|

Error code |

Description |

Lamp Check trans |

Control system response |

|

C1312 |

Retarder trigger low voltage |

off |

Retarder does not turn on |

|

C1313 |

Retarder trigger signal high voltage |

off |

Retarder does not turn on |

|

P0122 |

Intermittent or low gas pedal position sensor signal |

off |

Default value is used |

|

P0123 |

High gas pedal position sensor |

off |

Default value is used |

|

P0218 |

Oil temperature is too high |

off |

A control pattern is used in case of temperature |

|

P0562 |

Control unit low voltage |

off |

Prohibition of torque converter lockout. DNA |

|

P0602 |

The control unit is not programmed |

On |

Remains neutral |

|

P0610 |

Error of additional equipment of the car with the control unit |

On |

Uses TID A Calibration Data |

|

P0613 |

Control Unit CPU Error |

off |

All solenoids are off |

|

P0614 |

Incompatibility of ECM and TCM data for engine torque control |

On |

Only neutral, reverse and second gear. Torque lock inhibit, shift adaptation disabled |

|

P0634 |

Control unit temperature exceeded |

On |

DNS , SOL OFF , actively hydraulic control. |

|

P063E |

There is no input signal about the position of the throttle during auto detection |

On |

Default value is used |

|

P063F |

No coolant temperature signal during auto detection |

off |

— |

|

P0657 |

Open circuit HSD1 |

On |

SOL OFF , DNA . Prohibition of torque converter lock, prohibition of main |

|

P0658 |

Low voltage in the HSD circuit 1 |

On |

DNS , SOL OFF , hydraulic control is active |

|

P0659 |

High voltage in the HSD circuit 1 |

On |

DNS , SOL OFF , hydraulic control is active |

|

P0702 |

The control unit did not recognize the automatic transmission configuration |

On |

Uses standard configuration |

|

P0703 |

Malfunction in a chain of the gauge of a brake |

off |

On garbage trucks, the inclusion of N — D is not possible . If the code is active, then |

|

P0708 |

High signal from the current gear sensor. |

On |

Ignores the signal of the strip switch |

|

P070C |

Low oil level sensor signal |

off |

— |

|

P070D |

High oil level sensor signal |

off |

— |

|

P0711 |

Abnormal oil temperature sensor signal |

On |

Uses the default temperature |

|

P0712 |

Low oil temperature sensor signal |

On |

Uses standard temperature |

|

P0713 |

High oil temperature sensor signal |

On |

It uses the standard value tamper Aturi |

|

P0716 |

Turbine wheel speed sensor abnormal signal |

On |

DNS , automatic transmission is blocked on the current transfer |

|

P0717 |

No turbine wheel speed sensor signal |

On |

DNS , automatic transmission is blocked on the current transfer |

|

P0719 |

ABS brake signal low |

off |

Takes ABS off |

|

P071A |

Incompatible RELS Input |

On |

RELS function is disabled |

|

P071D |

Incorrect special function input (wire 101 and 142) |

On |

— |

|

P0721 |

Abnormal output speed sensor signal |

On |

DNS , automatic transmission remains in the current transmission |

|

P0722 |

No output speed sensor signal |

On |

DNS , automatic transmission remains in the current transmission |

|

P0726 |

Abnormal engine speed sensor signal |

off |

Uses standard turbine speed |

|

P0727 |

Missing engine speed sensor signal |

off |

Uses standard turbine speed |

|

P0729 |

6th gear ratio incorrect |

On |

DNS , trying to enable 5th , then 3rd gear |

|

P0731 |

1st gear ratio incorrect |

On |

DNS , trying to enable 2nd, then 5th gear |

|

P0732 |

2nd gear ratio incorrect |

On |

DNS , trying to enable 3rd, then 5th gear |

|

P0733 |

3rd gear ratio incorrect |

On |

DNS , trying to enable 4th, then 6th gear |

|

P0734 |

4th gear ratio incorrect |

On |

DNS , trying to turn on 5th, then 3rd gear |

|

P0735 |

5th gear ratio incorrect |

On |

DNS , trying to turn on the 6th, then 3rd, then 2nd gear |

|

P0736 |

Incorrect gear ratio in reverse gear |

On |

DNS blocked on neutral |

|

P0741 |

Torque converter slip clutch slides |

On |

— |

|

P0752 |

Jamming solenoid SS 1 pressure control valve |

On |

DNS |

|

P0776 |

Malfunction in the hydraulic circuit of the PCS 2 solenoid |

On |

DNS, RPR |

|

P0777 |

Malfunction in the hydraulic circuit of the PCS 2 solenoid |

On |

DNS, RPR |

|

P0796 |

Malfunction in the hydraulic circuit of the PCS 3 solenoid |

On |

DNS, RPR |

|

P0797 |

Malfunction in the hydraulic circuit of the PCS 3 solenoid |

On |

DNS, RPR |

|

P0842 |

PS voltage sensor low voltage 1. |

On |

DNS , automatic transmission remains in the current transmission |

|

P0843 |

Pressure Sensor High Voltage PS 1. |

On |

DNS , automatic transmission remains in the current transmission |

|

P0847 |

PS 2 pressure sensor low voltage |

On |

— |

|

P0848 |

High voltage pressure sensor PS 2 |

On |

— |

|

P0880 |

Power failure of the control unit during engine operation |

off |

— |

|

P0881 |

The voltage at the control unit is too low or is skipping |

off |

— |

|

P0882 |

The voltage at the control unit is below normal. |

On |

DNS , SOL OFF , hydraulic control is active |

|

P0883 |

The voltage on the control unit is above normal |

off |

— |

|

P088A |

Oil filter clogged |

off |

— |

|

P088B |

Oil filter heavily clogged |

off |

— |

|

P0894 |

No torque transmission in first gear |

On |

DNS remains in 1st gear |

|

P0897 |

Gear oil needs to be replaced |

On |

— |

|

P0960 |

Open circuit pressure modulation valve solenoid |

On |

— |

|

P0962 |

Low voltage modulation valve solenoid circuit |

On |

DNS , SOL OFF , hydraulic control active |

|

P0963 |

High voltage in the pressure modulation valve solenoid circuit |

On |

— |

|

P0964 |

PCS2 Solenoid Open Circuit |

On |

DNS , SOL OFF , hydraulic control active |

|

P0966 |

PCS 2 Solenoid Circuit Low Voltage |

On |

DNS , SOL OFF , hydraulic control is active |

|

P0967 |

PCS 2 Solenoid High Voltage |

On |

DNS , SOL OFF , hydraulic control is active |

|

P0968 |

PCS3 Solenoid Open Circuit |

On |

DNS , SOL OFF , hydraulic control is active |

|

P0970 |

PCS 3 Solenoid Circuit Low Voltage |

On |

DNS , SOL OFF , hydraulic control is active |

|

P0971 |

PCS 3 Solenoid Circuit High Voltage |

On |

DNS , SOL OFF , hydraulic control is active |

|

P0973 |

Low voltage in the solenoid circuit SS 1 |

On |

DNS , SOL OFF , hydraulic control is active |

|

P0974 |

High voltage in the solenoid circuit SS 1 |

On |

DNS , SOL OFF , hydraulic control is active |

|

P0975 |

Open circuit solenoid SS2 |

On |

On 7-speed automatic transmissions, 1st and 7th gears are not included |

|

P0976 |

Low voltage in the solenoid circuit SS 2 |

On |

On 7-speed automatic transmissions, 1st and 7th gears are not activated, torque converter lockout |

|

P0977 |

High voltage in the solenoid circuit SS 2 |

On |

On 7-speed automatic transmissions, 1st and 7th gears are not included |

|

P0989 |

The signal from the retarder is intermittent |

off |

Retarder does not turn on |

|

P0990 |

Retarder sensor signal has a short circuit |

off |

Retarder does not turn on |

|

P1739 |

Incorrect gear ratio in low gear |

On |

DNS , prohibition of work in 1 gear |

|

P1891 |

Accelerator pedal position sensor signal below normal |

off |

Uses the standard value for pedal depression |

|

P1892 |

Accelerator Pedal Position Sensor Signal Above Normal |

off |

Uses the standard value for pedal depression |

|

P2184 |

Coolant temperature sensor signal low voltage |

off |

Uses standard temperature |

|

P2185 |

Coolant Temperature Sensor High Voltage |

off |

Uses standard temperature |

|

P2637 |

Malfunction of the torque control system when shifting gears SEM |

On |

Disabling SEM |

|

P2641 |

Violation of the torque limiting system in the lower gears of LRTP |

On |

Disabling LRTP |

|

P2669 |

Open circuit HSD2 |

On |

SOL OFF , torque converter inhibit inhibit, main modulation |

|

P2670 |

HSD 2 low voltage |

On |

DNS , SOL OFF , hydraulic control active |

|

P2671 |

High voltage in the HSD 2 circuit |

On |

DNS , SOL OFF , hydraulic control active |

|

P2684 |

Open circuit HSD3 |

On |

SOL OFF , torque converter inhibit inhibit, main modulation |

|

P2685 |

HSD 3 Low Voltage |

On |

DNS , SOL OFF , hydraulic control is active |

|

P2686 |

HSD 3 High Voltage |

On |

DNS , SOL OFF , hydraulic control is active |

|

P2714 |

Malfunction in the hydraulic circuit of the PCS 4 solenoid |

On |

DNS, RPR |

|

P2715 |

Malfunction in the hydraulic circuit of the PCS 4 solenoid |

On |

DNS , SOL OFF , hydraulic control is active |

|

P2718 |

PCS4 Solenoid Open Circuit |

On |

DNS , SOL OFF , hydraulic control is active |

|

P2720 |

PCS 4 Solenoid Circuit Low Voltage |

On |

DNS , SOL OFF , hydraulic control is active |

|

P2721 |

PCS 4 Solenoid High Voltage |

On |

DNS , SOL OFF , hydraulic control is active |

|

P2723 |

Malfunction in the hydraulic circuit of the PCS 1 solenoid |

On |

DNS, RPR |

|

P2724 |

Malfunction in the hydraulic circuit of the PCS 1 solenoid |

On |

DNS, RPR |

|

P2727 |

PCS1 Solenoid Open Circuit |

On |

DNS , SOL OFF , hydraulic control is active |

|

P2729 |

Low voltage in the PCS 1 solenoid |

On |

DNS , SOL OFF , hydraulic control is active |

|

P2730 |

High voltage in the PCS 1 solenoid |

On |

DNS , SOL OFF , hydraulic control is active |

|

P2736 |

PCS5 Solenoid Open Circuit |

On |

Prohibition of retarder operation |

|

P2738 |

PCS 5 Solenoid Circuit Low Voltage |

On |

Prohibition of work in 1st gear, retarder operation, torque converter lock |

|

P2739 |

PCS 5 Solenoid Circuit High Voltage |

On |

Prohibition of retarder operation |

|

P2740 |

High temperature oil retarders |

off |

— |

|

P2742 |

Retarder oil temperature sensor low signal |

off |

Uses standard oil temperature |

|

P2743 |

Retarder oil temperature sensor high signal |

off |

Uses standard oil temperature |

|

P2761 |

Torque converter solenoid open circuit |

On |

Torque converter lockout |

|

P2763 |

Low voltage in the torque converter lock-up solenoid circuit |

On |

Torque converter lockout |

|

P2764 |

High voltage lock-up torque converter solenoid circuit |

On |

Torque converter lockout |

|

P2789 |

Clutch wear reaches limit value |

On |

— |

|

P278A |

Wrong Kickdown Signal |

off |

Kickdown mode ban |

|

P2793 |

Gear Shift Communication Error |

On |

Ignores PWM control, if the signal through the CAN — bus is also lost, the latter is locked in a selected direction |

|

P2808 |

Malfunction in the hydraulic circuit of the PCS 6 solenoid |

On |

DNS, RPR |

|

P2809 |

Malfunction in the hydraulic circuit of the PCS 6 solenoid |

On |

DNS, RPR |

|

P2812 |

PCS6 Solenoid Open Circuit |

On |

DNS , SOL OFF , hydraulic control is active |

|

P2814 |

PCS 6 Solenoid Circuit Low Voltage |

On |

DNS , SOL OFF , hydraulic control is active |

|

P2815 |

PCS 6 Solenoid Circuit High Voltage |

On |

DNS , SOL OFF , hydraulic control is active |

|

U0001 |

High Speed CAN Bus Counter Overflow ( IESCAN ) |

off |

Uses standard values; disables torque control when shifting gears |

|

U0010 |

CAN Bus Counter Overflow ( IESCAN ) |

off |

Uses standard values; disables torque control when shifting gears |

|

U0100 |

Loss of communication with the engine / power unit ( J 1586) |

On |

Uses default values |

|

U0103 |

Lost Communication With First Gear Shift |

On |

Remains in the selected gear, monitors the signal for changing the direction of movement. The display |

|

U0115 |

Communication error with engine control unit |

On |

Uses standard values, DNA |

|

U0291 |

Communication error with the secondary gear shifter |

On |

Remains in the selected gear, monitors the signal for changing the direction of movement. The display |

|

U0304 |

Primary gear selector not compatible with J 1939 protocol |

On |

DNS blocked in neutral |

|

U0333 |

Secondary switch not compatible with J 1939 protocol |

On |

DNS blocked in neutral |

|

U0400 |

Violation of data transmission protocol J 1939 |

On |

— |

|

U0404 |

Inadequate information from the primary gear shifter |

On |

Remains in the selected gear, monitors the signal for changing the direction of movement. The display |

|

U0442 |

The control unit receives incorrect data from the engine / powertrain control unit included in data bus J 1939 |

off |

— |

|

U0592 |

Inadequate information from the secondary gear shifter |

On |

Remains in the selected gear, monitors the signal for changing the direction of movement. The display |

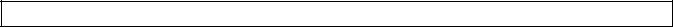

Table of

fault codes,

Automatic transmission Series 3000, 4000 with electronic control system Gen4

|

Error code |

Description |

Lamp Check Trans |

Control system response |

|

C1312 |

Low voltage signal to turn on the retarder |

OFF |

Retarder does not |

|

C1313 |

High voltage signal to turn on the retarder |

OFF |

Retarder does not |

|

P0122 |

Intermittent or low gas pedal position sensor signal |

OFF |

The default value is used. |

|

P0123 |

High signal level pedal position sensor gas |

OFF |

The default value is used. |

|

P0218 |

Oil temperature too high |

OFF |

A control pattern is used when the temperature is exceeded. Keeps 4 |

|

P0562 |

Low supply voltage control unit |

OFF |

The ban on locking torque converter. DNA |

|

P0602 |

Control unit not programmed |

ON |

Remains neutral |

|

P0610 |

Error of the additional equipment of the car with the control unit |

ON |

TID A calibration data is used. |

|

P0613 |

Control unit processor error |

OFF |

All solenoids are OFF. |

|

P0614 |

Incompatibility of ECM and TCM data to adjust engine torque |

ON |

Only neutral, rear and second gear. Torque lock |

|

P0634 |

Control unit temperature exceeded |

ON |

DNS, SOL OFF, active hydraulic control. |

|

P063E |

No auto throttle |

ON |

The default value is used. |

|

P063f |

No auto coolant |

OFF |

— |

|

P0657 |

HSD1 open circuit |

ON |

SOL OFF, DNA. Interlocking |

|

P0658 |

HSD1 low voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P0659 |

HSD1 high voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P0702 |

The control unit did not recognize the automatic transmission configuration. |

ON |

Uses standard configuration |

|

P0703 |

Brake Sensor Circuit Malfunction |

OFF |

On the garbage trucks cannot enable ND. If the code |

|

P0708 |

High level signal from the current transmission sensor. |

ON |

Ignore the signal of the strip switch |

|

P070C |

Low oil level sensor signal |

OFF |

— |

|

P070D |

High oil level sensor signal |

OFF |

— |

|

P0711 |

Non-standard oil temperature sensor signal |

ON |

Uses the default temperature |

|

P0712 |

Low oil temperature sensor signal |

ON |

Uses standard temperature value |

|

P0713 |

High oil temperature sensor signal |

ON |

Uses standard temperature value |

|

P0716 |

Non-standard Turbine Wheel Speed Sensor Signal |

ON |

DNS, automatic transmission is blocked on the current transfer |

|

P0717 |

Turbine wheel speed sensor signal missing |

ON |

DNS, automatic transmission is blocked on the current transfer |

|

P0719 |

ABS braking sensor signal low |

OFF |

Considers ABS OFF |

|

P071A |

Incompatible RELS input |

ON |

RELS OFF |

|

P071D |

Wrong input signal of the special function (wire 101 and 142) |

ON |

— |

|

P0721 |

Non-standard output speed sensor signal |

ON |

DNS, automatic transmission remains on the current transfer |

|

P0722 |

No output speed sensor signal |

ON |

DNS, automatic transmission stays on current |

|

P0726 |

Non-standard engine speed sensor signal |

OFF |

Uses standard turbine |

|

P0727 |

Missing engine speed sensor signal |

OFF |

Uses standard turbine |

|

P0729 |

Wrong gear ratio in 6th gear |

ON |

DNS, trying to enable 5th, then 3rd |

|

P0731 |

Incorrect gear ratio in 1st gear |

ON |

DNS, trying to enable 2nd, then 5th |

|

P0732 |

Wrong gear ratio in 2nd gear |

ON |

DNS, trying to enable 3rd, then 5th |

|

P0733 |

Incorrect gear ratio in 3rd gear |

ON |

DNS, trying to enable 4th, then 6th |

|

P0734 |

Incorrect gear ratio in 4th gear |

ON |

DNS, trying to enable 5th, then 3rd |

|

P0735 |

Invalid gear ratio in 5th gear |

ON |

DNS trying to enable 6th then the |

|

P0736 |

Wrong gear ratio in reverse gear |

ON |

DNS blocked on neutral |

|

P0741 |

Slipping clutch locking torque converter |

ON |

— |

|

P0752 |

Stuck solenoid SS1 pressure regulating valve |

ON |

DNS |

|

P0776 |

Malfunction in the PCS2 solenoid hydraulic circuit |

ON |

DNS, RPR |

|

P0777 |

Malfunction in the PCS2 |

ON |

DNS, RPR |

|

P0796 |

Fault in the hydraulic circuit of the PCS3 solenoid |

ON |

DNS, RPR |

|

P0797 |

Fault in the hydraulic circuit of the PCS3 solenoid |

ON |

DNS, RPR |

|

P0842 |

PS1 pressure sensor low voltage. |

ON |

DNS, automatic transmission stays on current |

|

P0843 |

PS1 pressure sensor high voltage. |

ON |

DNS, automatic transmission stays on current |

|

P0847 |

PS2 Pressure Sensor Low Voltage |

ON |

— |

|

P0848 |

PS2 Pressure Sensor High Voltage |

ON |

— |

|

P0880 |

The disappearance of the power control unit during engine operation |

OFF |

— |

|

P0881 |

Control unit voltage too low or jumping |

OFF |

— |

|

P0882 |

The voltage on the control unit is below normal |

ON |

DNS, SOL OFF, hydraulic |

|

P0883 |

The voltage on the control unit is above normal |

OFF |

— |

|

P088A |

Oil filter clogged |

OFF |

— |

|

P088B |

Oil filter heavily clogged |

OFF |

— |

|

P0894 |

No transfer of the moment in first gear |

ON |

DNS remains on 1 transmission |

|

P0897 |

Gear oil requires replacement |

ON |

— |

|

P0960 |

Open circuit solenoid valve modulation pressure |

ON |

— |

|

P0962 |

Low voltage in the solenoid circuit of the pressure modulating valve |

ON |

DNS, SOL OFF, hydraulic |

|

P0963 |

Modulation valve solenoid circuit high voltage pressure |

ON |

— |

|

P0964 |

PCS2 solenoid open circuit |

ON |

DNS, SOL OFF, hydraulic |

|

P0966 |

PCS2 solenoid circuit low voltage |

ON |

DNS, SOL OFF, hydraulic |

|

P0967 |

PCS2 solenoid circuit high voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P0968 |

PCS3 solenoid open circuit |

ON |

DNS, SOL OFF, hydraulic control active |

|

P0970 |

PCS3 solenoid circuit low voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P0971 |

PCS3 solenoid circuit high voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P0973 |

Low voltage in the circuit of the solenoid SS1 |

ON |

DNS, SOL OFF, hydraulic control active |

|

P0974 |

High voltage in the solenoid circuit SS1 |

ON |

DNS, SOL OFF, hydraulic control active |

|

P0975 |

SS2 solenoid open circuit |

ON |

On 7-speed automatic transmissions, 1st and 7th gears are not included. |

|

P0976 |

Low voltage in the solenoid circuit SS2 |

ON |

On 7-speed automatic transmissions, 1st and 7th gears are not included, prohibition of locking the torque converter |

|

P0977 |

High voltage in the solenoid circuit SS2 |

ON |

On 7-speed automatic transmissions, 1st and 7th gears are not included. |

|

P0989 |

The signal from the retarder has |

OFF |

Retarder does not |

|

P0990 |

The signal from the retarder has a short |

OFF |

Retarder does not |

|

P1739 |

Wrong gear ratio in low gear |

ON |

DNS, prohibition of work on 1 transfer |

|

P1891 |

Accelerator pedal position sensor signal below normal |

OFF |

Uses the standard pedal depression value. |

|

P1892 |

Accelerator pedal position sensor signal is above normal |

OFF |

Uses the standard pedal depression value. |

|

P2184 |

Low voltage signal coolant temperature sensor |

OFF |

Uses standard temperature value |

|

P2185 |

Coolant temperature sensor signal high voltage |

OFF |

Uses standard temperature value |

|

P2637 |

Disturbance in the operation of the torque control system when changing gears SEM |

ON |

Prohibition of the SEM system |

|

P2641 |

Disturbance in the system of torque limiting on the lower gears LRTP |

ON |

Disable LRTP system operation |

|

P2669 |

HSD2 open circuit |

ON |

SOL OFF, blocking the torque converter, banning the main modulation, DNA |

|

P2670 |

HSD2 low voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2671 |

HSD2 high voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2684 |

HSD3 open circuit |

ON |

SOL OFF, blocking the torque converter, banning the main modulation, DNA |

|

P2685 |

HSD3 low voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2686 |

HSD3 high voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2714 |

Fault in the hydraulic circuit of the PCS4 solenoid |

ON |

DNS, RPR |

|

P2715 |

Fault in the hydraulic circuit of the PCS4 solenoid |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2718 |

PCS4 solenoid open circuit |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2720 |

PCS4 solenoid circuit low voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2721 |

PCS4 solenoid circuit high voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2723 |

Malfunction in the PCS1 solenoid hydraulic circuit |

ON |

DNS, RPR |

|

P2724 |

Malfunction in the PCS1 solenoid hydraulic circuit |

ON |

DNS, RPR |

|

P2727 |

PCS1 solenoid open circuit |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2729 |

PCS1 solenoid circuit low voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2730 |

PCS1 solenoid circuit high voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2736 |

PCS5 solenoid open circuit |

ON |

The ban on the work of the retarder |

|

P2738 |

PCS5 solenoid circuit low voltage |

ON |

The prohibition of work on the 1st gear, the work of the retarder, |

|

P2739 |

PCS5 solenoid circuit high voltage |

ON |

The ban on the work of the retarder |

|

P2740 |

High oil retarder temperature |

OFF |

— |

|

P2742 |

Low signal level of the retarder oil |

OFF |

Uses standard oil temperature |

|

P2743 |

High signal level of the oil retarder temperature |

OFF |

Uses standard oil temperature |

|

P2761 |

Open circuit solenoid lockout torque converter |

ON |

Prohibition of locking torque converter |

|

P2763 |

Low voltage in the lock-up torque converter solenoid circuit |

ON |

Prohibition of locking torque converter |

|

P2764 |

High voltage in the torque converter lock-up solenoid circuit |

ON |

Prohibition of locking torque converter |

|

P2789 |

Friction clutch wear reaches the limit value |

ON |

— |

|

P278A |

Erroneous signal Kickdown |

OFF |

Kickdown mode ban |

|

P2793 |

Communication error with gear switch |

ON |

Ignores pulse width modulation, if the signal through the CAN bus is also lost, it is blocked in the last direction selected |

|

P2808 |

Fault in the hydraulic circuit of the PCS6 solenoid |

ON |

DNS, RPR |

|

P2809 |

Fault in the hydraulic circuit of the PCS6 solenoid |

ON |

DNS, RPR |

|

P2812 |

PCS6 solenoid open circuit |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2814 |

PCS6 solenoid circuit low voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

P2815 |

PCS6 solenoid circuit high voltage |

ON |

DNS, SOL OFF, hydraulic control active |

|

U0001 |

High Speed CAN Bus Counter (IESCAN) overflow |

OFF |

Uses standard values, prohibiting the operation of the torque control system when changing gears |

|

U0010 |

CAN Bus Counter Overflow (IESCAN) |

OFF |

Uses standard values, prohibiting the operation of the torque control system when changing gears |

|

U0100 |

Loss of communication with engine / powertrain unit (J1586) |

ON |

Uses standard values |

|

U0103 |

Loss of communication with the first gear selector |

ON |

Remains in the selected gear, monitors the signal to change the direction of movement. The display goes out for 10 seconds, then shows — / — — / — |

|

U0115 |

Communication error with engine control unit |

ON |

Uses standard values, DNA |

|

U0291 |

Communication error with secondary gear selector |

ON |

Remains in the selected gear, monitors the signal to change the direction of movement. The display |

|

U0304 |

Primary gear selector not compatible with J1939 protocol |

ON |

DNS blocked in neutral |

|

U0333 |

Secondary switch not compatible with J1939 protocol |

ON |

DNS blocked in neutral |

|

U0400 |

Violation of data transmission protocol J1939 |

ON |

— |

|

U0404 |

Inadequate information from the primary gear selector |

ON |

Remains in the selected gear, monitors the signal to change the direction of movement. The display goes out for 10 seconds, then shows — / — — / — |

|

U0442 |

The control unit receives incorrect data from the engine / power unit control unit that is included in the J1939 data bus. |

OFF |

— |

|

U0592 |

Inadequate information from the secondary gear selector |

ON |

Remains in the selected gear, monitors the signal to change the direction of movement. The display 10 sec, then shows — / — — / — |

When the control unit recognizes an error of control,

the corresponding error code

is stored in

memory. To save there

are 5 memory cells, the contents of which can be read through the display switch gear. Cells have

names from «d1» to «d5».

Stop the car to read the codes. Ignition must

be on!

·

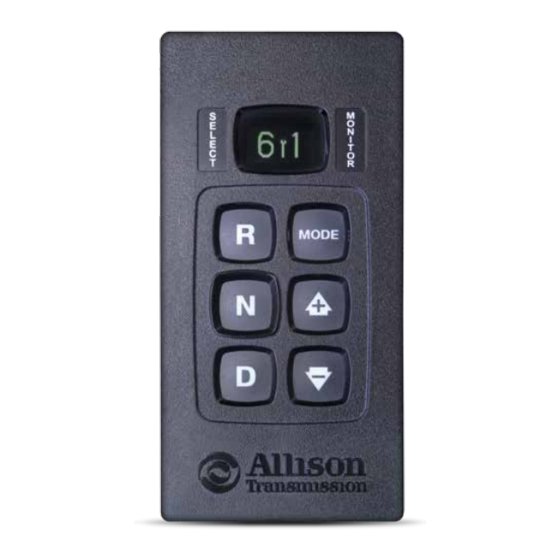

Read on button switch: Both buttons ↑ ↓ at the same time hold — With engine running

1 time; With the engine running 2 times.

·

Reading on lever switch: Press the button menu — With the engine stopped 1 time; With the engine running 2 times.

The display will show the error code stored in the «d1» field. Codes consist of a letter and a four-digit number. The code in this field will be

displayed until the next field is selected with the Mode button or the reading of codes is completed.

Important note: with active codes, the lamp « Mode ON» lights

up (Red LED on

the mode switching button). Only active

codes lead to blocking of automatic transmission functions.

End reading. To leave

the diagnostic mode,

select the neutral or press the «Menu» button or simultaneously two arrow keys until the display shows «N N «

In case of errors, call the

service center.

CAN (Controller Area Network) — Data bus Network via SAE J1939 protocol for connecting various vehicle systems.

DNA (Do Not Adapt)

— Prohibition of

adaptive mode automatic transmission.

DNS (Do Not Shift) — Prohibition of shifting. Automatic transmission remains on a certain gear and does not respond to commands. Torque converter is not

locked.

ECM (Engine Control Module)

— Engine control

unit.

HSD 1, 2,

… (High Side Driver)

— Power supply

control valves 1, 2, …

LRTP (Low Range Torque Protection) — Engine torque limitation on 1-3 gears.

PCS (Pressure Control Solenoid) — Pressure control solenoid.

RPR (Return to Previous Range)

— Switch to the

previous transfer.

SEM (Shift Energy Management) — Control system of the engine torque M during gear changes.

SOL OFF (Solenoids OFF) All solenoids are electrically disconnected. Until the engine is running, and the oil pump is spinning, movement is possible.

SS (Shift Solenoid)

— Solenoid gear

shift.

TID (Trans ID ) — TCM function to determine the configuration of the automatic transmission and the connected devices.

TCC — Torque

converter lock -up clutch.

TCM — Transmission Control Module

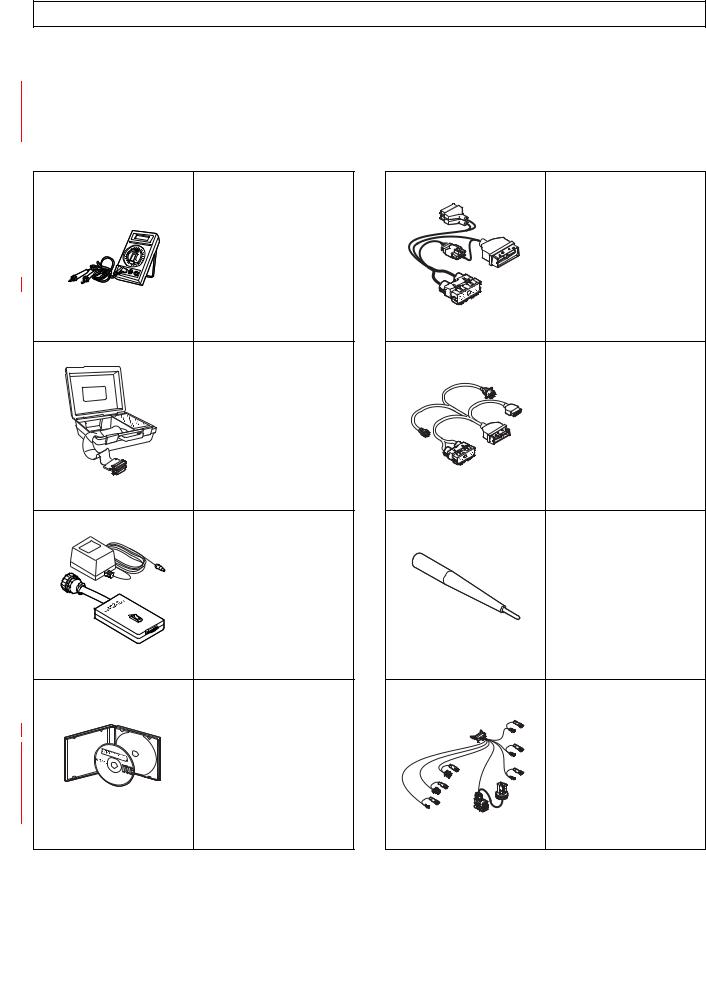

Allison Transmission 1000/2000 series fault codes

Allison Transmission 1000/2000 series fault codes

Allison Transmission 1000,2000 series fa

Adobe Acrobat Document

1.5 MB

Shift Selector Operation and Code Manual PDF

Oil level information, diagnostic codes and prognostic features for 3000/4000 Series Allison Transmissions

Allison Transmission Fault Codes Manual

Adobe Acrobat Document

2.3 MB

Allison Transmission TS3989EN Troubleshooting Manual

3000 and 4000 Product Families Troubleshooting Manual — Allison 4th Generation Controls

Allison Transmission TS3989EN Troublesho

Adobe Acrobat Document

9.6 MB

Shift Selector 5 Generation Fault Codes Manual PDF

Oil Level Information, Diagnostic Codes and Prognostic Features For 3000/4000 Series™ And Tc10™ Allison Transmissions

Allison Transmission 5th Gen Operation F

Adobe Acrobat Document

489.9 KB

Allison Transmission 3000/4000 series fault codes

Allison Transmission 3000/4000 series fault codes

Allison Transmission 3000,4000 series fa

Adobe Acrobat Document

318.1 KB

Allison Transmission Troubleshooting Code Manuals PDF

Allison Transmission Troubleshooting Code Manuals PDF

Allison Transmission TROUBLESHOOTING Cod

Adobe Acrobat Document

711.0 KB

Shift Selector Operation and Code Manual (MY 09 4th Generation — 4TH GENERATION ELECTRONIC CONTROLS)

Double-digit display and was release after July 2008, equipped with Model Year ’09 prognostics

Shift Selector Operation and Code Manual

Adobe Acrobat Document

664.8 KB

Allison Transmission 3000/4000 Operator’s Codes Manual PDF

Motorhome Series (MH) Transmissions : 3000 and 4000 Product Families WTEC III Controls and Aliison 4th Generation Controls

Allison Transmission 3000-4000.pdf

Adobe Acrobat Document

2.1 MB

Password: https://www.pdfmanual4trucks.com/

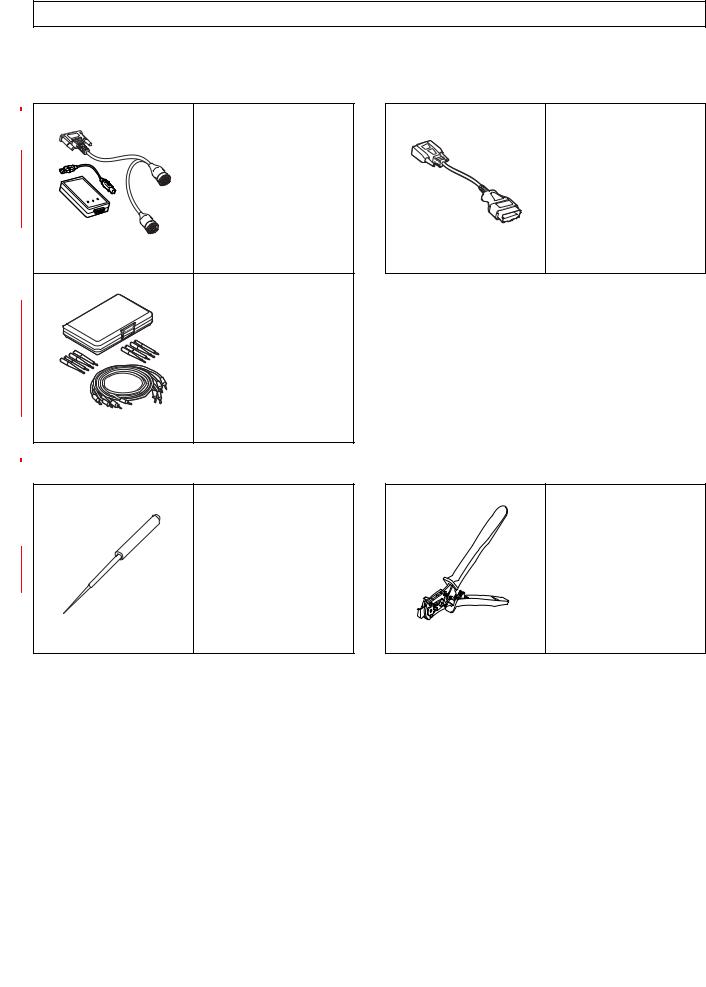

|

Title |

File Size |

Download Links |

|

Allison Transmission 1000 and 2000 Product Families Troubleshooting |

13.1Mb |

Download |

|

Allison Transmission 1000 and 2000 Series Fault Codes List |

18kb |

Download |

|

Allison Transmission 1000,2000 series fault code list [PDF] |

1.5Mb |

Download |

|

Allison Transmission DOC 7.0 PC Service Tools — User Guide PDF |

6.8Mb |

Download |

|

Allison Transmission Electronic Controls Troubleshooting Manual |

54.4Mb |

Download |

|

Allison Transmission TROUBLESHOOTING Codes Manual PDF [PDF] |

713.7kb |

Download |

Password: https://www.pdfmanual4trucks.com/

|

Title |

File Size |

Download Links |

|

Allison 3000-4000 Series Troubleshooting Manual [PDF] |

13.2Mb |

Download |

|

Allison Transmission — Shift Selector — Operator and Diagnostic |

148.3kb |

Download |

|

Allison Transmission 3000,4000 series fault code list [PDF] |

289.6kb |

Download |

|

Allison Transmission 30004000 series fault code list – download PDF |

320.1kb |

Download |

|

Allison Transmission Fault Codes Manual PDF [PDF] |

1.5Mb |

Download |

|

Allison Transmission Troubleshooting Manual GEN4 [PDF] |

2Mb |

Download |

|

Allison Transmission TS2973EN Troubleshooting Manual PDF [PDF] |

5.2Mb |

Download |

|

Shift Selector — Operator and Diagnostic Trouble Code manual |

1.3Mb |

Download |

Коды ошибок акпп аллисон

Основные неисправности и ошибки АКПП

Неправильная эксплуатация, отсутствие техобслуживания или естественное старение — вот причины, почему на панели приборов появляется сигнал «Ошибка АКПП». Водитель может заметить проблему до зажигания лампочки, если распознает признаки неисправности. Расшифровка кодов ошибок поможет узнать в какой цепи произошел сбой, но этого недостаточно для точной диагностики.

Симптомы неисправности АКПП

Водитель может распознать признаки неисправности АКПП тремя способами:

Проблемы DSG схожи по симптомам:

Если индикатор ошибки не гаснет, АКПП не переключается, уходит в аварийный режим, нет движения ни вперед, ни назад — это явный симптом неисправности. Без разборки агрегата не обойтись.

Что поможет избежать типичных неисправностей АКПП

Чтобы не искать способы устранения неисправности коробки автомат в Интернете или в учебниках, лучше заранее узнать, как избежать поломок:

Автоматическая коробка — сложное устройство, созданное по точным инженерным расчётам и конструктивным решениям. Выбирая жидкость и запчасти для АКПП, не стоит жадничать и покупать дешёвые аналоги. Они не выдержат режимов работы автомата, а только отнимут его ресурс.

Основы правильного обследования коробки автомат

Перед тем, как принять решение о ремонте автомата, мастера собирают историю «пациента» и снимают коды ошибок неисправности автоматической коробки передач. Диагностировать АКПП можно по сканеру ELM327. Чтобы самому поставить диагноз, придётся изучить устройство и характерные поломки своей коробки, запастись мануалами.

Коды ошибок помогают найти проблемный участок, но этот метод не даёт точных результатов. Дальше проводят дополнительные исследования:

Если проблема не выявлена, АКПП разбирают для осмотра и проведения тестов:

Разбор АКПП лучше доверить мастеру, знакомому с данной моделью. Однако, не стоит доверять «рентгеновскому» зрению специалиста и заказывать детали до дефектовки и установки диагноза.

Расшифровка кодов системы самодиагностики АКПП

Система бортовой диагностики автоматических коробок OBD-II указывает электроцепи, в которых произошел сбой. Если модуль управления двигателем (ЕСМ) или АКПП (TCM) получил нестандартные показания датчиков, то на бортовой панели загорится индикатор ошибок «Check Engine». Скорость срабатывания лампочки зависит от серьёзности неисправности.

К ошибкам АКПП относятся коды в формате Р07хх и Р08хх. Например, коды P0745 — Р0779 сообщают о проблемах цепи соленоидов. Так, ошибка АКПП группы 0765 — 0769 связана с повреждением соленоида «D», что значит обрыв, замыкание проводки, разрегулировку или поломку клапана. Компьютер выдаёт ошибку, если считывает неверные показания соленоида. Затем управление отключается, а коробка уходит в аварийный режим.

Что означает

Общий код уведомления, может означать:

· повреждение корпуса гидроблока;

Ошибка сообщает об отклонении показателей датчиков от нормы. Чаще всего это связано с неисправностью:

Если при нажатии тормоза не загорается стоп-сигнал, высвечивается ошибка. Возможная причина:

· обрыве или замыкании проводки;

· перегорании предохранителя или лампочек стоп-сигналов;

· неисправности гнезда лампочки;

ЕСМ контролирует обороты двигателя и делится показаниями с ТСМ. Код ошибки срабатывает, если ТСМ не получил сигнал от ЕСМ. Возможные причины:

· повреждение контактов или проводки;

· неправильного уровня масла;

· забитого фильтра, каналов гидроблока;

· неисправных соленоидов или датчиков;

· поломкой одного из модулей управления;

Блокировка ГДТ включается по сигналу ТСМ. Управляющий импульс формируется после сопоставления данных измерителя оборотов двигателя, поступивших от ЕСМ, и измерителя входных оборотов ISS. Ошибка возникает, когда:

· забился или устарел соленоид блокировки ГДТ;

· изношен фрикцион блокировки ГДТ;

· неисправен гидроблок или модуль управления блокировкой ГДТ;

Причины

Определить причину, почему не работает коробка автомат, можно только после сбора основных признаков и расшифровки кодов ошибок. Далее приведены примеры типичных неисправностей АКПП, игнорирование которых может привести к аварии.

Кулиса рычага

Кулиса селектора — связующий механизм между рычагом переключения передач и АКПП. Узел выходит из строя при недостатке смазки, попадании грязи, механической поломке. Неправильная работа механизма может быть связана с разрегулировкой.

Основной признак неисправности кулисы — тугое переключение режимов работы трансмиссии. Если долго не переводить селектор на нижние ступени, то со временем резинки усохнут, а рычаг покроется коррозией.

Появление люфта при качении селектора «влево-вправо» может стать причиной аварий, поскольку мешает чёткому переключению передач. Рычаг АКПП болтается чаще всего из-за разрегулировки, либо ослабления соединения кронштейна троса.

Утечка масла

Падение уровня ATF может стать причиной поломки всей АКПП, поскольку агрегат начинает работать «всухую». Недостаток давления приводит к проскальзыванию фрикционов и некорректному переключению передач. Появляются дёргания, рывки, пробуксовки. Возможные коды ошибок — Р070А — Р070F.

Утечка масла возникает из-за следующих проблем:

Блок управления

Неисправный модуль управления АКПП переводит коробку в аварийный режим: при заведённом двигателе режимы переключаются неправильно или вовсе не реагируют на движение селектора. Электроника выдаёт ошибки U0101, Р0700 — Р0702 и перестаёт работать по следующим причинам:

Проблемы с ТСМ АКПП могут произойти после неудачной перепрошивки, поэтому программирование лучше доверять сервис-центрам.

Неисправности гидроблока

Признаки неисправности гидроблока АКПП: удары и толчки при переключении передач, пробуксовка «на горячую». В запущенном случае может произойти масляное голодание, перегрев, ухудшение динамики автомобиля. Возможные коды ошибок — Р0700 — Р0702, Р0729 — P0736, и другие ошибки, указывающие на проблемы с соленоидами.

Неисправности и ошибки гидроблока АКПП появляются из-за старого масла и высоких нагрузок:

Корзина сцепления

Сцепление в роботе «выключает» крутящий момент, чтобы коробка безопасно переключила передачу. Частая проблема узла — пробуксовка. Это может значить, что:

Если во время движения автомобиль встаёт в аварийный режим, и нет движения ни вперёд, ни назад, нужно проверить выжимной подшипник и его направляющую. Разбитая от высоких нагрузок деталь приводит к поломке всей корзины, «сгрызая» нажимные лепестки. Понять, что АКПП умирает, можно по переключению рычага: сначала будет трудно включить определённую передачу, а когда коробка умрёт — невозможно.

Хруст при включении передней или задней передачи указывает, что сцепление срабатывает не до конца. Проблема может скрываться в актуаторе, выжимном подшипнике или деформированном диске сцепления. Возможный код ошибки — Р0810 — Р0813.

Неисправность гидротрансформатора

Неисправность гидротрансформатора АКПП проявляется в виде стука, шуршания, вибраций, плохой динамики, повышенного расхода топлива. Автомобиль будет двигаться с трудом и медленно набирать скорость. Если агрегат полностью вышел из строя, то машина будет глохнуть или не сдвинется с места. Возможные коды ошибок — Р0740 — Р0744.

Гидромуфта коробки автомат не работает и выдаёт ошибки по следующим причинам:

«Бублик» — главный загрязнитель и нагреватель масла АКПП. Ухудшение свойств жидкости приводит к падению давления, перегреву коробки. Жидкость может нагреваться до 120 — 150℃, «сжигая» детали автомата. Чтобы снизить нагрузку на гидротрансформатор, устанавливают дополнительные радиаторы охлаждения ATF.

Тормозная муфта

Тормозная муфта плавно фиксирует планетарный механизм автомата. Износ тормозной ленты становится причиной появления толчков, рывков и других неприятностей при переключении передач. Если машина буксует на месте, или не работает одна из передач, возможно, произошёл обрыв манжет поршня тормозной ленты.

Тормозная муфта не срабатывает в АКПП обычно при огромном пробеге, в простых коробках, типа Toyota А131Л, VW 010, Chrysler 31TH, ленту меняют в совсем изношенном состоянии. К этому времени муфта полностью пропитывается горелым маслом и клеевыми смолами от «съеденных» фрикционов.

Возможные коды ошибок Р0729 — P0736.

Профилактика неисправностей

Неисправности АКПП появляются из-за грязного масла и агрессивного вождения, способы их устранения заключаются в ремонте и замене деталей. Для профилактики заболеваний коробки нужно:

Заключение

Поломки АКПП приводят к сложному и дорогому ремонту. По справочникам неисправностей редко кто может «вылечить» агрегат, поэтому приходится обращаться в сервис. Предотвратить внеплановый ремонт АКПП поможет плановое техобслуживание и бережное отношение к автомобилю.

Код ошибки P2714 – электромагнитный клапан «D» управления давлением АКПП заклинил в выключенном состоянии

Код ошибки P2714 звучит как «электромагнитный клапан «D» управления давлением АКПП заклинил в выключенном состоянии». Часто, в программах, работающих со сканером OBD-2, название может иметь английское написание «Pressure Control Solenoid “D” Performance Or Stuck Off».

Техническое описание и расшифровка ошибки P2714

Этот диагностический код неисправности (DTC) является общим кодом трансмиссии. Ошибка P2714 считается общим кодом, поскольку применяется ко всем маркам и моделям транспортных средств. Хотя конкретные этапы ремонта могут несколько отличаться в зависимости от модели.

Код неисправности P2714 OBD-II устанавливается, когда модуль управления (PCM) обнаружил проблему с электромагнитным клапаном управления давлением трансмиссии «D». Большинство автоматических трансмиссий имеют по крайней мере три клапана, которые обозначаются A, B и C.

Набор кодов основан на конкретной неисправности, которая предупреждает PCM и включает контрольную лампу двигателя.

Электромагнитные клапаны регулировки давления в трансмиссии служат для управления давлением жидкости и правильной работы АКПП. PCM получает электронный сигнал, основанный на давлении внутри электромагнитного клапана. Автоматическая трансмиссия управляется лентами и муфтами, которые переключают передачи, оказывая давление жидкости в нужном месте в нужное время.

На основе сигналов от связанных устройств, контролирующих скорость транспортного средства, PCM управляет электромагнитными клапанами давления. Чтобы направлять жидкость с соответствующим давлением в различные гидравлические контуры. Которые изменяют передаточное число трансмиссии в нужное время.

Код P2714 устанавливается PCM, когда электромагнитный клапан управления давлением «D» не работает должным образом или застрял в положении «Выкл.».

Симптомы неисправности

Основным симптомом появления ошибки P2714 для водителя является подсветка MIL (индикатор неисправности). Также его называют Check engine или просто «горит чек».

Также они могут проявляться как:

Серьезность этого кода обычно умеренная, но может быстро перейти на более серьезный уровень, если не исправить своевременно.

Причины возникновения ошибки

Код P2714 может означать, что произошла одна или несколько следующих проблем:

Как устранить или сбросить код неисправности P2714

Некоторые предлагаемые шаги для устранения неполадок и исправления кода ошибки P2714:

Диагностика проблем

Перед тем, как начать процесс поиска и устранения любой неисправности, вам следует изучить бюллетени технического обслуживания (TSB) для конкретного автомобиля. В некоторых случаях это может сэкономить много времени, указав вам правильное направление.

Далее, необходимо проверить уровень жидкости и проверить ее состояние на предмет загрязнения. Перед заменой жидкости вам следует проверить записи транспортного средства, чтобы узнать, когда в последний раз меняли фильтр и жидкость.

После этого следует произвести подробный визуальный осмотр для проверки состояния проводки на предмет явных дефектов. Проверьте разъемы и проводку к электромагнитному клапану управления давлением трансмиссии, насосу трансмиссии и PCM. В зависимости от конфигурации, трансмиссионный насос может иметь электрический или механический привод.

Нормальные показания для проводки и соединений должны составлять 0 Ом сопротивления. Проверка целостности проводки всегда должна выполняться при отключенном питании от цепи. Чтобы избежать короткого замыкания и создания дополнительных повреждений.

Сопротивление или отсутствие целостности указывают на неисправную проводку, которая разомкнута или закорочена. В этом случае потребуется ремонт или замена.

На каких автомобилях чаще встречается данная проблема

Проблема с кодом P2714 может встречаться на различных машинах, но всегда есть статистика, на каких марках эта ошибка присутствует чаще. Вот список некоторых из них:

С кодом неисправности Р2714 иногда можно встретить и другие ошибки. Наиболее часто встречаются следующие: P0500, P0504, P0571, P0573, P0700, P0722, P0741, P0746, P0751, P0761, P0776, P0796, P0842, P0873, P0894, P0983, P1589, P2713, P2715, P2716, P2717, C1241, U660E.

Источник

Allison Transmission GEN4 Troubleshooting Manual

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

Руководство по эксплуатации и обслуживанию

АКПП Allison 3000 и 4000 cерий

Электронное управление Gen4.

Походный проезд, д. 4, стр. 1, 2 этаж, офис 207.

E-mail: allison@ndgs.ru или moscow@ndgs.ru

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

0. Условия использования руководства и ограничение ответственности.

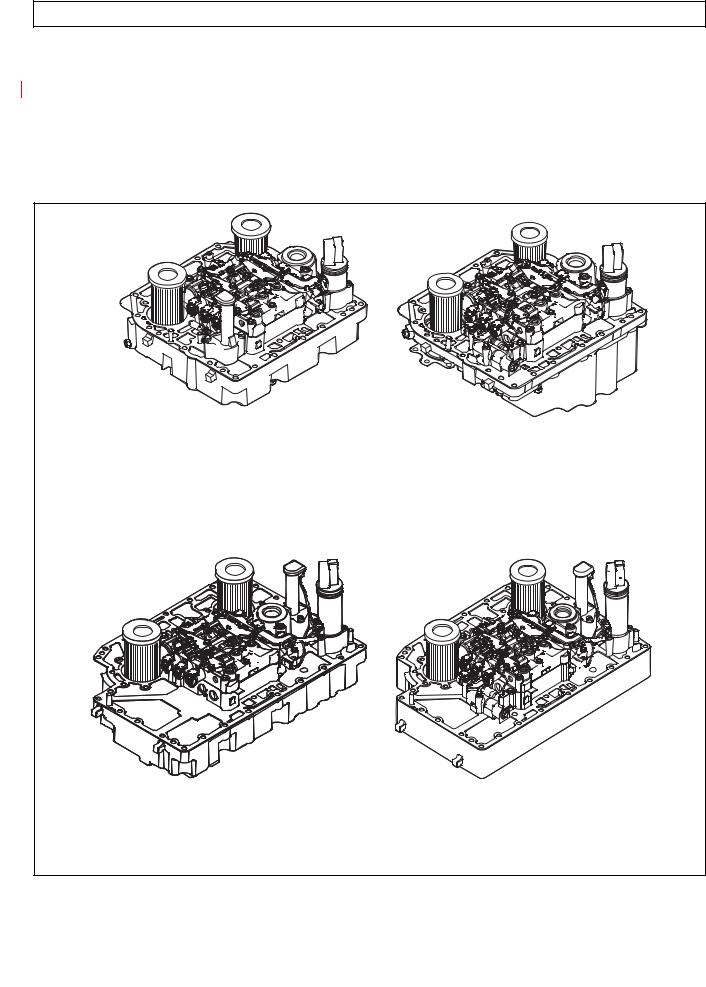

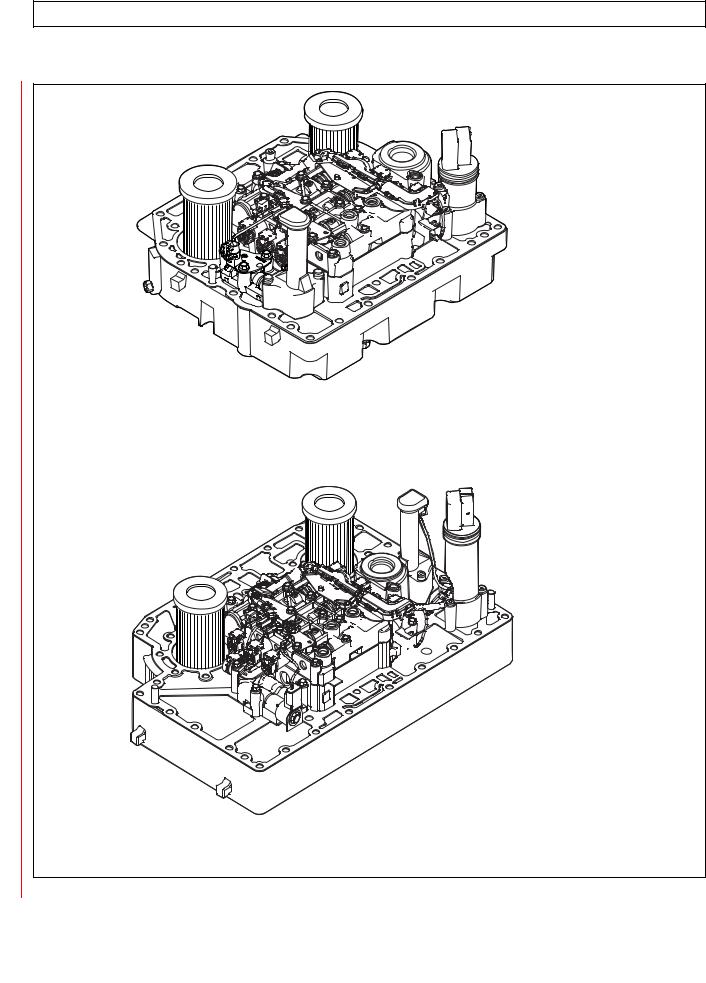

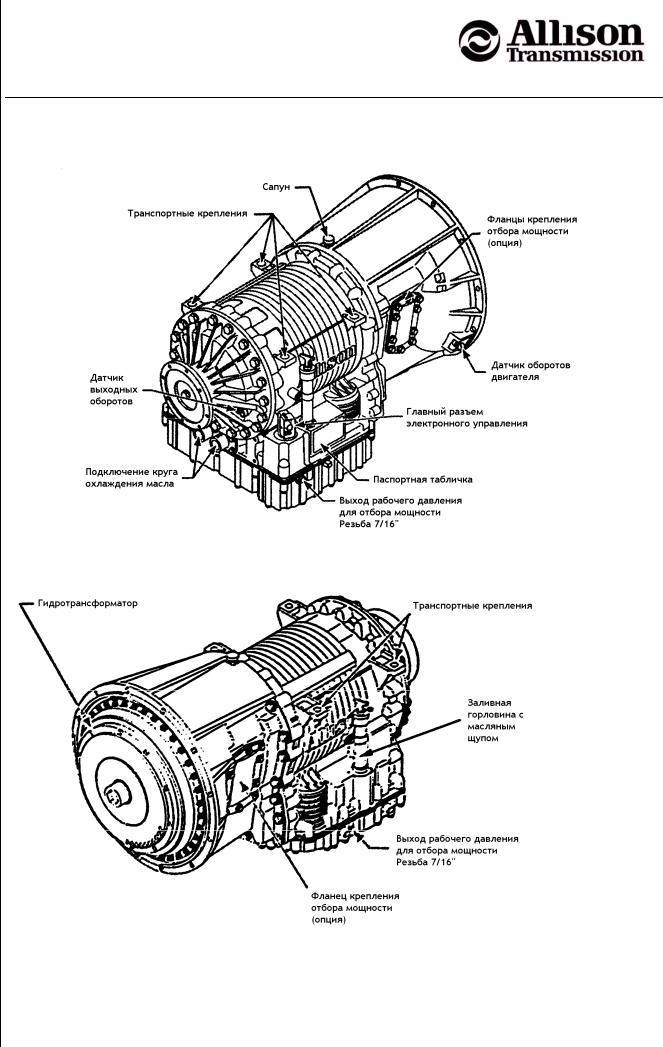

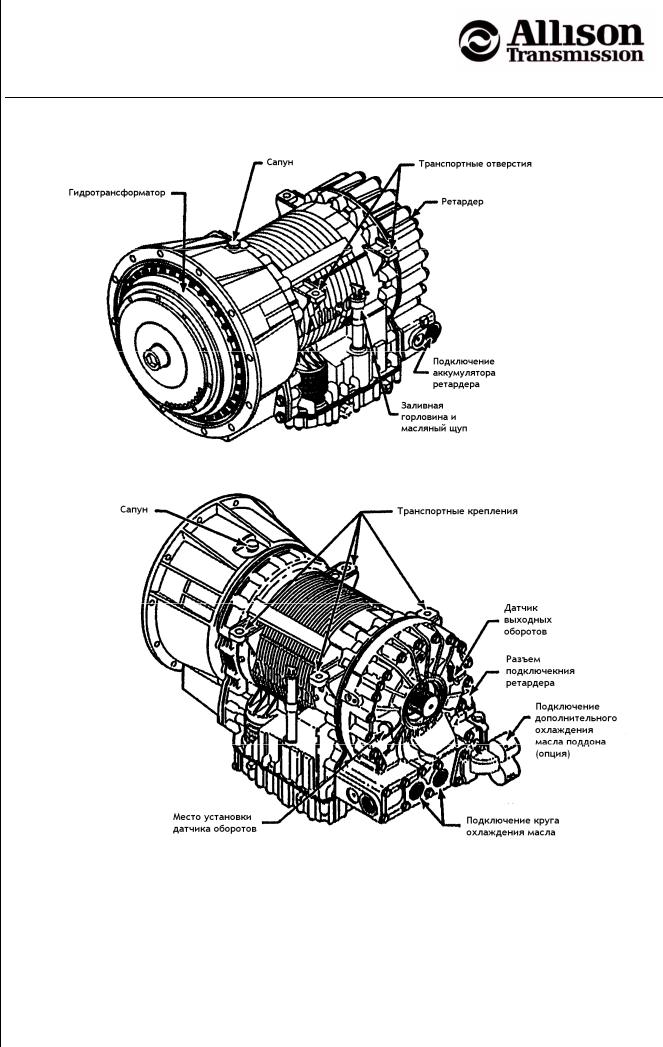

1.0.2 Вид АКПП 3000 Серии с ретардером.

1.0.3 Паспортная табличка АКПП.

1.1 Электронная система управления.

2.0.1 Общие указания по эксплуатации.

2.1.1 Элементы переключателя передач.

2.1.1.3 Светодиод включения дополнительного режима.

2.1.1.4 Кнопка меню (только для рычажного переключателя).

2.1.2 Выбор режима кнопочным переключателем.

2.1.3 Положения рычажного переключателя.

2.2 Другие элементы управления и контроля.

2.2.1 Контрольная лампа нарушения нормальной работы «Check Trans».

2.2.2 Контрольная лампа температуры масла АКПП.

2.2.3 Указатель температуры масла АКПП.

2.2.4 Управление ретардером (опция).

2.2.4.1 Аккумулятор ретардера.

2.3.1 Порядок переключения передач.

2.3.3 Торможение двигателем.

2.3.4 Торможение ретардером.

2.3.5 Предохранительные функции.

2.3.5.1 Защита от перекрутки двигателя и включения слишком низкой

2.3.5.2 Блокировка включения передачи.

2.3.5.3 Влияние температуры масла АКПП и ретардера на

2.3.6 Дополнительные функции.

2.3.6.1 «Быстрая нейтраль» для мусоровозов.

2.3.6.2 Блокировка движения для пожарных машин и спецтехники.

2.3.6.3 Выходной сигнал скорости.

2.4 Меры при буксировке автомобиля.

2.4.1 Запуск двигателя буксировкой.

2.4.2 Буксировка с выключенным двигателем.

2.5.1 Считывание кодов ошибок.

Руководство по эксплуатации и обслуживанию Allison 3000/4000 Gen4.

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

3.1.1 Проверка уровня масла посредством масляного щупа.

3.1.2 Проверка уровня масла через переключатель передач.

Периоды замены масла и фильтров .

Краткая информация по маслам.

4.1 Считывание кодов ошибок.

Руководство по эксплуатации и обслуживанию Allison 3000/4000 Gen4.

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

0. Условия использования руководства и ограничение ответственности

Представленный печатный документ и приводимая в нем информация служат как базисный материал для курсов обучения в НДГС и DGS Diesel- &Getriebeservice GmbH.

Целью обучения является ознакомление с конструкцией и возможностями охватываемых руководством АКПП. Приводимая информация не претендует на полноту и не подлежит автоматическому обновлению при внесении изменений в конструкцию. Учет изменений производится только при переработке издания автором.

Самую последнюю информацию можно найти в соответствующих публикациях Allison Transmission. В разделе литература представлен список изданий Allison Transmission.

Также можно зайти на сайт www.allisontransmission.com

ООО «НДГС», DGS Diesel- &Getriebeservice GmbH и Allison Transmission не несут ответственности за любой ущерб, возникший от использования данного руководства.

Содержимое данного издания и приводимая информация защищены авторскими правами. Копирование, распространение и частичное или полное воспроизведение без письменного разрешения DGS или Allison Transmission не допускаются.

Руководство по эксплуатации и обслуживанию Allison 3000/4000 Gen4.

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

Автоматические трансмиссии Allison 3000 и 4000 Серии – полностью автоматические коробки передач, использующие самые современные технологии с электронной системой управления с шестью (или семью) передачами вперед и одной назад.

Приведенные параметры зависят от применения АКПП (типа транспортного средства). Чтобы получить точные спецификации, обратитесь в ООО «НДГС» или зайдите на сайты www.ndgs.ru или www.allisontransmission.com

Для всех серий имеются различные модификации:

Модификация с возможностью установки КОМ.

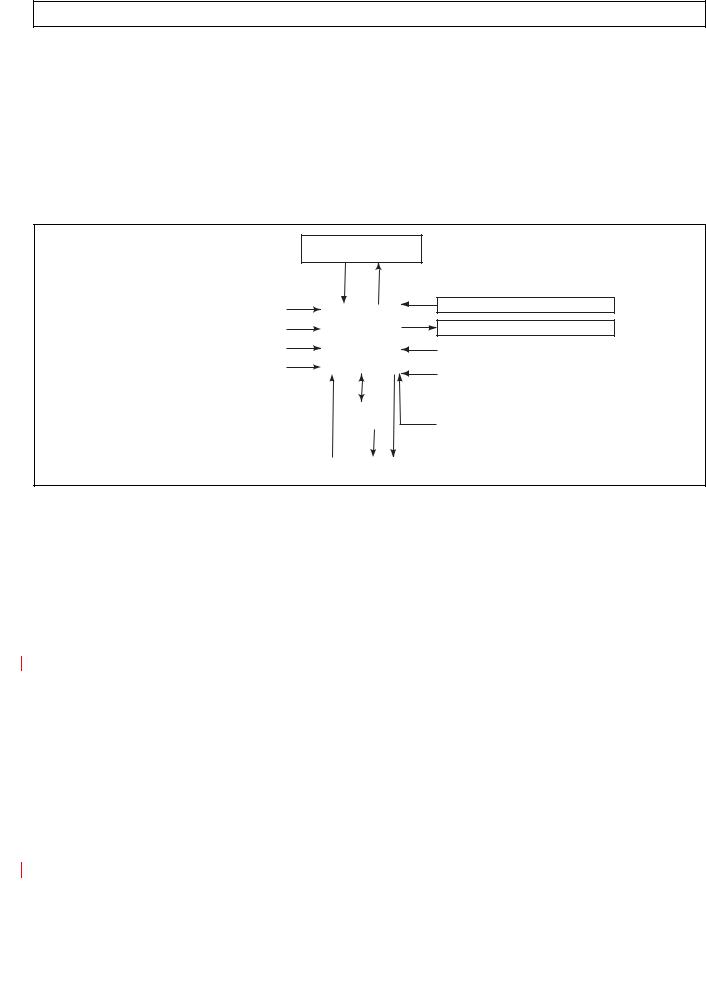

Все модельные ряды построены по общему принципу:

На входе АКПП стоит гидротрансформатор с функцией блокирования (Lock-Up) и встроенным демпфером крутильных колебаний.

После гидротрансформатора следуют косозубые планетарные ряды, организованные по запатентованной схеме, позволяющие плавно переключать передачи без разрыва потока мощности.

Автоматическое переключение управляется электронной системой на основе следующих входных данных:

Положение переключателя передач – Информация о выбранном водителем режиме

Частота вращения выходного вала – Информация о скорости автомобиля

Положение педали акселератора – Информация о режиме работы двигателя

На АКПП может быть установлено до двух отборов мощности

На выходе может быть установлен ретардер

Руководство по эксплуатации и обслуживанию Allison 3000/4000 Gen4.

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

Руководство по эксплуатации и обслуживанию Allison 3000/4000 Gen4.

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

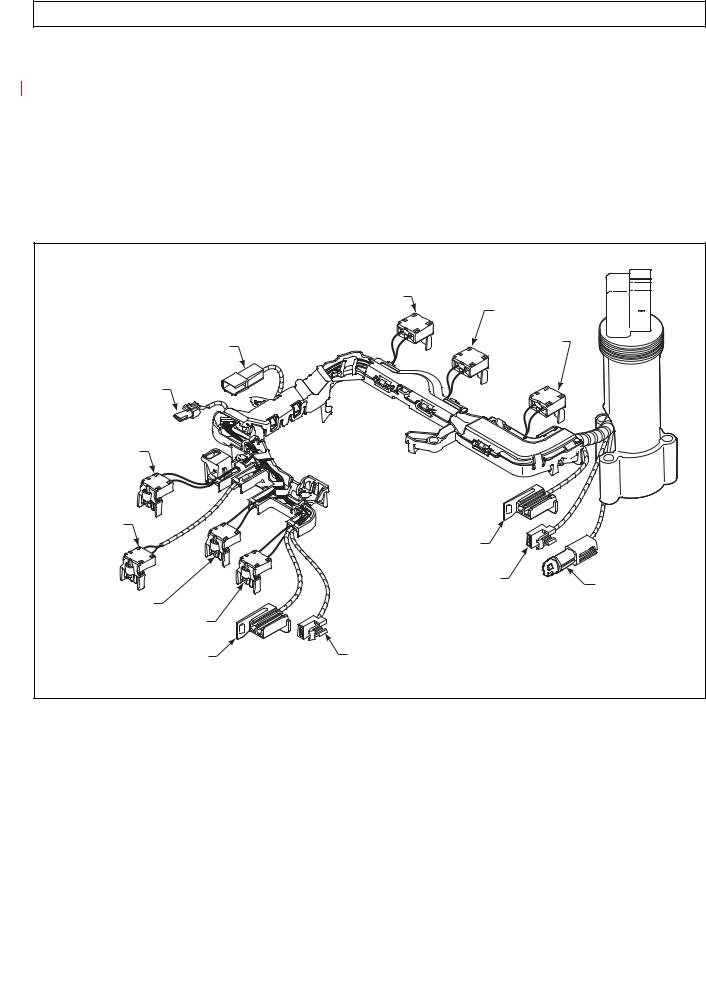

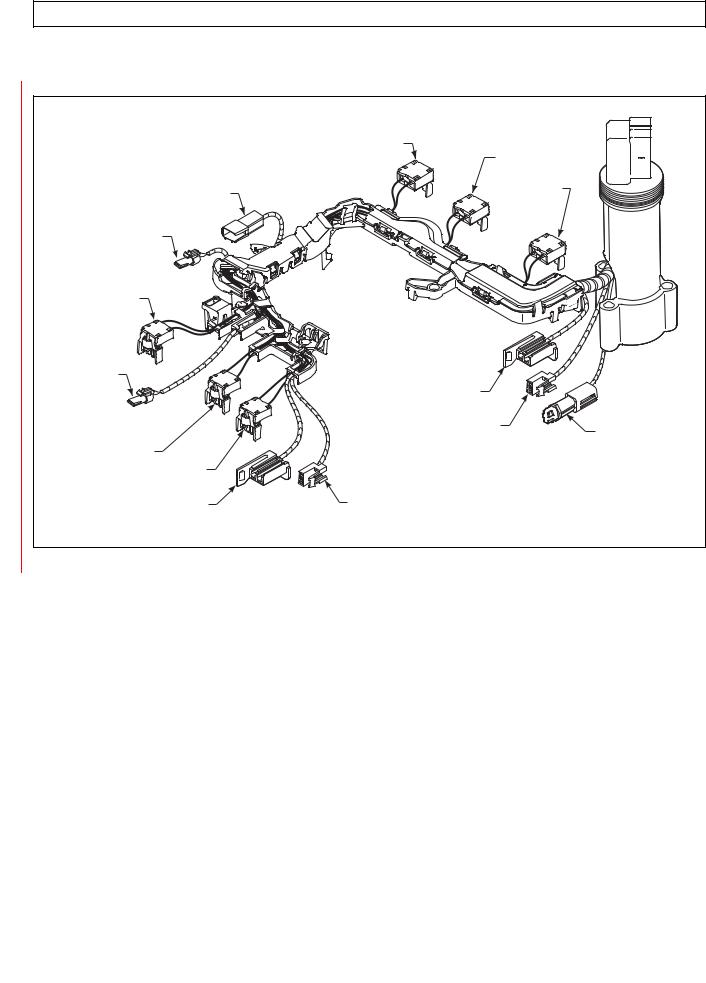

1.0.2 Вид АКПП 3000 Серии с ретардером

Руководство по эксплуатации и обслуживанию Allison 3000/4000 Gen4.

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

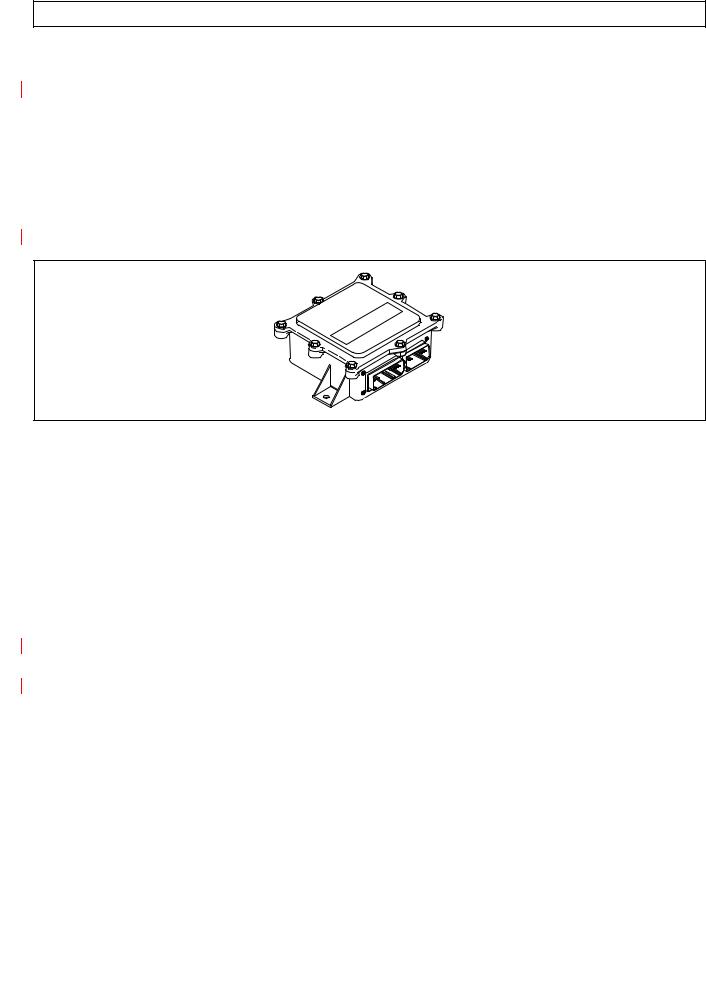

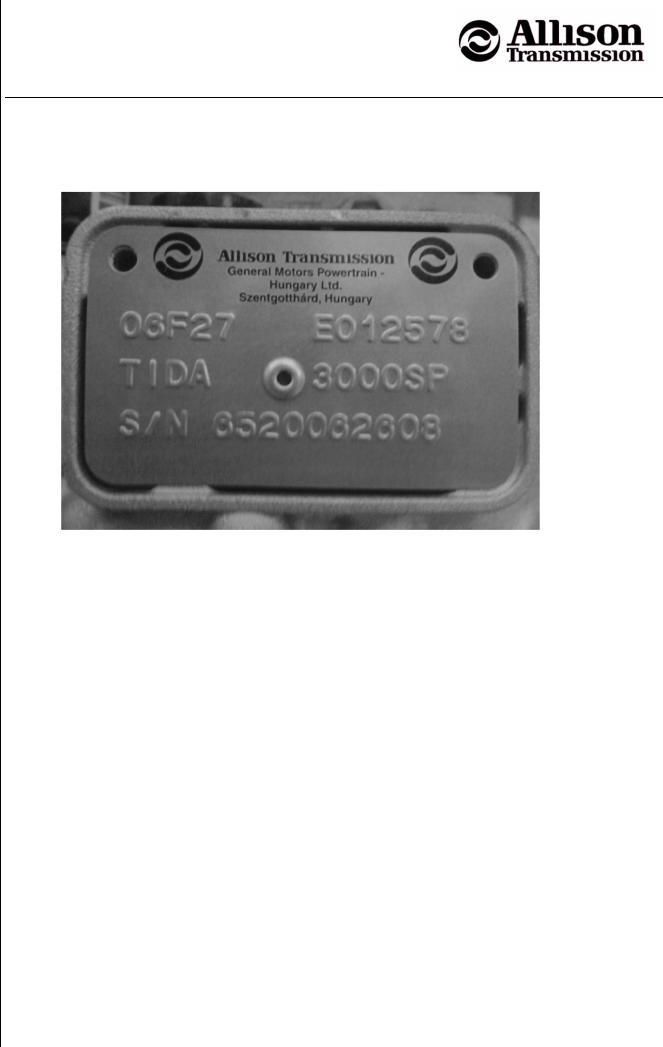

При заказе запасных частей или при решении технических вопросов, а также при проведении гарантийного ремонта, потребуется серийный номер АКПП.

На паспортной табличке можно найти следующую информацию:

Производитель и завод-производитель

Идентификационный номер АКПП Allison

Идентификационный код АКПП

10-значный серийный номер АКПП

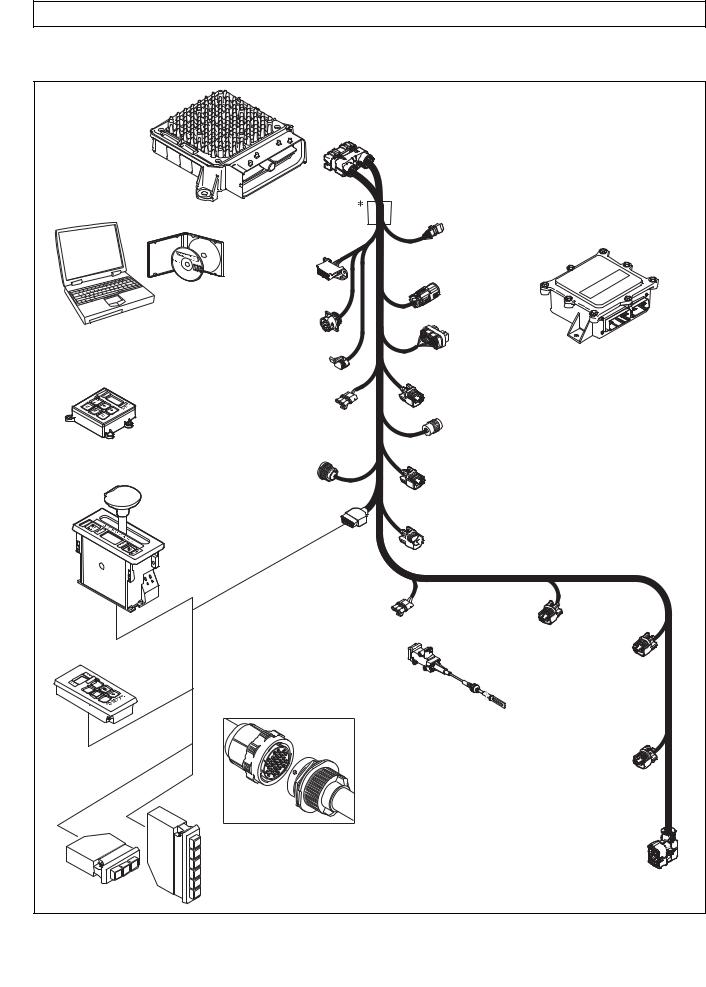

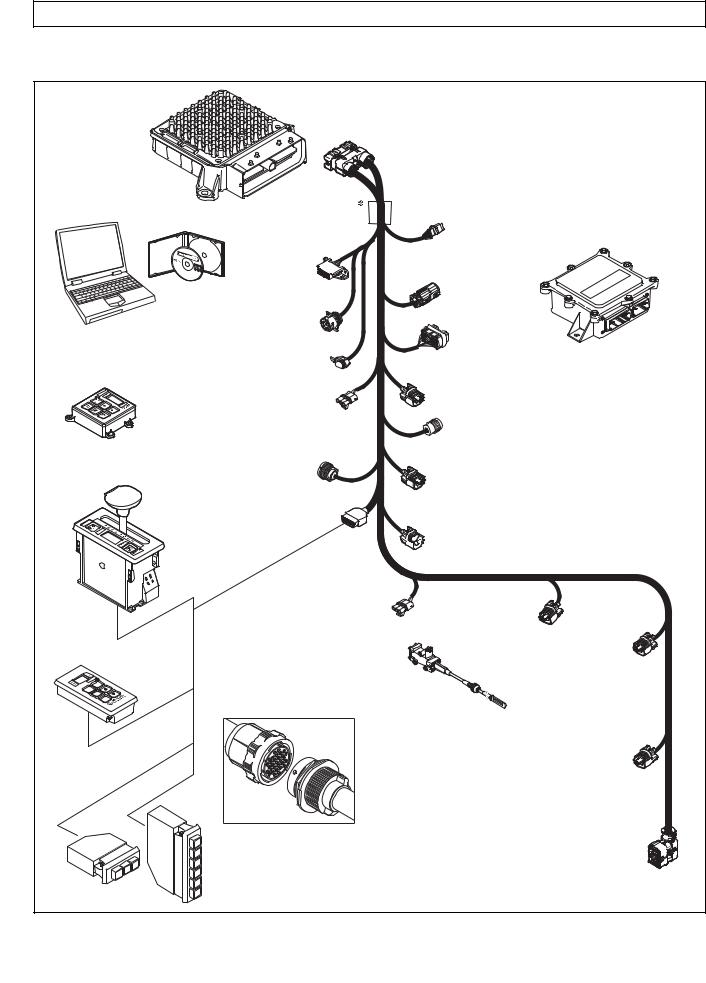

1.1 Электронная система управления

С 2005 модельного года АКПП 3000 и 4000 Серии оснащаются электронной системой управления Allison 4-го поколения (сокращенно Gen4).

Постоянные улучшения и расширения возможностей системы позволяют добавлять новые функции.

Система состоит из следующих компонентов:

Блок управления АКПП (TCM=»Transmission Control Module»);

Три датчика частоты вращения: коленвала двигателя, турбины, выходного вала

Электронный переключатель передач;

Руководство по эксплуатации и обслуживанию Allison 3000/4000 Gen4.

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

Электрогидравлический блок управляющих клапанов.

Блок управления обрабатывает информацию различных датчиков, а также информацию от других систем автомобиля и подаёт сигналы на электромагнитные клапаны для переключения передач.

Блок управления отслеживает скорости вращения выходного вала, коленвала двигателя и турбинного колеса, а также температуру и давление масла. При нарушении нормальной работы в памяти TCM сохраняются коды ошибок, которые можно считать с дисплея переключателя передач.

Электронная система управления отвечает также за отбор мощности, ретардер и другие функции такие, как торможение двигателем, защита от превышения оборотов, блокировка включения передач, «быстрая нейтраль».

Электронная система управления Gen4 совместима с протоколом связи CAN и может обмениваться информацией с другими системам автомобиля.

Руководство по эксплуатации и обслуживанию Allison 3000/4000 Gen4.

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

2.0.1 Общие указания по эксплуатации

Почему полностью автоматическая трансмиссия?

На Вашем автомобиле установлена АКПП Allison 3000/4000 Серии. Эта полностью автоматическая трансмиссия с электронным управлением, использующая самые современные технологии, облегчает управление Вашим коммерческим транспортным средством в тяжелых уличных условиях. В особенности при коротких перевозках в режиме частых остановок автоматическая трансмиссия оказывается оптимальной.

АКПП имеет в зависимости от конструкции и программы управления 4, 5, 6 или 7 передач вперед и 1 назад.

В качестве муфты включения и отключения АКПП служит гидротрансформатор со встроенным механизмом блокировки, который автоматически блокирует гидротрансформатор в движении и разблокирует при остановках. Гидротрансформатор обеспечивает высокий крутящий момент и плавность при трогании, а механизм блокировки

АКПП спроектирована для удобного обслуживания. Ознакомьтесь, пожалуйста, с руководством по техническому обслуживанию.

Для оптимального переключения передач и повышения срока жизни АКПП, всегда следите за следующим:

Несколько советов (базовых правил) по эксплуатации АКПП

Перемену направления движения производить только при остановке автомобиля

и холостых оборотах двигателя.

Используйте стояночный тормоз только при холостых оборотах двигателя.

Следите за тем, чтобы в режиме Drive ручной газ и повышение оборотов

Не допускайте движения автомобиля на нейтральной передаче

На светофоре или в аналогичных ситуациях не выключайте передачу.

Включайте нейтраль только при остановках более 5 минут.

Не допускайте работу двигателя более 5 минут при стоянке автомобиля и

Если вы покидаете автомобиль, включайте нейтраль.

Следите за уровнем масла в АКПП

Соблюдайте периоды обслуживания

Руководство по эксплуатации и обслуживанию Allison 3000/4000 Gen4.

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

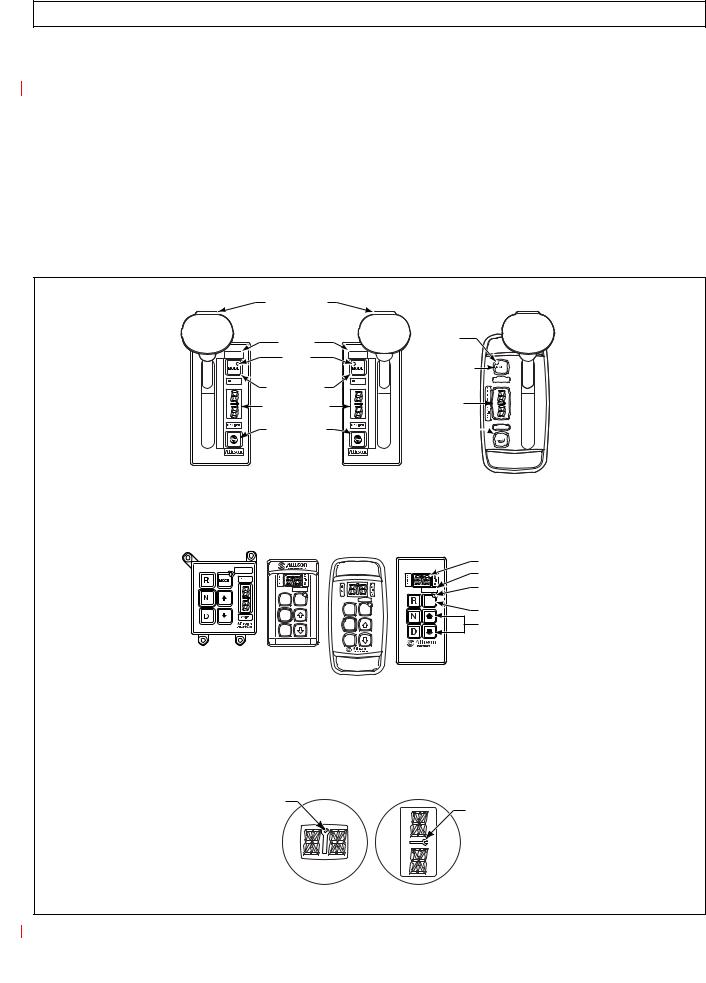

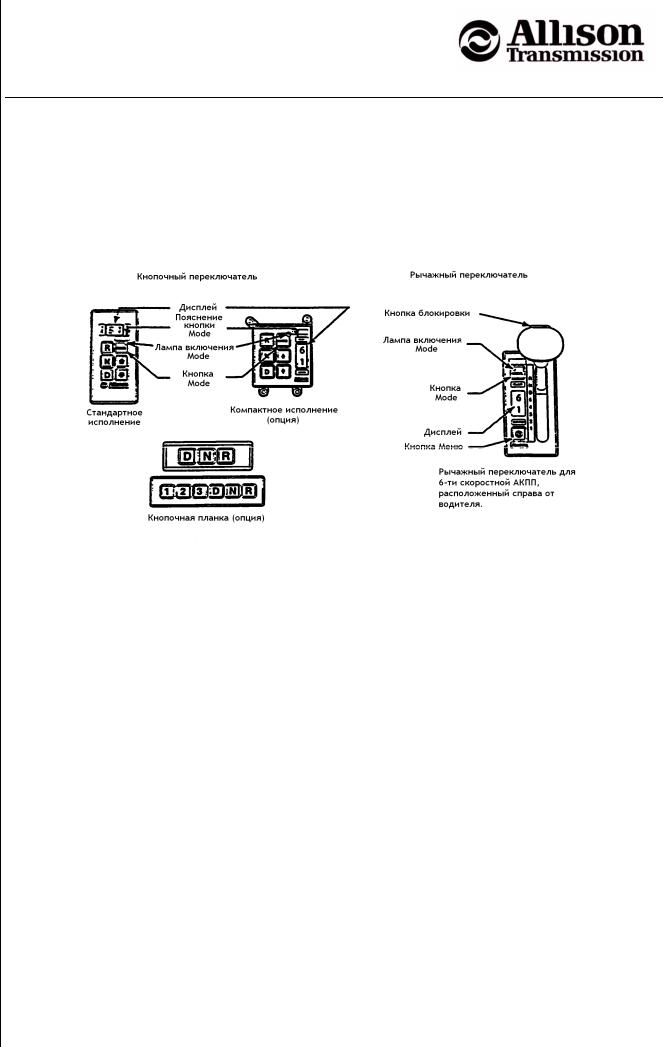

Переключатель передач может быть выполнен в виде кнопочной панели или рычага. Оба варианта электронные.

Как специальный вариант есть упрощенные кнопочные панели. Эти панели сохраняют все функции управления, однако на них отсутствует возможность диагностики и проверки уровня масла, поскольку отсутствует дисплей.

2.1.1 Элементы переключателя передач

Переключатель передач имеет двухэлементный цифровой дисплей

Во время нормальной работы на дисплее отображается два значения. Слева отображается высшая достигаемая передача. В нормальных условиях она определяется положением рычага переключателя передач или задается кнопочным переключателем. Справа на дисплее отображается текущая передача.

При активировании дополнительной функции АКПП может автоматически выбирать передачу, отличающуюся от выбранной водителем. Так, например, при торможении двигателем включается 2-ая передача.

При включении некоторых функций, а также для защиты АКПП в некоторых случаях может быть заблокировано включение передачи. В этом случае независимо от выбора передачи справа будет показана нейтральная передача N. Для снятия блокировки требуется выключить дополнительные функции или устранить причину блокировки.

Показания при нарушении работы

Если жидкокристаллический дисплей полностью высвечен более 12 секунд, это означает, что ему не удалось подключиться к системе управления. Выключите зажигание и включите снова.

Руководство по эксплуатации и обслуживанию Allison 3000/4000 Gen4.

Автоматические коробки передач

Allison 3000 и 4000 Серии

с электронным управлением Gen4.

Если дисплей не горит и в обоих полях через 10 сек. появляются прочерки, подключение к блоку управления нарушено или имеется код ошибки.

Если дисплей не горит вообще, проверьте его подключение.

При ошибках, включающих диагностическую лампу «Check Trans», в поле выбранной передачи ничего не горит, а справа отображается текущая передача.

Если при движении возникает критическая ошибка, управление не реагирует на выбранную передачу, и АКПП остается на включенной в текущий момент передаче, пока двигатель не будет остановлен и зажигание выключено. После этого в случае критической ошибки АКПП будет оставаться в нейтрали, пока не будет устранена причина ошибки.

Показания в режиме диагностики

В режиме проверки уровня масла будет показан код уровня масла.

В режиме диагностики отображаются сохраненные (прошлые) и текущие (активные) коды ошибок.

(«Mode» = Режим) Кнопка режима Mode выполняет две функции:

Кнопкой режима включается запрограммированная дополнительная функция. Для контроля включения режима загорается светодиод. В большинстве случаев дополнительный режим — это особый (например, экономичный) режим переключения передач.

Примеры дополнительных режимов:

«Динамика» — переключение происходит на высоких оборотах двигателя, используется вся его мощность

«Экономия» — двигатель работает в пределах оборотов обеспечивающих наибольшую экономичность.

В режиме диагностики ошибок кнопка Mode переключает сохраненные коды ошибок

2.1.1.3 Светодиод включения дополнительного режима

На кнопке Mode находится красный светодиод. Включение этого диода может означать две вещи:

При нормальной работе это означает, что включен второй режим.

В режиме диагностики, — что отображаемый код ошибки является активным (причина ошибки не устранена)

2.1.1.4 Кнопка меню (только для рычажного переключателя)

Проверка уровня масла и диагностика

Проверка уровня масла (нажать 1 раз)

Диагностика (нажать 2 раза)

При кнопочном переключателе эти функции вызываются соответствующим нажатием

одновременно двух стрелочных кнопок.

Руководство по эксплуатации и обслуживанию Allison 3000/4000 Gen4.

Источник

Allison Transmission 1000 — 2000 Fault Codes DTC

Allison Transmission 1000 — 2000 Fault Codes DTC

Allison Transmission 1000 — 2000 Fault C

Adobe Acrobat Document

19.7 KB

ALLISON 1000, 2000 & 24000 Transmission Fault Codes DTC

DTC Description

Check

Trans

Light Page

P0121 Pedal Postion Sensor Performance Problem No 5-15

P0122 Pedal Postion Sensor Circuit Low Voltage No 5-16

P0123 Pedal Postion Sensor Circuit High Voltage No 5-19

P0218 Transmission Fluid Over Temperature No 5-22

P0562 System Voltage Low Yes 5-26

P0563 System Voltage High Yes 5-29

P0602 TCM Not Programmed Yes 5-33

P0606 Controller Internal Performance Yes 5-34

P0701 Transmission Control System Performance No 5-35

P0703 Brake Switch Circuit No 5-37

P0705 Transmission Range Sensor Circuit (PRNDL Input) No 5-41

P0706 Transmission Range Sensor Circuit Performance Yes 5-45

P0708 Transmission Range Sensor Circuit High Input Yes 5-49

P0710 Transmission Fluid Temperature Sensor Malfunction No 5-53

P0711 Transmission Fluid Temperature Sensor Circuit Performance Yes 5-57

P0712 Transmission Fluid Temperature Sensor Circuit Low Input (High Temperature) Yes 5-61

P0713 Transmission Fluid Temperature Sensor Circuit Low Input (Low Temperature) Yes 5-65

P0716 Turbine Speed Sensor Circuit Performance Yes 5-69

P0717 Turbine Speed Sensor Circuit No Signal Yes 5-73

P0721 Output Speed Sensor Circuit Performance Yes 5-77

P0722 Output Speed Sensor Circuit No Signal Yes 5-81

P0726 Engine Speed Input Circuit Performance Yes 5-85

P0727 Engine Speed Sensor Circuit No Signal Yes 5-89

P0731 Incorrect 1st Gear Ratio Yes 5-93

P0732 Incorrect 2nd Gear Ratio Yes 5-97

P0733 Incorrect 3rd Gear Ratio Yes 5-101

P0734 Incorrect 4th Gear Ratio Yes 5-105

P0735 Incorrect 5th Gear Ratio Yes 5-109

P0736 Incorrect Reverse Ratio Yes 5-113

P0741 Torque Converter Clutch System Stuck Off Yes 5-117

P0742 Torque Converter Clutch System Stuck On Yes 5-120

P0748 Pressure Control Solenoid A Electrical Yes 5-123

P0763 Shift Solenoid C Electrical Yes 5-127

P0768 Shift Solenoid D Electrical Yes 5-131

P0773 Shift Solenoid E Electrical Yes 5-135

P0778 Pressure Control Solenoid B Electrical Yes 5-139

P0840 Transmission Pressure Switch Solenoid C Circuit Yes 5-143

P0841 Transmission Pressure Switch Solenoid C Circuit Stuck Open Yes 5-147

P0842 Transmission Pressure Switch Solenoid C Circuit Stuck Closed Yes 5-151

P0843 Transmission Pressure Switch Solenoid C Circuit High Yes 5-155

P0845 Transmission Pressure Switch Solenoid D Circuit Yes 5-159

P0846 Transmission Pressure Switch Solenoid D Circuit Yes 5-163

P0847 Transmission Pressure Swtich Solenoid D Circuit Yes 5-167

P0848 Transmission Pressure Switch Solenoid D Circuit Yes 5-171

P1688 Unmanaged Engine Torque Delivered to TCM Yes 5-175

P1709 Transmission Pressure Switch Solenoid E Circuit Yes 5-177

P1710 Transmission Pressure Switch Solenoid E Circuit Stuck Open Yes 5-181

P1711 Transmission Pressure Switch Solenoid E Circuit Stuck Closed Yes 5-185

P1712 Transmission Pressure Switch Solenoid E Circuit High Yes 5-189

P1713 Transmission Pressure Switch Reverse Circuit Yes 5-193

P1714 Transmission Pressure Switch Reverse Circuit Stuck On Yes 5-197

P1716 Transmission Pressure Switch Reverse Circuit High no 5-201

P1718 Incorrect Neutral Gear Ration No 5-205

P1720 Solenoid A Controlled Clutch Not Engaged Yes 5-209

P1721 Solenoid B Controlled Clutch Not Engaged Yes 5-213

P1723 Solenoid A Controlled Clutch Engaged Yes 5-217

P1724 Solenoid B Controlled Clutch Engaged Yes 5-221

P1726 Shift Solenoid D Controlled Clutch Engaged No 5-225

P1727 Shift Controlled E Clutch Engaged No 5-229

P1760 TCM Supply Voltage No 5-233

P1779 Engine Torque Delivered To ECM Yes 5-236

P1835 Kickdown Circuit Yes 5-238

P1860 Torque Converter Clutch PWM Solenoid Circuit —Electrical Yes 5-241

P1875 4WD Low Switch Circuit Yes 5-245

P1891 Throttle Postion Sensor Pulse Width Modulation (PWM) Signal Low Input No 5-249

P1892 Throttle Postion Sensor Pulse Width Modulation (PWM) Signal High Input No 5-252

U1000 Serial Data Communication Link Malfunction (Class2) No* 5-255

U1016 Class 2 Powertrain Controller State of Health Failure No* 5-258

U1041 Class 2 ABS Controller State of Health Failure No* 5-261

U1064 Class 2 TBC Controller State of Health Failure No* 5-264

U1096 Class 2 IPC Controller State of Health Failure No* 5-267

U1300 Serial Data Communication Link Low (Class2) No 5-270

U1301 Serial Data Communication Link High (Class2) No 5-273

U2104 Can Bus Rest Counter Overrun Yes 5-276

U2105 Can Bus Error ECM Yes 5-279

Симптомы неисправности АКПП

- горит индикатор неисправности трансмиссии (шестеренка с восклицательным знаком)

- некорректное переключение передач (“пинается”, медленно переключается)

- не включается какая-либо передача (автомобиль не начинает движение)

- трансмиссия перешла в “аварийной режим”

- автомобиль глохнет из-за смены скорости

- работает только 3-я передача

- трансмиссия издает разные звуки (воет, гудит)

- движение автомобиля происходит при установленном рычаге в позицию “N”

- горит индикатор неисправности CHECK ENGINE

Коды ошибок АКПП

P0700 – Управление АКПП, запрос неисправностей (MIL) — неисправность электрической цепи

P0701 – Система управления АКПП — диапазон/функционирование

P0702 – Система управления АКПП — электрическая неисправность

P0703 – Выключатель стоп-сигналов B — неисправность электрической цепи

P0704 – Концевой выключатель (датчик положения) педали сцепления — неисправность электрической цепи

P0705 – Датчик положения селектора АКПП, входной сигнал PRNDL — неисправность электрической цепи

P0706 – Датчик положения селектора КПП — диапазон/функционирование

P0707 – Датчик положения селектора АКПП — низкий уровень сигнала

P0708 – Датчик положения селектора АКПП — высокий уровень входного сигнала

P0709 – Датчик положения селектора АКПП — ненадежный контакт электрической цепи

P0710 – Датчик температуры рабочей жидкости АКПП — неисправность электрической цепи

P0711 – Датчик температуры рабочей жидкости КПП — диапазон/функционирование

P0712 – Датчик температуры рабочей жидкости КПП — низкий уровень сигнала

P0713 – Датчик температуры рабочей жидкости КПП — высокий уровень входного сигнала

P0714 – Датчик температуры рабочей жидкости КПП — ненадежный контакт электрической цепи

P0715 – Датчик частоты вращения входного вала АКПП (турбины гидротрансформатора) — неисправность электрической цепи

P0716 – Датчик частоты вращения входного вала АКПП (турбины гидротрансформатора) — диапазон/функционирование

P0717 – Датчик частоты вращения входного вала АКПП (турбины гидротрансформатора) — нет сигнала

P0718 – Датчик частоты вращения входного вала АКПП (турбины гидротрансформатора) — ненадежный контакт электрической цепи

P0719 – Выключатель стоп-сигналов B — низкий уровень сигнала

P0720 – Датчик частоты вращения выходного вала — неисправность электрической цепи

P0721 – Датчик частоты вращения выходного вала — диапазон/функционирование

P0722 – Датчик частоты вращения выходного вала — нет сигнала

P0723 – Датчик частоты вращения выходного вала — ненадежный контакт электрической цепи

P0724 – Выключатель стоп-сигналов B — высокий уровень сигнала

P0725 – Частота вращения коленчатого вала, входной сигнал — неисправность электрической цепи

P0726 – Частота вращения коленчатого вала, входной сигнал — диапазон/функционирование

P0727 – Частота вращения коленчатого вала, входной сигнал — нет сигнала

P0728 – Частота вращения коленчатого вала, входной сигнал — ненадежный контакт электрической цепи

P0729 – 6-я передача — некорректное передаточное отношение

P0730 – Некорректное передаточное отношение

P0731 – 1-я передача — некорректное передаточное отношение

P0732 – 2-я передача — некорректное передаточное отношение

P0733 – 3-я передача — некорректное передаточное отношение

P0734 – 4-я передача — некорректное передаточное отношение

P0735 – 5-я передача — некорректное передаточное отношение

P0736 – Передача заднего хода — некорректное передаточное отношение

P0737 – Электронный блок управления АКПП, частота вращения — выходная цепь

P0738 – Электронный блок управления АКПП, частота вращения — низкий уровень выходного сигнала

P0739 – Электронный блок управления АКПП, частота вращения — высокий уровень выходного сигнала

P0740 – Электромагнитный клапан муфты блокировки гидротрансформатора — неисправность электрической цепи

P0741 – Электромагнитный клапан муфты блокировки гидротрансформатора — функционирование или «залипание» в закрытом состоянии

P0742 – Электромагнитный клапан муфты блокировки гидротрансформатора — «залипание» в открытом состоянии

P0743 – Электромагнитный клапан муфты блокировки гидротрансформатора — электрическая неисправность

P0744 – Электромагнитный клапан муфты блокировки гидротрансформатора — ненадежный контакт электрической цепи

P0745 – Электромагнитный клапан управления давлением рабочей жидкости КПП — неисправность электрической цепи

P0746 – Электромагнитный клапан управления давлением рабочей жидкости КПП — функционирование или «залипание» в закрытом состоянии

P0747 – Электромагнитный клапан управления давлением рабочей жидкости КПП — «залипание» в открытом состоянии

P0748 – Электромагнитный клапан управления давлением рабочей жидкости КПП — электрическая неисправность

P0749 – Электромагнитный клапан управления давлением рабочей жидкости КПП — ненадежный контакт электрической цепи

P0750 – Э/м клапан А переключения передач — неисправность электрической цепи

P0751 – Э/м клапан А переключения передач — функционирование или «залипание» в закрытом состоянии

P0752 – Э/м клапан А переключения передач — «залипание» в открытом состоянии

P0753 – Э/м клапан А переключения передач — электрическая неисправность

P0754 – Э/м клапан А переключения передач — ненадежный контакт электрической цепи

P0755 – Э/м клапан В переключения передач — неисправность электрической цепи

P0756 – Э/м клапан В переключения передач — функционирование или «залипание» в закрытом состоянии

P0757 – Э/м клапан В переключения передач — «залипание» в открытом состоянии

P0758 – Э/м клапан В переключения передач — электрическая неисправность

P0759 – Э/м клапан B переключения передач — ненадежный контакт электрической цепи

P0760 – Э/м клапан С переключения передач — неисправность электрической цепи

P0761 – Э/м клапан С переключения передач — функционирование или «залипание» в закрытом состоянии

P0762 – Э/м клапан С переключения передач — «залипание» в открытом состоянии

P0763 – Э/м клапан С переключения передач — электрическая неисправность

P0764 – Э/м клапан C переключения передач — ненадежный контакт электрической цепи

P0765 – Э/м клапан D переключения передач — неисправность электрической цепи

P0766 – Э/м клапан D переключения передач — функционирование или «залипание» в закрытом состоянии

P0767 – Э/м клапан D переключения передач — «залипание» в открытом состоянии

P0768 – Э/м клапан D переключения передач — электрическая неисправность

P0769 – Э/м клапан D переключения передач — ненадежный контакт электрической цепи

P0770 – Э/м клапан E переключения передач — неисправность электрической цепи

P0771 – Э/м клапан E переключения передач — функционирование или «залипание» в закрытом состоянии

P0772 – Э/м клапан E переключения передач — «залипание» в открытом состоянии

P0773 – Э/м клапан E переключения передач — электрическая неисправность

P0774 – Э/м клапан E переключения передач — ненадежный контакт электрической цепи

P0775 – Э/м клапан В управления давлением — неисправность

P0776 – Э/м клапан B управления давлением — функционирование или «залипание» в закрытом состоянии

P0777 – Э/м клапан В управления давлением — «залипание» в открытом состоянии

P0778 – Э/м клапан В управления давлением — электрическая неисправность

P0779 – Э/м клапан В управления давлением — ненадежный контакт электрической цепи

P0780 – Выбор передачи — неисправность переключения

P0781 – Выбор передачи, 1-2 — неисправность переключения

P0782 – Выбор передачи, 2-3 — неисправность переключения

P0783 – Выбор передачи, 3-4 — неисправность переключения

P0784 – Выбор передачи, 4-5 — неисправность переключения

P0785 – Электромагнитный клапан переключения / синхронизации передач — неисправность электрической цепи

P0786 – Электромагнитный клапан переключения / синхронизации передач — диапазон/функционирование

P0787 – Электромагнитный клапан синхронизации переключения передач — низкий уровень

P0788 – Электромагнитный клапан синхронизации переключения передач — высокий уровень

P0789 – Электромагнитный клапан синхронизации переключения передач — ненадежный контакт электрической цепи

P0790 – Переключатель выбора режима работы АКПП — неисправность электрической цепи

P0791 – Датчик частоты вращения промежуточного вала КПП — неисправность электрической цепи

P0792 – Датчик частоты вращения промежуточного вала КПП — диапазон/функционирование

P0793 – Датчик частоты вращения промежуточного вала КПП — нет сигнала