3. SLMP

The following table lists error codes that are stored in the end code at abnormal completion in SLMP.

Error code

C059h

The sub command is specified incorrectly. Or, a command that is not prescribed is received.

C05Ch

The request message is incorrect.

C061h

The request data length does not correspond to the number of data points.

CCCAh

A non-existent Index is specified.

CCD0h

Number of data value differs from the prescribed value.

CCD1h

Number of data value is greater than the prescribed value.

CCD2h

Number of data value is smaller than the prescribed value.

CCD3h

A non-existent Sub Index is specified.

CCC8h

The Write only object is read.

CCC9h

(1) A value is written to the Read only object.

(2) A value is written to an object which is not the Read only object for all AL states but for the present AL state with

Write disabled.

CCC7h

(1) A value is written to the object mapped to a response message.

(2) The following writings are performed when the object mapped to a response message is not allowed to be

changed.

A value other than «0» is written to Sub Index0.

A value is written to the corresponding Sub Index 1 to 32.

CCCBh

The object that cannot be mapped to response message is written to the object mapped to a response message.

CCCCh

The total size of the object mapped to a response message exceeds 64 bytes.

CCD4h

A value outside the parameter range was written.

CCD5h

A value that is greater than the parameter range is written.

CCD6h

A value that is smaller than the parameter range is written.

CCDAh

A value is written to a parameter object outside the writing range set in the Parameter block setting.

Cause

3 — 8

|

|

Ремонт сервоусилителя Mitsubishi

Также для восстановления подобного промышленного оборудования понадобится хорошая материально-техническая база. При выполнении всех выше перечисленных условий, шансы на успешный ремонт сервоусилителя Mitsubishi возрастают в геометрической прогрессии.

Именно поэтому за ремонтом сервоусилителей, независимо от производителя лучше всего обращаться в специализированный сервисный центр, который отвечает всем техническим требованиям, такой как Кернел. Наш цент имеет отличную материально-техническую базу, а за время существования с 2002 года специалисты компании накопили бесценный опыт в том числе опыт в ремонте сервоусилителей Mitsubishi.

Особенности ремонта сервоусилителя Mitsubishi

- Аппаратная часть;

- Программная часть.

В первую очередь ремонтируется аппаратная часть промышленного сервоусилителя. После глубокой диагностики неисправного блока выявляются все неисправные компоненты, которые в последствии заменяются на оригинальные запасные части (по возможности), в случае если сервопривод уже давно снят с производства и найти оригинальные запчасти просто невозможно они заменяются на аналоги.

Данный вид ремонта называется компонентным. От других видов его отличает две немаловажные детали.

- Значительное удешевление ремонта;

- Существенное сокращение времени ремонта.

По завершении ремонта аппаратной части сервоусилителя наступает очередь программной. В зависимости от серии выбирается программный продукт и зашивается в блок.

Заключительный этап ремонта сервоусилителя Mitsubishi это проверка на специализированном стенде. Все блоки проверяются без нагрузки и с нагрузкой не менее двух часов.

Коды предупреждений и ошибок сервоусилителя Mitsubishi

При обнаружении неисправности при работе сервоусилителя будет активирована соответствующая защита и выведено предупреждающее сообщение на индикатор сервоусилителя или цифрового пульта.

Коды аварийной сигнализации выводятся при возникновении соответствующей сигнализации. При нормальной работе (отсутствие неполадок) через контакты CN1-10, CN1-11 и CN1-12 выводятся стандартные сигналы состояния (к примеру частота или направление вращения). При возникновении аварийной сигнализации, установите сигнал состояния «Серво выкл.» и прервите питание силового контура.

Коды неисправностей и предупреждений сервоусилителя Mitsubishi MR-E приведены в файле PDF который доступен по ссылке ниже. Дополнительно в файле указаны способы устранения неисправностей и их сброс.

Посмотреть все коды ошибок сервоусилителя Mitsubishi MR-E

Схемы

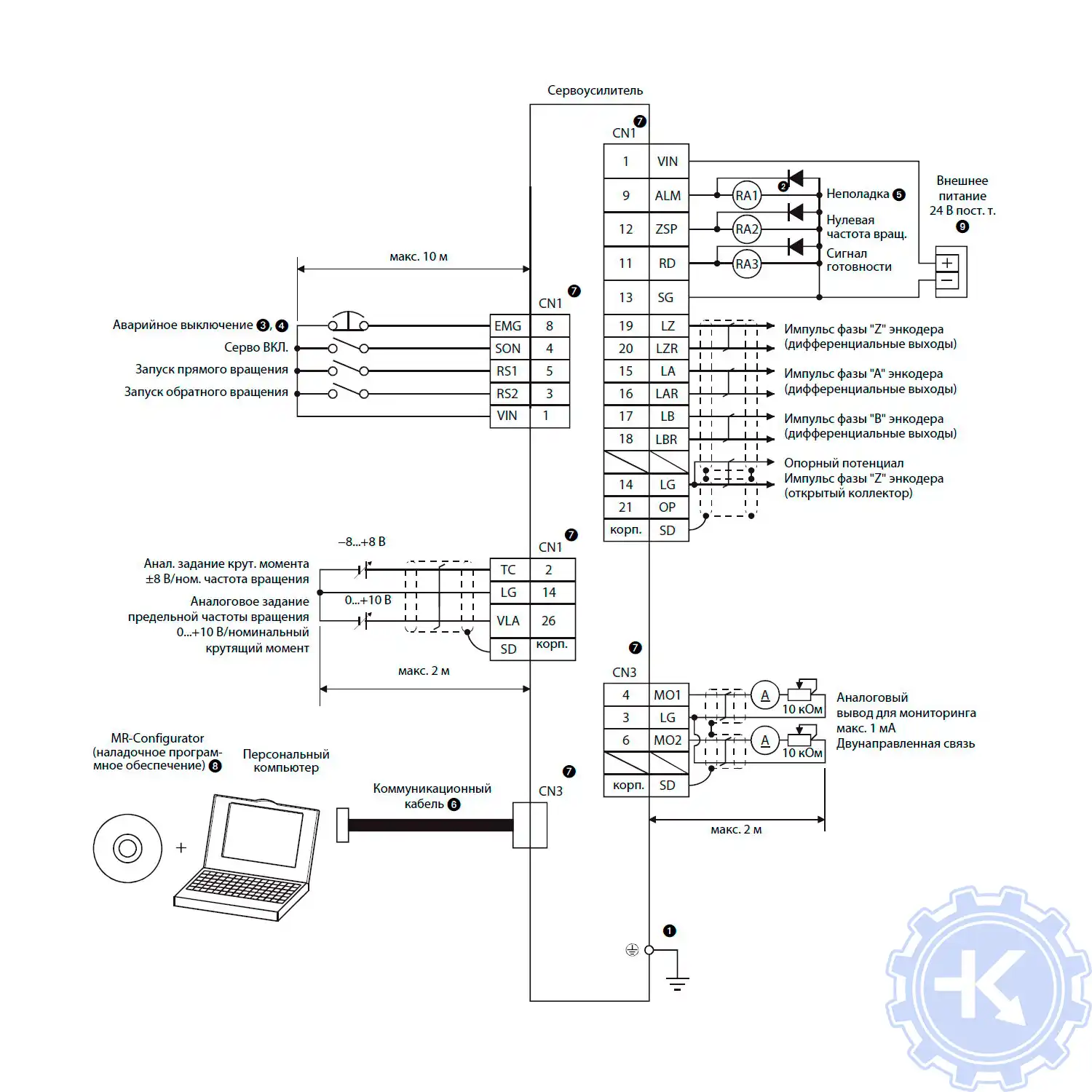

В некоторых случает может понадобится схема подключения сервоусилителей, ниже мы показаны схемы сервоусилителя Mitsubishi.

Базовые схемы конфигурации сервоусилителей Mitsubishi

|

Конфигурация системы MR-E-100AG-QW003 |

Конфигурация системы MR-E-200AG-QW003 |

|

|

|

Схемы типовых подключений сервоусилителей Mitsubishi

|

Сервопривод Mitsubishi Схема регулировки частоты вращения |

Сервопривод Mitsubishi Схема регулировки крутящего момента |

|

|

|

Блок схема сервоусилителя Mitsubishi

|

Mitsubishi MR-E-Super с аналоговым входом |

|

Преимущество ремонта сервоусилителя Mitsubishi в нашем сервисном центре

Во время эксплуатации электроприводов Mitsubishi может возникнуть проблема, далеко не всегда возникшую проблему можно исправить на месте своими силами, наш сервисный центр готов вам в этом помочь, выполнив качественный ремонт сервоусилителей Mitsubishi в сжатые сроки с полугодовой гарантией.

Мы не только восстановим неисправный блок, но и подскажем как действовать в той или иной ситуации для максимально долгой и безаварийной работы сервоусилителя.

Работы, проводимые при ремонте сервоусилителя Mitsubishi в :

- Предварительный осмотр на возможность восстановления бесплатный;

- Мы производим ремонт сервоусилителя Mitsubishi на компонентном уровне (экономия бюджета и времени)

- При ремонте сервоусилителей ни каких конструктивных изменений не вносим;

- Ремонт блоков с применением оригинальных запасных частей (по возможности).

- Вы платите исключительно за результат — работающий сервопривод;

- Гарантия на ремонт сервоусилителя Mitsubishi и на запасные части замененные в процессе ремонта 6 месяцев;

- Сроки ремонта варьируются от 5 до 15 рабочих дней;

За два десятилетия существования сервисного центра нашими специалистами были успешно проведены тысячи подобных ремонтов с каждым разом поднимая квалификацию наших инженеров. Ниже представлен далеко не полный список сервоусилителей Mitsubishi серии MR-E ремонтируемые в нашем сервисном центре.

|

MR-E Super Сервоусилитель 1(3) x 200-230В/50-60Гц (управление импульсной последовательностью) |

|

|

MR-E-10A-QW003 |

Ремонт сервоусилителя MR-E-A для двигателей до 100 Вт |

|

MR-E-20A-QW003 |

Ремонт сервоусилителя MR-E-A для двигателей до 200 Вт |

|

MR-E-40A-QW003 |

Ремонт сервоусилителя MR-E-A для двигателей до 400 Вт |

|

MR-E-70A-QW003 |

Ремонт сервоусилителя MR-E-A для двигателей до 750 Вт |

|

MR-E Super Сервоусилитель 3 x 200-230В/50-60Гц (управление импульсной последовательностью) |

|

|

MR-E-100A-QW003 |

Ремонт сервоусилителя MR-E-A для двигателей до 1кВт |

|

MR-E-200A-QW003 |

Ремонт сервоусилителя MR-E-A для двигателей до 2кВт |

|

MR-E Super Сервоусилитель 1(3) x 200-230В/50-60Гц (управление аналоговым сигналом) |

|

|

MR-E-10AG-QW003 |

Ремонт сервоусилителя MR-E-AG для двигателей до 100 Вт |

|

MR-E-20AG-QW003 |

Ремонт сервоусилителя MR-E-AG для двигателей до 200 Вт |

|

MR-E-40AG-QW003 |

Ремонт сервоусилителя MR-E-AG для двигателей до 400 Вт |

|

MR-E-70AG-QW003 |

Ремонт сервоусилителя MR-E-AG для двигателей до 750 Вт |

|

MR-E Super Сервоусилитель 3 x 200-230В/50-60Гц (управление аналоговым сигналом) |

|

|

MR-E-100AG-QW003 |

Ремонт сервоусилителя MR-E-AG для двигателей до 1кВт |

|

MR-E-200AG-QW003 |

Ремонт сервоусилителя MR-E-AG для двигателей до 2кВт |

В таблице представлены исключительно сервоусилители Mitsubishi серии MR-E ремонт которых мы вам предлагаем, также специалисты нашей компании ремонтируют сервоусилители не зависимо от серии и под каким брендом они были выпущены.

Оставить заявку на ремонт сервоусилителя Mitsubishi

У вас остались вопросы, связанные с ремонтом или сбросом ошибок, а также программированием и настройкой сервоусилителей Mitsubishi? Оставьте заявку на ремонт сервоусилителя Mitsubishi в нашим менеджерам. Связаться с ними можно несколькими способами:

- Заказав обратный звонок (кнопка в правом нижнем углу сайта)

- Посредством чата (кнопка расположена с левой стороны сайта)

- Позвонив по номеру телефона:

- +7(8482) 79-78-54;

- +7(8482) 55-96-39;

- +7(917) 121-53-01

- Написав на электронную почту: 89171215301@mail.ru

За время существования сервисного центра нашими специалистами были отремонтированы десятки и сотни тысяч единиц промышленной электроники. Вот далеко не полный список производителей промышленной электроники и оборудования, ремонтируемой в нашей компании.

Все ошибки Mitsubishi AIRTREK, ASX, CARISMA,COLT, DELICA, DIAMANTE, DION, ECLIPSE, ENDEAVOR, GALANT, GRANDIS, GTO, i-MiEV, IO, L200, LANCER, LANCER CLASSIC, LANCER EVO, MINICA, MIRAGE, MONTERO, OUTLANDER, PAJERO, PAJERO SPORT, SPACE STAR, SPACE WAGON, TOWN BOX

FUSO, FUSO Canter, FUSO Fighter, FUSO Super Great

Ошибки Mitsubishi по протоколу OBDI. Самодиагностика.

11 – Датчик кислорода – неисправность

12 – Датчик массового расхода воздуха – неисправность

13 – Датчик температуры впускного воздуха – неисправность

14 – Датчик положения дроссельной заслонки (TPS) – неисправность

15 – Датчик положения двигателя на холостом ходу – неисправность

21 – Датчик температуры охлаждающей жидкости – неисправность

22 – Датчик положения коленчатого вала – неисправность

23 – Датчик положения распределительного вала – неисправность

24 – Датчик скорости автомобиля – неисправность

25 – Датчик барометрического давления – неисправность

31 – Датчик детонации – неисправность

32 – Датчик абсолютного давления – неисправность

36 – Неисправность сигнала регулировки времени зажигания

39 – Датчик кислорода – неисправность

41 – Неисправность форсунки / форсунок

42 – Топливный насос – неисправность

43 – Система отработавших газов (EGR) – неисправность

44 – Катушка зажигания (цилиндры № 1 и № 4) – неисправность

52 – Катушка зажигания (цилиндры № 2 и № 5) – неисправность

53 – Катушка зажигания (цилиндры № 3 и № 6) – неисправность

55 – Управление холостым ходом (IAC) – неисправность датчика положения клапана

59 – Кислородный датчик (задний) – неисправность

61 – Модуль управления трансмиссией – снижение мощности – некорректный сигнал

62 – Система VIC – неисправность датчика положения клапана

71 – Неисправность электромагнитного вакуумного клапана управления тягой (Traction Control)

72 – Неисправность соленоида вентиляционного клапана системы управления тягой (Traction Control)

Ошибки Mitsubishi по протоколу OBDII

Топливная система и воздухоподача

P0000-P0099, P0100-P0199, P0200-P0299

P0001 – Управление регулятором подачи топлива — обрыв цепи

P0002 – Управление регулятором подачи топлива — параметры цепи

P0003 – Управление регулятором подачи топлива — низкое напряжение

P0004 – Управление регулятором подачи топлива — высокое напряжение

P0005 – Клапан отсечки подачи топлива — обрыв цепи

P0006 – Клапан отсечки подачи топлива — низкий уровень сигнала

P0007 – Клапан отсечки подачи топлива — высокий уровень сигнала

P0008 – Система синхронизации фаз, банк 1 — характеристика двигателя

P0009 – Система синхронизации фаз, банк 2 — характеристика двигателя

P0010 – Привод системы изменения фаз газораспределения, впуск/левый/передний, банк 1 — неисправность электрической цепи

P0011 – Положение распределительного вала, впуск/левый/передний, банк 1 — слишком ранний угол открывания клапанов / нарушение функционирования системы

P0012 – Положение распределительного вала, впуск/левый/передний, банк 1 — слишком поздний угол открывания клапанов

P0013 – Привод системы изменения фаз газораспределения, впуск/левый/передний, банк 1 — неисправность электрической цепи

P0014 – Привод системы изменения фаз газораспределения, выпуск/правый/задний, банк 1 — слишком ранний угол открывания / функционирование системы

P0015 – Привод системы изменения фаз газораспределения, выпуск/правый/задний, банк 1 — слишком поздний угол открывания

P0016 – Положение коленчатого и распределительного валов, банк 1, датчик А — нет соответствия

P0017 – Положение коленчатого и распределительного валов, банк 1, датчик В — корреляция

P0018 – Положение коленчатого и распределительного валов, банк 2, датчик А — корреляция

P0019 – Положение коленчатого и распределительного валов, банк 2, датчик B — корреляция

P0020 – Привод системы изменения фаз газораспределения, впуск/левый/передний, банк 2 — неисправность электрической цепи

P0021 – Положение распределительного вала, впуск/левый/передний, банк 2 — слишком ранний угол открывания клапанов / нарушение функционирования системы

P0022 – Положение распределительного вала, впуск/левый/передний, банк 2 — слишком поздний угол открывания клапанов

P0023 – Привод системы изменения фаз газораспределения, выпуск/правый/задний, банк 2 — неисправность электрической цепи

P0024 – Положение распределительного вала, выпуск/правый/задний, банк 2 — слишком ранний угол открывания / функционирование системы

P0025 – Положение распределительного вала, выпуск/правый/задний, банк 2 — слишком поздний угол открывания

P0030 – Подогреваемый кислородный датчик 1, банк 1, управление нагревателем — неисправность электрической цепи

P0031 – Подогреваемый кислородный датчик 1, банк 1, управление нагревателем — низкое напряжение цепи

P0032 – Подогреваемый кислородный датчик 1, банк 1, управление нагревателем — высокое напряжение цепи

P0033 – Перепускной клапан турбокомпрессора — неисправность электрической цепи

P0034 – Перепускной клапан турбокомпрессора — низкий уровень сигнала

P0035 – Перепускной клапан турбокомпрессора — высокий уровень сигнала

P0036 – Подогреваемый кислородный датчик 2, банк 1, управление нагревателем — неисправность электрической цепи

P0037 – Подогреваемый кислородный датчик 2, банк 1, управление нагревателем — низкое напряжение цепи

P0038 – Подогреваемый кислородный датчик 2, банк 1, управление нагревателем — высокое напряжение цепи

P0039 – Перепускной клапан турбокомпрессора/перепускной клапан приводного нагнетателя, управление — диапазон/функционирование

P0040 – Перепутано подключение кислородных датчиков 1, банка 1 и банка 2

P0041 – Перепутано подключение кислородных датчиков 2, банка 1 и банка 2

P0045 – Э/м клапан управления давлением турбонаддува/ клапан управления давлением наддува приводного нагнетателя — обрыв цепи

P0046 – Э/м клапан управления давлением турбонаддува / давлением наддува приводного нагнетателя — диапазон/функционирование

P0047 – Э/м клапан управления давлением турбонаддува / давлением наддува приводного нагнетателя — низкий уровень сигнала

P0048 – Э/м клапан управления давлением турбонаддува / давлением наддува приводного нагнетателя — высокий уровень сигнала

P0049 – Турбина турбокомпрессора / нагнетателя — превышение скорости

P0050 – Подогреваемый кислородный датчик 1, банк 2, управление нагревателем — неисправность электрической цепи

P0051 – Подогреваемый кислородный датчик 1, банк 2, управление нагревателем — низкий уровень сигнала

P0052 – Подогреваемый кислородный датчик 1, банк 2, управление нагревателем — высокий уровень сигнала

P0053 – Подогреваемый кислородный датчик 1, банк 1 — сопротивление нагревателя

P0054 – Подогреваемый кислородный датчик 1, банк 2 — сопротивление нагревателя

P0055 – Подогреваемый кислородный, банк 1, датчик 3 — сопротивление нагревателя

P0056 – Подогреваемый кислородный датчик 2, банк 2, управление нагревателем — неисправность электрической цепи

P0057 – Подогреваемый кислородный датчик 2, банк 2, управление нагревателем — низкое напряжение цепи нагревателя

P0058 – Подогреваемый кислородный датчик 2, банк 2, управление нагревателем — высокий уровень сигнала

P0059 – Подогреваемый кислородный датчик 1, банк 2 — сопротивление нагревателя

P0060 – Подогреваемый кислородный датчик, банк 2, датчик 2 — сопротивление нагревателя

P0061 – Подогреваемый кислородный датчик, банк 2, датчик 3 — сопротивление нагревателя

P0065 – Форсунка с дополнительным воздушным каналом — диапазон/функционирование

P0066 – Форсунка с дополнительным воздушным каналом — неисправность электрической цепи / низкое напряжение

P0067 – Форсунка с дополнительным воздушным каналом — высоко напряжение цепи

P0068 – Датчик абсолютного давления во впускном коллекторе/датчик расхода воздуха (MAF) — несоответствие положению дроссельной заслонки

P0069 – Датчик абсолютного давления во впускном коллекторе / датчик атмосферного давления — корреляция

P0070 – Датчик температуры окружающего воздуха — неисправность электрической цепи

P0071 – Датчик температуры окружающего воздуха — диапазон/функционирование

P0072 – Датчик температуры окружающего воздуха — низкий уровень сигнала

P0073 – Датчик температуры окружающего воздуха — высокий уровень выходного сигнала

P0074 – Датчик температуры окружающего воздуха — ненадежный контакт электрической цепи

P0087 – Давление в системе / в топливном коллекторе — слишком низкое

P0088 – Давление в системе / в топливном коллекторе — слишком высокое

P0089 – Регулятор давления топлива 1 — функционирование

P0090 – Регулятор давления топлива 1 — обрыв цепи

P0091 – Регулятор давления топлива 1 — короткое замыкание на массу

P0092 – Регулятор давления топлива 1 — короткое замыкание на «+»

P0093 – Значительная утечка в топливной системе

P0094 – Незначительная утечка в топливной системе

P0100 – Датчик расхода воздуха (массового — MAF) / (объемного — VAF) — неисправность электрической цепи

P0101 – Датчик расхода воздуха (MAF) / (VAF) — диапазон/функционирование

P0102 – Датчик расхода воздуха (MAF) / (VAF) — низкий уровень входного сигнала

P0103 – Датчик расхода воздуха (MAF) / (VAF) — высокий уровень входного сигнала

P0104 – Датчик расхода воздуха (MAF) / (VAF) — ненадежный контакт электрической цепи

P0105 – Датчик абсолютного давления во впускном коллекторе (МАР) / датчик атмосферного давления — неисправность электрической цепи

P0106 – Датчик абсолютного давления во впускном коллекторе/датчик атмосферного давления — диапазон/функционирование

P0107 – Датчик абсолютного давления во впускном коллекторе/датчик атмосферного давления — низкий уровень сигнала

P0108 – Датчик абсолютного давления во впускном коллекторе/датчик атмосферного давления — высокий уровень сигнала

P0109 – Датчик абсолютного давления во впускном коллекторе (МАР) / датчик атмосферного давления — ненадежный контакт электрической цепи

P0110 – Датчик температуры воздуха на впуске — неисправность электрической цепи

P0111 – Датчик температуры воздуха на впуске — диапазон/функционирование

P0112 – Датчик температуры воздуха на впуске — низкий уровень сигнала

P0113 – Датчик температуры воздуха на впуске — высокий уровень входного сигнала

P0114 – Датчик температуры воздуха на впуске — ненадежный контакт электрической цепи

P0115 – Датчик температуры охлаждающей жидкости — неисправность электрической цепи

P0116 – Датчик температуры охлаждающей жидкости — диапазон/функционирование

P0117 – Датчик температуры охлаждающей жидкости — низкий уровень сигнала

P0118 – Датчик температуры охлаждающей жидкости — высокий уровень входного сигнала

P0119 – Датчик температуры охлаждающей жидкости — ненадежный контакт электрической цепи

P0120 – Датчик А положения дроссельной заслонки / датчик А положения педали акселератора — неисправность электрической цепи

P0121 – Датчик А положения дроссельной заслонки / датчик А положения педали акселератора — диапазон/функционирование

P0122 – Датчик «А» положения дроссельной заслонки / датчик «А» положения педали акселератора — низкий уровень сигнала

P0123 – Датчик А положения дроссельной заслонки / датчик А положения педали акселератора — высокий уровень сигнала

P0124 – Датчик А положения дроссельной заслонки / датчик А положения педали акселератора — ненадежный контакт электрической цепи

P0125 – Температура охлаждающей жидкости недостаточна для управления топливоподачей с обратной связью

P0126 – Температура охлаждающей жидкости недостаточна для стабильной работы

P0127 – Слишком высокая температура воздуха на впуске

P0128 – Термостат системы охлаждения — температура охлаждающей жидкости ниже температуры открывания термостата

P0129 – Слишком низкое атмосферное давление

P0130 – Кислородный датчик 1, банк 1 — неисправность электрической цепи

P0131 – Кислородный датчик 1, банк 1 — низкое напряжение

P0132 – Кислородный датчик 1, банк 1 — высокое напряжение

P0133 – Кислородный датчик 1, банк 1 — малое быстродействие

P0134 – Кислородный датчик 1, банк 1 — нет отклика

P0135 – Подогреваемый кислородный датчик 1, банк 1, управление нагревателем — неисправность электрической цепи

P0136 – Кислородный датчик 2, банк 1 — неисправность электрической цепи

P0137 – Кислородный датчик 2, банк 1 — низкое напряжение

P0138 – Кислородный датчик 2, банк 1 — высокое напряжение

P0139 – Кислородный датчик 2, банк 1 — малое быстродействие

P0140 – Кислородный датчик 2, банк 1 — нет отклика

P0141 – Подогреваемый кислородный датчик 2, банк 1, управление нагревателем — неисправность электрической цепи

P0148 – Неправильная подача топлива

P0149 – Неправильный угол опережения впрыска

P0150 – Кислородный датчик 1, банк 2 — неисправность электрической цепи

P0151 – Кислородный датчик 1, банк 2 — низкое напряжение

P0152 – Кислородный датчик 1, банк 2 — высокое напряжение

P0153 – Кислородный датчик 1, банк 2 — малое быстродействие

P0154 – Кислородный датчик 1, банк 2 — нет отклика

P0155 – Кислородный датчик 1, банк 2, управление нагревателем — неисправность электрической цепи

P0156 – Кислородный датчик 2, банк 2 — неисправность электрической цепи

P0157 – Кислородный датчик 2, банк 2 — низкое напряжение

P0158 – Кислородный датчик 2, банк 2 — высокое напряжение

P0159 – Кислородный датчик 2, банк 2 — малое быстродействие

P0160 – Кислородный датчик 2, банк 2 — нет отклика

P0161 – Подогреваемый кислородный датчик 2, банк 2, управление нагревателем — неисправность электрической цепи

P0168 – Слишком высокая температура топлива

P0169 – Несоответствующий состав топлива

P0170 – Топливный баланс, банк 1 — неисправность

P0171 – Слишком бедная топливовоздушная смесь, банк 1

P0172 – Слишком богатая топливовоздушная смесь, банк 1

P0173 – Топливный баланс, банк 2 — неисправность

P0174 – Слишком бедная топливовоздушная смесь, банк 2

P0175 – Слишком богатая топливовоздушная смесь, банк 2

P0176 – Датчик состава смеси — неисправность электрической цепи

P0177 – Датчик состава смеси — диапазон/функционирование

P0178 – Датчик состава смеси — низкий уровень сигнала

P0179 – Датчик состава смеси — высокий уровень сигнала

P0180 – Датчик температуры топлива A — неисправность электрической цепи

P0181 – Датчик температуры топлива A — диапазон/функционирование

P0182 – Датчик температуры топлива A — низкий уровень сигнала

P0183 – Датчик температуры топлива A — высокий уровень входного сигнала

P0184 – Датчик температуры топлива A — ненадежный контакт электрической цепи

P0185 – Датчик температуры топлива B — неисправность электрической цепи

P0186 – Датчик температуры топлива B — диапазон/функционирование

P0187 – Датчик температуры топлива B — низкий уровень входного сигнала

P0188 – Датчик температуры топлива B — высокий уровень входного сигнала

P0189 – Датчик температуры топлива B — ненадежный контакт электрической цепи

P0190 – Датчик давления в топливном коллекторе — неисправность электрической цепи

P0191 – Датчик давления в топливном коллекторе — диапазон/функционирование

P0192 – Датчик давления в топливном коллекторе — низкий уровень сигнала

P0193 – Датчик давления в топливном коллекторе — высокий уровень входного сигнала

P0194 – Датчик давления в топливном коллекторе — ненадежный контакт электрической цепи

P0195 – Датчик температуры моторного масла — неисправность электрической цепи

P0196 – Датчик температуры моторного масла — диапазон/функционирование

P0197 – Датчик температуры моторного масла — низкий уровень сигнала

P0198 – Датчик температуры моторного масла — высокий уровень входного сигнала

P0199 – Датчик температуры моторного масла — ненадежный контакт электрической цепи

P0200 – Форсунка — неисправность электрической цепи

P0201 – Форсунка 1 — неисправность электрической цепи

P0202 – Форсунка 2 — неисправность электрической цепи

P0203 – Форсунка 3 — неисправность электрической цепи

P0204 – Форсунка 4 — неисправность электрической цепи

P0205 – Форсунка 5 — неисправность электрической цепи

P0206 – Форсунка 6 — неисправность электрической цепи

P0207 – Форсунка 7 — неисправность электрической цепи

P0208 – Форсунка 8 — неисправность электрической цепи

P0213 – Форсунка холодного пуска 1 — неисправность электрической цепи

P0214 – Форсунка холодного пуска 2 — неисправность электрической цепи

P0215 – Э/м клапан отсечки подачи топлива — неисправность электрической цепи

P0216 – Управление углом опережения впрыска топлива — неисправность электрической цепи

P0217 – Перегрев двигателя

P0218 – Перегрев коробки передач

P0219 – Превышение допустимой частоты вращения коленчатого вала

P0220 – Датчик В положения дроссельной заслонки / датчик В положения педали акселератора — неисправность электрической цепи

P0221 – Датчик В положения дроссельной заслонки / датчик В положения педали акселератора — диапазон/функционирование

P0222 – Датчик В положения дроссельной заслонки / датчик В положения педали акселератора — низкий уровень входного сигнала

P0223 – Датчик В положения дроссельной заслонки / датчик В положения педали акселератора — высокий уровень входного сигнала

P0224 – Датчик В положения дроссельной заслонки / датчик В положения педали акселератора — ненадежный контакт электрической цепи

P0230 – Реле топливного насоса — неисправность электрической цепи

P0231 – Реле топливного насоса — низкое напряжение цепи

P0232 – Реле топливного насоса — высокое напряжение цепи

P0233 – Реле топливного насоса — ненадежный контакт электрической цепи

P0234 – Давление турбонаддува — превышен верхний предел

P0235 – Датчик давления наддува A турбокомпрессора/приводного нагнетателя — неисправность электрической цепи

P0236 – Датчик давления наддува A турбокомпрессора/приводного нагнетателя — диапазон/функционирование

P0237 – Датчик давления наддува A турбокомпрессора/приводного нагнетателя — низкий уровень входного сигнала

P0238 – Датчик давления наддува A турбокомпрессора/приводного нагнетателя — высокий уровень входного сигнала

P0239 – Датчик давления наддува B турбокомпрессора/приводного нагнетателя — неисправность электрической цепи

P0240 – Датчик давления наддува B турбокомпрессора/приводного нагнетателя — диапазон/функционирование

P0241 – Датчик давления наддува B турбокомпрессора/приводного нагнетателя — низкий уровень входного сигнала

P0242 – Датчик давления наддува B турбокомпрессора/приводного нагнетателя — высокий уровень входного сигнала

P0243 – Клапан А управления перепуском газов мимо турбины — неисправность цепи

P0244 – Клапан А управления перепуском газов мимо турбины — диапазон/функционирование

P0245 – Клапан А управления перепуском газов мимо турбины — низкое напряжение цепи

P0246 – Клапан А управления перепуском газов мимо турбины — высокое напряжение цепи

P0247 – Клапан управления перепуском газов мимо турбины B — неисправность цепи

P0248 – Клапан В управления перепуском газов мимо турбины — диапазон/функционирование

P0249 – Клапан управления перепуском газов мимо турбины B — низкий уровень сигнала

P0250 – Клапан управления перепуском газов мимо турбины B — высокий уровень сигнала

P0251 – Дозатор топлива А, ротор/кулачок/форсунка — неисправность электрической цепи

P0252 – Дозатор топлива А, ротор/кулачок/форсунка — диапазон/функционирование

P0253 – Дозатор топлива А, ротор/кулачок/форсунка — низкий уровень сигнала

P0254 – Дозатор топлива А, ротор/кулачок/форсунка — высокий уровень сигнала

P0255 – Дозатор топлива А, ротор/кулачок/форсунка — ненадежный контакт электрической цепи

P0256 – Дозатор топлива B, ротор/кулачок/форсунка — неисправность электрической цепи

P0257 – Дозатор топлива B, ротор/кулачок/форсунка — диапазон/функционирование

P0258 – Дозатор топлива B, ротор/кулачок/форсунка — низкий уровень сигнала

P0259 – Дозатор топлива B, ротор/кулачок/форсунка — высокий уровень сигнала

P0260 – Дозатор топлива B, ротор/кулачок/форсунка — ненадежный контакт электрической цепи

P0261 – Форсунка 1 — низкий уровень сигнала

P0262 – Форсунка 1 — высокий уровень сигнала

P0263 – Цилиндр 1 — неправильный баланс мощности

P0264 – Форсунка 2 — низкий уровень сигнала

P0265 – Форсунка 2 — высокий уровень сигнала

P0266 – Цилиндр 2 — неправильный баланс мощности

P0267 – Форсунка 3 — низкий уровень сигнала

P0268 – Форсунка 3 — высокий уровень сигнала

P0269 – Цилиндр 3 — неправильный баланс мощности

P0270 – Форсунка 4 — низкий уровень сигнала

P0271 – Форсунка 4 — высокий уровень сигнала

P0272 – Цилиндр 4 — неправильный баланс мощности

P0273 – Форсунка 5 — низкий уровень сигнала

P0274 – Форсунка 5 — высокий уровень сигнала

P0275 – Цилиндр 5 — неправильный баланс мощности

P0276 – Форсунка 6 — низкий уровень сигнала

P0277 – Форсунка 6 — высокий уровень сигнала

P0278 – Цилиндр 6 — неправильный баланс мощности

P0279 – Форсунка 7 — низкий уровень сигнала

P0280 – Форсунка 7 — высокий уровень сигнала

P0281 – Цилиндр 7 — неправильный баланс мощности

P0282 – Форсунка 8 — низкий уровень сигнала

P0283 – Форсунка 8 — высокий уровень сигнала

P0284 – Цилиндр 8 — неправильный баланс мощности

P0297 – Превышение допустимой скорости автомобиля

P0298 – Слишком высокая температура моторного масла

P0299 – Турбокомпрессор / приводной нагнетатель — низкое давление наддува

Система зажигания

P0300-P0399

P0300 – Случайные / множественные пропуски зажигания (воспламенения)

P0301 – Цилиндр 1 — пропуски зажигания (воспламенения)

P0302 – Цилиндр 2 — пропуски зажигания (воспламенения)

P0303 – Цилиндр 3 — пропуски зажигания (воспламенения)

P0304 – Цилиндр 4 — пропуски зажигания (воспламенения)

P0305 – Цилиндр 5 — пропуски зажигания (воспламенения)

P0306 – Цилиндр 6 — пропуски зажигания (воспламенения)

P0307 – Цилиндр 7 — пропуски зажигания (воспламенения)

P0308 – Цилиндр 8 — пропуски зажигания (воспламенения)

P0313 – Пропуски зажигания (воспламенения) — низкий уровень топлива

P0314 – Пропуск зажигания (воспламенения) в одном цилиндре — номер цилиндра не распознается

P0315 – Коленчатый вал — отсутствие изменения положения

P0316 – Пропуски зажигания (воспламенения) при запуске — первые 1000 оборотов

P0317 – Нет данных по характеристикам неровностей дорожного покрытия

P0318 – Датчик состояния дорожного покрытия A — неисправность электрической цепи

P0319 – Датчик состояния дорожного покрытия B — неисправность электрической цепи

P0320 – Датчик положения коленчатого вала / датчик частоты вращения коленчатого вала — неисправность электрической цепи

P0321 – Датчик положения коленчатого вала / датчик частоты вращения коленчатого вала — диапазон/функционирование

P0322 – Датчик положения коленчатого вала/датчик частоты вращения коленчатого вала — нет сигнала

P0323 – Датчик положения коленчатого вала / датчик частоты вращения коленчатого вала — ненадежный контакт электрической цепи

P0324 – Ошибка в системе управления по детонации

P0325 – Датчик детонации 1, банк 1 — неисправность электрической цепи

P0326 – Датчик детонации 1, банк 1 — диапазон/функционирование

P0327 – Датчик детонации 1, банк 1 — низкий уровень сигнала

P0328 – Датчик детонации 1, банк 1 — высокий уровень входного сигнала

P0329 – Датчик детонации 1, банк 1 — ненадежный контакт электрической цепи

P0330 – Датчик детонации 2, банк 2 — неисправность электрической цепи

P0331 – Датчик детонации 2, банк 2 — диапазон/функционирование

P0332 – Датчик детонации 2, банк 2 — низкий уровень сигнала

P0333 – Датчик детонации 2, банк 2 — высокий уровень входного сигнала

P0334 – Датчик детонации 2, банк 2 — ненадежный контакт электрической цепи

P0335 – Датчик положения коленчатого вала — неисправность электрической цепи

P0336 – Датчик положения коленчатого вала — диапазон/функционирование

P0337 – Датчик положения коленчатого вала — низкий уровень сигнала

P0338 – Датчик положения коленчатого вала — высокий уровень сигнала

P0339 – Датчик положения коленчатого вала — ненадежный контакт электрической цепи

P0340 – Датчик положения распределительного вала A, банк 1 — неисправность электрической цепи

P0341 – Датчик положения распределительного вала A, банк 1 — диапазон/функционирование

P0342 – Датчик положения распределительного вала A, банк 1 — низкий уровень сигнала

P0343 – Датчик положения распределительного вала A, банк 1 — высокий уровень входного сигнала

P0344 – Датчик положения распределительного вала A, банк 1 — ненадежный контакт электрической цепи

P0345 – Датчик положения распределительного вала A, банк 2 — неисправность электрической цепи

P0346 – Датчик положения распределительного вала A, банк 2 — диапазон/функционирование

P0347 – Датчик положения распределительного вала A, банк 2 — низкий уровень сигнала

P0348 – Датчик положения распределительного вала A, банк 2 — высокий уровень сигнала

P0349 – Датчик положения распределительного вала A, банк 2 — ненадежный контакт электрической цепи

P0350 – Катушка зажигания, первичная/вторичная обмотки — неисправность электрической цепи

P0351 – Катушка зажигания A, первичная/вторичная обмотки — неисправность электрической цепи

P0352 – Катушка зажигания В, первичная/вторичная обмотки — неисправность электрической цепи

P0353 – Катушка зажигания С, первичная/вторичная обмотки — неисправность электрической цепи

P0354 – Катушка зажигания D, первичная/вторичная обмотки — неисправность электрической цепи

P0355 – Катушка зажигания Е, первичная/вторичная обмотки — неисправность электрической цепи

P0356 – Катушка зажигания F, первичная/вторичная обмотки — неисправность электрической цепи

P0357 – Катушка зажигания G, первичная/вторичная обмотки — неисправность электрической цепи

P0358 – Катушка зажигания H, первичная/вторичная обмотки — неисправность электрической цепи

P0363 – Пропуск зажигания (воспламенения) — отсутствие подачи топлива

P0364 – Зарезервировано (ISO/SAE)

P0365 – Датчик В положения распределительного вала, банк 1 — неисправность электрической цепи

P0366 – Датчик В положения распределительного вала, банк 1 — диапазон/функционирование

P0367 – Датчик В положения распределительного вала, банк 1 — низкий уровень сигнала

P0368 – Датчик В положения распределительного вала, банк 1 — высокий уровень сигнала

P0369 – Датчик В положения распределительного вала, банк 1 — ненадежный контакт электрической цепи

P0370 – Опорная точка синхронизации фаз, сигнал А высокого разрешения — неисправность

P0371 – Опорная точка синхронизации фаз, сигнал А высокого разрешения — слишком много импульсов

P0372 – Опорная точка синхронизации фаз, сигнал А высокого разрешения — слишком мало импульсов

P0373 – Опорная точка синхронизации фаз, сигнал А высокого разрешения — хаотичные/пропадающие импульсы

P0374 – Опорная точка синхронизации фаз, сигнал А высокого разрешения — нет импульсов

P0375 – Опорная точка синхронизации фаз, сигнал В высокого разрешения — неисправность

P0376 – Опорная точка синхронизации фаз, сигнал В высокого разрешения — слишком много импульсов

P0377 – Опорная точка синхронизации фаз, сигнал В высокого разрешения — слишком мало импульсов

P0378 – Опорная точка синхронизации фаз, сигнал B высокого разрешения — хаотичные/пропадающие импульсы

P0379 – Опорная точка синхронизации фаз, сигнал В высокого разрешения — нет импульсов

P0380 – Свечи накаливания, цепь А — неисправность

P0381 – Индикатор свечей накаливания — неисправность электрической цепи

P0382 – Свечи накаливания, цепь В — неисправность

P0383 – Блок управления свечами накаливания — низкий уровень сигнала

P0384 – Блок управления свечами накаливания — высокий уровень сигнала

P0385 – Датчик положения коленчатого вала B — неисправность электрической цепи

P0386 – Датчик положения коленчатого вала B — диапазон/функционирование

P0387 – Датчик положения коленчатого вала B — низкий уровень входного сигнала

P0388 – Датчик положения коленчатого вала B — высокий уровень входного сигнала

P0389 – Датчик положения коленчатого вала B — ненадежный контакт электрической цепи

P0390 – Датчик «А» положения распределительного вала B, банк 2 — неисправность электрической цепи

P0391 – Датчик В положения распределительного вала, банк 2 — диапазон/функционирование

P0392 – Датчик В положения распределительного вала, банк 2 — низкий уровень входного сигнала

P0393 – Датчик В положения распределительного вала, банк 2 — высокий уровень входного сигнала

P0394 – Датчик B положения распределительного вала, банк 2 — ненадежный контакт электрической цепи

P0395 – Датчик давления в цилиндре, цилиндр 1 — неисправность электрической цепи

P0396 – Датчик давления в цилиндре, цилиндр 1 — диапазон/функционирование

P0397 – Датчик давления в цилиндре, цилиндр 1 — низкий уровень сигнала

P0398 – Датчик давления в цилиндре, цилиндр 1 — высокий уровень сигнала

P0399 – Датчик давления в цилиндре, цилиндр 1 — ненадежный/пропадающий контакт электрической цепи

Контроль выбросов

P0400-P0499

P0400 – Система рециркуляции отработавших газов (EGR) — неисправность каналов системы

P0401 – Система рециркуляции отработавших газов (EGR) — недостаточный уровень рециркуляции

P0402 – Система рециркуляции отработавших газов (EGR) — чрезмерный уровень рециркуляции

P0403 – Система рециркуляции отработавших газов (EGR) — неисправность электрической цепи

P0404 – Система рециркуляции отработавших газов (EGR) — диапазон/функционирование

P0405 – Датчик положения клапана А системы рециркуляции ОГ (EGR) — низкий уровень сигнала

P0406 – Датчик положения клапана А системы рециркуляции ОГ (EGR) — высокий уровень сигнала

P0407 – Датчик положения клапана B системы рециркуляции ОГ (EGR) — низкий уровень входного сигнала

P0408 – Датчик положения клапана B системы рециркуляции ОГ (EGR) — высокий уровень входного сигнала

P0409 – Датчик А системы рециркуляции отработавших газов (EGR) — неисправность электрической цепи

P0410 – Система подачи воздуха на выпуск — неисправность

P0411 – Система подачи воздуха на выпуск — некорректный расход

P0412 – Э/м клапан А подачи воздуха на выпуск — неисправность электрической цепи

P0413 – Э/м клапан А подачи воздуха на выпуск — обрыв цепи

P0414 – Э/м клапан А подачи воздуха на выпуск — короткое замыкание

P0415 – Э/м клапан B подачи воздуха на выпуск — неисправность электрической цепи

P0416 – Э/м клапан B подачи воздуха на выпуск — обрыв цепи

P0417 – Э/м клапан B подачи воздуха на выпуск — короткое замыкание в цепи

P0418 – Реле насоса А подачи воздуха на выпуск — неисправность электрической цепи

P0419 – Реле B насоса системы подачи воздуха на выпуск — неисправность электрической цепи

P0420 – Каталитический нейтрализатор, банк 1 — эффективность ниже требуемой

P0421 – Прогрев каталитического нейтрализатора, банк 1 — эффективность ниже требуемой

P0422 – Основной каталитический нейтрализатор, банк 1 — эффективность ниже требуемой

P0423 – Подогреваемый каталитический нейтрализатор, банк 1 — эффективность ниже требуемой

P0424 – Подогреваемый каталитический нейтрализатор, банк 1 — эффективность ниже требуемой

P0425 – Датчик температуры каталитического нейтрализатора, банк 1

P0426 – Датчик температуры каталитического нейтрализатора, банк 1 — диапазон/функционирование

P0427 – Датчик температуры каталитического нейтрализатора, банк 1 — низкий уровень сигнала

P0428 – Датчик температуры каталитического нейтрализатора, банк 1 — высокий уровень входного сигнала

P0429 – Нагреватель каталитического нейтрализатора, банк 1 — неисправность электрической цепи

P0430 – Каталитический нейтрализатор, банк 2 — эффективность ниже требуемой

P0431 – Прогрев каталитического нейтрализатора, банк 2 — эффективность ниже требуемой

P0432 – Основной каталитический нейтрализатор, банк 2 — эффективность ниже требуемой

P0433 – Подогреваемый каталитический нейтрализатор, банк 2 — эффективность ниже требуемой

P0434 – Подогреваемый каталитический нейтрализатор, банк 2 — температура ниже требуемой

P0435 – Датчик температуры каталитического нейтрализатора, банк 2

P0436 – Датчик температуры каталитического нейтрализатора, банк 2 — диапазон/функционирование

P0437 – Датчик температуры каталитического нейтрализатора, банк 2 — низкий уровень входного сигнала

P0438 – Датчик температуры каталитического нейтрализатора, банк 2 — высокий уровень входного сигнала

P0439 – Нагреватель каталитического нейтрализатора, банк 2 — неисправность электрической цепи

P0440 – Система улавливания паров топлива — неисправность

P0441 – Система улавливания паров топлива — некорректный расход

P0442 – Система улавливания паров топлива — незначительная утечка

P0443 – Э/м клапан аккумулятора паров топлива — неисправность электрической цепи

P0444 – Э/м клапан аккумулятора паров топлива — обрыв цепи

P0445 – Э/м клапан аккумулятора паров топлива — короткое замыкание

P0446 – Система улавливания паров топлива, управление продувкой — неисправность электрической цепи

P0447 – Система улавливания паров топлива, управление продувкой — обрыв цепи

P0448 – Система улавливания паров топлива, управление продувкой — короткое замыкание

P0449 – Система улавливания паров топлива, клапан управления продувкой — неисправность электрической цепи

P0450 – Датчик давления системы улавливания паров топлива — неисправность электрической цепи

P0451 – Датчик давления системы улавливания паров топлива — диапазон/функционирование

P0452 – Датчик давления системы улавливания паров топлива — низкий уровень сигнала

P0453 – Датчик давления системы улавливания паров топлива — высокий уровень сигнала

P0454 – Датчик давления системы улавливания паров топлива — ненадежный контакт электрической цепи

P0455 – Система улавливания паров топлива — значительная утечка

P0456 – Система улавливания паров топлива — крайне незначительная утечка

P0457 – Система улавливания паров топлива — утечка (ослабла или открыта крышка топливозаливной горловины)

P0458 – Система улавливания паров топлива, клапан аккумулятора паров топлива — низкий уровень сигнала

P0459 – Система улавливания паров топлива, клапан аккумулятора паров топлива — высокий уровень сигнала

P0460 – Датчик уровня топлива — неисправность электрической цепи

P0461 – Датчик уровня топлива — диапазон/функционирование

P0462 – Датчик уровня топлива — низкий уровень сигнала

P0463 – Датчик уровня топлива — высокий уровень входного сигнала

P0464 – Датчик уровня топлива — ненадежный контакт электрической цепи

P0465 – Датчик расхода через аккумулятор паров топлива — неисправность электрической цепи

P0466 – Датчик расхода через аккумулятор паров топлива — диапазон/функционирование

P0467 – Датчик расхода через аккумулятор паров топлива — низкий уровень сигнала

P0468 – Датчик расхода через аккумулятор паров топлива — высокий уровень сигнала

P0469 – Датчик расхода через аккумулятор паров топлива — ненадежный контакт электрической цепи

P0470 – Датчик давления отработавших газов — неисправность электрической цепи

P0471 – Датчик давления отработавших газов — диапазон/функционирование

P0472 – Датчик давления отработавших газов — низкий уровень сигнала

P0473 – Датчик давления отработавших газов — высокий уровень входного сигнала

P0474 – Датчик давления отработавших газов — ненадежный контакт электрической цепи

P0475 – Клапан управления давлением отработавших газов — неисправность электрической цепи

P0476 – Клапан управления давлением отработавших газов — диапазон/функционирование

P0477 – Клапан управления давлением отработавших газов — низкий уровень сигнала

P0478 – Клапан управления давлением отработавших газов — высокий уровень входного сигнала

P0479 – Клапан управления давлением отработавших газов — ненадежный контакт электрической цепи

P0480 – Электродвигатель вентилятора 1 системы охлаждения — неисправность электрической цепи

P0481 – Электродвигатель вентилятора 2 системы охлаждения — неисправность электрической цепи

P0482 – Электродвигатель вентилятора системы охлаждения 3 — неисправность электрической цепи

P0483 – Электродвигатель вентилятора системы охлаждения, нормальная проверка — неисправность

P0484 – Электродвигатель вентилятора системы охлаждения — превышение допустимой силы тока в цепи

P0485 – Электродвигатель вентилятора системы охлаждения, питание / масса — неисправность электрической цепи

P0486 – Датчик положения клапана В системы рециркуляции ОГ (EGR) — неисправность электрической цепи

P0487 – Система рециркуляции отработавших газов (EGR), управление положением дроссельной заслонки — неисправность электрической цепи

P0488 – Система рециркуляции отработавших газов (EGR), управление положением заслонки — проблемы диапазона / функционирования

P0489 – Система рециркуляции отработавших газов (EGR) — низкое напряжение цепи

P0490 – Система рециркуляции отработавших газов (EGR) — высокое напряжение цепи

P0491 – Система подачи воздуха на выпуск, банк 1 — неисправность

P0492 – Система подачи воздуха на выпуск, банк 2 — неисправность

P0493 – Превышение частоты вращения электродвигателя вентилятора системы охлаждения (блокировка муфты)

P0494 – Электродвигатель вентилятора системы охлаждения — низкая скорость

P0495 – Электродвигатель вентилятора системы охлаждения — высокая скорость

P0496 – Система улавливания паров топлива — высокий расход при продувке

P0497 – Система улавливания паров топлива — низкий расход при продувке

P0498 – Система улавливания паров топлива, управление продувкой — низкий уровень сигнала

P0499 – Система улавливания паров топлива, управление продувкой — высокий уровень сигнала

Контроль скорости и холостого хода

P0500-P0599

P0500 – Датчик скорости автомобиля — неисправность электрической цепи

P0501 – Датчик скорости автомобиля — диапазон/функционирование

P0502 – Датчик скорости автомобиля — низкий уровень сигнала

P0503 – Датчик скорости автомобиля — сигналы хаотичные / пропадающие / высокого уровня

P0504 – Выключатель А/В стоп-сигналов (датчик положения педали тормоза) — корреляция

P0505 – Система управления частотой вращения холостого хода — неисправность

P0506 – Система управления частотой вращения холостого хода — частота вращения ниже допустимой

P0507 – Система управления частотой вращения холостого хода — частота вращения выше допустимой

P0508 – Управление перепуском воздуха на холостом ходу — низкий уровень сигнала

P0509 – Управление перепуском воздуха на холостом ходу — высокий уровень сигнала

P0510 – Датчик полностью закрытого положения дроссельной заслонки — неисправность электрической цепи

P0511 – Управление перепуском воздуха на холостом ходу — неисправность электрической цепи

P0512 – Цепь управления стартером — неисправность

P0513 – Некорректный ключ иммобилайзера (неправильный код)

P0514 – Датчик температуры аккумуляторной батареи — диапазон/функционирование

P0515 – Датчик температуры аккумуляторной батареи — диапазон/функционирование

P0516 – Датчик температуры аккумуляторной батареи — низкое напряжение цепи

P0517 – Датчик температуры аккумуляторной батареи — высокое напряжение цепи

P0518 – Управление перепуском воздуха на холостом ходу — ненадежный контакт электрической цепи

P0519 – Управление перепуском воздуха на холостом ходу — функционирование

P0520 – Датчик давления моторного масла — неисправность электрической цепи

P0521 – Датчик давления моторного масла — диапазон/функционирование

P0522 – Датчик давления моторного масла — низкое напряжение

P0523 – Датчик давления моторного масла — высокое напряжение

P0524 – Давление моторного масла слишком низкое

P0525 – Система поддержания скорости (круиз-контроль), управление приводом — диапазон/функционирование

P0526 – Электродвигатель вентилятора системы охлаждения, датчик скорости — неисправность электрической цепи

P0527 – Электродвигатель вентилятора системы охлаждения, датчик скорости — диапазон/функционирование

P0528 – Электродвигатель вентилятора системы охлаждения, датчик скорости — нет сигнала

P0529 – Электродвигатель вентилятора системы охлаждения, датчик скорости — ненадежный контакт электрической цепи

P0530 – Датчик давления хладагента системы кондиционирования — неисправность электрической цепи

P0531 – Датчик давления хладагента системы кондиционирования — диапазон/функционирование

P0532 – Датчик давления хладагента системы кондиционирования — низкий уровень сигнала

P0533 – Датчик давления хладагента системы кондиционирования — высокий уровень входного сигнала

P0534 – Недостаток хладагента в системе кондиционирования

P0535 – Датчик температуры за испарителем (кондиционер) — неисправность электрической цепи

P0536 – Датчик температуры за испарителем (кондиционер) — диапазон/функционирование

P0537 – Датчик температуры за испарителем системы кондиционирования — низкий уровень сигнала

P0538 – Датчик температуры за испарителем системы кондиционирования — высокий уровень сигнала

P0539 – Датчик температуры за испарителем системы кондиционирования — ненадежный контакт электрической цепи

P0550 – Датчик/выключатель по давлению усилителя рулевого управления — неисправность электрической цепи

P0551 – Датчик-выключатель по давлению усилителя рулевого управления — диапазон/функционирование

P0552 – Датчик/выключатель по давлению усилителя рулевого управления — низкий уровень сигнала

P0553 – Датчик/выключатель по давлению усилителя рулевого управления — высокий уровень сигнала

P0554 – Датчик/выключатель по давлению усилителя рулевого управления — ненадежный контакт электрической цепи

P0555 – Датчик давления в системе усилителя тормозной системы — неисправность электрической цепи

P0556 – Датчик давления в системе усилителя тормозной системы — диапазон/функционирование

P0557 – Датчик давления в системе усилителя тормозной системы — низкий уровень сигнала

P0558 – Датчик давления в системе усилителя тормозной системы — высокий уровень входного сигнала

P0559 – Датчик давления в системе усилителя тормозной системы — ненадежный контакт электрической цепи

P0564 – Система поддержания скорости (круиз-контроль), многофункциональный переключатель (входной сигнал А) — неисправность электрической цепи

P0565 – Главный выключатель системы поддержания скорости (круиз-контроля), сигнал «ON» — неисправность

P0566 – Главный выключатель системы поддержания скорости (круиз-контроля), сигнал «OFF» — неисправность

P0567 – Переключатель выбора режима работы системы поддержания скорости (круиз-контроля), сигнал «RESUME» — неисправность

P0568 – Главный выключатель системы поддержания скорости (круиз-контроля), сигнал «SET» — неисправность

P0569 – Переключатель выбора режима работы системы поддержания скорости (круиз-контроля), сигнал «COAST» — неисправность

P0570 – Система поддержания скорости (круиз-контроль), сигнал датчика положения педали акселератора — неисправность

P0571 – Выключатель педали тормоза A (система поддержания скорости) — неисправность электрической цепи

P0572 – Концевой выключатель А педали тормоза (система поддержания скорости) — низкий уровень сигнала

P0573 – Концевой выключатель А педали тормоза (система поддержания скорости) — высокий уровень сигнала

P0574 – Система поддержания скорости (круиз-контроль) — слишком высокая скорость автомобиля

P0575 – Система поддержания скорости (круиз-контроль) — неисправность цепи входного сигнала

P0576 – Система поддержания скорости (круиз-контроль) — низкий уровень входного сигнала

P0577 – Система поддержания скорости (круиз-контроль) — высокий уровень входного сигнала

P0578 – Система поддержания скорости (круиз-контроль), многофункциональный переключатель (входной сигнал А) — цепь блокирована

P0579 – Система поддержания скорости (круиз-контроль), многофункциональный переключатель (входной сигнал А) — диапазон/функционирование

P0580 – Система поддержания скорости (круиз-контроль), многофункциональный переключатель (входной сигнал А) — низкий уровень сигнала

P0581 – Система поддержания скорости (круиз-контроль), многофункциональный переключатель (входной сигнал А) — высокий уровень сигнала

P0582 – Система поддержания скорости (круиз-контроль), управление разрежением — обрыв цепи

P0583 – Система поддержания скорости (круиз-контроль), управление разрежением — низкое напряжение цепи

P0584 – Система поддержания скорости (круиз-контроль), управление разрежением — высокое напряжение цепи

P0585 – Система поддержания скорости (круиз-контроль), многофункциональный переключатель (входной сигнал А/В) — корреляция

P0597 – Система управления нагревателем термостата — обрыв цепи

P0598 – Система управления нагревателем термостата — низкое напряжение цепи

P0599 – Система управления нагревателем термостата — высокое напряжение цепи

Электронный блок управления (ЭБУ) и его подсистемы

P0600-P0699

P0600 – Шина данных CAN — неисправность

P0601 – Электронный блок управления двигателем — ошибка контрольной суммы памяти

P0602 – Электронный блок управления двигателем — ошибка программирования

P0603 – Электронный блок управления двигателем — ошибка памяти КАМ

P0604 – Электронный блок управления двигателем — ошибка памяти RAM

P0605 – Электронный блок управления двигателем — ошибка памяти ROM

P0606 – Электронный блок управления двигателем (ECM) / блок управления силовым агрегатом (PCM) — неисправность процессора

P0607 – Электронный блок управления двигателем — функционирование

P0608 – Электронный блок управления двигателем, датчик скорости автомобиля (выходной сигнал А) — неисправность

P0609 – Электронный блок управления двигателем, датчик скорости автомобиля (выходной сигнал В) — неисправность

P0610 – Электронный блок управления двигателем — ошибка опции автомобиля

P0611 – Блок управления топливными форсунками — функционирование

P0612 – Блок управления топливными форсунками — цепь управления реле

P0613 – Электронный блок управления КПП (TCM) — ошибка процессора

P0614 – Электронный блок управления двигателем (ECM) / электронный блок управления КПП (TCM) — несоответствие

P0615 – Реле стартера — неисправность электрической цепи

P0616 – Реле стартера — низкий уровень сигнала

P0617 – Реле стартера — высокий уровень сигнала

P0618 – Блок управления подачей альтернативного топлива — ошибка памяти KAM

P0619 – Блок управления подачей альтернативного топлива — ошибка памяти RAM/ROM

P0620 – Управление генератором — неисправность электрической цепи

P0621 – Индикатор зарядки — неисправность электрической цепи

P0622 – Генератор, управление обмоткой возбуждения — неисправность электрической цепи

P0623 – Индикатор зарядки, управление — неисправность электрической цепи

P0624 – Индикатор незакрытой крышки заливной горловины, управление — неисправность электрической цепи

P0625 – Вывод обмотки возбуждения генератора — низкий уровень сигнала

P0626 – Вывод обмотки возбуждения генератора — высокий уровень сигнала

P0627 – Управление топливным насосом — обрыв цепи

P0628 – Управление топливным насосом — низкий уровень сигнала

P0629 – Управление топливным насосом — высокий уровень сигнала

P0630 – VIN не запрограммирован или не подходит — ECM/PCM

P0631 – Не запрограммирован электронный блок управления АКПП или не соответствует идентификационному номеру автомобиля

P0632 – Не запрограммирован одометр — ECM/PCM

P0633 – Не запрограммирован ключ иммобилайзера — ECM/PCM

P0634 – Электронный блок управления силовым агрегатом/двигателем/КПП (PCM/ECM/TCM) — высокая внутренняя температура

P0635 – Управление усилителем рулевого управления — неисправность электрической цепи

P0636 – Управление усилителем рулевого управления — низкий уровень сигнала

P0637 – Управление усилителем рулевого управления — высокий уровень сигнала

P0638 – Управление приводом дроссельной заслонки, банк 1 — диапазон/функционирование

P0639 – Управление приводом дроссельной заслонки, банк 2 — диапазон/функционирование

P0640 – Управление подогревом воздуха на впуске — неисправность электрической цепи

P0641 – Опорное напряжение датчика A — обрыв цепи

P0642 – Опорное напряжение датчика A — низкий уровень сигнала

P0643 – Опорное напряжение датчика A — высокий уровень сигнала

P0644 – Дисплей водителя, обмен данными (последовательный) — неисправность электрической цепи

P0645 – Реле электромагнитной муфты компрессора кондиционера — неисправность электрической цепи

P0646 – Реле электромагнитной муфты компрессора кондиционера — низкий уровень сигнала

P0647 – Реле электромагнитной муфты компрессора кондиционера — высокий уровень сигнала

P0648 – Индикатор иммобилайзера, управление — неисправность электрической цепи

P0649 – Индикатор системы поддержания скорости (круиз-контроля), управление — неисправность цепи

P0650 – Индикатор неисправности (MIL), управление — неисправность электрической цепи

P0651 – Опорное напряжение датчика B — обрыв цепи

P0652 – Опорное напряжение датчика B — низкий уровень

P0653 – Опорное напряжение датчика B — высокое напряжение цепи

P0654 – Частота вращения коленчатого вала, выходной сигнал — неисправность электрической цепи

P0655 – Индикатор перегрева двигателя — неисправность электрической цепи

P0656 – Индикация уровня топлива — неисправность электрической цепи

P0666 – Датчик внутренней температуры электронного блока управления двигателем/КПП/силового агрегата (ECM/PCM/TCM) — неисправность электрической цепи

P0667 – Датчик внутренней температуры электронного блока управления двигателем/КПП/силового агрегата (ECM/PCM/TCM) — диапазон/функционирование

P0668 – Датчик внутренней температуры электронного блока управления двигателем/КПП/силового агрегата (ECM/PCM/TCM) — низкий уровень сигнала

P0669 – Датчик внутренней температуры электронного блока управления двигателем/КПП/силового агрегата (ECM/PCM/TCM) — высокий уровень сигнала

P0670 – Блок управления свечами накаливания — неисправность электрической цепи

P0671 – Свеча накаливания, цилиндр 1 — неисправность электрической цепи

P0672 – Свеча накаливания, цилиндр 2 — неисправность электрической цепи

P0673 – Свеча накаливания, цилиндр 3 — неисправность электрической цепи

P0674 – Свеча накаливания, цилиндр 4 — неисправность электрической цепи

P0675 – Свеча накаливания, цилиндр 5 — неисправность электрической цепи

P0676 – Свеча накаливания, цилиндр 6 — неисправность электрической цепи

P0677 – Свеча накаливания, цилиндр 7 — неисправность электрической цепи

P0678 – Свеча накаливания, цилиндр 8 — неисправность электрической цепи

P0683 – Связь блока управления свечами накаливания с ECM/PCM

P0684 – Связь блока управления свечами накаливания с ECM/PCM, ошибка связи — диапазон/функционирование

P0685 – Реле системы управления двигателем — обрыв цепи

P0686 – Реле системы управления двигателем — низкий уровень сигнала

P0687 – Реле системы управления двигателем — короткое замыкание на массу

P0688 – Реле системы управления двигателем — короткое замыкание на «+»

P0689 – Реле системы управления двигателем — низкий уровень сигнала в контрольной цепи

P0690 – Реле системы управления двигателем — высокий уровень сигнала в контрольной цепи

P0691 – Электродвигатель вентилятора 1 системы охлаждения — низкий уровень сигнала

P0692 – Электродвигатель вентилятора 1 системы охлаждения — высокий уровень сигнала

P0693 – Электродвигатель вентилятора 2 системы охлаждения — низкий уровень сигнала

P0694 – Электродвигатель вентилятора 2 системы охлаждения — высокий уровень сигнала

P0695 – Электродвигатель вентилятора 3 системы охлаждения — низкий уровень сигнала

P0696 – Электродвигатель вентилятора 3 системы охлаждения — высокий уровень сигнала

Трансмиссия

P0700-P0799, P0800-P0899, P0900-P0999

P0700 – Управление АКПП, запрос неисправностей (MIL) — неисправность электрической цепи

P0701 – Система управления АКПП — диапазон/функционирование

P0702 – Система управления АКПП — электрическая неисправность

P0703 – Выключатель стоп-сигналов B — неисправность электрической цепи

P0704 – Концевой выключатель (датчик положения) педали сцепления — неисправность электрической цепи

P0705 – Датчик положения селектора АКПП, входной сигнал PRNDL — неисправность электрической цепи

P0706 – Датчик положения селектора КПП — диапазон/функционирование

P0707 – Датчик положения селектора АКПП — низкий уровень сигнала

P0708 – Датчик положения селектора АКПП — высокий уровень входного сигнала

P0709 – Датчик положения селектора АКПП — ненадежный контакт электрической цепи

P0710 – Датчик температуры рабочей жидкости АКПП — неисправность электрической цепи

P0711 – Датчик температуры рабочей жидкости КПП — диапазон/функционирование

P0712 – Датчик температуры рабочей жидкости КПП — низкий уровень сигнала

P0713 – Датчик температуры рабочей жидкости КПП — высокий уровень входного сигнала

P0714 – Датчик температуры рабочей жидкости КПП — ненадежный контакт электрической цепи

P0715 – Датчик частоты вращения входного вала АКПП (турбины гидротрансформатора) — неисправность электрической цепи

P0716 – Датчик частоты вращения входного вала АКПП (турбины гидротрансформатора) — диапазон/функционирование

P0717 – Датчик частоты вращения входного вала АКПП (турбины гидротрансформатора) — нет сигнала

P0718 – Датчик частоты вращения входного вала АКПП (турбины гидротрансформатора) — ненадежный контакт электрической цепи

P0719 – Выключатель стоп-сигналов B — низкий уровень сигнала

P0720 – Датчик частоты вращения выходного вала — неисправность электрической цепи

P0721 – Датчик частоты вращения выходного вала — диапазон/функционирование

P0722 – Датчик частоты вращения выходного вала — нет сигнала

P0723 – Датчик частоты вращения выходного вала — ненадежный контакт электрической цепи

P0724 – Выключатель стоп-сигналов B — высокий уровень сигнала

P0725 – Частота вращения коленчатого вала, входной сигнал — неисправность электрической цепи

P0726 – Частота вращения коленчатого вала, входной сигнал — диапазон/функционирование

P0727 – Частота вращения коленчатого вала, входной сигнал — нет сигнала

P0728 – Частота вращения коленчатого вала, входной сигнал — ненадежный контакт электрической цепи

P0729 – 6-я передача — некорректное передаточное отношение

P0730 – Некорректное передаточное отношение

P0731 – 1-я передача — некорректное передаточное отношение

P0732 – 2-я передача — некорректное передаточное отношение

P0733 – 3-я передача — некорректное передаточное отношение

P0734 – 4-я передача — некорректное передаточное отношение

P0735 – 5-я передача — некорректное передаточное отношение

P0736 – Передача заднего хода — некорректное передаточное отношение

P0737 – Электронный блок управления АКПП, частота вращения — выходная цепь

P0738 – Электронный блок управления АКПП, частота вращения — низкий уровень выходного сигнала

P0739 – Электронный блок управления АКПП, частота вращения — высокий уровень выходного сигнала

P0740 – Электромагнитный клапан муфты блокировки гидротрансформатора — неисправность электрической цепи

P0741 – Электромагнитный клапан муфты блокировки гидротрансформатора — функционирование или «залипание» в закрытом состоянии

P0742 – Электромагнитный клапан муфты блокировки гидротрансформатора — «залипание» в открытом состоянии

P0743 – Электромагнитный клапан муфты блокировки гидротрансформатора — электрическая неисправность

P0744 – Электромагнитный клапан муфты блокировки гидротрансформатора — ненадежный контакт электрической цепи

P0745 – Электромагнитный клапан управления давлением рабочей жидкости КПП — неисправность электрической цепи

P0746 – Электромагнитный клапан управления давлением рабочей жидкости КПП — функционирование или «залипание» в закрытом состоянии

P0747 – Электромагнитный клапан управления давлением рабочей жидкости КПП — «залипание» в открытом состоянии

P0748 – Электромагнитный клапан управления давлением рабочей жидкости КПП — электрическая неисправность

P0749 – Электромагнитный клапан управления давлением рабочей жидкости КПП — ненадежный контакт электрической цепи

P0750 – Э/м клапан А переключения передач — неисправность электрической цепи

P0751 – Э/м клапан А переключения передач — функционирование или «залипание» в закрытом состоянии

P0752 – Э/м клапан А переключения передач — «залипание» в открытом состоянии

P0753 – Э/м клапан А переключения передач — электрическая неисправность

P0754 – Э/м клапан А переключения передач — ненадежный контакт электрической цепи

P0755 – Э/м клапан В переключения передач — неисправность электрической цепи

P0756 – Э/м клапан В переключения передач — функционирование или «залипание» в закрытом состоянии

P0757 – Э/м клапан В переключения передач — «залипание» в открытом состоянии

P0758 – Э/м клапан В переключения передач — электрическая неисправность

P0759 – Э/м клапан B переключения передач — ненадежный контакт электрической цепи

P0760 – Э/м клапан С переключения передач — неисправность электрической цепи

P0761 – Э/м клапан С переключения передач — функционирование или «залипание» в закрытом состоянии

P0762 – Э/м клапан С переключения передач — «залипание» в открытом состоянии

P0763 – Э/м клапан С переключения передач — электрическая неисправность

P0764 – Э/м клапан C переключения передач — ненадежный контакт электрической цепи

P0765 – Э/м клапан D переключения передач — неисправность электрической цепи

P0766 – Э/м клапан D переключения передач — функционирование или «залипание» в закрытом состоянии

P0767 – Э/м клапан D переключения передач — «залипание» в открытом состоянии

P0768 – Э/м клапан D переключения передач — электрическая неисправность

P0769 – Э/м клапан D переключения передач — ненадежный контакт электрической цепи

P0770 – Э/м клапан E переключения передач — неисправность электрической цепи

P0771 – Э/м клапан E переключения передач — функционирование или «залипание» в закрытом состоянии

P0772 – Э/м клапан E переключения передач — «залипание» в открытом состоянии

P0773 – Э/м клапан E переключения передач — электрическая неисправность

P0774 – Э/м клапан E переключения передач — ненадежный контакт электрической цепи

P0775 – Э/м клапан В управления давлением — неисправность

P0776 – Э/м клапан B управления давлением — функционирование или «залипание» в закрытом состоянии

P0777 – Э/м клапан В управления давлением — «залипание» в открытом состоянии

P0778 – Э/м клапан В управления давлением — электрическая неисправность

P0779 – Э/м клапан В управления давлением — ненадежный контакт электрической цепи

P0780 – Выбор передачи — неисправность переключения

P0781 – Выбор передачи, 1-2 — неисправность переключения

P0782 – Выбор передачи, 2-3 — неисправность переключения

P0783 – Выбор передачи, 3-4 — неисправность переключения

P0784 – Выбор передачи, 4-5 — неисправность переключения

P0785 – Электромагнитный клапан переключения / синхронизации передач — неисправность электрической цепи

P0786 – Электромагнитный клапан переключения / синхронизации передач — диапазон/функционирование

P0787 – Электромагнитный клапан синхронизации переключения передач — низкий уровень

P0788 – Электромагнитный клапан синхронизации переключения передач — высокий уровень

P0789 – Электромагнитный клапан синхронизации переключения передач — ненадежный контакт электрической цепи

P0790 – Переключатель выбора режима работы АКПП — неисправность электрической цепи

P0791 – Датчик частоты вращения промежуточного вала КПП — неисправность электрической цепи

P0792 – Датчик частоты вращения промежуточного вала КПП — диапазон/функционирование

P0793 – Датчик частоты вращения промежуточного вала КПП — нет сигнала

P0794 – Датчик частоты вращения промежуточного вала КПП — ненадежный контакт электрической цепи

P0795 – Э/м клапан С управления давлением рабочей жидкости КПП — неисправность электрической цепи

P0796 – Э/м клапан C управления давлением рабочей жидкости КПП — функционирование или «залипание» в закрытом состоянии

P0797 – Э/м клапан C управления давлением рабочей жидкости КПП — «залипание» в открытом состоянии

P0798 – Э/м клапан С управления давлением рабочей жидкости КПП — электрическая неисправность

P0799 – Э/м клапан C управления давлением рабочей жидкости КПП — ненадежный контакт электрической цепи

P0800 – Управление раздаточной коробкой, запрос неисправностей (MIL) — неисправность электрической цепи

P0801 – Цепь блокировки включения передачи заднего хода — неисправность электрической цепи

P0802 – Управление АКПП, запрос неисправностей (MIL) — обрыв цепи

P0803 – Электромагнитный клапан цепи повышения передачи (1-4 передача), пропуски при переключении — неисправность электрической цепи

P0804 – Индикатор пропуска переключения в цепи повышения передачи (1-4 передача) — неисправность электрической цепи

P0805 – Датчик положения сцепления (муфты) — неисправность электрической цепи

P0806 – Датчик положения сцепления (муфты) — диапазон/функционирование

P0807 – Датчик положения сцепления (муфты) — низкий уровень сигнала

P0808 – Датчик положения сцепления (муфты) — высокий уровень сигнала

P0809 – Датчик положения сцепления (муфты) — ненадежный контакт электрической цепи

P0810 – Ошибка в управлении сцеплением (муфтой)

P0811 – Повышенное проскальзывание сцепления (муфты)

P0812 – Передача заднего хода — неисправность входной цепи

P0813 – Передача заднего хода — неисправность выходной цепи

P0814 – Индикатор положения селектора — неисправность электрической цепи

P0815 – Переключатель выбора передач КПП, повышение передачи — неисправность электрической цепи

P0816 – Переключатель выбора передач КПП, понижение передачи — неисправность электрической цепи

P0817 – Цепь блокировки стартера — неисправность

P0818 – Датчик-выключатель разъединения потока мощности — неисправность электрической цепи

P0819 – Переключатель выбора передач КПП, повышение/понижение передачи — корреляция с диапазоном

P0820 – Датчик положения X-Y рычага переключения — неисправность электрической цепи

P0821 – Датчик положения X рычага переключения — неисправность электрической цепи

P0822 – Датчик положения Y рычага переключения — неисправность электрической цепи

P0823 – Датчик положения X рычага переключения — ненадежный контакт электрической цепи

P0824 – Датчик положения Y рычага переключения — ненадежный контакт электрической цепи

P0825 – Переключатель положения (рычаг переключения качающегося типа) — неисправность электрической цепи

P0826 – Переключатель выбора передач КПП, повышение/понижение передачи — неисправность электрической цепи

P0827 – Переключатель выбора передач КПП, повышение/понижение передачи — низкий уровень сигнала

P0828 – Переключатель выбора передач КПП, повышение/понижение передачи — высокий уровень сигнала

P0829 – Переключение с 5-й на 6-ю передачу

P0830 – Концевой выключатель (датчик положения) А педали сцепления — неисправность электрической цепи

P0831 – Концевой выключатель (датчик положения) А педали сцепления — низкий уровень сигнала

P0832 – Концевой выключатель (датчик положения) А педали сцепления — высокий уровень сигнала

P0833 – Концевой выключатель (датчик положения) B педали сцепления — неисправность электрической цепи

P0834 – Концевой выключатель (датчик положения) B педали сцепления — низкий уровень входного сигнала

P0835 – Концевой выключатель (датчик положения) В педали сцепления — высокий уровень входного сигнала

P0836 – Выключатель режима 4WD — неисправность электрической цепи

P0837 – Выключатель режима 4WD — диапазон/функционирование

P0838 – Выключатель режима 4WD — низкий уровень сигнала

P0839 – Выключатель режима 4WD — высокий уровень входного сигнала

P0840 – Датчик А давления рабочей жидкости КПП — неисправность электрической цепи

P0841 – Датчик А давления рабочей жидкости КПП — диапазон/функционирование

P0842 – Датчик А давления рабочей жидкости КПП — низкий уровень сигнала

P0843 – Датчик А давления рабочей жидкости КПП — высокий уровень сигнала

P0844 – Датчик А давления рабочей жидкости АКПП — ненадежный контакт электрической цепи

P0845 – Датчик B давления рабочей жидкости КПП — неисправность электрической цепи

P0846 – Датчик В давления рабочей жидкости КПП — диапазон/функционирование

P0847 – Датчик B давления рабочей жидкости КПП — низкий уровень входного сигнала

P0848 – Датчик В давления рабочей жидкости КПП — высокий уровень входного сигнала

P0849 – Датчик B давления рабочей жидкости КПП — ненадежный контакт электрической цепи

P0850 – Выключатель запрещения запуска («P»/»N») — неисправность цепи входного сигнала

P0851 – Выключатель запрещения запуска («P»/»N») — низкий уровень входного сигнала

P0852 – Выключатель запрещения запуска («P»/»N») — высокий уровень входного сигнала

P0853 – Выключатель режима движения — неисправность цепи входного сигнала

P0854 – Выключатель режима движения — низкий уровень входного сигнала

P0855 – Выключатель режима движения — высокий уровень входного сигнала

P0856 – Входной сигнал противобуксовочной системы — неисправность

P0857 – Входной сигнал противобуксовочной системы — диапазон/функционирование

P0858 – Входной сигнал противобуксовочной системы — низкий уровень

P0859 – Входной сигнал противобуксовочной системы — высокий уровень

P0860 – Линия связи блока управления переключением — неисправность

P0861 – Линия связи блока управления переключением — низкий уровень сигнала

P0862 – Линия связи блока управления переключением — высокий уровень входного сигнала

P0863 – Электронный блок управления КПП (TCM), связь — неисправность электрической цепи

P0864 – Электронный блок управления КПП (TCM), связь — диапазон/функционирование

P0865 – Электронный блок управления КПП (TCM), связь — низкий уровень входного сигнала

P0866 – Электронный блок управления КПП (TCM), связь — высокий уровень входного сигнала

P0867 – Датчик давления рабочей жидкости АКПП

P0868 – Датчик давления рабочей жидкости АКПП — низкое

P0869 – Датчик давления рабочей жидкости АКПП — высокое

P0870 – Датчик C давления рабочей жидкости КПП — неисправность электрической цепи

P0871 – Датчик С давления рабочей жидкости КПП — диапазон/функционирование

P0872 – Датчик C давления рабочей жидкости КПП — низкий уровень сигнала

P0873 – Датчик C давления рабочей жидкости КПП — высокий уровень сигнала

P0874 – Датчик C давления рабочей жидкости КПП — ненадежный контакт электрической цепи

P0875 – Датчик D давления рабочей жидкости АКПП — неисправность электрической цепи

P0876 – Датчик D давления рабочей жидкости КПП — диапазон/функционирование

P0877 – Датчик D давления рабочей жидкости АКПП — низкое напряжение цепи

P0878 – Датчик D давления рабочей жидкости АКПП — высокое напряжение цепи

P0879 – Датчик D давления рабочей жидкости КПП — ненадежный контакт электрической цепи

P0880 – Электронный блок управления АКПП — неисправность цепи питания

P0881 – Электронный блок управления АКПП — неисправность цепи питания (диапазон / функционирование)

P0882 – Электронный блок управления АКПП — низкое напряжение цепи питания

P0883 – Электронный блок управления АКПП — высокое напряжение цепи питания

P0884 – Электронный блок управления КПП (TCM), входной сигнал питания — ненадежный контакт электрической цепи

P0885 – Реле питания электронного блока управления КПП (TCM), управление — обрыв цепи

P0886 – Реле питания электронного блока управления КПП (TCM), управление — низкий уровень сигнала

P0887 – Реле питания электронного блока управления КПП (TCM), управление — высокий уровень сигнала

P0888 – Реле питания электронного блока управления КПП (TCM) — неисправность контрольной цепи