Ошибка 42:10 HP DesignJet T120 | T125 | T130 | T520 | T525 | T530

Данная ошибка возникает с плоттерами старых моделей HP DesignJet T120 и T520, а также с новыми моделями HP DesignJet T125 T130 T525 и T530. С чем это связано и как это устранить рассмотрим ниже.

System error (Системная ошибка): 42:10

Описание проблемы: Проблема с приводом узла каретки

Узлы, которые могут быть связаны с данной ошибкой:

Шлейф (кабель) каретки, плата каретки, мотор привода каретки, ремень каретки, лента энкодера

Корректирующее действие:

1. Выключите питание и отсоедините шнур питания. Снова подсоедините кабель питания и включите принтер.

2. Перейдите в меню поддержи, нажав кнопку питания и удерживая ее в течении 15 секунд.

3. Перейдите в меню диагностики и выберете пункт 2. И запустите утилиту 2.1

4. После выполнения этой диагностики принтер выдаст одну из следующих системных ошибок:

● 42.1:10 замените двигатель каретки и выполните описанные ниже действия по устранению неполадок на месте.

● Мотор привода каретки – CQ890-67006

● 02:10 замените каретку в сборе и выполните действия по устранению неполадок на месте.

● Каретка в сборе (24) – CQ890-67002

● Каретка в сборе (36) – CQ893-67011

5. Пользователь должен организовать визит сервисного инженера для замены нужной детали в зависимости от системной ошибки.

Выявить точную проблему поможет детальная диагностика. В 90% случаях выходит из строя мотор каретки. Также не обязательно брать каретку в сборе, если именно она вышла из строя. В зависимости от того, какой узел вышел из строя, его можно заменить отдельно. То есть из набора каретки можно отдельно приобрести или заменить каждую деталь в отдельности, будь то плата каретки, шлейф каретки, ролик натяжителя, лента энкодера или ремень привода каретки. Ниже указаны цены по замене каждого компонента без учета деталей. Более детальную информацию Вы можете получить, перейдя на страницу ремонт плоттеров HP DesignJet T 120 T520.

- Замена шлейфа каретки 3 000 рублей

- Замена каретки в сборе 3 500 рублей

- Замена мотора привода узла каретки 2 500 рублей

- Замена ремня привода каретки 3 500 рублей

- Замена ленты позиционирования 2 200 рублей

| Обращайтесь в наш сервисный центр, будем рады Вам помочь! |

| Ответим на интересующие Вас вопросы ( в чатах моментальные ответы / Будние дни). |

| Связаться с нами можно по телефонам: |

| 8 ( 499 ) 720 – 60 – 20 | с 9 :00 до 18 :00 |

| 8 ( 495 ) 507 — 80 – 10 | в любой день с 11:00 до 23 : 00 |

Hey,

Im assuming the carriage motor is the scan axis motor that has been replaced.

Check the quality of the drive belt, is it torn or worn out?

Where along the path does the carriage assembly stop?

Is there any noises associated, possibly grind sound?

With the printer off and the carriage in the middle of the printer, hold the belt firmly and try to move the carriage.

If it moves at all, the clip on the back of the carriage that holds the belt in place is broken. You would have to replace the carriage assembly.

I have had the 42:10 error come up on a T2300 before for the clip being broken.

Hope this helps,

Tom

Ошибка 42:10 HP DesignJet T120 | T125 | T130 | T520 | T525 | T530

Данная ошибка возникает с плоттерами старых моделей HP DesignJet T120 и T520, а также с новыми моделями HP DesignJet T125 T130 T525 и T530. С чем это связано и как это устранить рассмотрим ниже.

System error (Системная ошибка): 42:10

Описание проблемы: Проблема с приводом узла каретки

Узлы, которые могут быть связаны с данной ошибкой:

Шлейф (кабель) каретки, плата каретки, мотор привода каретки, ремень каретки, лента энкодера

Корректирующее действие:

1. Выключите питание и отсоедините шнур питания. Снова подсоедините кабель питания и включите принтер.

2. Перейдите в меню поддержи, нажав кнопку питания и удерживая ее в течении 15 секунд.

3. Перейдите в меню диагностики и выберете пункт 2. И запустите утилиту 2.1

4. После выполнения этой диагностики принтер выдаст одну из следующих системных ошибок:

● 42.1:10 замените двигатель каретки и выполните описанные ниже действия по устранению неполадок на месте.

● Мотор привода каретки – CQ890-67006

● 02:10 замените каретку в сборе и выполните действия по устранению неполадок на месте.

● Каретка в сборе (24) – CQ890-67002

● Каретка в сборе (36) – CQ893-67011

5. Пользователь должен организовать визит сервисного инженера для замены нужной детали в зависимости от системной ошибки.

Выявить точную проблему поможет детальная диагностика. В 90% случаях выходит из строя мотор каретки. Также не обязательно брать каретку в сборе, если именно она вышла из строя. В зависимости от того, какой узел вышел из строя, его можно заменить отдельно. То есть из набора каретки можно отдельно приобрести или заменить каждую деталь в отдельности, будь то плата каретки, шлейф каретки, ролик натяжителя, лента энкодера или ремень привода каретки. Ниже указаны цены по замене каждого компонента без учета деталей. Более детальную информацию Вы можете получить, перейдя на страницу ремонт плоттеров HP DesignJet T 120 T520.

- Замена шлейфа каретки 3 000 рублей

- Замена каретки в сборе 3 500 рублей

- Замена мотора привода узла каретки 2 500 рублей

- Замена ремня привода каретки 3 500 рублей

- Замена ленты позиционирования 2 200 рублей

| Обращайтесь в наш сервисный центр, будем рады Вам помочь! |

| Ответим на интересующие Вас вопросы ( в чатах моментальные ответы / Будние дни). |

| Связаться с нами можно по телефонам: |

| 8 ( 499 ) 720 – 60 – 20 | с 9 :00 до 18 :00 |

| 8 ( 495 ) 507 — 80 – 10 | в любой день с 11:00 до 23 : 00 |

- Sign up

- Sign in

- HP Community

- Printers

- DesignJet, Large Format Printers and Digital Press

- HP Designjet T520 Error code 42:10

Options

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Create an account on the HP Community to personalize your profile and ask a question

Your account also allows you to connect with HP support faster, access a personal dashboard to manage all of your devices in one place, view warranty information, case status and more.

Get help with Large Format Printers, with direct access to all Latex Knowledge Center · Ask anything · Find anything · Share anything at HP LKC

11-22-2019

03:13 AM

HP Recommended

- Mark as New

- Bookmark

- Subscribe

- Permalink

- Flag Post

Product: HP Designjet T520 error 42:10

Operating System: Microsoft Windows 10 (64-bit)

I have HP Designjet T520 when I switch it on it has error 42:10 and then I deside to change CQ890-67023 AmpXL Main PCA Pro

and then problem still persist and then I change CQ890-67006 AmpXL 24 Carriage motor SV/Unity But still problem is the same please help me to know what could be the problem!!!!!!!!!!??

Thanks&Regard,

Denis A Minja,

Phone:+255 683100024,

:+255 686571136,

SKYPE: denis.minja3

Daresaalam — Tanzania.

1 REPLY 1

12-28-2019

07:31 PM

HP Recommended

- Mark as New

- Bookmark

- Subscribe

- Permalink

- Flag Post

Hey there!

When this error appears the first thing to do is go to Diagnostics menu and run 2.1 Carriage Servo

There wil be two related errors prompted that can be the root problem.

42.1:10 Which indicates the motor needs to be replaced. (in your case its already changed)

and at last 02:10 Replace the carriage assembly.

* Other potential parts associated are: Trailing Cables, encoder Strip, carriage board.

Hope it helps!

Was this reply helpful?

Yes

No

Be alert for scammers posting fake support phone numbers and/or email addresses on the community.

If you think you have received a fake HP Support message, please report it to us by clicking on «Flag Post».

† The opinions expressed above are the personal opinions of the authors, not of HP. By using this site, you accept the Terms of Use and Rules of Participation.

-

English

Open Menu

† The opinions expressed above are the personal opinions of the authors, not of HP. By using this site, you accept the <a href=»https://www8.hp.com/us/en/terms-of-use.html» class=»udrlinesmall»>Terms of Use</a> and <a href=»/t5/custom/page/page-id/hp.rulespage» class=»udrlinesmall»> Rules of Participation</a>.

- Sign up

- Sign in

- HP Community

- Printers

- DesignJet, Large Format Printers and Digital Press

- HP Designjet T520 Error code 42:10

Options

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Create an account on the HP Community to personalize your profile and ask a question

Your account also allows you to connect with HP support faster, access a personal dashboard to manage all of your devices in one place, view warranty information, case status and more.

Get help with Large Format Printers, with direct access to all Latex Knowledge Center · Ask anything · Find anything · Share anything at HP LKC

11-22-2019

03:13 AM

HP Recommended

- Mark as New

- Bookmark

- Subscribe

- Permalink

- Flag Post

Product: HP Designjet T520 error 42:10

Operating System: Microsoft Windows 10 (64-bit)

I have HP Designjet T520 when I switch it on it has error 42:10 and then I deside to change CQ890-67023 AmpXL Main PCA Pro

and then problem still persist and then I change CQ890-67006 AmpXL 24 Carriage motor SV/Unity But still problem is the same please help me to know what could be the problem!!!!!!!!!!??

Thanks&Regard,

Denis A Minja,

Phone:+255 683100024,

:+255 686571136,

SKYPE: denis.minja3

Daresaalam — Tanzania.

1 REPLY 1

12-28-2019

07:31 PM

HP Recommended

- Mark as New

- Bookmark

- Subscribe

- Permalink

- Flag Post

Hey there!

When this error appears the first thing to do is go to Diagnostics menu and run 2.1 Carriage Servo

There wil be two related errors prompted that can be the root problem.

42.1:10 Which indicates the motor needs to be replaced. (in your case its already changed)

and at last 02:10 Replace the carriage assembly.

* Other potential parts associated are: Trailing Cables, encoder Strip, carriage board.

Hope it helps!

Was this reply helpful?

Yes

No

Be alert for scammers posting fake support phone numbers and/or email addresses on the community.

If you think you have received a fake HP Support message, please report it to us by clicking on «Flag Post».

† The opinions expressed above are the personal opinions of the authors, not of HP. By using this site, you accept the Terms of Use and Rules of Participation.

-

English

Open Menu

† The opinions expressed above are the personal opinions of the authors, not of HP. By using this site, you accept the <a href=»https://www8.hp.com/us/en/terms-of-use.html» class=»udrlinesmall»>Terms of Use</a> and <a href=»/t5/custom/page/page-id/hp.rulespage» class=»udrlinesmall»> Rules of Participation</a>.

Introduction: This document explains the general procedure to follow when the printer shows continuous or intermittent System Error 86:01 (also 86:10 or 86:11) or 42:10 when initializing or printing. This document can be used with the following printers:

HP Designjet T-Series Printers: T610/T620/T1100/T1120/T1200/T770/T2300/T790/T1300/Z2100/Z3100/Z3200/Z5200/Z5400.

Generally, System Error 86:01 refers to paper jams or obstructions (problems moving the carriage) in the Scan Axis area. On the other hand, System Error 42:10 refers to a Scan Axis Motor Failure (electrical problem caused by difficulties moving the carriage – too much force needed to move it due to obstructions, high friction or restrictions). However, it is important to understand that System Error 86:01 is not always a real visible paper jam and it should never be confused with System Error 81:01 (Paper Axis). On the other hand, System Error 42:10 is not always a problem with the Scan Axis Motor. Troubleshooting for both errors, consequently, is basically the same.

In simple terms, ANY restriction or obstruction preventing the carriage from freely moving will cause the printer to stop working and show any of these errors.

The best and easier way to diagnose the problem is to locate the spot where the carriage stops when the printer shows the error (in case of no real paper jam). Most likely the main possible cause of the issue will be there.

If service onsite is needed, a proper diagnosis of the failing component is indispensable. Even if one component looks like the obvious cause of the problem, it is important to check other Scan Axis components.

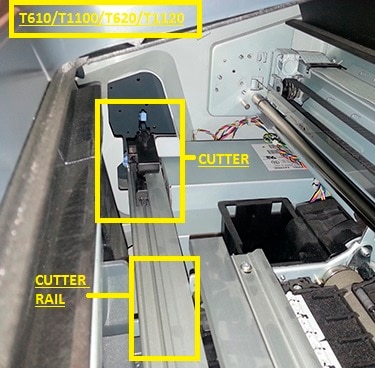

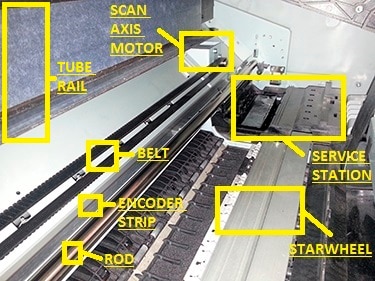

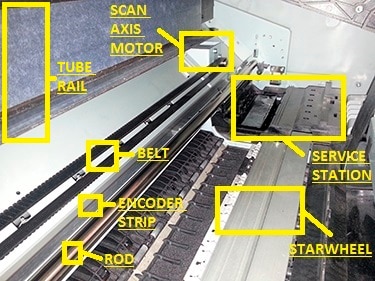

Check the following picture to better identify the main Scan Axis components:

In case no visible obstructions are found in the Scan Axis area, here there are some of the most common causes of these errors.

Possible hardware causes:

-

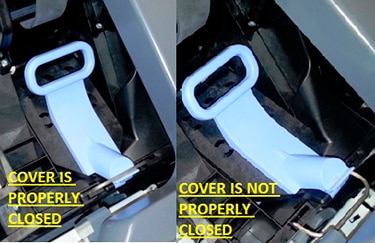

Carriage: With the printer unplugged and no paper loaded, MANUALLY move it from side to side, check for general obstructions. It must move freely across the entire Scan Axis area. If the carriage is locked by the Service Station (right hand side) it will not be possible to manually take the carriage out. If so, the recommendation is to restart the printer, wait for the carriage to come out and then unplug the printer. The Carriage Cover MUST be properly closed (blue latch must engage the metal piece in front of the carriage). If required, for ideal troubleshooting, it is recommended to remove all printheads (PHs) from the carriage to look for pieces of paper under the PHs. Also, check if they are delaminated (thin plastic strip at the bottom) as this may make them crash with the paper. Keep them out during the rest of the diagnosis.

-

Cutter: For printers with the cutter NOT attached to the carriage (T610/T1100/T620/T1120/Z2100/Z3100/Z3200/Z5200), make sure it is completely toward the left hand side of the printer (when facing it). No pieces of paper must be obstructing its movement. It must engage and disengage correctly and it should freely move (with no friction) through its rail. For printers with the cutter attached to the carriage (T770/T1200/T790/T1300/T2300/Z5400), make sure that it slides freely when the carriage is manually moved from side to side. It must be deactivated (up position) and no pieces of paper must be obstructing its movement. It must engage and disengage correctly. For ideal troubleshooting (if the cutter is suspected as part of the problem) it is recommended to remove it. For any printer it is a Customer Self Replaceable part.

-

Belt: if it is loose, worn-out, shredded or broken, the Scan Axis Motor will not be able to grab it and move it. In some cases, the part of the belt being worn-out (missing teeth) or shredded will “slip” when it is grabbed by the motor. Noises are common when this happens. Because of this, it is important to closely check the entire belt, inch by inch. If it starts missing teeth, they will get either all over the Scan Axis or on top of the printouts. Also, check (if possible) the Belt Tensioner (left end of the belt when facing the printer), it may be broken or out of place. Depending on the printer series, the tensioner may not be included with the belt.

-

Carriage rod: It must be properly oiled. The carriage must slide freely through it, if not; clean and oil the rod using synthetic oil.

-

Encoder strip: It must not be scratched, bent or damaged. If dirty, proceed to clean it using a non-abrasive liquid and a lint-free cloth. Hold the cloth in an inverted “U” shape around the Encoder Strip. Wipe until no ink residue appears on the cloth.

-

Service station: Pieces or paper may have fallen in it. Check for obstruction, especially if the carriage stops on it when it shows the System Error. If so, it is important to also remove all PHs.

-

Starwheel assembly: If there are pieces of paper under it, it will not be able to move up and down correctly. If it remains only in the up position, the carriage may touch it when it moves from side to side. When the lever on the left is up, paper must be able to manually pass under the Starwheel Assembly and through the complete Paper Axis area (from the back to the front) with no problems.

-

Trailing Cable/Ink tubes: The Ink Tubes must freely move and follow the movement of the carriage. They must also slide freely through the Tube Rail. The Trailing Cable must freely move and follow the movement of the carriage and tubes. On the T610/T1100/T620/T1120/Z2100/Z3100/Z3200/Z5200 the Trailing Cable is located separate from the Ink Tubes. On the T770/T1200/T790/T1300/T2300/Z5400 the Trailing Cable is attached to the Ink Tubes.

-

Scan Axis Motor: Check if it is able to move the carriage while initializing (if the error is continuous), if so the motor is OK. Scan Axis Motor issues can be easily mistaken with encoder reading issues (Carriage Encoder Sensor is not able to read the Encoder Strip). If the motor is not apparently moving it is a good idea to restart the printer with the Window Sensor is blocked and check if the carriage moves at least a couple of millimeters (pay close attention). If it moves then most likely the motor is not the problem. In this case the issue has to do with encoder reading; service will be needed.

note:

If any issue persists, it will be necessary to run some internal tests. For more information about this or if any further assistance is needed, contact HP Technical Support.

-

mio-print

- Новичок

- Сообщения: 17

- Зарегистрирован: 08 авг 2017 16:16

- Последний визит: 11 ноя 2021 11:40

- Изменить репутацию:

Репутация: нет - Откуда: Москва

HP LATEX 370 ошибка 42:10

Может кто сталкивался с такой ошибкой. Принтер не включается, начитает загружаться, а потом выдает ошибку 42:10

Вроде связано с серво двигателем. читал что нужно войти в сервисное меню и запустить диагностику серво двигателя, но не знаю как туда войти.

-

Roman Saw

- Постоянный участник

- Сообщения: 102

- Зарегистрирован: 15 окт 2018 23:12

- Последний визит: 31 май 2022 19:08

- Изменить репутацию:

Репутация:

Голосов: 2 - Откуда: Красноярск

Re: HP LATEX 370 ошибка 42:10

Сообщение Roman Saw » 29 июл 2020 19:29

Ось каретки почистить и смазать.На каком этапе выскакивает ?

-

mio-print

- Новичок

- Сообщения: 17

- Зарегистрирован: 08 авг 2017 16:16

- Последний визит: 11 ноя 2021 11:40

- Изменить репутацию:

Репутация: нет - Откуда: Москва

Re: HP LATEX 370 ошибка 42:10

Сообщение mio-print » 29 июл 2020 19:46

Смазал, да и регулярно смазываю и сейчас смазал, все равно, загружается почти полностью остается секунд 10 и выкидывает ошибку

каретка ходит туда сюда когда загружается, материал выгрузил

-

Roman Saw

- Постоянный участник

- Сообщения: 102

- Зарегистрирован: 15 окт 2018 23:12

- Последний визит: 31 май 2022 19:08

- Изменить репутацию:

Репутация:

Голосов: 2 - Откуда: Красноярск

Re: HP LATEX 370 ошибка 42:10

Сообщение Roman Saw » 30 июл 2020 06:46

Шлейфы смотреть, Двигатели редко выходят из строя.

-

mio-print

- Новичок

- Сообщения: 17

- Зарегистрирован: 08 авг 2017 16:16

- Последний визит: 11 ноя 2021 11:40

- Изменить репутацию:

Репутация: нет - Откуда: Москва

Re: HP LATEX 370 ошибка 42:10

Сообщение mio-print » 30 июл 2020 09:53

В общем достал картридж для чистки голов и он запустился, видимо картридж испортился

-

mio-print

- Новичок

- Сообщения: 17

- Зарегистрирован: 08 авг 2017 16:16

- Последний визит: 11 ноя 2021 11:40

- Изменить репутацию:

Репутация: нет - Откуда: Москва

Re: HP LATEX 370 ошибка 42:10

Сообщение mio-print » 30 июл 2020 15:52

а где находится датчик энкодерной ленты?

-

decopoligraf

- Постоянный участник

- Сообщения: 174

- Зарегистрирован: 05 окт 2014 10:37

- Последний визит: 02 янв 2023 12:37

- Изменить репутацию:

Репутация:

Голосов: 2 - Откуда: Sepuhov

Re: HP LATEX 370 ошибка 42:10

Сообщение decopoligraf » 25 авг 2022 18:51

Датчик находится в карете!

-

decopoligraf

- Постоянный участник

- Сообщения: 174

- Зарегистрирован: 05 окт 2014 10:37

- Последний визит: 02 янв 2023 12:37

- Изменить репутацию:

Репутация:

Голосов: 2 - Откуда: Sepuhov

Re: HP LATEX 370 ошибка 42:10

Сообщение decopoligraf » 06 окт 2022 22:39

Чистящий картридж мог закончится и нужно перемотать и новую полоску чистую наклейть сверху!

Вернуться в «Принтеры HEWLETT-PACKARD»

Кто сейчас на конференции

Сейчас этот форум просматривают: нет зарегистрированных пользователей и 2 гостя

В данной статье мы поговорим об общем положении ошибок. Все системные ошибки можно посмотреть в сервисном мануале вашего плоттера. Опытные мастера без проблем определяют причину возникновения той или иной ошибки и устраняют их в большинстве случаев на территории заказчика. Большинство ошибок плоттера не имеют прямую связь с кодом ошибки и не могут быть исправлены описанными действиями, но тем не менее существуют и не критические ошибки, которые устраняются действиями рядового пользователя. В таких случаях компания HP рекомендует вызывать квалифицированных инженеров.

При некоторых ошибках можно продолжать работу, нажав кнопку Enter на передней панели; при других ошибках продолжать работу нельзя — попробуйте выключить и включить принтер, если ошибка не исчезла, то требуется квалифицированное вмешательство.

Код ошибки состоит из четырех цифр; в таблице 1 приведены расшифровки первых двух цифр, в таблице 2 — последних двух. Чтоб открыть таблицу нажмите на кнопку Показать/Скрыть

Таблица 1: первые две цифры кода ошибки

Таблица 2: последние две цифры кода ошибки

Утилита просмотра лог-файла ошибок

Подробное описание кодов ошибок плоттеров HP

Если Вы умный, смелый, ловкий и умелый, желаете работать в дружном коллективе и зарабатывать достойную заработную плату, то просто позвоните нам,…

Для юридических лиц мы рекомендуем заключить договор на сервисное техническое обслуживание. В случае, если Вы заключите договор во время покупки…

Introduction: This document explains the general procedure to follow when the printer shows continuous or intermittent System Error 86:01 (also 86:10 or 86:11) or 42:10 when initializing or printing. This document can be used with the following printers:

HP Designjet T-Series Printers: T610/T620/T1100/T1120/T1200/T770/T2300/T790/T1300/Z2100/Z3100/Z3200/Z5200/Z5400.

Generally, System Error 86:01 refers to paper jams or obstructions (problems moving the carriage) in the Scan Axis area. On the other hand, System Error 42:10 refers to a Scan Axis Motor Failure (electrical problem caused by difficulties moving the carriage – too much force needed to move it due to obstructions, high friction or restrictions). However, it is important to understand that System Error 86:01 is not always a real visible paper jam and it should never be confused with System Error 81:01 (Paper Axis). On the other hand, System Error 42:10 is not always a problem with the Scan Axis Motor. Troubleshooting for both errors, consequently, is basically the same.

In simple terms, ANY restriction or obstruction preventing the carriage from freely moving will cause the printer to stop working and show any of these errors.

The best and easier way to diagnose the problem is to locate the spot where the carriage stops when the printer shows the error (in case of no real paper jam). Most likely the main possible cause of the issue will be there.

If service onsite is needed, a proper diagnosis of the failing component is indispensable. Even if one component looks like the obvious cause of the problem, it is important to check other Scan Axis components.

Check the following picture to better identify the main Scan Axis components:

In case no visible obstructions are found in the Scan Axis area, here there are some of the most common causes of these errors.

Possible hardware causes:

-

Carriage: With the printer unplugged and no paper loaded, MANUALLY move it from side to side, check for general obstructions. It must move freely across the entire Scan Axis area. If the carriage is locked by the Service Station (right hand side) it will not be possible to manually take the carriage out. If so, the recommendation is to restart the printer, wait for the carriage to come out and then unplug the printer. The Carriage Cover MUST be properly closed (blue latch must engage the metal piece in front of the carriage). If required, for ideal troubleshooting, it is recommended to remove all printheads (PHs) from the carriage to look for pieces of paper under the PHs. Also, check if they are delaminated (thin plastic strip at the bottom) as this may make them crash with the paper. Keep them out during the rest of the diagnosis.

-

Cutter: For printers with the cutter NOT attached to the carriage (T610/T1100/T620/T1120/Z2100/Z3100/Z3200/Z5200), make sure it is completely toward the left hand side of the printer (when facing it). No pieces of paper must be obstructing its movement. It must engage and disengage correctly and it should freely move (with no friction) through its rail. For printers with the cutter attached to the carriage (T770/T1200/T790/T1300/T2300/Z5400), make sure that it slides freely when the carriage is manually moved from side to side. It must be deactivated (up position) and no pieces of paper must be obstructing its movement. It must engage and disengage correctly. For ideal troubleshooting (if the cutter is suspected as part of the problem) it is recommended to remove it. For any printer it is a Customer Self Replaceable part.

-

Belt: if it is loose, worn-out, shredded or broken, the Scan Axis Motor will not be able to grab it and move it. In some cases, the part of the belt being worn-out (missing teeth) or shredded will “slip” when it is grabbed by the motor. Noises are common when this happens. Because of this, it is important to closely check the entire belt, inch by inch. If it starts missing teeth, they will get either all over the Scan Axis or on top of the printouts. Also, check (if possible) the Belt Tensioner (left end of the belt when facing the printer), it may be broken or out of place. Depending on the printer series, the tensioner may not be included with the belt.

-

Carriage rod: It must be properly oiled. The carriage must slide freely through it, if not; clean and oil the rod using synthetic oil.

-

Encoder strip: It must not be scratched, bent or damaged. If dirty, proceed to clean it using a non-abrasive liquid and a lint-free cloth. Hold the cloth in an inverted “U” shape around the Encoder Strip. Wipe until no ink residue appears on the cloth.

-

Service station: Pieces or paper may have fallen in it. Check for obstruction, especially if the carriage stops on it when it shows the System Error. If so, it is important to also remove all PHs.

-

Starwheel assembly: If there are pieces of paper under it, it will not be able to move up and down correctly. If it remains only in the up position, the carriage may touch it when it moves from side to side. When the lever on the left is up, paper must be able to manually pass under the Starwheel Assembly and through the complete Paper Axis area (from the back to the front) with no problems.

-

Trailing Cable/Ink tubes: The Ink Tubes must freely move and follow the movement of the carriage. They must also slide freely through the Tube Rail. The Trailing Cable must freely move and follow the movement of the carriage and tubes. On the T610/T1100/T620/T1120/Z2100/Z3100/Z3200/Z5200 the Trailing Cable is located separate from the Ink Tubes. On the T770/T1200/T790/T1300/T2300/Z5400 the Trailing Cable is attached to the Ink Tubes.

-

Scan Axis Motor: Check if it is able to move the carriage while initializing (if the error is continuous), if so the motor is OK. Scan Axis Motor issues can be easily mistaken with encoder reading issues (Carriage Encoder Sensor is not able to read the Encoder Strip). If the motor is not apparently moving it is a good idea to restart the printer with the Window Sensor is blocked and check if the carriage moves at least a couple of millimeters (pay close attention). If it moves then most likely the motor is not the problem. In this case the issue has to do with encoder reading; service will be needed.

note:

If any issue persists, it will be necessary to run some internal tests. For more information about this or if any further assistance is needed, contact HP Technical Support.

Curing System Error

Help and Support

System error 16.42:10 means the printer has detected a curing system failure.

(The Curing Module(s) fixes the latex ink (cures) at around 80–116°C for satisfactory durability depending on the

substrate.)

There are either 3 or 4 curing modules in your printer depending on the model:

3 Curing Modules: HP Latex 115, 310, 315

4 Curing Modules: HP Latex 330, 335, 360, 365, 370, 560, 570

This error will normally appear when the printer is warming up before printing.

Why am I getting this error?

The error relates to a fault with Curing Fan 2 which is located on the right middle side of the heater closest to the front panel on the Latex 300 Series. (Fan 2 is on the left middle side on the Latex 500 Series.)

If the error is intermittent you may also experience curing issues in this area of your prints.

Is there anything I can do to fix this?

- Restart the printer

- Check that you have the correct power requirements for the printer. (Check the Site Preparation Guide available on HP’s website)

I’ve tried the above but the error still appears. What do I do?

In our experience this error normally means that there is a hardware fault with the Curing Module

Normally the Curing Module will need to be replaced by a technician to resolve the error.

Get in touch with our support team to discuss this error and get a quotation for repair.

System Error 16.42:10

Coverage:

England & Wales

Fill in the form for help & support

The information provided on this website is designed to provide helpful information on the subjects discussed. Every effort has been made to ensure the accuracy of all information on this website. We are not responsible for any damage or issues arising from the information on this website.

Our Service

DTech Support are conveniently located in the Midlands to provide a range of support services for HP Designjet & Latex Printers.

If your HP Designjet or Latex Printer has a problem or fault then book one of our local HP Engineers to visit your offices and get up & running in no time.

Simply fill in the form above (or call 0330 0432135) & we will respond with a full quotation. We support the entire range of HP Designjet Plotters, HP Latex Printers and ONYX Rip Software.