| 5110 | Transfer/separation high voltage problem |

| 5300 | Broken cleaning lamp wire |

| 5500 | Drum surface potential sensor problem 1 |

| 5510 | Drum surface potential sensor problem 2 |

| 5600 | Drum surface potential problem 1 |

| 5610 | Drum surface potential problem 2 |

| 6000 | Broken fixing heater wire |

| 6020 | Abnormally high fixing unit thermistor temperature |

| 6030 | Broken fixing unit thermistor |

| 6050 | Abnormally low fixing unit thermistor temperature |

| 6100 | Broken fixing heater wire |

| 6200 | Abnormally low fixing unit thermistor temperature |

| 6300 | Abnormally high fixing unit thermistor temperature |

| 6400 | Zero-crossing signal problem |

| 6410 | Fixing unit connector insertion problem |

| 6420 | Fixing fuse cut problem |

| 6420 | Broken fixing unit thermistor wire |

| 7100 | Toner sensor problem |

| 7300 | Broken external temperature thermistor wire (для KM-1505/1510/1810/4230/5230/6230) |

| Toner sensor problem/ Toner hopper problem (для KM-2530/3530/3035/4035/5035/6230/4530/5530/6330/7530/6030/8030) | |

| 7310 | Short-circuited external temperature thermistor |

| 7400 | Image formation unit connector insertion problem |

| Developing unit connector insertion problem (для 2550) | |

| 7410 | Drum unit connector insertion problem |

| 7750 | Drum type mismatch problem A (для 1635/2035) |

| 7760 | Drum type mismatch problem B (для 1635/2035) |

| 7800 | Broken external temperature thermistor |

| 7810 | Short-circuited external temperature thermistor |

KM-1500, FS-1018/1118 (KM-1820)

| Код ошибки | Описание |

|---|---|

| 0220 | Communication problem between the main board and operation board (для 1018/1118) |

| F— | Controller system error (для 1018/1118) |

| F010 | ROM checksum error (для 1118) |

| F012 | |

| 7980 | Waste toner reservoir overflow problem (when the total number of copies is less than 100 thousand sheets) |

| 7990 | Waste toner reservoir overflow problem (when the total number of copies is 100 thousand sheets or more) |

KM-1505/1510/1810/1525/1530/2030

| Код ошибки | Описание |

|---|---|

| 0210 | Printer board communication problem (для 1505/1510/1810) |

| 0400 | DIMM problem |

| 0410 | Bitmap problem |

| 0430 | DMA problem |

| 1040 | Optical system problem (AGC) |

Kyocera-Mita 3035/4035/5035

| Код ошибки | Описание |

|---|---|

| 0100 | Operation unit PCB backup memory read/write error |

| 0110 | Operation unit PCB backup memory data problem |

| 0210 | MMI communication problem |

| 0320 | Energy save communication problem |

| 7450 | Image formation unit fuse cut problem |

Kyocera Mita 4230/5230

| Код ошибки | Описание |

|---|---|

| 0010 | Memory copy PCB 1 communication problem |

| 0030 | Memory copy PCB 2 communication problem |

| 0100 | RAM/ROM problem |

| 0220 | Communication problem between the engine PCB and main PCB |

| 0230 | Scanner communication problem |

| 0260 | Memory copy PCB 1 communication problem |

| 0320 | Large paper deck communication problem /Paper feed desk communication problem |

| 0360 | Memory copy PCB 2 communication problem |

| 0370 | Communication microcomputer problem |

| 1040 | Optical system problem (AGC) |

| 2100 | Paper conveying motor problem |

| 2200 | Side registration motor problem |

| 2300 | Paper feed motor problem |

| 2310 | Desk drive motor problem |

| 2410 | Upper lift motor problem |

| 2420 | Lower lift motor problem |

| 2430 | Upper desk lift motor problem |

| 2440 | Lower desk lift motor problem |

| 3320 | Scanner watchdog problem |

| 3400 | Original detection position problem |

| 7400 | Toner hopper problem |

| 9200 | Deck paper conveying motor problem |

| 9210 | Paper deck motor 1 problem |

| 9220 | Paper deck motor 2 problem |

| 9230 | Right lift position problem |

| 9240 | Left lift position problem |

Kyocera-Mita 6030/8030

| Код ошибки | Описание |

|---|---|

| 0060 | Main PWB type mismatch error |

| 0130 | Backup memory (EEPROM) device problem |

| 0140 | Backup memory (EEPROM) data problem |

| 0220 | Scanner communication problem |

| 0330 | Relay board communication problem |

| 0460 | Duplex unit communication problem |

| 0470 | Sheet inserter communication problem (optional document finisher) |

| 0500 | Paper feed unit communication error (cassette 1 and 2) |

| 0510 | Paper feed unit communication error (cassette 3 and 4) |

| 0700 | Side feeder EEPROM error (optional side feeder) |

| 0750 | Document finisher EEPROM error |

| 0970 | Cleaning unit EEPROM error |

| 1200 | Duplex side registration motor error |

| 2100 | Developing motor error |

| 2200 | Drive motor error |

| 2300 | Fuser motor error |

| 2550 | Transfer motor error |

| 3210 | CIS lamp problem |

| 3310 | Optical system (AGC) problem (DP) |

| 3500 | Communication error between scanner and SHD |

| 3900 | Backup memory read/write error (scanner PWB) |

| 3910 | |

| 4120 | BD initialization (C) problem |

| 7200 | Broken drum thermistor wire |

| 7210 | Shorted drum thermistor |

| 9040 | DP lift motor going up error |

| 9050 | DP lift motor going down error |

| 9060 | DP EEPROM error |

| 9070 | Communication problem between DP and SHD |

| 9080 | Communication problem between DP and CIS |

Kyocera Mita 6230

| Код ошибки | Описание |

|---|---|

| 0010 | Memory PCB communication problem |

| 0100 | RAM/ROM problem |

| 0260 | Memory copy PCB 1 communication problem |

| 0350 | Mailbox communication problem |

| 0370 | Communication microcomputer problem |

| 0380 | Hard disk problem |

| 0390 | DIMM problem |

| 1040 | Optical system problem (AGC) |

| 2100 | Drive motor problem / Paper conveying motor problem |

| 2200 | Paper feed motor problem |

| 2300 | Large paper deck right lift motor problem |

| 2310 | Large paper deck left lift motor problem |

| 2420 | Upper lift motor problem |

| 2430 | Lower lift motor problem |

| 6500 | Broken fixing unit thermistor wire |

| 7200 | Broken drum thermistor wire |

| 7210 | Shorted drum thermistor |

| 7220 | Broken drum heater wire |

KyoceraMita 6330/7530

| Код ошибки | Описание |

|---|---|

| 1060 | Large paper deck left lift motor problem |

| 2550 | Drive motor problem |

| 7520 | Shorted drum thermistor |

| 7530 | Broken drum thermistor wire |

Ошибки финишеров

| Код ошибки | Описание |

|---|---|

| 8010 | Finisher paper conveying motor problem |

| 8030 | Finisher (upper) paper conveying belt problem |

| 8140 | Finisher tray elevation motor problem /Main tray problem |

| 8170 | Finisher front side registration motor problem |

| 8180 | Finisher rear side registration motor problem |

| Finisher rear jogger motor problem (для 4230/5230) | |

| 8190 | Finisher trailing edge registration motor problem |

| 8210 | Finisher stapler motor problem |

| 8220 | Finisher rear stapler problem |

| 8300 | Document finisher centerfold unit communication problem |

| 8310 | Document finisher centerfold unit side registration guide problem |

| 8320 | Document finisher centerfold unit centering plate problem |

| 8330 | Document finisher centerfold blade problem |

Ошибки финишеров KM-2530/3530/3035/4035/5035

| Код ошибки | Описание |

|---|---|

| 8300 | Booklet stitcher paper ejection motor problem |

| 8310 | Booklet stitcher elevation motor problem |

| 8320 | Booklet stitcher rear jog motor problem |

| 8330 | Booklet stitcher front jog motor problem |

| 8340 | Booklet stitcher staple motor problem |

| 8350 | Booklet stitcher batch processing motor problem |

| 8360 | Booklet stitcher stapler shift motor problem |

| 8370 | Booklet stitcher paddle motor problem |

| 8380 | Booklet stitcher folding problem |

| 8390 | Booklet stitcher backup RAM data problem |

| 8400 | Booklet stitcher incorrect type problem |

| 8410 | Booklet stitcher punch motor problem |

| 8420 | Booklet stitcher shift motor problem |

| 8430 | Booklet stitcher punch communication problem |

| 8440 | Booklet stitcher punch sensor problem |

| 8450 | Booklet stitcher side punch sensor problem |

| 8460 | Booklet stitcher punch backup RAM data problem |

| 8470 | Booklet stitcher punch dust sensor problem |

| 8480 | Booklet stitcher broken punch power source wire problem |

| 8500 | Mailbox drive motor problem |

Ошибки финишера KM-6230

| Код ошибки | Описание |

|---|---|

| 8180 | Finisher rear jogger motor problem |

| 8310 | Booklet stitcher paper ejection motor problem |

| 8320 | Booklet stitcher elevation motor problem |

| 8330 | Booklet stitcher jog motor problem |

| 8340 | Booklet stitcher staple motor problem |

| 8350 | Booklet stitcher stapler unit shift motor problem |

| 8360 | Booklet stitcher stack level detection sensor problem |

| 8370 | Booklet stitcher punch motor problem |

| 8380 | Booklet stitcher punch shift motor problem |

| 8390 | Booklet stitcher swing motor problem |

| 8400 | Booklet stitcher backup RAM data problem |

| 8410 | Booklet stitcher punch unit backup RAM data problem |

| 8420 | Booklet stitcher positioning plate motor problem |

| 8430 | Booklet stitcher folding motor problem |

| 8440 | Booklet stitcher guide motor problem |

| 8450 | Booklet stitcher jog motor problem |

| 8460 | Booklet stitcher rear staple motor problem |

| 8470 | Booklet stitcher front staple motor problem |

| 8480 | Booklet stitcher thrust motor problem |

| 8490 | Booklet stitcher communication error |

Ошибки финишеров KM-6330/7530/6030/8030

| Код ошибки | Описание |

|---|---|

| 8000 | Document finisher incorrect type problem (для 6330/7530) |

| 8020 | Finisher punch motor problem |

| 8040 | Finisher lower paper conveying belt problem |

| 8150 | Finisher multi job tray problem |

| 8170 | Front upper side-registration guide problem |

| 8180 | Finisher rear upper side-registration guide problem |

| 8190 | Finisher lower side-registration guide problem |

| 8220 | Finisher front clincher problem |

| 8230 | Finisher rear stapler problem |

| 8240 | Finisher rear clincher problem |

Tech Support 24/7

Ask a Tech Specialist Online

Connect with the Expert via email, text or phone. Include photos, documents, and more. Get step-by-step instructions from verified Tech Support Specialists.

On this page, you will find more information about the most common causes and most relevant solutions for the Printer error ‘C7400’. Do you need help straight away? Visit our support page.

Error information

What causes the C7400 error?

The Kyocera documentation indicates that error code ‘C7400’ is caused by the following problem: «Developing Unit Connection Insertion Problem Absence of the developing unit is detected».

Do you think there is another cause for this error? Let others know in the comments.

How to solve Kyocera Printer error C7400

We’ve created a list of solutions which you can follow if you want to solve this Printer problem yourself. Do you need more help? Visit our support page if you need professional support with Printer right away.

Tech Support 24/7

Ask a Tech Specialist Online

Connect with the Expert via email, text or phone. Include photos, documents, and more. Get step-by-step instructions from verified Tech Support Specialists.

Have you found a solution yourself, but it is not in the list? Share your solution in the comments below.

Need more help?

Do you need more help?

Tech experts are ready to answer your questions.

Ask a question

- Code: C0030

- Description: Fax control PWB system problem

Processing with the fax software was disabled due to a hardware or software problem. - Causes: Defective fax control PWB.

- Remedy: Replace the fax control PWB and verify the operation.

- Code: C0060

- Description: Main PWB type mismatch error

- Causes: Defective PWB.

- Remedy: Run maintenance item U935 to contact the Service Administrative Division.

- Code: C0070

- Description: Abnormal detection of fax control PWB incompatibility

In the initial communication with the fax control PWB, any normal communication command is not transmitted. - Causes: Defective fax software.

Defective fax control PWB. - Remedy: Defective fax software. Install the fax software.

Defective fax control PWB. Replace the fax control PWB and verify the operation.

- Code: C0100

- Description: Backup memory (EEPROM) device problem (Main PWB)

Reading from or writing to EEPROM cannot be performed. - Causes: Defective main PWB.

Device damage of EEPROM. - Remedy: Defective main PWB. Replace the main PWB and check for correct operation.

Device damage of EEPROM. Contact the Service Administrative Division.

- Code: C0120

- Description: MAC address data error

For data in which the MAC address is invalid. - Causes: Defective main PWB.

- Remedy: Replace the main PWB and check for correct operation.

- Code: C0150

- Description: Backup memory (EEPROM) device problem (Engine PWB)

Reading from or writing to EEPROM cannot be performed. - Causes: Defective engine PWB.

Device damage of EEPROM. - Remedy: Defective engine PWB. Replace the engine PWB and check for correct operation.

Device damage of EEPROM. Contact the Service Administrative Division.

- Code: C0160

- Description: Backup memory (EEPROM) data problem (Engine PWB)

Reading data from EEPROM is abnormal. Read and write data does not match 5 times continuously. - Causes: Data damage of EEPROM.

- Remedy: Contact the Service Administrative Division.

- Code: C0170

- Description: Copy counts problem

A checksum error is detected in the main and engine backup memories for the copy counters. - Causes: Data damage of EEPROM.

Defective PWB. - Remedy: Data damage of EEPROM. Contact the Service Administrative Division.

Defective PWB. Replace the main PWB or engine PWB and check for correct operation.

- Code: C0180

- Description: Machine number mismatch error

Machine number of main PWB and engine PWB does not match. - Causes: Data damage of EEPROM.

- Remedy: Data damage of EEPROM. Contact the Service Administrative Division.

- Code: C0620

- Description: FAX image DIMM problem

DIMM is not installed correctly. DIMM cannot be accessed. - Causes: DIMM installed incorrectly.

Defective main PWB. - Remedy: DIMM installed incorrectly. Check if the DIMM is inserted into the socket on the main PWB correctly.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: C0630

- Description: DMA problem

DMA transmission of image data does not complete within the specified period of time. - Causes: Poor contact in the connector terminals.

Defective main PWB. - Remedy: Poor contact in the connector terminals. Check the connection the signal cable for CIS and the main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: C0640

- Description: Hard disk drive problem

The hard disk cannot be accessed. - Causes: Poor contact in the connector terminals.

Defective hard disk.

Defective main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC49 on the main PWB and the connector on the hard disk. Repair or replace if necessary.

Defective hard disk. Run U024 (HDD formatting) without turning the power off to initialize the hard disk. Replace the hard disk drive and check for correct operation if the problem is still detected after initialization.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: C0650

- Description: FAX image DIMM check problem

Improper DIMM is installed. - Causes: DIMM installed incorrectly.

DIMM of another machine is installed.

Defective main PWB. - Remedy: DIMM installed incorrectly. Check if the DIMM is inserted into the socket on the main PWB correctly.

DIMM of another machine is installed. Perform maintenance mode U671 (RECOVERY FAX DIMM).

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: C0800

- Description: Image processing problem

JAM05 is detected twice. - Causes: Defective main PWB.

- Remedy: Defective main PWB. Replace the main PWB and check for correct operation.

- Code: C0830

- Description: Fax control PWB flash program area checksum error

A checksum error occurred with the program of the fax control PWB. - Causes: Defective fax software.

Defective fax control PWB. - Remedy: Defective fax software. Install the fax software.

Defective fax control PWB. Replace the fax control PWB and verify the operation.

- Code: C0840

- Description: Faults of RTC

The time is judged to go back based on the comparison of the RTC time and the current time or five years or more have passed. - Causes: Defective main PWB.

The battery is disconnected from the main PWB. - Remedy: Defective main PWB. Replace the main PWB and check for correct operation.

The battery is disconnected from the main PWB. Check visually and remedy if necessary.

- Code: C0870

- Description: Fax control PWB to main PWB high capacity data transfer problem

High-capacity data transfer between the fax control PWB and the scanner MIP PWB was not normally performed even if the data transfer was retried 10 times. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the interface PWB and the connector on the fax control PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the fax control PWB or main PWB and check for correct operation.

- Code: C0920

- Description: Fax file system error

The backup data is not retained for file system abnormality of flash memory of the fax control PWB. - Causes: Defective fax control PWB.

- Remedy: Defective fax control PWB. Replace the fax control PWB and verify the operation.

- Code: C1010

- Description: Lift motor 1 error

After cassette 1 is inserted, lift switch 1 does not turn on within 12 s. This error is detected four times successively. - Causes: Poor contact in the connector terminals.

Broken gears or couplings of lift motor 1.

Defective lift motor 1.

Poor contact in the connector terminals.

Defective lift switch 1.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector of lift motor 1 and the connector YC8 on the engine PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Broken gears or couplings of lift motor 1. Replace lift motor 1.

Defective lift motor 1. Check for continuity across the coil. If none, replace lift motor 1.

Poor contact in the connector terminals. Check the connection of connector of lift switch 1 and the connector YC8 on the engine PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective lift switch 1. Check if YC8-B9 on the engine PWB goes low when lift switch 1 is turned off. If not, replace lift switch 1.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C1020

- Description: Lift motor 2 error

After cassette 2 is inserted, lift switch 2 does not turn on within 12 s. This error is detected four times successively. - Causes: Poor contact in the connector terminals.

Broken gears or couplings of lift motor 2.

Defective lift motor 2.

Poor contact in the connector terminals.

Defective lift switch 2.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector of lift motor 2 and the connector YC8 on the engine PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Broken gears or couplings of lift motor 2. Replace lift motor 2.

Defective lift motor 2. Check for continuity across the coil. If none, replace lift motor 2.

Poor contact in the connector terminals. Check the connection of connector of lift switch 2 and the connector YC8 on the engine PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective lift switch 2. Check if YC8-B15 on the engine PWB goes low when lift switch 2 is turned off. If not, replace lift switch 2.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C1030

- Description: PF lift motor 1 error (optional paper feeder)

After cassette 3 is inserted, PF lift switch 1 does not turn on within 12 s. This error is detected four times successively. - Causes: Poor contact in the connector terminals.

Broken gears or couplings of PF lift motor 1.

Defective PF lift motor 1.

Defective PF lift switch 1. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Broken gears or couplings of PF lift motor 1. Replace PF lift motor 1.

Defective PF lift motor 1. Check for continuity across the coil. If none, replace PF lift motor 1.

Defective PF lift switch 1. Check if YC1-7 on the PF main PWB goes low when PF lift switch 1 is turned off. If not, replace PF lift switch 1.

- Code: C1040

- Description: PF lift motor 2 error (optional paper feeder)

After cassette 4 is inserted, PF lift switch 2 does not turn on within 12 s. This error is detected four times successively. - Causes: Poor contact in the connector terminals

Broken gears or couplings of PF lift motor 2.

Defective PF lift motor 2.

Defective PF lift switch 2. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Broken gears or couplings of PF lift motor 2. Replace PF lift motor 2.

Defective PF lift motor 2. Check for continuity across the coil. If none, replace PF lift motor 2.

Defective PF lift switch 2. Check if YC1-9 on the PF main PWB goes low when PF lift switch 2 is turned off. If not, replace PF lift switch 2.

- Code: C1100

- Description: PF lift motor 1 error (optional 3000sheet paper feeder)

A motor over-current signal is detected continuously for 1 s or longer. - Causes: Poor contact in the connector terminals.

PF lift motor 1 does not rotate correctly (the motor is overloaded). - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

PF lift motor 1 does not rotate correctly (the motor is overloaded). Check the gears and remedy if necessary.

- Code: C1110

- Description: PF lift motor 2 error (optional 3000sheet paper feeder)

A motor over-current signal is detected continuously for 1 s or longer. - Causes: Poor contact in the connector terminals.

PF lift motor 2 does not rotate correctly (the motor is overloaded). - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

PF lift motor 2 does not rotate correctly (the motor is overloaded). Check the gears and remedy if necessary.

- Code: C1120

- Description: PF left lift position problem (optional 3000-sheet paper feeder)

Level switch 1 does not turn on within 30 s of PF lift motor 1 turning on. - Causes: Poor contact in the connector terminals.

Defective level switch 1.

Defective PF lift motor 1.

The PF left lift does not rise properly. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective level switch 1. Check if YC5-4 on the PF main PWB goes low when level switch 1 is turned off. If not, replace level switch 1.

Defective PF lift motor 1. Check for continuity across the coil. If none, replace PF lift motor 1.

The PF left lift does not rise properly. Check the gears and belts, and remedy if necessary.

- Code: C1130

- Description: PF right lift position problem (optional 3000-sheet paper feeder)

Level switch 2 does not turn on within 30 s of PF lift motor 2 turning on. - Causes: Poor contact in the connector terminals.

Defective level switch 2.

Defective PF lift motor 2.

The PF right lift does not rise properly. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective level switch 2. Check if YC5-7 on the PF main PWB goes low when level switch 2 is turned off. If not, replace level switch 2.

Defective PF lift motor 2. Check for continuity across the coil. If none, replace PF lift motor 2.

The PF right lift does not rise properly. Check the gears and belts, and remedy if necessary.

- Code: C1800

- Description: Paper feeder communication error (optional paper feeder)

A communication error from paper feeder is detected 10 times in succession. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the PF main PWB or engine PWB and check for correct operation.

- Code: C1900

- Description: Paper feeder EEPROM error (optional paper feeder)

When writing the data, the write data and the read data is not continuously in agreement three times. - Causes: Poor contact in the connector terminals.

Defective engine PWB.

Defective paper feeder. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective engine PWB. Replace the engine PWB and check for correct operation.

Defective paper feeder. Replace the paper feeder with another unit and check the operation. If the operation is normal, replace or repair optional paper feeder.

- Code: C2000

- Description: Drive motor problem

Stable OFF is detected for 1 s continuously after drive motor stability. The drive motor is not stabilized in 6 s since the motor is activated. - Causes: Poor contact in the connector terminals.

Defective drive transmission system.

Defective drive motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC11 on the engine PWB and the connector on the drive motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective drive transmission system. Check if the rollers and gears rotate smoothly. If not, grease the bushings and gears. Check for broken gears and replace if any.

Defective drive motor. Replace the drive motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C2250

- Description: Main charger cleaning motor error

A locking error has been detected three times in a row during a reciprocating cleaning motion. - Causes: Poor contact in the connector terminals.

Defective drive transmission system.

Defective main charger cleaning motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 on the engine PWB and the connector on the main charger cleaning motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective drive transmission system. Check if the rollers and gears rotate smoothly. If not, grease the bushings and gears. Check for broken gears and replace if any.

Defective main charger cleaning motor. Replace the main charger cleaning motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C2500

- Description: Paper feed motor error

Stable OFF is detected for 1 s continuously after paper feed motor stability. The paper feed motor is not stabilized in 6 s since the motor is activated. - Causes: Poor contact in the connector terminals.

Defective drive transmission system.

Defective paper feed motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC11 on the engine PWB and the connector on the paper feed motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective drive transmission system. Check if the rollers and gears rotate smoothly. If not, grease the bushings and gears. Check for broken gears and replace if any.

Defective paper feed motor. Replace the paper feed motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C2600

- Description: PF paper conveying/drive motor error (optional 3000-sheet paper feeder/ paper feeder)

The lock signal of the motor is detected above 450 ms. - Causes: Poor contact in the connector terminals.

Defective drive transmission system.

Defective PF paper conveying/drive motor.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective drive transmission system. Check if the rollers and gears rotate smoothly. If not, grease the bushings and gears. Check for broken gears and replace if any.

Defective PF paper conveying/drive motor. Replace the PF paper conveying/drive motor.

Defective PWB. Replace the PF main PWB or engine PWB and check for correct operation.

- Code: C3100

- Description: Scanner carriage problem

The home position is not correct when the power is turned on or at the start of copying using the table. - Causes: Poor contact in the connector terminals.

Defective home position switch.

Defective scanner motor.

The mirror frame, exposure lamp, or scanner wire is defective.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC8 on the ISM PWB and the connector of the home position switch, and the connection of connector YC7 on the ISM PWB and the connector on the scanner motor and the continuity across the connector terminals. Repair or replace if necessary.

Defective home position switch. Replace the scanner home position switch.

Defective scanner motor. Replace the scanner motor.

The mirror frame, exposure lamp, or scanner wire is defective. Check if the mirror flames and exposure lamp are on the rail. And check the scanner wire winds correctly.

Defective PWB. Replace the ISM PWB or ISC PWB and check for correct operation.

- Code: C3200

- Description: Exposure lamp problem

When input value at the time of exposure lamp illumination does not exceed the threshold value between 5 s. - Causes: Poor contact in the connector terminals.

Defective exposure lamp.

Incorrect shading position.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 on the ISM PWB and the connector on the inverter PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective exposure lamp or inverter PWB. Replace the exposure lamp or inverter PWB.

Incorrect shading position. Adjust the position of the contact glass (shading plate). If the problem still occurs, replace the scanner home position switch.

Defective PWB. Replace the ISM PWB, ISC PWB or CCD PWB and check for correct operation.

- Code: C3210

- Description: CIS lamp problem

When input value at the time of CIS illumination does not exceed the threshold value between 5 s. - Causes: Poor contact in the connector terminals.

Defective DP driver PWB.

Defective DP inverter PWB.

Defective CIS. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the ISM PWB and the connector on the DP driver PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective DP driver PWB. Replace the DP driver PWB and check for correct operation.

Defective DP inverter PWB. Replace the DP inverter PWB and check for correct operation.

Defective CIS. Replace the CIS and check for correct operation.

- Code: C3300

- Description: Optical system (AGC) problem

After AGC, correct input is not obtained at CCD. - Causes: Poor contact in the connector terminals.

Defective exposure lamp or inverter PWB.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 on the ISM PWB and the connector on the inverter PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective exposure lamp or inverter PWB. Replace the exposure lamp or inverter PWB.

Defective PWB. Replace the ISM PWB, ISC PWB or CCD PWB and check for correct operation.

- Code: C3310

- Description: CIS AGC problem

After AGC, correct input is not obtained at CIS. - Causes: Defective DP driver PWB.

CIS output problem.

Defective DP inverter PWB. - Remedy: Defective DP driver PWB. Replace the DP driver PWB and check for correct operation.

CIS output problem. Replace the CIS and check for correct operation.

Defective DP inverter PWB. Replace the DP inverter PWB and check for correct operation.

- Code: C3500

- Description: Communication error between scanner and SHD

An error code is detected. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC2 on the CCD PWB and the connector YC2 on the ISC PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the CCD PWB or ISC PWB and check for correct operation.

- Code: C3900

- Description: Backup memory read/write problem (ISC PWB)

Read and write data does not match. - Causes: Defective backup RAM or PWB.

- Remedy: Replace the ISC PWB or ISM PWB and check for correct operation.

- Code: C3910

- Description: Backup memory data problem (ISC PWB)

Data in the specified area of the backup memory does not match the specified values. - Causes: Defective backup RAM or PWB.

- Remedy: Replace the ISC PWB or ISM PWB and check for correct operation.

- Code: C4000

- Description: Polygon motor synchronization problem

The polygon motor does not reach the stable speed within 20 s of the START signal turning on. - Causes: Poor contact in the connector terminals.

Defective polygon motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC3 on the engine PWB and laser scanner unit, and the continuity across the connector terminals. Repair or replace if necessary.

Defective polygon motor. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C4010

- Description: Polygon motor steady-state problem

Stable OFF is detected for 20 s continuously after polygon motor stability. - Causes: Poor contact in the connector terminals.

Defective polygon motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC3 on the engine PWB and laser scanner unit, and the continuity across the connector terminals. Repair or replace if necessary.

Defective polygon motor. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C4100

- Description: BD initialization problem

5 consecutive BD errors were detected during an 800 ms interval after the polygon motor stabilized. - Causes: Poor contact in the connector terminals.

Defective polygon motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC3 on the engine PWB and laser scanner unit, and the continuity across the connector terminals. Repair or replace if necessary.

Defective polygon motor. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C6000

- Description: Fuser heater break

Fuser thermistor 1 detected less than 70°C/158°F for 10 s during warm-up and ready in. During warm-up, the temperature at the fuser unit thermistor 1 does not rise by 1°C/1.8°F continuously for 5 s. Fuser thermistor 2 detected less than 40°C/104°F for 10 s during warm-up and ready in. During warm-up, the temperature at the fuser unit thermistor 2 does not rise by 1°C/1.8°F continuously for 5 s. - Causes: Defective fuser heater 1 or 2.

Installation defectiveness on fuser thermistor 1.

Defective fuser thermostat.

Defective PWB. - Remedy: Defective fuser heater 1 or 2. Replace the fuser heater 1 or 2.

Installation defectiveness on fuser thermistor 1. Check the mounting state of the fuser thermistor 1. If any problem is found, repair it.

Defective fuser thermostat. Replace the fuser thermostat.

Defective PWB. Replace the power source PWB or engine PWB and check for correct operation.

- Code: C6020

- Description: Abnormally high fuser thermistor temperature

Fuser thermistor 1 or 2 is detected 250°C/482°F or more for 40 ms. - Causes: Installation defectiveness on fuser thermistor 1 or 2.

Defective fuser thermistor unit 1 or 2.

Defective engine PWB. - Remedy: Installation defectiveness on fuser thermistor 1 or 2. Check the mounting state of the fuser thermistor 1 or 2. If any problem is found, repair it.

Defective fuser thermistor unit 1 or 2. Replace the fuser thermistor 1 or 2.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C6030

- Description: Fuser thermistor break error

The fuser thermistor break signal is detected continuously for 1 s. - Causes: Installation defectiveness on fuser thermistor 1 or 2.

Defective fuser thermistor 1 or 2.

Defective engine PWB. - Remedy: Installation defectiveness on fuser thermistor 1 or 2. Check the mounting state of the fuser thermistor 1 or 2. If any problem is found, repair it.

Defective fuser thermistor 1 or 2. Replace the fuser thermistor 1 or 2.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C6040

- Description: Fuser thermistor 1 detection error

Fuser thermistor 1 detected an abnormal value for at least 1 s. - Causes: Installation defectiveness on fuser thermistor 1.

Defective fuser thermistor 1.

Defective engine PWB. - Remedy: Installation defectiveness on fuser thermistor 1. Check the mounting state of the fuser thermistor 1. If any problem is found, repair it.

Defective fuser thermistor 1. Replace the fuser thermistor 1.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C6050

- Description: Abnormally low fuser thermistor temperature

Fuser thermistor 1 is detected 80°C/ 176°F less than 1 s continuously during copying. - Causes: Defective fuser heater 1 or 2.

Installation defectiveness on fuser thermistor 1.

Defective PWB. - Remedy: Defective fuser heater 1 or 2. Replace the fuser heater 1 or 2.

Installation defectiveness on fuser thermistor 1. Check the mounting state of the fuser thermistor 1. If any problem is found, repair it.

Defective PWB. Replace the power source PWB or engine PWB and check for correct operation.

- Code: C6400

- Description: Zero-cross signal error

While fuser heater ON/OFF control is performed, the zero-cross signal is not input within 3 s. - Causes: Defective PWB

- Remedy: Replace the power source PWB or engine PWB and check for correct operation.

- Code: C6410

- Description: Fuser unit connector insertion problem

Absence of the fuser unit is detected. - Causes: Fuser unit connector inserted incorrectly.

Defective fuser unit connector. - Remedy: Fuser unit connector inserted incorrectly. Reinsert the fuser unit connector if necessary.

Defective fuser unit connector. Replace the fuser unit.

- Code: C7300

- Description: Toner container problem

Toner level is not detected when toner empty is detected. - Causes: Poor contact in the connector terminals.

Defective toner container sensor. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 on the engine PWB and the continuity across the connector terminals. Repair or replace if necessary.

Defective toner container sensor. Replace the toner container sensor.

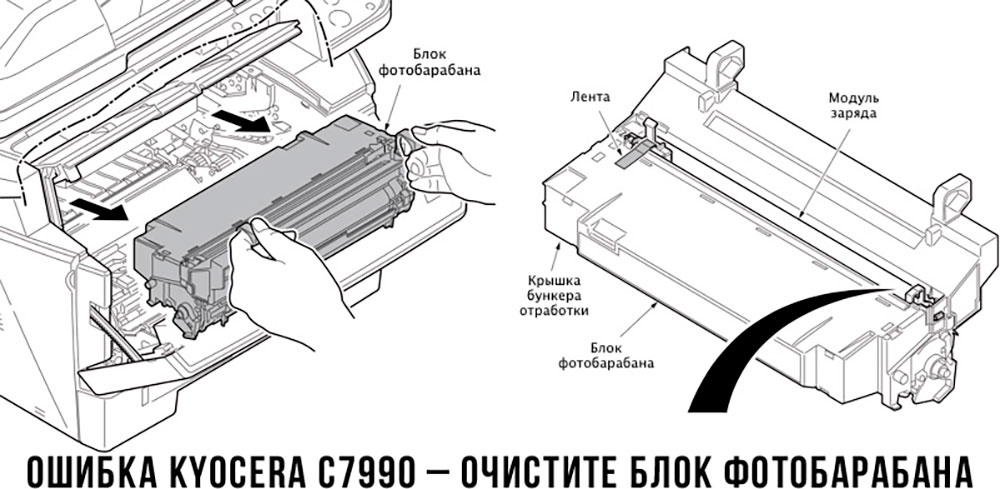

- Code: C7400

- Description: Developing unit connector insertion problem Absence of the developing unit is detected.

- Causes: Developing unit connector inserted incorrectly.

Defective developing unit connector. - Remedy: Developing unit connector inserted incorrectly. Reinsert the developing unit connector if necessary.

Defective developing unit connector. Replace the developing unit.

- Code: C7410

- Description: Drum unit connector insertion problem

Absence of the drum unit is detected. - Causes: Drum unit connector inserted incorrectly.

Defective drum unit connector. - Remedy: Drum unit connector inserted incorrectly. Reinsert the drum unit connector if necessary.

Defective drum unit connector. Replace the drum unit.

- Code: C7800

- Description: Broken external thermistor wire

The thermistor output value is 4.5 V or more. - Causes: Poor contact in the connector terminals.

Defective humidity sensor. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC10 on the engine PWB and the continuity across the connector terminals. Repair or replace if necessary.

Defective humidity sensor. Replace the humidity sensor.

- Code: C7900

- Description: Drum EEPROM error

Reading from or writing to EEPROM cannot be performed. - Causes: Poor contact in the connector terminals.

Defective drum unit. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the engine PWB and the continuity across the connector terminals. Repair or replace if necessary.

Defective drum unit. Replace the drum unit.

- Code: C7910

- Description: Developing unit EEPROM error

Reading from or writing to EEPROM cannot be performed. - Causes: Poor contact in the connector terminals.

Defective developing unit. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the engine PWB and the continuity across the connector terminals. Repair or replace if necessary.

Defective developing unit. Replace the developing unit.

- Code: C8020

- Description: Punch motor problem (optional 3000sheet document finisher)

The error signal of the punch motor is detected for more than 500 ms while the punch motor is operating. - Causes: Poor contact in the connector terminals.

Defective punch motor.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the punch PWB and the continuity across the connector terminals. Repair or replace if necessary.

Defective punch motor. Replace the punch motor.

Defective PWB. Replace the punch PWB or finisher main PWB and check for correct operation.

- Code: C8030

- Description: Tray upper limit detection problem (optional document finisher)

When the tray elevation motor raises a tray, the ON status of the tray upper limit sensor is detected. - Causes: The tray upper limit sensor, paper surface sensor 1/2 connector makes poor contact.

Defective tray upper limit sensor, paper surface sensor 1/2.

Defective finisher main PWB. - Remedy: The tray upper limit sensor, paper surface sensor 1/2 connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective tray upper limit sensor, paper surface sensor 1/2. Replace the sensor.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8040

- Description: Belt problem (optional document finisher)

The belt sensor does not turn on/off within specified time of the belt solenoid turning on. - Causes: The belt sensor, belt solenoid connector makes poor contact.

Defective belt sensor.

Defective belt solenoid.

Defective finisher main PWB. - Remedy: The belt sensor, belt solenoid connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective belt sensor. Replace the belt sensor.

Defective belt solenoid. Replace the belt solenoid.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8050

- Description: Paper conveying belt motor 1 problem (optional 3000-sheet document finisher)

Paper conveying belt home position sensor 1 does not turn off within 1.5 s. Paper conveying belt home position sensor 1 does not turn on within 2.5 s. Jam 88 is indicated. - Causes: Poor contact in the connector terminals.

Defective paper conveying belt home position sensor 1.

Defective paper conveying belt motor 1.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC2 on the inner tray PWB and the connector on paper conveying belt motor 1, and the continuity across the connector terminals. Repair or replace if necessary.

Defective paper conveying belt home position sensor 1. Replace paper conveying belt home position sensor 1.

Defective paper conveying belt motor 1. Replace paper conveying belt motor 1.

Defective PWB. Replace the inner tray PWB or finisher main PWB and check for correct operation.

- Code: C8060

- Description: Paper conveying belt motor 2 problem (optional 3000-sheet document finisher)

Paper conveying belt home position sensor 2 does not turn off within 1.5 s. Paper conveying belt home position sensor 2 does not turn on within 1.5 s. - Causes: Poor contact in the connector terminals.

Defective paper conveying belt home position sensor 2.

Defective paper conveying belt motor 2.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC6 on the inner tray PWB and the connector on paper conveying belt motor 2, and the continuity across the connector terminals. Repair or replace if necessary.

Defective paper conveying belt home position sensor 2. Replace paper conveying belt home position sensor 2.

Defective paper conveying belt motor 2. Replace paper conveying belt motor 2.

Defective PWB. Replace the inner tray PWB or finisher main PWB and check for correct operation.

- Code: C8070

- Description: Inner tray communication error (optional 3000-sheet document finisher)

Communication with the inner tray is not possible although the connection is detected. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC6 and YC24 on the finisher main PWB and the connector YC1 and YC4 on the inner tray PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the inner tray PWB or finisher main PWB and check for correct operation.

- Code: C8140

- Description: Main tray problem (optional 3000sheet document finisher)

The main tray is not detected by the main tray upper limit detection sensor or the main tray paper upper surface detection sensor within 20 s since the tray has started ascending. The main tray upper limit detection sensor or the main tray paper upper surface detection

Tray elevation motor problem (optional document finisher) The tray low limit sensor or paper surface sensor 1/2 cannot be detected to be on within 10 s since the tray elevation motor is activated. - Causes: Poor contact in the connector terminals.

Defective main tray motor.

Defective main tray

Defective finisher main PWB.

The tray elevation motor connector makes poor contact.

The tray elevation motor malfunctions.

The tray lower limit sensor, paper surface sensor 1/2 connector makes poor contact.

Defective tray lower limit sensor, paper surface sensor 1/2.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC11 on the finisher main PWB and the connector on the main tray motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective main tray motor. Replace the main tray motor.

Defective main tray upper limit detection sensor/main tray paper upper surface detection sensor/main tray lower limit detection sensor. Replace the sensor.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

The tray elevation motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

The tray elevation motor malfunctions. Replace the tray elevation motor.

The tray lower limit sensor, paper surface sensor 1/2 connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective tray lower limit sensor, paper surface sensor 1/2. Replace the sensor.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8170

- Description: Side registration motor 1 problem (optional 3000-sheet document finisher)

When operation returned to a home position is performed at the time of initial operation and a home position is not detected even if 3 s passed. Jam 88 is indicated.

Finisher front side registration motor problem (optional built-in finisher) When the front-side registration home-position sensor is turned on during initialization, the sensor did not turn on while it has moved by 106 pulses. When the front-side registration home-position sensor is turned off during initialization, the sensor did not turn on in 3 s. - Causes: Poor contact in the connector terminals.

Defective side registration motor 1.

Defective PWB.

The front side registration motor connector makes poor contact.

Defective front side registration motor.

The front side registration home position sensor connector makes poor contact.

Defective front side registration home position sensor.

Defective finisher control PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC2 on the inner tray PWB and the connector on side registration motor 1, and the continuity across the connector terminals. Repair or replace if necessary.

Defective side registration motor 1. Replace side registration motor 1.

Defective PWB. Replace the inner tray PWB or finisher main PWB and check for correct operation.

The front side registration motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective front side registration motor. Replace front side registration motor.

The front side registration home position sensor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective front side registration home position sensor. Replace the front side registration home position sensor.

Defective finisher control PWB. Replace the finisher control PWB and check for correct operation.

- Code: C8180

- Description: Side registration motor 2 problem (optional 3000-sheet document finisher)

When operation returned to a home position is performed at the time of initial operation and a home position is not detected even if 3 s passed. Jam 88 is indicated.

Finisher rear side registration motor problem (optional built-in finisher) When the rear-side registration home-position sensor is turned on during initialization, the sensor did not turn on while it has moved by 106 pulses. When the rear-side registration home-position sensor is turned off during initialization, the sensor did not turn on in 3 s. - Causes: Poor contact in the connector terminals.

Defective side registration motor 2.

Defective PWB.

The rear side registration motor connector makes poor contact.

Defective rear side registration motor.

The rear side registration home position sensor connector makes poor contact.

Defective rear side registration home position sensor.

Defective finisher control PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC8 on the inner tray PWB and the connector of side registration motor 2, and the continuity across the connector terminals. Repair or replace if necessary.

Defective side registration motor 2. Replace side registration motor 2.

Defective PWB. Replace the inner tray PWB or finisher main PWB and check for correct operation.

The rear side registration motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective rear side registration motor. Replace rear side registration motor.

The rear side registration home position sensor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective rear side registration home position sensor. Replace the rear side registration home position sensor.

Defective finisher control PWB. Replace the finisher control PWB and check for correct operation.

- Code: C8190

- Description: Finisher trailing edge registration motor problem (optional built-in finisher)

When the trailing edge registration home-position sensor is turned on during initialization, the sensor did not turn on while it has moved by 106 pulses. When the trailing edge registration home-position sensor is turned off during initialization, the sensor did not turn on in 3 s. - Causes: The trailing edge registration motor connector makes poor contact.

Defective trailing edge registration motor.

The trailing edge registration home position sensor connector makes poor contact.

Defective trailing edge registration home position sensor.

Defective finisher control PWB. - Remedy: The trailing edge registration motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective trailing edge registration motor. Replace trailing edge registration motor.

The trailing edge registration home position sensor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective trailing edge registration home position sensor. Replace the trailing edge registration home position sensor.

Defective finisher control PWB. Replace the finisher control PWB and check for correct operation.

- Code: C8210

- Description: Stapler moving motor 1 error (optional 3000-sheet document finisher)

When operation returned to a home position is performed at the time of initial operation and a home position is not detected even if 1.5 s passed.

Stapler problem (optional document finisher) Jam 82 is indicated.

Finisher stapler problem (optional built-in finisher) The stapler home position sensor does not change state from nondetection to detection within 200 ms of the start of stapler motor counterclockwise (forward) rotation. During initialization, the stapler home position sensor does not change state from non-detection to detection within 600 ms of the start of stapler motor clockwise (reverse) rotation. - Causes: Poor contact in the connector terminals.

Defective stapler moving motor 1.

Defective finisher main PWB.

The stapler connector makes poor contact.

The stapler is blocked with a staple.

The stapler is broken.

Defective finisher main PWB.

The stapler connector makes poor contact.

The stapler is blocked with a staple.

The stapler is broken.

Defective finisher control PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC9 on the finisher main PWB and the connector of stapler moving motor 1, and the continuity across the connector terminals. Repair or replace if necessary.

Defective stapler moving motor 1. Replace stapler moving motor 1.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

The stapler connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

The stapler is blocked with a staple. Remove the stapler cartridge, and check the cartridge and the stapling section of the stapler.

The stapler is broken. Replace the stapler and check for correct operation.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

The stapler connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

The stapler is blocked with a staple. Remove the stapler cartridge, and check the cartridge and the stapling section of the stapler.

The stapler is broken. Replace the front stapler and check for correct operation.

Defective finisher control PWB. Replace the finisher control PWB and check for correct operation.

- Code: C8220

- Description: Stapler moving motor 2 error (optional 3000-sheet document finisher)

When operation returned to a home position is performed at the time of initial operation and a home position is not detected even if 3.5 s passed. - Causes: Poor contact in the connector terminals.

Defective stapler moving motor 2.

Defective staple relay PWB.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC10 on the finisher main PWB and the connector of staple relay PWB and stapler moving motor 2, and the continuity across the connector terminals. Repair or replace if necessary.

Defective stapler moving motor 2. Replace stapler moving motor 2.

Defective staple relay PWB. Replace the staple relay PWB and check for correct operation.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8230

- Description: Stapler motor problem (optional 3000sheet document finisher)

Jam 82 is indicated. - Causes: Poor contact in the connector terminals.

Defective stapler motor.

Defective staple relay PWB.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC10 on the finisher main PWB and the connector of staple relay PWB and stapler motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective stapler motor. Replace the stapler motor.

Defective staple relay PWB. Replace the staple relay PWB and check for correct operation.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8300

- Description: Center-folding unit communication error (optional center-folding unit of 3000-sheet document finisher)

Communication with the center-folding unit is not possible although the connection is detected. - Causes: Poor contact in the connector terminals.

Defective centerfold set switch.

Defective centerfold main PWB.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 and YC20 on the finisher main PWB and the connector YC1 and YC2 on the centerfold main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold set switch. Replace the centerfold set switch.

Defective centerfold main PWB. Replace the centerfold main PWB and check for correct operation.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8310

- Description: Centerfold side registration motor 2 problem (optional center-folding unit of 3000-sheet document finisher)

The home position is not detected when initial operation even if 1 s passed. - Causes: Poor contact in the connector terminals.

Defective centerfold side registration motor 2.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC6 on the centerfold main PWB and the connector of centerfold side registration motor 2, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold side registration motor 2. Replace centerfold side registration motor 2.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

- Code: C8320

- Description: Centerfold paper conveying belt motor problem (optional center-folding unit of 3000-sheet document finisher)

The home position is not detected when initial operation even if 2.5 s passed.

Adjustment motor 2 problem (optional document finisher) The adjustment sensor 2 does not turn on/off within specified time of the adjustment motor 2 turning on. - Causes: Poor contact in the connector terminals.

Defective centerfold paper conveying belt motor 1/2.

Defective PWB.

The adjustment sensor 2, adjustment motor 2 connector makes poor contact.

Defective adjustment sensor 2.

Defective adjustment motor 2.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC6, YC7 on the centerfold main PWB and the connector of centerfold paper conveying belt motor 1/2, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold paper conveying belt motor 1/2. Replace centerfold paper conveying belt motor 1/2.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

The adjustment sensor 2, adjustment motor 2 connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective adjustment sensor 2. Replace the adjustment sensor 2.

Defective adjustment motor 2. Replace the adjustment motor 2.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8330

- Description: Blade motor problem (optional center-folding unit of 3000-sheet document finisher)

The home position is not detected when initial operation even if 1.5 s passed.

Adjustment motor 1 problem (optional document finisher) The adjustment sensor 1 does not turn on/off within specified time of the adjustment motor 1 turning on. - Causes: Poor contact in the connector terminals.

Defective blade motor.

Defective PWB.

The adjustment sensor 1, adjustment motor 1 connector makes poor contact.

Defective adjustment sensor 1.

Defective adjustment motor 1.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC8 on the centerfold main PWB and the connector of the blade motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective blade motor. Replace the blade motor.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

The adjustment sensor 1, adjustment motor 1 connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective adjustment sensor 1. Replace the adjustment sensor 1.

Defective adjustment motor 1. Replace the adjustment motor 1.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8340

- Description: Centerfold staple motor problem (optional center-folding unit of 3000sheet document finisher)

Jam 89 is indicated. - Causes: Poor contact in the connector terminals.

Defective centerfold staple motor.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC9 on the centerfold main PWB and the connector of the centerfold staple motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold staple motor. Replace the centerfold staple motor.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

- Code: C8350

- Description: Centerfold side registration motor 1 problem (optional center-folding unit of 3000-sheet document finisher)

The home position is not detected when initial operation even if 1 s passed.

Roller motor problem (optional document finisher) The roller sensor does not turn on/off within specified time of the roller motor turning on. - Causes: Poor contact in the connector terminals.

Defective centerfold side registration motor 1.

Defective PWB.

The roller sensor, roller motor connector makes poor contact.

Defective roller sensor.

Defective roller motor.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC7 on the centerfold main PWB and the connector of centerfold side registration motor 1, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold side registration motor 1. Replace centerfold side registration motor 1.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

The roller sensor, roller motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective roller sensor. Replace the roller sensor.

Defective roller motor. Replace the roller motor.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8360

- Description: Centerfold main motor problem (optional center-folding unit of 3000sheet document finisher)

The motor lock signal is detected above 1 s during driving the centerfold main motor.

Slide motor problem (optional document finisher) The slide sensor does not turn on/off within specified time of the slide motor turning on. - Causes: Poor contact in the connector terminals.

Defective centerfold main motor.

Defective PWB.

The slide sensor, slide motor connector makes poor contact.

Defective slide sensor.

Defective slide motor.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC12 on the centerfold main PWB and the connector of the centerfold main motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold main motor. Replace the centerfold main motor.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

The slide sensor, slide motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective slide sensor. Replace the slide sensor.

Defective slide motor. Replace the slide motor.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8440

- Description: Sensor adjusting problem (optional document finisher)

The sensor cannot be adjusted within the specified range. - Causes: The paper entry sensor connector makes poor contact.

Defective paper entry sensor.

The optical path of the paper entry sensor is blocked by foreign matter.

Defective finisher main PWB. - Remedy: The paper entry sensor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective paper entry sensor. Replace the paper entry sensor and check for correct operation.

The optical path of the paper entry sensor is blocked by foreign matter. Remove the foreign matter.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8460

- Description: EEPROM problem (optional document finisher)

Reading from or writing to EEPROM cannot be performed. - Causes: Defective EEPROM or finisher main PWB.

- Remedy: Replace the finisher main PWB and check for correct operation.

- Code: C8500

- Description: Mailbox communication error (optional mailbox of 3000-sheet document finisher)

Communication with the mailbox is not possible although the connection is detected. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of the connector of the mailbox and the connector YC7 on the finisher main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the mailbox main PWB or finisher main PWB and check for correct operation.

- Code: C8510

- Description: Mailbox drive motor problem (optional mailbox of 3000-sheet document finisher)

The motor lock signal is detected above 500 ms during driving the mailbox drive motor. - Causes: Poor contact in the connector terminals.

Defective mailbox drive motor.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 on the mailbox main PWB and the connector of the mailbox drive motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective mailbox drive motor. Replace the mailbox drive motor.

Defective PWB. Replace the mailbox main PWB or finisher main PWB and check for correct operation.

- Code: C8800

- Description: Document finisher communication error (optional 3000-sheet document finisher)

A communication error from document finisher is detected 10 times in succession. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the engine PWB and the connector on the finisher main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the finisher main PWB or engine PWB and check for correct operation.

- Code: C8900

- Description: Finisher backup problem (optional 3000-sheet document finisher)

Read and write data does not match 3 times in succession. - Causes: Poor contact in the connector terminals.

EEPROM installed incorrectly.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the finisher main PWB and the connector of the machine, and the continuity across the connector terminals. Repair or replace if necessary.

EEPROM installed incorrectly. Install EEPROM correctly.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8910

- Description: Punch backup problem (optional of 3000-sheet document finisher)

Read and write data does not match 3 times in succession. - Causes: Poor contact in the connector terminals.

Defective punch PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the punch PWB and the connector YC4 on the finisher main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective punch PWB. Replace the punch PWB and check for correct operation.

- Code: C8920