Продолжаем серию наших обзоров, посвященных скрупулезному рассмотрению ошибок, возникающих на ризографе. Ранее мы рассмотрели уже большую часть ошибок. Теперь пришло время рассмотреть во всех подробностях ошибки, которые так или иначе связаны с индикатором «i».

Для правильной и качественной работы ризографу необходима информация технического характера, которая описывает установленные в ризограф расходные материалы. Может случиться так, что вы заправили неподходящую краску и тогда на экране количества копий сразу же возникнет латинская буква «H», которая будет говорить, что информация, которая была считана с чипа тубы краски не допустима на данной модели. И для решения данной проблемы вам достаточно задать необходимые параметры для нормальной работы ризографа.

Из ранее сказанного вытекает вывод, что сигнализация данного индикатора – это больше информация технического характера, чем ошибка, поэтому, даже если вы зададите неверный параметр, то ризограф от этого не сломается, а просто будет некачественно печатать.

-

Код ошибки H1 (место положения 3, красящий цилиндр)

Описание.

Данный код сообщает, что ризограф не может определить цвет краски в красящем цилиндре.Устранение.

Для исправления данной ситуации вам достаточно задать параметр 1 для черных чернил или параметр 2 для цветных. -

Код ошибки H2 (место положения 3, красящий цилиндр)

Описание.

Необходима надстройка прижима для чернил.Устранение.

Данный код говорит, что вам необходимо отрегулировать силу прижима в зависимости от используемых чернил, т.е. вам надо задать кол-во чернил для подачи, что прямо отразится от насыщенности оттиска. Так параметр 1 соответствует светлой заливке, а параметр 5 темной. -

Код ошибки H3 (место положения 3, красящий цилиндр)

Описание.

Регулировка плотности контрольного оттиска.Устранение.

Принцип схож с кодом ошибки H2. Только данная настройка осуществляется конкретно для пробного оттиска и не зависит от H2. -

Код ошибки H4 (место положения 4, узел изготовления мастера)

Описание.

Необходимо задать плотность прожига кадра мастер-пленки.Устранение.

Здесь нужно отрегулировать опорный прижим для изготовления мастера, т.е. от 1 (светлой) к 10 (темной). -

Код ошибки H5 (место положения 4, узел изготовления мастера)

Описание.

Необходима настройка прижима мастер-пленки.Устранение.

Для того, чтобы отрегулировать прижим мастер-пленки, вам нужно задать требуемый параметр от 1 к 5 или от светлого к темному. -

Код ошибки H6 (место положения 4, узел изготовления мастера)

Описание.

Необходимо задать плотность прожига кадра мастер-пленки для пробного оттиска.Устранение.

Все точно также, как в пункте 4, только эта настройка производится конкретно для пробного оттиска.

В силу того, что вы можете не владеть информацией с правильными настройками, рекомендуем вам настраивать выше указанные параметры постепенно от меньшего к большому по достижению необходимого вам качества печати.

Таким образом, чтобы задать нужный вам параметр необходимо ввести его значение с помощью клавиатуры количества копий, а затем нажать кнопку «старт» для завершения установки.

Вот мы и разобрались с ошибками, которые могут возникать на ризографе. Теперь вы сможете сэкономить на ненужном вызове специалиста, т.к. теперь вы можете сами исправить большинство «дежурных» ошибок. Желаем вам удачной и без ошибок работы вашего ризографа.

|

Type |

Point |

Description |

|

A01 |

201 |

Master-positioning sensor does not go ON even after the write pulse motor is activated during the master-positioning, master-cut, or master-loading operation. |

|

A01 |

202 |

Master-positioning sensor does not go OFF even when the write pulse motor is reversed during the master-positioning or at start of master-making operation. |

|

A01 |

206 |

Timeout error during master-making operation |

|

A01 |

211 |

Master-positioning sensor is ON during standby. |

|

A01 |

214 |

Master-positioning sensor is ON at the start of master making. |

|

A01 |

215 |

Faulty gate-array control for the write pulse motor (motor does not stop within set time) |

|

A02 |

509 |

Master-loading sensor was OFF when the master was checked at a specified drum angle during the master-loading operation. |

|

A04 |

303 |

Master-disposal jam sensor was OFF at both 120 and 180 degrees drum angle. |

|

A04 |

314 |

Master-disposal error (recovery error). |

|

A05 |

304 |

Master-disposal jam sensor was ON at the completion of the master-disposal operation. |

|

A05 |

312 |

The master-disposal jam sensor was ON at the start of master-making operation. |

|

A05 |

315 |

The master-disposal jam sensor was ON when the master disposal box was set in the machine. |

|

A06 |

403 |

Paper-feed-tray upper or lower safety switch is OFF. |

|

A07 |

409 |

Paper-ejection sensor was OFF when the paper should have arrived, and the paper sensor was ON when the machine stopped (Paper misfeed). |

|

A07 |

412 |

Paper sensor was OFF three times in succession when a paper misfeed was detected (paper misfeed). |

|

A07 |

413 |

Paper sensor was ON when the paper should have left the paper sensor (long-length paper mode error). |

|

A07 |

418 |

The paper sensor was ON at the start of machine operation when the START button was pressed. |

|

A07 |

429 |

Paper feed error (recovery error). |

|

A07 |

432 |

Paper sensor was ON when the machine went into paper feed retry movement after a paper misfeed. |

|

A08 |

410 |

Paper-ejection sensor was OFF when paper should have arrived, and the paper sensor was OFF when the machine stopped (paper jam on the print drum). |

|

A08 |

421 |

Paper sensor was ON when the paper should have left the paper sensor during feeding of long paper in long-length paper mode (paper longer than 555 mm). |

|

A08 |

430 |

Paper jam on print drum (recovery error). |

|

A09 |

411 |

Paper-ejection sensor was ON when the paper should have left the paper-ejection sensor. |

|

A09 |

417 |

Paper-ejection sensor was ON at the start of machine operation when the START button was pressed. |

|

A09 |

431 |

Paper-ejection error (recovery error). |

|

A10 |

102 |

Original-registration-sensor remaining jam |

|

A10 |

103 |

Original-IN-sensor remaining jam |

|

A10 |

105 |

Original-registration-sensor non-arrival jam |

|

A10 |

106 |

Original-IN-sensor non-arrival jam |

|

A10 |

107 |

Original-OUT-sensor non-arrival jam |

|

A10 |

109 |

An original feed error occurred, due to opening the AF. |

|

A10 |

162 |

No original in AF during AF master making. |

|

A16 |

525 |

Waiting for the master to be removed. |

|

A17 |

209 |

Cutter home-position switch is OFF at the start of master-making or master-set operation. |

|

A34 |

218 |

Request to resetting the master. |

|

B01 |

730 |

Keycard counter: No card |

|

B22 |

721 |

With the «Tape separation» function set ON, no power is supplied to the job separator when start key is pressed. |

|

B22 |

727 |

After cluster-A signal turned ON, BUSY-signal stayed «L» more than 7 seconds (power to job separator was turned OFF while the tape is being ejected. |

|

B23 |

722 |

With the «Tape separation» function set ON, no tape detected in the job separator when the start key is pressed. |

|

B23 |

723 |

No tape remains in job separator upon completion of the tape-ejection operation. |

|

B24 |

724 |

Tape jam detected when the start key is pressed with the «Tape separation» function set to ON. |

|

B24 |

725 |

Job separator tape-jam detection signal is «H» within 1,200 milliseconds after the cluster-A signal turns ON (tape misfeed). |

|

B24 |

726 |

Job separator tape-jam detection signal is «L» when the BUSY signal changes from «L» to «H» (or after 7 sec. at «L») after the cluster-A signal goes ON (tape misfeed). |

|

B31 |

916 |

Network cable is not connected when the machine is powered ON. |

|

B32 |

917 |

Communication error on the network. |

|

B32 |

920 |

Error detected by Network Interface Card (NIC) — NAK (negative acknowledgement was received). |

|

B33 |

931 |

DHCP server is not found with DHCP ON. |

|

B34 |

919 |

Error detected on the locally connected printer. |

|

C01 |

512 |

The ink sensor did not go ON even when inking was performed for the preset period. |

|

C01 |

563 |

Ink remaining amount is zero. |

|

C01 |

574 |

Inkless error was detected 5 times consecutively on one same ink bottle. |

|

C02 |

200 |

The master end was detected twice in succession at 10-milliseconds intervals during master transport. |

|

C02 |

240 |

Master remaining amount is zero |

|

C02 |

253 |

Masterless error was detected twice consecutively on one same master-roll. |

|

C03 |

308 |

Compression detection position was reached before the master-compression-motor encoder-sensor count reached the specified level, after the master compression motor turned ON in the compression direction. |

|

C03 |

313 |

Master removal box full detected by the master removal count. |

|

C04 |

402 |

Paper detection sensor is OFF (no paper on the feed tray). |

|

D01 |

526 |

Print drum is not set in the machine (drum connection signal, drum safety switch, and drum-lock sensor is OFF. |

|

D01 |

527 |

Print drum connection signal is OFF when the print drum was inserted in the machine. |

|

D01 |

528 |

Print drum safety switch is OFF when the print drum was inserted in the machine. |

|

D01 |

529 |

Print drum lock sensor is OFF when the print drum was inserted in the machine (time-out: 5 seconds). |

|

D01 |

530 |

Print drum connection signal does not go OFF within 5 seconds after the print drum safety switch went OFF when the print drum was pulled out. |

|

D02 |

532 |

Incorrect print drum is used. |

|

D03 |

533 |

Ink cartridge set sensor is OFF. |

|

D04 |

534 |

Incorrect ink cartridge is used. |

|

D04 |

560 |

Ink TAG is not detected on ink bottle. |

|

D04 |

561 |

Ink cartridge communication error (communication with the ink cartridge was interfered by noise). |

|

D04 |

562 |

Wrong ink cartridge information. |

|

D04 |

564 |

Detected a mismatch in ink cartridge information |

|

D05 |

210 |

Master detection sensor is OFF (not detecting master). |

|

D07 |

310 |

Disposal-box safety switch is OFF. |

|

D08 |

224 |

Master making unit is not set (both the safety switch and lock sensor are OFF). |

|

D08 |

226 |

Master making unit safety switch is still OFF when the master making unit is set in position. |

|

D08 |

227 |

Master making unit lock sensor is still OFF when the master making unit is set in position (timeout: 5 seconds). |

|

D08 |

228 |

Master making unit lock sensor is still ON even after the master making unit safety switch went OFF, when the master making unit was pulled out of the machine. |

|

D09 |

212 |

Master-making-unit set sensor is OFF (sensor light path is free). |

|

D11 |

535 |

Front cover set switch is OFF. |

|

D13 |

9 |

The rear cover is opened (serviceman safety switch is OFF). |

|

D17 |

236 |

Incorrect master roll. |

|

D17 |

237 |

Master roll undetected. |

|

D17 |

238 |

Master roll communication error. |

|

D17 |

239 |

Wrong master roll detected. |

|

D17 |

241 |

Detected a mismatch in master roll information. |

|

D18 |

522 |

Print drum ready for release (solenoid is ON). |

|

D19 |

223 |

Master making unit ready for release (solenoid is ON). |

|

D22 |

540 |

Error in access to the Drum PCB (unable to read from or write on the Drum PCB). |

|

D22 |

542 |

Abnormal data on Drum PCB. |

|

E01 |

10 |

Battery voltage was less than 2.5 V when the power was switched ON (weak battery: time to replace battery). |

|

E02 |

11 |

Master counter reached the value set for the maintenance call (value set by test mode). [The message appears when either the power is turned ON, the unit is reset, or when the machine operation ended.] |

|

E02 |

12 |

Copy counter reached the value set for the maintenance call (value by set test mode). [The message appears when either the power is turned ON, the unit is reset, or when the machine operation ended.] |

|

E02 |

22 |

Maintenance counter inside the print drum reached the value set for the maintenance call (value set by test mode). [The message appears when either the power is turned ON, the unit is reset, or when the machine operation ended.] |

|

F01 |

15 |

There is no master on the print drum at the start of printing. |

|

F02 |

18 |

Paper size does not match with the image size on the print drum at the start of printing. |

|

F03 |

16 |

Multi-up was selected using custom size paper. |

|

F05 |

19 |

In master making, the print quantity selected is less than the minimum print quantity. |

|

F10 |

21 |

Paper size does not match with the size of image on the print drum when test print is selected and activated. |

|

F21 |

32 |

Next original is not in placed on AF for multi-up operation. |

|

F22 |

33 |

Next original is not placed on flatbed for multi-up operation. |

|

F37 |

50 |

Original was set on the AF with book mode selected, when master making is activated. |

|

F50 |

910 |

Auto-printer-selection is disabled due to error on linked printer. |

|

F54 |

923 |

Auto-printer-selection is disabled due to no paper in the linked printer. |

|

F55 |

924 |

Auto-printer-selection is disabled while receiving print data from PC. |

|

F58 |

927 |

Cannot print from linked printer (Initializing NET-C). |

|

H1 |

566 |

Requesting ink color information input (Ink-TAG related). |

|

H2 |

567 |

Requesting print density information input (Ink-TAG related). |

|

H3 |

568 |

Requesting test printing print density information input (Ink-TAG related). |

|

H4 |

242 |

Requesting master-making density information input (Master-TAG related). |

|

H5 |

243 |

Requesting Print density information input (Master-TAG related). |

|

H6 |

244 |

Requesting test printing print density information input (Master-TAG related). |

|

P01 |

520 |

Main encoder sensor does not go ON/OFF within 10 milliseconds after the main motor activates. |

|

P01 |

521 |

B-positioning sensor status does not change even after 3,033 pulses after the main motor activates. |

|

P01 |

524 |

Clamp unit is not at the home position while the print drum is in operation (except during master disposal). |

|

P01 |

537 |

Print drum failed to stop at position B. (over-run) |

|

P01 |

538 |

Print drum is not locked during operation. (Print-drum lock position sensor: OFF) |

|

P02 |

400 |

Both the upper and lower limit sensors were ON at the same time. |

|

P02 |

401 |

Overload current was detected in the elevator motor. |

|

P02 |

404 |

The lower-limit sensor does not go OFF within 2 seconds after the elevator motor operates in the raising direction from the lower-limit position. |

|

P02 |

405 |

The upper-limit sensor does not go ON within 12 seconds after the elevator motor operates in the raising direction. |

|

P02 |

406 |

The upper-limit sensor does not go OFF within 2 seconds after the elevator motor operates in the lower direction from the upper-limit position. |

|

P02 |

407 |

The lower-limit sensor does not go ON within 12 seconds after the elevator motor operates in the lowering direction. |

|

P02 |

408 |

The upper-limit sensor is OFF continuously for over 2 seconds during operation of the elevator servo action to raise the feed tray. |

|

P03 |

500 |

Clamp sensor A is OFF after the completion of the clamp unit initialization or home positioning movement. |

|

P03 |

501 |

Clamp sensor B does not change within 1 second from the time the clamp motor operates in the correct direction. |

|

P03 |

502 |

Clamp sensor B does not change within 1 second from the time the clamp motor operates in the reverse direction. |

|

P03 |

503 |

Clamp sensor A does not go ON within 3 seconds when the clamp unit makes initialization movement. |

|

P03 |

504 |

At the start of Clamp plate open/close action, the the detection sequence of clamp-sensors A & B is abnormal. |

|

P03 |

505 |

At the start of print drum Positon-A compensation movement, the detection sequence of clamp-sensors A & B is abnormal. |

|

P03 |

506 |

At the start of Clamp unit Home-positioning movement, the detection sequence of clamp-sensors A & B is abnormal. |

|

P03 |

507 |

Clamp sensor A is ON after the clamp release action is completed. |

|

P03 |

508 |

Clamp sensor A is ON after the A-position compensating movement is completed. |

|

P03 |

545 |

Clamp unit is not in the home position while the print drum is in movement (cause due to the clamp motor). |

|

P04 |

513 |

The overflow sensor was ON for a set number of times in succession during the 10-millisecond-interval overflow-sensor check. |

|

P05 |

603 |

The vertical-centering sensor does not switch ON even when the vertical-positioning pulse motor activated in the image-down direction for 5 seconds during vertical home positioning movement. |

|

P05 |

604 |

The vertical-centering sensor does not switch OFF even when the vertical-positioning pulse motor activated in the image-up direction for 5 seconds during vertical home positioning movement. |

|

P05 |

605 |

Even though the vertical positioning motor stopped according to the vertical centering sensor detection, the stopping position does not correspond with the programmed position. (GA control error). |

|

P05 |

612 |

The one-step-positioning key was pressed with vertical-print-position information undefined. |

|

P08 |

951 |

Print job executed was not in correct RisoRinc format. |

|

P11 |

600 |

Print pressure HP sensor does not switch ON within 3.9 seconds after the print pressure pulse motor activated towards higher pressure during home positioning operation. |

|

P11 |

601 |

Print pressure HP sensor does not switch OFF within 4.6 seconds after the print pressure pulse motor activated towards lower pressure during home positioning operation. |

|

P11 |

602 |

Even though the print pressure control pulse motor stopped according to the print pressure HP sensor detection, the stopping position does not correspond with the programmed position. (GA control error). |

|

P12 |

301 |

Master compression motor lock when moving compression plate up. |

|

P12 |

305 |

Master compression sensor does not go ON within 6.5 seconds after the master compression motor operates in the return direction. |

|

P12 |

306 |

Master compression sensor does not go OFF within 2 seconds after the master compression motor operates in the compress direction. |

|

P12 |

307 |

Master compression plate maximum position is not detected within 6.5 seconds after the master compression motor operates in the compress direction. |

|

P12 |

309 |

Master-compression-motor encoder sensor count did not change as the master compression motor activated in the compress direction and moved out from the home position. |

|

P12 |

316 |

Master-compression-motor encoder sensor count did not change within 10 milliseconds after the master compression motor activated. |

|

P12 |

300 |

Overload current was detected in the master removal motor. |

|

P13 |

203 |

Cutter HP switch does not go OFF within 100 milliseconds after the cutter motor is activated. |

|

P13 |

204 |

Cutter HP switch does not go ON within 300 milliseconds after the cutter motor is activated. |

|

P13 |

205 |

Master-positioning sensor is ON when the print drum rotates through the preset angle following master cutting. |

|

P13 |

221 |

Both the cutter HP switch and cutter stop position switch are ON at the same time. |

|

P13 |

222 |

Cutter HP switch does not go ON within 450 milliseconds after the cutter home positioning operation started. |

|

P13 |

231 |

Cutter HP switch does not go OFF within 500 milliseconds after the cutter moved out from the home position. |

|

P13 |

232 |

Cutter stop position switch does not go ON within 2 seconds after the cutting operation started. |

|

P13 |

233 |

Cutter stop position switch does not go OFF within 500 milliseconds after the cutter activates to move from the stop position to the home position. |

|

P13 |

234 |

Cutter HP switch does not go ON within 2 seconds after the cutter home positioning operation started. |

|

P14 |

114 |

Incorrect main-unit data. |

|

P14 |

115 |

The scanner operation is not completed within the set time. |

|

P14 |

116 |

Timeout error for black shading compensation. (RZ3 series only) |

|

P14 |

117 |

Timeout error for white shading compensation. (RZ3 series only) |

|

P14 |

123 |

Offset adjustment not completed within set time. (RZ3 series only) |

|

P14 |

124 |

Gain adjustment not completed within set time. (RZ3 series only) |

|

P14 |

125 |

Offset adjustment not completed. |

|

P14 |

126 |

Gain adjustment not completed. |

|

P14 |

135 |

Malfunction detected during offset adjustment. (RZ3 series only) |

|

P14 |

136 |

Malfunction detected during offset adjustment. (RZ3 series only) |

|

P14 |

137 |

Malfunction detected during black shading compensation. (RZ3 series only) |

|

P14 |

138 |

Malfunction detected during white shading compensation. (RZ3 series only) |

|

P14 |

170 |

Even though the read pulse motor stopped according to the sensor detection, the stopping position does not correspond with the programmed position. (GA control error). |

|

P15 |

4 |

Communication error with AF-CPU. |

|

P15 |

110 |

ABC (auto-base-control) timeout. The original does not move from the ABC scanning position on the AF unit. |

|

P15 |

111 |

Operation command was made to the AF unit without 24 volts supplied to the AF unit. |

|

P15 |

130 |

Timeout error in receiving reply from the AF unit after command signal was sent from the Riso printer to the AF unit. |

|

P15 |

131 |

Riso printer received an undefined command from the AF unit. |

|

P15 |

132 |

Riso printer detected communication sequence error from the AF unit. |

|

P15 |

133 |

Communication error with AF unit (ACK or NAK error). |

|

P15 |

134 |

Riso printer could not send command to the AF unit within the set time. |

|

P15 |

160 |

AF unit detection signal went OFF while the AF unit is in operation. |

|

P17 |

20 |

Solenoid counter is not connected. |

|

P18 |

531 |

Print drum lock sensor is still ON even after 100 milliseconds after the print drum lock solenoid is activated. |

|

P19 |

207 |

TPH pressure sensor does not go OFF within 2 seconds after the thermal-pressure motor activates in the decompressing direction, or during home positioning operation. |

|

P19 |

208 |

TPH pressure sensor does not go ON within 2 seconds after the thermal-pressure motor activates in the decompressing direction. |

|

P19 |

216 |

TPH pressure sensor does not go OFF within 500 millisecond after the thermal-pressure motor activates in the compressing direction. |

|

P19 |

217 |

TPH pressure sensor does not go ON within 2 seconds after the thermal-pressure motor activates in the compressing direction. |

|

P20 |

415 |

Paper-ejection-wing home sensor does not go OFF within 7,000 milliseconds after the paper ejection wing motor activates in the counterclockwise direction from the home position. |

|

P20 |

416 |

Overload current was detected in the paper-ejection motor. |

|

P20 |

437 |

Paper-ejection encoder sensor status does not change within 10 milliseconds after the paper-ejection motor is activated. |

|

P24 |

539 |

Inking-motor encoder sensor status does not change within 20 milliseconds after the inking-motor is activated. |

|

P25 |

26 |

Battery voltage was below 2.3 volts (too low) when the power is turned ON. |

|

P92 |

570 |

EEPROM on the print drum PCB was being accessed while the print drum was in releasing action from the machine. |

|

P93 |

932 |

No reply from the NET-C network interface card while accessing to the network interface card. |

|

P93 |

933 |

No response from NET-C for 90 seconds during NET-C initialization. |

|

P94 |

225 |

TPH code does not match with the machine code when the power is turned ON with the master-making unit in operating position or when the master-making unit is inserted in operating position while the power is ON. |

|

P95 |

59 |

Machine serial-number information sent from SH-PCB does not match with the machine serial number information in the MCTL PCB. |

|

P96 |

171 |

TPH resistance value not input. |

|

P96 |

172 |

Scanner adjustment not completed. |

|

P96 |

433 |

Paper size width potentiometer test-mode setting is not completed. |

|

P96 |

569 |

Either the print drum color information or ink category information is still not input. |

|

P96 |

613 |

Print pressure data missing. |

|

P98 |

2 |

No reply from Mini-Rosa PCB when the machine power is turned ON even though the Rosa connection signal is ON. |

|

P98 |

5 |

Hardware error. |

|

P98 |

6 |

FRAM checksum error. |

|

P98 |

7 |

Mini Rosa PCB not connected. |

|

P98 |

38 |

Machine data on EEPROM does not match with that on the SH-PCB. |

|

P98 |

39 |

Improper EEPROM on the SH-PCB. |

|

P98 |

46 |

The DIMM capacity does not match. |

|

P98 |

51 |

Touch-panel communication error |

|

P98 |

53 |

Failure in calling out the saved Memory settings (program, mode, user paper information). |

|

P98 |

54 |

Failure in saving the Memory settings (program, mode, user paper information). |

|

P98 |

55 |

Machine type code from SH-PCB does not match with the machine information on the H8-PCB. |

|

P98 |

63 |

The test-mode memory data stored was outside the adjustment range. |

|

P98 |

64 |

An undefined command was sent in communication between SH-PCB and MCTL PCB. |

|

P98 |

65 |

Communication error 01 between SH-PCB and MCTL PCB (MCTL PCB side). |

|

P98 |

67 |

Communication error 03 between SH-PCB and MCTL PCB (MCTL PCB side). |

|

P98 |

68 |

Communication error 04 between SH-PCB and MCTL PCB (MCTL PCB side). |

|

P98 |

69 |

Communication error 05 between SH-PCB and MCTL PCB (MCTL PCB side). |

|

P98 |

70 |

Communication error 06 between SH-PCB and MCTL PCB (MCTL PCB side). |

|

P98 |

71 |

Communication error 07 between SH-PCB and MCTL PCB (MCTL PCB side). |

|

P98 |

72 |

Communication error 08 between SH-PCB and MCTL PCB (MCTL PCB side). |

|

P98 |

73 |

Communication error 09 between SH-PCB and MCTL PCB (MCTL PCB side). |

|

P98 |

74 |

Communication error 10 between SH-PCB and MCTL PCB (SH-PCB side) |

|

P98 |

75 |

Communication error 11 between SH-PCB and MCTL PCB (SH-PCB side) |

|

P98 |

76 |

Communication error 12 between SH-PCB and MCTL PCB (SH-PCB side) |

|

P98 |

77 |

Communication error 13 between SH-PCB and MCTL PCB (SH-PCB side) |

|

P98 |

78 |

Communication error 14 between SH-PCB and MCTL PCB (SH-PCB side) |

|

P98 |

79 |

Communication error 15 between SH-PCB and MCTL PCB (SH-PCB side) |

|

P98 |

80 |

Communication error 16 between SH-PCB and MCTL PCB (SH-PCB side) |

|

P98 |

81 |

Communication error 17 between SH-PCB and MCTL PCB (SH-PCB side) |

|

P98 |

82 |

Communication error 18 between SH-PCB and MCTL PCB (SH-PCB side) |

|

P98 |

83 |

Communication error 19 between SH-PCB and MCTL PCB (SH-PCB side) |

|

P98 |

84 |

Communication error 20 between SH-PCB and MCTL PCB (SH-PCB side) |

|

P98 |

98 |

Machine serial number information on the SH-PCB EEPROM does not match with that in the FRAM. |

|

P98 |

119 |

Image processing PCB trouble. |

|

P98 |

120 |

Scanner communication problem. (RZ3 series only) |

|

P98 |

129 |

Faulty Scanner GA PCB. (RZ3 series only) |

|

P98 |

245 |

Master transfer time-out error during master making (Write pulse motor error). |

|

P98 |

246 |

Master transfer time-out error during master making (Load pulse motor error). |

|

P98 |

614 |

Vertical print position data missing. |

|

P98 |

934 |

Main read/write communication error (detected by read/write side). |

|

P98 |

935 |

Main read/write communication error (detected by machine side). |

|

P98 |

937 |

Serial number data missing. |

|

P98 |

938 |

FRAM version-down. |

|

P98 |

947 |

24V-A does not go ON (a possible burnt 24-volt group-A fuse). |

|

P98 |

948 |

24V-B does not go ON (a possible burnt 24-volt group-B fuse). |

|

P98 |

949 |

24V-A does not go OFF. |

|

P98 |

950 |

24V-B does not fo OFF. |

|

P98 |

952 |

Checksum error on the ROSA flash-memory. |

|

P98 |

953 |

Unsuccessful writing on the ROSA flash-memory. |

|

P99 |

936 |

Software error |

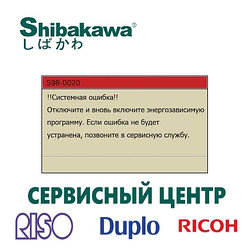

Как и обещали в этой статье пойдет речь о неисправностях требующие ремонт ризографа Riso CZ 180. Хотелось бы напомнить, что ризограф это сложный цифровой аппарат и не все ошибки пользователь может устранить сам. Поэтому прежде чем производить какие-либо действия взвесьте свои силы, чтобы после этого не обращаться к специалисту по дорогостоящему ремонту. Напомним, что индикация поломки ризографа состоит из шестизначных символов. Первые две цифры и буквы означают какой блок не работает, вторые три цифры через дефис поясняют, где она возникла.

Р01-заблокирован главный двигатель

Это системная ошибка связанная с блокировкой главного двигателя. Для её устранения нажмите клавишу RESET. Если P01 не исчезла вызовите сервисного инженера

| Трехзначное число | Возникновение неисправности |

| 520 | Сенсор энкодера не получил ответа в течении 10 мс после запуска главного мотора |

| 521 | Статус датчика позиции А не получил 3,033 импульсов после запуска главного двигателя |

| 524 | Пластина зажима не вернулась в начальное положение во время работы барабана (исключение во время выброса мастера) |

| 537 | Печатный барабан не остановился в позиции А |

Р02-заблокирован мотор лотка подъёма

Это системная ошибка вызванная с блокировкой электромотора подъёмного лотка. Чтобы устранить её нажмите клавишу RESET или включите, выключите аппарат. При повторном появлении вызовите сервисного инженера.

| Трехзначное число | Возникновение неисправности |

| 400 | Верхний и нижний датчик предела одновременно находится в включенном состоянии |

| 401 | В двигателе подъёмного лотка была обнаружена перегрузка по току |

| 404 | Нижний сенсор предела не выходит в выключенное состояние в течении двух секунд после запуска электродвигателя лотка |

| 405 | Датчик верхнего предела не включается в течении 12 секунд после запуска мотора лотка |

| 406 | Верхний сенсор предела не выключается в течении 2 секунд после работы двигателя лотка |

| 407 | Нижний датчик предела не включается в течении 12 секунд после запуска электромотора лотка |

| 408 | Верхний сенсор предела выключен более 2 секунд во время работы двигателя лотка |

Р03-заблокирован двигатель замка

Это системная ошибка вызванная блокировкой мотора зажима (СLAMP) Для устранения нажмите клавишу RESET, если не устранится вызовите сервисного инженера

| Трехзначное число | Возникновение неисправности |

| 500 | После завершения инициализации блок зажима не встал в выключенное положение |

| 501 | Во время работы мотора зажима датчик зажима не выключился в течении одной секунды |

| 502 | Во время работы электромотора зажима датчик не включился в течении 2,5 секунд |

| 504 | Во время начала зажима пластины обнаружен выключенный датчик зажима |

| 505 | При положении барабана в позиции А датчик зажима обнаружен в выключенном состоянии |

| 506 | В положении блока позиционирования зажима находясь в исходном состоянии датчик зажима включен |

| 507 | Сенсор зажима выключен после завершения открытия зажимной пластины |

| 508 | Опто-датчик зажима включен после движения барабана в позиции А |

| 515 | Барабан находится не в позиции А и не в позиции В, когда двигатель зажима начинает работать |

P04 — чернила переполнены

Системная ошибка вызванная переполнением чернил. после устранения переполнения чернил, нажмите клавишу Reset. Если неисправность осталось вызовите сервисного инженера.

| Трехзначное число | Возникновение неисправности |

| 513 | Сенсор переполнения включен более 10 мс. Проверти датчик переполнения. |

Р05 — блокировка мотора вертикального поднятия

Системная ошибка связанная с блокировкой мотора вертикального поднятия. Нажать клавишу «Reset» или выключить и включить питание. Если ошибка не устранилась, требуется ремонт сервисным инженером

| Трехзначное число | Возникновение неисправности |

| 603 | Не включился сенсор вертикального центрирования, даже когда импульсный двигатель вращает в нижнее положение. Нет ответа включения более 5 секунд |

| 604 | Датчик вертикального центрирование не выключился, в то время пока импульсный мотор вертикального положения двигается вверх в течении 5 секунд |

| 605 | Во время вертикального центрирования сенсор и импульсный двигатель работают, но позиция остановки не соответствует программному позиционированию. |

| 612 | Информация вертикального позиционирования не соответствует действительности |

Р08 — коммуникационная неисправность

Системная ошибка. устраняется включением выключением аппарата

| Трехзначное число | Возникновение неисправности |

| 951 | Не корректные данные RINC |

P12 заблокирован двигатель удаления мастера

Системная ошибка. Не работает двигатель или механизм удаления мастера. Устраняется нажатием клавиши «Reset»

| Трехзначное число | Возникновение неисправности |

| 301 | Блокировка электромотора прижимной пластины блока съема мастера |

| 302 | Двигатель прижимной пластины блока сжатия двигателя, работая в обратном направлении, в течении 3 секунд не выключил сенсор |

| 305 | При работе мотора блока съема мастера, работающий в режиме возврата, в течении 1 секунды не дал сигнал включения |

| 306 | В течении 3 секунд не поступил сигнал выключения, при направлении пластины в сторону сжатия |

| 309 | В направлении пластины в сторону сжатия не изменилось положения энкодера |

| 313 | при движении в направлении сжатия в течении 1 секунды не поступил сигнал выключения на опто пару |

| 316 | После активации двигателя блока выброса мастера с энкодера не поступил сигнал в течении 10 миллисекунд. |

Р13 — блокировка электродвигателя блока отреза мастера

Системная ошибка, связанная с блоком отреза мастера. Устраняется нажатием клавиши «Reset». В противном случае оправитесь в сервисный центр.

| Трехзначное число | Возникновение неисправности |

| 205 | Включен один из выключателей ножа при вращении барабана |

| 221 | Нож мастера находится в неверном положении |

| 222 | Переключатель не включается в течении 450 миллисекунд, после ухода ножа в начальное положение |

| 231 | Выключатель положения ножа не выключился в течении 500 миллисекунд, после начала отрезания |

| 232 | Переключатель ножа не включился в течении 2 секунд, после начала подачи команды отреза |

| 233 | Через 500 миллисекунд не перешел в выключенное состояния датчик ножа, после запуска резки пленки |

| 234 | Переключатель ножа не реагирует более 2 секунд, во время начала отрезания мастера |

Р17 — соленоид счетчика не подключен

Системная ошибка. Не подключен или обрыв электромагнита счетчика мастера или количества копии. Проверить цепь электромагнита или подключить счетчик. Требуется сервисный инженер.

| Трехзначное число | Возникновение неисправности |

| 020 | Счетчик количества мастер пленки не подключен |

| 021 | Счетчик количества копии не подключен |

Р20 — блокировка двигателя в блоке выхода бумаги

Неисправность в блоке выхода бумаги, блокировка мотора в блокею Нажать «Reset». Если неисправность осталось вызвать сервис.

| Трехзначное число | Возникновение неисправности |

| 437 | После активации электромотора выходного лотка, энкодер не выработал сигнал в течении 10 миллисекунд |

Р24 — блокировка помпы чернил

Системная ошибка. Неисправность помпы подачи краски. Нажмите клавишу «Reset» или выключите и включите аппарат. При повторной возникновении неисправности, обратитесь в сервис.

| Трехзначное число | Возникновение неисправности |

| 539 | FG сенсор не изменился, в течении 20 миллисекунд, после активации помпы |

Р93 — NET-C / NET-D аппаратная ошибка

Неисправность карты сетевого интерфейса. Выключите и включите аппарат. При повторном возникновении вызвать сервисного инженера.

| Трехзначное число | Возникновение неисправности |

| 932 | Нет ответа между сетевым интерфейсом аппарата и сетевой карты |

Р96 не введены данные

Системная ошибка. Не введены данные в аппарат. С помощью сервисного режима введите нужные параметры.

| Трехзначное число | Возникновение неисправности |

| 171 | Не введены значения TPH (термоголовки) |

| 172 | Не завершена настройка сканера |

Р98 — Аппаратная ошибка

Системная ошибка. Неисправность возникшая в сбои в электронных плат или аппарата. Выключите и включите аппарат. Вызвать сервисного инженера.

| Трехзначное число | Возникновение неисправности |

| 002 | Нет ответа от SH3M PCB |

| 005 | Аппаратная ошибка |

| 006 | Ошибка проверки суммы EEPROM |

| 025 | Дефект RF PCB. Неверные параметры инициализации RF PCB |

| 034 | Невозможно произвести запись в EEPROM/ Не удается получить доступ к EEPROM |

| 035 | Неисправность данных EEPROM |

| 039 | Неверный EEPROM |

| 053 | Неверные параметры пользовательских данных EEPROM |

| 054 | Неудачная запись параметров пользователя в EEPROM |

| 063 | Параметры тестового режима выходят за диапазон |

| 064 | Ошибка связи SH PCB and MCTL PCB |

| 065 | Ошибка связи SH PCB(01) and MCTL PCB |

| 067 | Ошибка связи SH PCB(02) and MCTL PCB |

| 068 | Ошибка связи SH PCB(03) and MCTL PCB |

| 069 | Ошибка связи SH PCB(04) and MCTL PCB |

| 070 | Ошибка связи SH PCB(05) and MCTL PCB |

| 071 | Ошибка связи SH PCB(06) and MCTL PCB |

| 072 | Ошибка связи SH PCB(07) and MCTL PCB |

| 072 | Ошибка связи SH PCB(08) and MCTL PCB |

| 073 | Ошибка связи SH PCB(09) and MCTL PCB |

| 074 | Ошибка связи SH PCB and MCTL PCB (10) — on SH PCB |

| 075 | Ошибка связи SH PCB and MCTL PCB (11) — on SH PCB |

| 076 | Ошибка связи SH PCB and MCTL PCB (12) — on SH PCB |

| 077 | Ошибка связи SH PCB and MCTL PCB (13) — on SH PCB |

| 078 | Ошибка связи SH PCB and MCTL PCB (14) — on SH PCB |

| 079 | Ошибка связи SH PCB and MCTL PCB (15) — on SH PCB |

| 080 | Ошибка связи SH PCB and MCTL PCB (16) — on SH PCB |

| 081 | Ошибка связи SH PCB and MCTL PCB (17) — on SH PCB |

| 082 | Ошибка связи SH PCB and MCTL PCB (18) — on SH PCB |

| 083 | Ошибка связи SH PCB and MCTL PCB (19) — on SH PCB |

| 084 | Ошибка связи SH PCB and MCTL PCB (20) — on SH PCB |

| 119 | Дефект платы изображения |

| 121 | Ошибка настройки сканера 1 |

| 122 | Ошибка настройки сканера 2 |

| 245 | Неисправность время ожидания изготовления мастера (related to Write pulse motor) |

| 246 | Неисправность время ожидания изготовления мастера (related to Load pulse motor). |

| 934 | Ошибка связи между MCTL PCB and RF PCB. (on RF PCB side) |

| 935 | Ошибка связи между MCTL PCB and RF PCB. (MCTL PCB side) |

| 938 | Неверная версия EEPROM |

Продолжаем серию наших обзоров, посвященных скрупулезному рассмотрению ошибок, возникающих на ризографе. Ранее мы рассмотрели уже большую часть ошибок. Теперь пришло время рассмотреть во всех подробностях ошибки, которые так или иначе связаны с индикатором «i».

Для правильной и качественной работы ризографу необходима информация технического характера, которая описывает установленные в ризограф расходные материалы. Может случиться так, что вы заправили неподходящую краску и тогда на экране количества копий сразу же возникнет латинская буква «H», которая будет говорить, что информация, которая была считана с чипа тубы краски не допустима на данной модели. И для решения данной проблемы вам достаточно задать необходимые параметры для нормальной работы ризографа.

Из ранее сказанного вытекает вывод, что сигнализация данного индикатора – это больше информация технического характера, чем ошибка, поэтому, даже если вы зададите неверный параметр, то ризограф от этого не сломается, а просто будет некачественно печатать.

-

Код ошибки H1 (место положения 3, красящий цилиндр)

Описание.

Данный код сообщает, что ризограф не может определить цвет краски в красящем цилиндре.Устранение.

Для исправления данной ситуации вам достаточно задать параметр 1 для черных чернил или параметр 2 для цветных. -

Код ошибки H2 (место положения 3, красящий цилиндр)

Описание.

Необходима надстройка прижима для чернил.Устранение.

Данный код говорит, что вам необходимо отрегулировать силу прижима в зависимости от используемых чернил, т.е. вам надо задать кол-во чернил для подачи, что прямо отразится от насыщенности оттиска. Так параметр 1 соответствует светлой заливке, а параметр 5 темной. -

Код ошибки H3 (место положения 3, красящий цилиндр)

Описание.

Регулировка плотности контрольного оттиска.Устранение.

Принцип схож с кодом ошибки H2. Только данная настройка осуществляется конкретно для пробного оттиска и не зависит от H2. -

Код ошибки H4 (место положения 4, узел изготовления мастера)

Описание.

Необходимо задать плотность прожига кадра мастер-пленки.Устранение.

Здесь нужно отрегулировать опорный прижим для изготовления мастера, т.е. от 1 (светлой) к 10 (темной). -

Код ошибки H5 (место положения 4, узел изготовления мастера)

Описание.

Необходима настройка прижима мастер-пленки.Устранение.

Для того, чтобы отрегулировать прижим мастер-пленки, вам нужно задать требуемый параметр от 1 к 5 или от светлого к темному. -

Код ошибки H6 (место положения 4, узел изготовления мастера)

Описание.

Необходимо задать плотность прожига кадра мастер-пленки для пробного оттиска.Устранение.

Все точно также, как в пункте 4, только эта настройка производится конкретно для пробного оттиска.

В силу того, что вы можете не владеть информацией с правильными настройками, рекомендуем вам настраивать выше указанные параметры постепенно от меньшего к большому по достижению необходимого вам качества печати.

Таким образом, чтобы задать нужный вам параметр необходимо ввести его значение с помощью клавиатуры количества копий, а затем нажать кнопку «старт» для завершения установки.

Вот мы и разобрались с ошибками, которые могут возникать на ризографе. Теперь вы сможете сэкономить на ненужном вызове специалиста, т.к. теперь вы можете сами исправить большинство «дежурных» ошибок. Желаем вам удачной и без ошибок работы вашего ризографа.

Type

Point

Description

A01

201

Master-positioning sensor does not go ON even after the write pulse motor is activated during the master-positioning, master-cut, or master-loading operation.

A01

202

Master-positioning sensor does not go OFF even when the write pulse motor is reversed during the master-positioning or at start of master-making operation.

A01

206

Timeout error during master-making operation

A01

211

Master-positioning sensor is ON during standby.

A01

214

Master-positioning sensor is ON at the start of master making.

A01

215

Faulty gate-array control for the write pulse motor (motor does not stop within set time)

A02

509

Master-loading sensor was OFF when the master was checked at a specified drum angle during the master-loading operation.

A04

303

Master-disposal jam sensor was OFF at both 120 and 180 degrees drum angle.

A04

314

Master-disposal error (recovery error).

A05

304

Master-disposal jam sensor was ON at the completion of the master-disposal operation.

A05

312

The master-disposal jam sensor was ON at the start of master-making operation.

A05

315

The master-disposal jam sensor was ON when the master disposal box was set in the machine.

A06

403

Paper-feed-tray upper or lower safety switch is OFF.

A07

409

Paper-ejection sensor was OFF when the paper should have arrived, and the paper sensor was ON when the machine stopped (Paper misfeed).

A07

412

Paper sensor was OFF three times in succession when a paper misfeed was detected (paper misfeed).

A07

413

Paper sensor was ON when the paper should have left the paper sensor (long-length paper mode error).

A07

418

The paper sensor was ON at the start of machine operation when the START button was pressed.

A07

429

Paper feed error (recovery error).

A07

432

Paper sensor was ON when the machine went into paper feed retry movement after a paper misfeed.

A08

410

Paper-ejection sensor was OFF when paper should have arrived, and the paper sensor was OFF when the machine stopped (paper jam on the print drum).

A08

421

Paper sensor was ON when the paper should have left the paper sensor during feeding of long paper in long-length paper mode (paper longer than 555 mm).

A08

430

Paper jam on print drum (recovery error).

A09

411

Paper-ejection sensor was ON when the paper should have left the paper-ejection sensor.

A09

417

Paper-ejection sensor was ON at the start of machine operation when the START button was pressed.

A09

431

Paper-ejection error (recovery error).

A10

102

Original-registration-sensor remaining jam

A10

103

Original-IN-sensor remaining jam

A10

105

Original-registration-sensor non-arrival jam

A10

106

Original-IN-sensor non-arrival jam

A10

107

Original-OUT-sensor non-arrival jam

A10

109

An original feed error occurred, due to opening the AF.

A10

162

No original in AF during AF master making.

A16

525

Waiting for the master to be removed.

A17

209

Cutter home-position switch is OFF at the start of master-making or master-set operation.

A34

218

Request to resetting the master.

B01

730

Keycard counter: No card

B22

721

With the «Tape separation» function set ON, no power is supplied to the job separator when start key is pressed.

B22

727

After cluster-A signal turned ON, BUSY-signal stayed «L» more than 7 seconds (power to job separator was turned OFF while the tape is being ejected.

B23

722

With the «Tape separation» function set ON, no tape detected in the job separator when the start key is pressed.

B23

723

No tape remains in job separator upon completion of the tape-ejection operation.

B24

724

Tape jam detected when the start key is pressed with the «Tape separation» function set to ON.

B24

725

Job separator tape-jam detection signal is «H» within 1,200 milliseconds after the cluster-A signal turns ON (tape misfeed).

B24

726

Job separator tape-jam detection signal is «L» when the BUSY signal changes from «L» to «H» (or after 7 sec. at «L») after the cluster-A signal goes ON (tape misfeed).

B31

916

Network cable is not connected when the machine is powered ON.

B32

917

Communication error on the network.

B32

920

Error detected by Network Interface Card (NIC) — NAK (negative acknowledgement was received).

B33

931

DHCP server is not found with DHCP ON.

B34

919

Error detected on the locally connected printer.

C01

512

The ink sensor did not go ON even when inking was performed for the preset period.

C01

563

Ink remaining amount is zero.

C01

574

Inkless error was detected 5 times consecutively on one same ink bottle.

C02

200

The master end was detected twice in succession at 10-milliseconds intervals during master transport.

C02

240

Master remaining amount is zero

C02

253

Masterless error was detected twice consecutively on one same master-roll.

C03

308

Compression detection position was reached before the master-compression-motor encoder-sensor count reached the specified level, after the master compression motor turned ON in the compression direction.

C03

313

Master removal box full detected by the master removal count.

C04

402

Paper detection sensor is OFF (no paper on the feed tray).

D01

526

Print drum is not set in the machine (drum connection signal, drum safety switch, and drum-lock sensor is OFF.

D01

527

Print drum connection signal is OFF when the print drum was inserted in the machine.

D01

528

Print drum safety switch is OFF when the print drum was inserted in the machine.

D01

529

Print drum lock sensor is OFF when the print drum was inserted in the machine (time-out: 5 seconds).

D01

530

Print drum connection signal does not go OFF within 5 seconds after the print drum safety switch went OFF when the print drum was pulled out.

D02

532

Incorrect print drum is used.

D03

533

Ink cartridge set sensor is OFF.

D04

534

Incorrect ink cartridge is used.

D04

560

Ink TAG is not detected on ink bottle.

D04

561

Ink cartridge communication error (communication with the ink cartridge was interfered by noise).

D04

562

Wrong ink cartridge information.

D04

564

Detected a mismatch in ink cartridge information

D05

210

Master detection sensor is OFF (not detecting master).

D07

310

Disposal-box safety switch is OFF.

D08

224

Master making unit is not set (both the safety switch and lock sensor are OFF).

D08

226

Master making unit safety switch is still OFF when the master making unit is set in position.

D08

227

Master making unit lock sensor is still OFF when the master making unit is set in position (timeout: 5 seconds).

D08

228

Master making unit lock sensor is still ON even after the master making unit safety switch went OFF, when the master making unit was pulled out of the machine.

D09

212

Master-making-unit set sensor is OFF (sensor light path is free).

D11

535

Front cover set switch is OFF.

D13

9

The rear cover is opened (serviceman safety switch is OFF).

D17

236

Incorrect master roll.

D17

237

Master roll undetected.

D17

238

Master roll communication error.

D17

239

Wrong master roll detected.

D17

241

Detected a mismatch in master roll information.

D18

522

Print drum ready for release (solenoid is ON).

D19

223

Master making unit ready for release (solenoid is ON).

D22

540

Error in access to the Drum PCB (unable to read from or write on the Drum PCB).

D22

542

Abnormal data on Drum PCB.

E01

10

Battery voltage was less than 2.5 V when the power was switched ON (weak battery: time to replace battery).

E02

11

Master counter reached the value set for the maintenance call (value set by test mode). [The message appears when either the power is turned ON, the unit is reset, or when the machine operation ended.]

E02

12

Copy counter reached the value set for the maintenance call (value by set test mode). [The message appears when either the power is turned ON, the unit is reset, or when the machine operation ended.]

E02

22

Maintenance counter inside the print drum reached the value set for the maintenance call (value set by test mode). [The message appears when either the power is turned ON, the unit is reset, or when the machine operation ended.]

F01

15

There is no master on the print drum at the start of printing.

F02

18

Paper size does not match with the image size on the print drum at the start of printing.

F03

16

Multi-up was selected using custom size paper.

F05

19

In master making, the print quantity selected is less than the minimum print quantity.

F10

21

Paper size does not match with the size of image on the print drum when test print is selected and activated.

F21

32

Next original is not in placed on AF for multi-up operation.

F22

33

Next original is not placed on flatbed for multi-up operation.

F37

50

Original was set on the AF with book mode selected, when master making is activated.

F50

910

Auto-printer-selection is disabled due to error on linked printer.

F54

923

Auto-printer-selection is disabled due to no paper in the linked printer.

F55

924

Auto-printer-selection is disabled while receiving print data from PC.

F58

927

Cannot print from linked printer (Initializing NET-C).

H1

566

Requesting ink color information input (Ink-TAG related).

H2

567

Requesting print density information input (Ink-TAG related).

H3

568

Requesting test printing print density information input (Ink-TAG related).

H4

242

Requesting master-making density information input (Master-TAG related).

H5

243

Requesting Print density information input (Master-TAG related).

H6

244

Requesting test printing print density information input (Master-TAG related).

P01

520

Main encoder sensor does not go ON/OFF within 10 milliseconds after the main motor activates.

P01

521

B-positioning sensor status does not change even after 3,033 pulses after the main motor activates.

P01

524

Clamp unit is not at the home position while the print drum is in operation (except during master disposal).

P01

537

Print drum failed to stop at position B. (over-run)

P01

538

Print drum is not locked during operation. (Print-drum lock position sensor: OFF)

P02

400

Both the upper and lower limit sensors were ON at the same time.

P02

401

Overload current was detected in the elevator motor.

P02

404

The lower-limit sensor does not go OFF within 2 seconds after the elevator motor operates in the raising direction from the lower-limit position.

P02

405

The upper-limit sensor does not go ON within 12 seconds after the elevator motor operates in the raising direction.

P02

406

The upper-limit sensor does not go OFF within 2 seconds after the elevator motor operates in the lower direction from the upper-limit position.

P02

407

The lower-limit sensor does not go ON within 12 seconds after the elevator motor operates in the lowering direction.

P02

408

The upper-limit sensor is OFF continuously for over 2 seconds during operation of the elevator servo action to raise the feed tray.

P03

500

Clamp sensor A is OFF after the completion of the clamp unit initialization or home positioning movement.

P03

501

Clamp sensor B does not change within 1 second from the time the clamp motor operates in the correct direction.

P03

502

Clamp sensor B does not change within 1 second from the time the clamp motor operates in the reverse direction.

P03

503

Clamp sensor A does not go ON within 3 seconds when the clamp unit makes initialization movement.

P03

504

At the start of Clamp plate open/close action, the the detection sequence of clamp-sensors A & B is abnormal.

P03

505

At the start of print drum Positon-A compensation movement, the detection sequence of clamp-sensors A & B is abnormal.

P03

506

At the start of Clamp unit Home-positioning movement, the detection sequence of clamp-sensors A & B is abnormal.

P03

507

Clamp sensor A is ON after the clamp release action is completed.

P03

508

Clamp sensor A is ON after the A-position compensating movement is completed.

P03

545

Clamp unit is not in the home position while the print drum is in movement (cause due to the clamp motor).

P04

513

The overflow sensor was ON for a set number of times in succession during the 10-millisecond-interval overflow-sensor check.

P05

603

The vertical-centering sensor does not switch ON even when the vertical-positioning pulse motor activated in the image-down direction for 5 seconds during vertical home positioning movement.

P05

604

The vertical-centering sensor does not switch OFF even when the vertical-positioning pulse motor activated in the image-up direction for 5 seconds during vertical home positioning movement.

P05

605

Even though the vertical positioning motor stopped according to the vertical centering sensor detection, the stopping position does not correspond with the programmed position. (GA control error).

P05

612

The one-step-positioning key was pressed with vertical-print-position information undefined.

P08

951

Print job executed was not in correct RisoRinc format.

P11

600

Print pressure HP sensor does not switch ON within 3.9 seconds after the print pressure pulse motor activated towards higher pressure during home positioning operation.

P11

601

Print pressure HP sensor does not switch OFF within 4.6 seconds after the print pressure pulse motor activated towards lower pressure during home positioning operation.

P11

602

Even though the print pressure control pulse motor stopped according to the print pressure HP sensor detection, the stopping position does not correspond with the programmed position. (GA control error).

P12

301

Master compression motor lock when moving compression plate up.

P12

305

Master compression sensor does not go ON within 6.5 seconds after the master compression motor operates in the return direction.

P12

306

Master compression sensor does not go OFF within 2 seconds after the master compression motor operates in the compress direction.

P12

307

Master compression plate maximum position is not detected within 6.5 seconds after the master compression motor operates in the compress direction.

P12

309

Master-compression-motor encoder sensor count did not change as the master compression motor activated in the compress direction and moved out from the home position.

P12

316

Master-compression-motor encoder sensor count did not change within 10 milliseconds after the master compression motor activated.

P12

300

Overload current was detected in the master removal motor.

P13

203

Cutter HP switch does not go OFF within 100 milliseconds after the cutter motor is activated.

P13

204

Cutter HP switch does not go ON within 300 milliseconds after the cutter motor is activated.

P13

205

Master-positioning sensor is ON when the print drum rotates through the preset angle following master cutting.

P13

221

Both the cutter HP switch and cutter stop position switch are ON at the same time.

P13

222

Cutter HP switch does not go ON within 450 milliseconds after the cutter home positioning operation started.

P13

231

Cutter HP switch does not go OFF within 500 milliseconds after the cutter moved out from the home position.

P13

232

Cutter stop position switch does not go ON within 2 seconds after the cutting operation started.

P13

233

Cutter stop position switch does not go OFF within 500 milliseconds after the cutter activates to move from the stop position to the home position.

P13

234

Cutter HP switch does not go ON within 2 seconds after the cutter home positioning operation started.

P14

114

Incorrect main-unit data.

P14

115

The scanner operation is not completed within the set time.

P14

116

Timeout error for black shading compensation. (RZ3 series only)

P14

117

Timeout error for white shading compensation. (RZ3 series only)

P14

123

Offset adjustment not completed within set time. (RZ3 series only)

P14

124

Gain adjustment not completed within set time. (RZ3 series only)

P14

125

Offset adjustment not completed.

P14

126

Gain adjustment not completed.

P14

135

Malfunction detected during offset adjustment. (RZ3 series only)

P14

136

Malfunction detected during offset adjustment. (RZ3 series only)

P14

137

Malfunction detected during black shading compensation. (RZ3 series only)

P14

138

Malfunction detected during white shading compensation. (RZ3 series only)

P14

170

Even though the read pulse motor stopped according to the sensor detection, the stopping position does not correspond with the programmed position. (GA control error).

P15

4

Communication error with AF-CPU.

P15

110

ABC (auto-base-control) timeout. The original does not move from the ABC scanning position on the AF unit.

P15

111

Operation command was made to the AF unit without 24 volts supplied to the AF unit.

P15

130

Timeout error in receiving reply from the AF unit after command signal was sent from the Riso printer to the AF unit.

P15

131

Riso printer received an undefined command from the AF unit.

P15

132

Riso printer detected communication sequence error from the AF unit.

P15

133

Communication error with AF unit (ACK or NAK error).

P15

134

Riso printer could not send command to the AF unit within the set time.

P15

160

AF unit detection signal went OFF while the AF unit is in operation.

P17

20

Solenoid counter is not connected.

P18

531

Print drum lock sensor is still ON even after 100 milliseconds after the print drum lock solenoid is activated.

P19

207

TPH pressure sensor does not go OFF within 2 seconds after the thermal-pressure motor activates in the decompressing direction, or during home positioning operation.

P19

208

TPH pressure sensor does not go ON within 2 seconds after the thermal-pressure motor activates in the decompressing direction.

P19

216

TPH pressure sensor does not go OFF within 500 millisecond after the thermal-pressure motor activates in the compressing direction.

P19

217

TPH pressure sensor does not go ON within 2 seconds after the thermal-pressure motor activates in the compressing direction.

P20

415

Paper-ejection-wing home sensor does not go OFF within 7,000 milliseconds after the paper ejection wing motor activates in the counterclockwise direction from the home position.

P20

416

Overload current was detected in the paper-ejection motor.

P20

437

Paper-ejection encoder sensor status does not change within 10 milliseconds after the paper-ejection motor is activated.

P24

539

Inking-motor encoder sensor status does not change within 20 milliseconds after the inking-motor is activated.

P25

26

Battery voltage was below 2.3 volts (too low) when the power is turned ON.

P92

570

EEPROM on the print drum PCB was being accessed while the print drum was in releasing action from the machine.

P93

932

No reply from the NET-C network interface card while accessing to the network interface card.

P93

933

No response from NET-C for 90 seconds during NET-C initialization.

P94

225

TPH code does not match with the machine code when the power is turned ON with the master-making unit in operating position or when the master-making unit is inserted in operating position while the power is ON.

P95

59

Machine serial-number information sent from SH-PCB does not match with the machine serial number information in the MCTL PCB.

P96

171

TPH resistance value not input.

P96

172

Scanner adjustment not completed.

P96

433

Paper size width potentiometer test-mode setting is not completed.

P96

569

Either the print drum color information or ink category information is still not input.

P96

613

Print pressure data missing.

P98

2

No reply from Mini-Rosa PCB when the machine power is turned ON even though the Rosa connection signal is ON.

P98

5

Hardware error.

P98

6

FRAM checksum error.

P98

7

Mini Rosa PCB not connected.

P98

38

Machine data on EEPROM does not match with that on the SH-PCB.

P98

39

Improper EEPROM on the SH-PCB.

P98

46

The DIMM capacity does not match.

P98

51

Touch-panel communication error

P98

53

Failure in calling out the saved Memory settings (program, mode, user paper information).

P98

54

Failure in saving the Memory settings (program, mode, user paper information).

P98

55

Machine type code from SH-PCB does not match with the machine information on the H8-PCB.

P98

63

The test-mode memory data stored was outside the adjustment range.

P98

64

An undefined command was sent in communication between SH-PCB and MCTL PCB.

P98

65

Communication error 01 between SH-PCB and MCTL PCB (MCTL PCB side).

P98

67

Communication error 03 between SH-PCB and MCTL PCB (MCTL PCB side).

P98

68

Communication error 04 between SH-PCB and MCTL PCB (MCTL PCB side).

P98

69

Communication error 05 between SH-PCB and MCTL PCB (MCTL PCB side).

P98

70

Communication error 06 between SH-PCB and MCTL PCB (MCTL PCB side).

P98

71

Communication error 07 between SH-PCB and MCTL PCB (MCTL PCB side).

P98

72

Communication error 08 between SH-PCB and MCTL PCB (MCTL PCB side).

P98

73

Communication error 09 between SH-PCB and MCTL PCB (MCTL PCB side).

P98

74

Communication error 10 between SH-PCB and MCTL PCB (SH-PCB side)

P98

75

Communication error 11 between SH-PCB and MCTL PCB (SH-PCB side)

P98

76

Communication error 12 between SH-PCB and MCTL PCB (SH-PCB side)

P98

77

Communication error 13 between SH-PCB and MCTL PCB (SH-PCB side)

P98

78

Communication error 14 between SH-PCB and MCTL PCB (SH-PCB side)

P98

79

Communication error 15 between SH-PCB and MCTL PCB (SH-PCB side)

P98

80

Communication error 16 between SH-PCB and MCTL PCB (SH-PCB side)

P98

81

Communication error 17 between SH-PCB and MCTL PCB (SH-PCB side)

P98

82

Communication error 18 between SH-PCB and MCTL PCB (SH-PCB side)

P98

83

Communication error 19 between SH-PCB and MCTL PCB (SH-PCB side)

P98

84

Communication error 20 between SH-PCB and MCTL PCB (SH-PCB side)

P98

98

Machine serial number information on the SH-PCB EEPROM does not match with that in the FRAM.

P98

119

Image processing PCB trouble.

P98

120

Scanner communication problem. (RZ3 series only)

P98

129

Faulty Scanner GA PCB. (RZ3 series only)

P98

245

Master transfer time-out error during master making (Write pulse motor error).

P98

246

Master transfer time-out error during master making (Load pulse motor error).

P98

614

Vertical print position data missing.

P98

934

Main read/write communication error (detected by read/write side).

P98

935

Main read/write communication error (detected by machine side).

P98

937

Serial number data missing.

P98

938

FRAM version-down.

P98

947

24V-A does not go ON (a possible burnt 24-volt group-A fuse).

P98

948

24V-B does not go ON (a possible burnt 24-volt group-B fuse).

P98

949

24V-A does not go OFF.

P98

950

24V-B does not fo OFF.

P98

952

Checksum error on the ROSA flash-memory.

P98

953

Unsuccessful writing on the ROSA flash-memory.

P99

936

Software error

-

17.01.2019

О ризографе

Разработчиком ризографа является компания Riso, которая известная с далеких времен как производитель краски для печати, в дальнейшем, занялась наладкой производства машин трафаретной печати и расходных материалов для них. Таким образом появился новый

О ризографе

-

04.09.2018

05.02.2014

Вопрос:

как сбросит ошибку H101

Ответ:

Скорее всего, был установлен новый барабан, т.к. данный код говорит о том, что необходимо выбрать параметр краски и раскатать его выбранной краской,т.е. необходимо выполнить процедуру раскадки барабана с соответствующей краской.

Задайте свой вопрос

Чтобы задать вопрос, Вам необходимо авторизоваться

-

11-02-2010

#1

Junior Member

- Rep Power

- 0

error h101 for riso RZ

hello

i want to know how illiminate the trouble code h101 for riso rz

thanks

-

11-02-2010

#2

Trusted Tech

50+ Posts

- Rep Power

- 30

you need to input the value on the machine for the ink color the value is 1-black or 2-color

you need to go into service mode the go to 890 and input what color of ink the drum is weather its black or color and that should get rid of your issue

-

09-28-2013

#3

Trusted Tech

50+ Posts

- Rep Power

- 20

Re: error h101 for riso RZ

Originally Posted by djdan73

you need to input the value on the machine for the ink color the value is 1-black or 2-color

you need to go into service mode the go to 890 and input what color of ink the drum is weather its black or color and that should get rid of your issue

is there a list of what all the errors mean and how to enter the appropriate code?

-

09-30-2013

#4

Re: error h101 for riso RZ

Originally Posted by pj4nh

is there a list of what all the errors mean and how to enter the appropriate code?

Yes, get a manual. See Paul the manual guru.

-

03-11-2015

#5

Trusted Tech

50+ Posts

- Rep Power

- 17

Re: error h101 for riso RZ

Double click on ur start key to go zero on display panel. Machine will Ready to printgood luck

-

04-19-2015

#6

Re: error h101 for riso RZ

The machine either has «knock off» ink (generic) or «knock off» masters (generic) installed in the machine.

Try installing Genuine Riso ink and masters and the problem should be solved.

We are the largest supplier of USED RISO drums (over 400 in stock) and spare PARTS (most models) in the U.S.Let us know if we can help.Lindsey Interdonati

PresidentOnly Great Copiers

Wilmington, NC 28405

-

07-21-2015

#7

Trusted Tech

50+ Posts

- Rep Power

- 17

Re: error h101 for riso RZ

I could be need to set the drums with the code number 890 test mode only team you can do with a genuine ink, the chip of the generic inks tend to unset the drum cards again