Struggling with troubleshooting and repair? Keep your equipment running smoothly by using the following guide to diagnose any trip codes. The following are some of the common errors you might encounter:

Emerson Commander SK Fault & Trip Codes by Control Techniques

| Trip Code | Condition | Possible Cause |

| UU | DC Bus under voltage | Low AC Supply Voltage

Low DC Bus voltage when supplied by an external DC power supply |

| OU | DC Bus over voltage | Deceleration rate set too fast for the inertia of the machine

Mechanical load driving the motor |

| OI.AC** | Drive output instantaneous over current | Insufficient ramp times

Phase to phase or phase to ground short circuit on the drives output Drive requires autotuning to the motor Motor or motor connections changed, re-autotune drive to motor |

| OI.br** | Braking Resistor instantaneous over current | Excessive current in braking resistor

Braking resistor value to small |

| O.SPd | Over Speed | Excessive motor speed (typically caused by a mechanical load driving the motor |

| tunE | Autotune stopped before completion | Run command removed before autotune compelte |

| It.br | I2t on Braking Resistor | Excessive braking resistor energy |

| lt.AC | l2t on drive output current | Excessive Mechanical load

High impedance phase to phase or phase to ground short circuit at drive output Drive requires re-autotuning to motor |

| O.ht1 | IGBT over heat based on dries thermal model | Over heat software thermal module |

| O.ht2 | Over heat based on drives heatsink | Heatsink temperature exceeds maximum allowable |

| th | Motor thermistor trip | Excessive motor temperature |

| O.Ld1* | User +24v or digital output overload | Excessive load or short circuit on +24v output |

| cL1 | Analogue input 1 current mode, current loss | Input current less than 3mA when 4-20 or 20-4mA modes selected |

| SCL | Serial communication loss time-out | Loss of communication when drive is under remote control |

| EEF | Internal Drive EEPROM trip | Possible loss of parameter values |

| PH | Input phase imbalance or input phase loss | One of the input phases has become disconnected from the drive (applies to 200/400v three phase drives only, not dual rated drives. |

| rS | Failure to measure motors stator resistance | Motor too small for drive

Motor cable disconnected during measurement |

| C.Err | SmartStick data error | Bad connection or memory corrupt within SmartStick |

| C.dAt | SmartStick data does not exist | New/empty SmartStick being read |

| C.Acc | SmartStick read/write error fail | Bad connection or faulty SmartStick |

| C.rtg | SmartStick/drive rating change | Already programmed SmartStick read by a drive of a different rating |

| O.cL | Overload on current loop input | Input current exceeds 25mA |

| HFxx trip | Hardware faults | Internal drive hardware fault |

HF01 to HF03

Not used

HF04

Low DC bus at power up- may indicate an AC Input or pre-charge problem

HF05

No internal handshake signal from second processor (DSP) at start up

HF06

Unexpected interrupt

HF07

Watchdog failure

HF08

Interrupt crash (code overrun)

HF09 to HF10

Not used

HF11

Access to the EEPROM failed- tried to read stored parameter data but failed

HF12 to HF19

Not used

HF20

Power stage – code error Tried to read power board and read back erroneous

HF21

Power stage – unrecognized frame size

HF22

Overcurrent detection at power up- possible output short or bridge failure

HF23

DSP software overrun

HF24

Not Used

HF25

DSP Communications failure- communication from main to 2nd processor

HF26

Soft start relay failed to close; or soft start monitor failed; or braking

IGBT short circuit at power up

HF27

Power stage thermistor fault

HF28

Power circuit thermistor 2 or 3 fault Internal fan fault on size 3 only

HF29

Fan failure (current too high – only on drives with a fan) see note below

HF30

Not used

HF31

Internal Cap Bank Fan failure- check for fan rotation/blockage Size 4 and up

HF32

Power circuit temperature feedback multiplexer failure

Looking for more information about Control Techniques equipment? Read on here.

Shopping for new or refurbished Control Techniques parts? Shop for the parts you’re looking for here, or find out more about how MRO Electric can help you repair your equipment.

Joe Kaminski is an industrial automation specialist at MRO Electric. He has a background in industrial engineering and supply chain management. Joe has worked in the automation industry for over 10 years providing support to some of the largest companies in the world. For more info, visit www.mroelectric.com.

Struggling with troubleshooting and repair? Keep your equipment running smoothly by using the following guide to diagnose any trip codes. The following are some of the common errors you might encounter:

Emerson Commander SK Fault & Trip Codes by Control Techniques

| Trip Code | Condition | Possible Cause |

| UU | DC Bus under voltage | Low AC Supply Voltage

Low DC Bus voltage when supplied by an external DC power supply |

| OU | DC Bus over voltage | Deceleration rate set too fast for the inertia of the machine

Mechanical load driving the motor |

| OI.AC** | Drive output instantaneous over current | Insufficient ramp times

Phase to phase or phase to ground short circuit on the drives output Drive requires autotuning to the motor Motor or motor connections changed, re-autotune drive to motor |

| OI.br** | Braking Resistor instantaneous over current | Excessive current in braking resistor

Braking resistor value to small |

| O.SPd | Over Speed | Excessive motor speed (typically caused by a mechanical load driving the motor |

| tunE | Autotune stopped before completion | Run command removed before autotune compelte |

| It.br | I2t on Braking Resistor | Excessive braking resistor energy |

| lt.AC | l2t on drive output current | Excessive Mechanical load

High impedance phase to phase or phase to ground short circuit at drive output Drive requires re-autotuning to motor |

| O.ht1 | IGBT over heat based on dries thermal model | Over heat software thermal module |

| O.ht2 | Over heat based on drives heatsink | Heatsink temperature exceeds maximum allowable |

| th | Motor thermistor trip | Excessive motor temperature |

| O.Ld1* | User +24v or digital output overload | Excessive load or short circuit on +24v output |

| cL1 | Analogue input 1 current mode, current loss | Input current less than 3mA when 4-20 or 20-4mA modes selected |

| SCL | Serial communication loss time-out | Loss of communication when drive is under remote control |

| EEF | Internal Drive EEPROM trip | Possible loss of parameter values |

| PH | Input phase imbalance or input phase loss | One of the input phases has become disconnected from the drive (applies to 200/400v three phase drives only, not dual rated drives. |

| rS | Failure to measure motors stator resistance | Motor too small for drive

Motor cable disconnected during measurement |

| C.Err | SmartStick data error | Bad connection or memory corrupt within SmartStick |

| C.dAt | SmartStick data does not exist | New/empty SmartStick being read |

| C.Acc | SmartStick read/write error fail | Bad connection or faulty SmartStick |

| C.rtg | SmartStick/drive rating change | Already programmed SmartStick read by a drive of a different rating |

| O.cL | Overload on current loop input | Input current exceeds 25mA |

| HFxx trip | Hardware faults | Internal drive hardware fault |

HF01 to HF03

Not used

HF04

Low DC bus at power up- may indicate an AC Input or pre-charge problem

HF05

No internal handshake signal from second processor (DSP) at start up

HF06

Unexpected interrupt

HF07

Watchdog failure

HF08

Interrupt crash (code overrun)

HF09 to HF10

Not used

HF11

Access to the EEPROM failed- tried to read stored parameter data but failed

HF12 to HF19

Not used

HF20

Power stage – code error Tried to read power board and read back erroneous

HF21

Power stage – unrecognized frame size

HF22

Overcurrent detection at power up- possible output short or bridge failure

HF23

DSP software overrun

HF24

Not Used

HF25

DSP Communications failure- communication from main to 2nd processor

HF26

Soft start relay failed to close; or soft start monitor failed; or braking

IGBT short circuit at power up

HF27

Power stage thermistor fault

HF28

Power circuit thermistor 2 or 3 fault Internal fan fault on size 3 only

HF29

Fan failure (current too high – only on drives with a fan) see note below

HF30

Not used

HF31

Internal Cap Bank Fan failure- check for fan rotation/blockage Size 4 and up

HF32

Power circuit temperature feedback multiplexer failure

Looking for more information about Control Techniques equipment? Read on here.

Shopping for new or refurbished Control Techniques parts? Shop for the parts you’re looking for here, or find out more about how MRO Electric can help you repair your equipment.

Joe Kaminski is an industrial automation specialist at MRO Electric. He has a background in industrial engineering and supply chain management. Joe has worked in the automation industry for over 10 years providing support to some of the largest companies in the world. For more info, visit www.mroelectric.com.

Частотные преобразователи Emerson, равно как и частотники других производителей, предназначены для изменения параметров тока под рабочую частоту промышленной техники. Их используют в управлении насосными станциями, системами водоснабжения, производственными линиями, вентиляторами и т. д. Плавную работу частотников обеспечивает микропроцессор и электронные модули (транзисторы или тиристоры).

Emerson — широко известный и очень надежный американский бренд, но даже такая электроника подвержена неисправностям. На это влияют многие факторы: нарушение норм эксплуатации, механические повреждения, нестабильное электропитание, естественный износ и т. д. Инженерная компания 555 специализируется на ремонте частотных преобразователей Emerson и готова справиться со сложной задачей в кратчайшие сроки.

Основные виды неисправностей и их причины

Наиболее распространенными являются следующие неполадки в работе частотных преобразователей тока:

- Перегрев электродвигателя. Вероятная причина — система охлаждения не справляется с оборотами, на которых работает двигатель. Возможно, что дело в неподходящих климатических условиях (слишком высокая температура в рабочем цехе) или в неисправности воздушных вентиляторов.

- Двигатель не вращается или вращается с неизменной скоростью. Причиной могут послужить некорректно настроенные параметры выходной или опорной частоты тока. Более точную информацию можно получить, если на дисплее преобразователя высветится код с ошибкой.

- Устройство не реагирует на команды с пульта управления. Наиболее вероятная причина — некорректно заданная частота тока.

- Низкий уровень напряжения на входе или выходе преобразователя. Тут необходимо откалибровать напряжение до допустимого уровня.

Причинами неполадок в работе частотника также зачастую становятся: нарушение правил монтажа, эрозия и масляные загрязнения, агрессивная внешняя среда, попадание внутрь влаги и пыли, неисправность клемм входа/выхода и др.

Высвечивающиеся на дисплее ошибки частотника Emerson позволяют быстро и точно диагностировать характер неполадок в его работе. Предлагаем вашему вниманию некоторые из типичных ошибок устройства:

| Код Ошибки | Диагностика неисправности |

| cL.A1 28 | Потеря тока в одном из аналоговых входов. В этой ситуации следует проверить корректность подключения и отсутствие повреждений в электропроводке управления. |

| FAN.F 173 | Не запускается внутренний вентилятор. Рекомендуется проверить правильность подключения вентилятора и отсутствие механических препятствий его вращению. Если по первым двум пунктам нарекания отсутствую, требуется замена вентилятора. |

| FI.In 237 | Несовместимость пользовательской микропрограммы с микропрограммой силового блока. В такой ситуации следует перепрограммировать электропривод. |

| Oht.r 102 | Перегрев выпрямителя. Рекомендованные действия: проверить изоляцию кабеля двигателя; усилить вентиляцию; снизить нагрузку на двигатель и т. д. |

| OI.SC 222 | Короткое замыкание на выходе фазы. Рекомендуется проверить отсутствие замыкания в выходном кабеле и целостность изоляции электромотора. |

| Pb.HF 235 | Отказ силовой платы. С такой проблемой следует обращаться в сервисный центр. |

| th.br 10 | Перегрузка тормозного резистора. Рекомендованные действия: проверить проводку, сопротивление и изоляцию неисправного элемента. |

| thS 25 | Замыкание термистора электромотора. Следует проверить целостность его цепи. При необходимости — заменить термистор или двигатель. |

| Oht.C 219 | Перегрев платы в блоке управления. Рекомендуется оптимизировать вентиляцию с помощью настроек системы охлаждения. |

Особенности ремонта частотников Emerson

Непреложное правило, которого необходимо придерживаться, — ремонт частотного преобразователя следует доверять профессионалам. Квалифицированные специалисты смогут провести комплексную диагностику устройства и выявить неисправные элементы в его механизме. Следующий этап работы — компонентный ремонт. Поврежденные узлы ремонтируются или заменяются новыми. Финальный шаг — проверка программных настроек. Ее следует выполнять в соответствии с инструкцией по эксплуатации, которую выпускает завод-изготовитель.

Преимущества ремонта частотных преобразователей в Инженерной компании 555

- Солидный опыт в ремонте частотников Emerson.

- Использование в работе только оригинальных комплектующих.

- Гарантия 12 месяцев.

- Экономия свыше 50 % средств по отношению к покупке нового оборудования.

- Доступные цены.

- Оперативное выполнение работы (в течение двух недель).

Обращайтесь в Инженерную компанию 555 прямо сейчас, чтобы как можно скорее получить отремонтированное оборудование.

Каталог

Показывать по элементов

Заявка на ремонт

Инженерная компания 555 осуществляет ремонт промышленной электроники EMERSON в Москве, Санкт-Петербурге, Челябинске и других регионах России. Чтобы узнать о ремонте в вашем регионе, позвоните по телефону +7 (800) 555-89-01 или оставьте заявку:

Звоните +7 (800) 555-89-01

Работать с нами просто, схема взаимодействия

1

Консультация по телефону

2

Отправка оборудования на осмотр

3

Оценка стоимости ремонта

4

Оплата счета

5

Ремонт и отправка оборудования

1Консультация по телефону

2Отправка оборудования на осмотр

3Оценка стоимости ремонта

4Оплата счета

5Ремонт и отправка оборудования

Преимущества сотрудничества с нами

Оплата только за результат — работающий блок

Гарантия на работоспособность блока целиком 12 месяцев

Срок ремонта от 5 до 15 дней

Бесплатный предварительный осмотр на предмет ремонтопригодности

Не вносим конструктивных изменений

Ремонт на компонентном уровне

Наша лаборатория расположена в Санкт-Петербурге, но обратиться за помощью вы можете из любой точки России.

Закажите обратный звонок или наберите в рабочее время многоканальный телефон

– +7 (800) 555-89-01 (звонок по России бесплатный).

Расскажите о своей проблеме и получите инструкцию к дальнейшим действиям.

Компания ООО «Барс-Гидравлик Групп» на протяжении нескольких лет успешно сотрудничает с ООО «Инженерная компания 555» в вопросах ремонта сложного промышленного оборудования. За время работы наш партнер зарекомендовал себя с самой лучшей стороны. Заказы выполняются в кротчайшие сроки при соблюдении высокого качества работ. Организация приема и выдачи заказов четкая. Гарантийные обязательства выполняются в полном объеме.

Выражаем благодарность Вашим специалистам за профессионализм и оперативное решение поставленных задач.

Особенно хочется отметить высокую клиентоориентированность персонала Вашей компании, готовность помочь в самых сложных ситуациях.

Мы высоко ценим сложившиеся между нашими компаниями открытые и доверительные партнерские отношения и искренне желаем «Инженерной компании «555» долгих лет успеха и процветания.

Читать весь

отзыв

ООО «Инженерная компания «555» оказывала нашей компании услуги по ремонту электродвигателей и проявила пунктуальность, аккуратность и ответственность в работе.

Результат выполненных работ говорит о качественном оборудовании и высококвалифицированных кадрах.

Сотрудники компании готовы выполнить новые для себя виды работ и оказать консультационные услуги, что характеризует их как профессионалов своего дела.

Рекомендуем ООО «ИК «555» как ответственного и надежного поставщика услуг.

Читать весь

отзыв

Сообщаем, что наша организация сотрудничает с ООО «Инженерная компания «555» с мая 2016 года по настоящее время.

За этот период мы обращались к услугам компании более 10 раз.

Благодаря серьезному и квалифицированному подходу сотрудников ООО «Инженерная компания «555» ремонтные работы произведены качественно с учетом сроков, и обеспечены гарантийным сопровождением.

Планируем в дальнейшем работать с ООО «Инженерная компания «555»

Читать весь

отзыв

Уважаемый Дмитрий Васильевич!

ОАО «Октябрьский электровагоноремонтный завод» успешно работает с ООО «Инженерная компания «555» несколько лет, очень довольны данным сотрудничеством. В работе компании наибольшую ценность для нас представляет готовность работать на условиях, удобных Заказчику, качественный ремонт оборудования в заявленные сроки и самое главное, финансовая защищенность Заказчика. В инженерной компании работают внимательные, доброжелательные сотрудники, готовые в любой момент решить проблему Заказчика. Мы рады, что выбрали ООО «Инженерная компания «555» в качестве партнера. Гарантируем дальнейшее сотрудничество!

Читать весь

отзыв

ЗАО «Охтинское» выражает глубокую признательность и истинную благодарность ООО Инженерной компании «555» за качественную работу компании по ремонту сложного оборудования промышленной электроники, оперативность и технически грамотное отношение к работе в течении всего периода сотрудничества.

Мы надеемся на дальнейшее успешное развитие деловых отношений в сфере ремонта промышленной электроники.

Читать весь

отзыв

Техническое обслуживание оборудования

Помимо ремонта, компания ik555 предлагает услугу по техническому обслуживанию оборудования нашими инженерами на вашем предприятии, либо в нашей лаборатории

- Крупнейшая лаборатория в России по ремонту промышленной электроники на компонентном уровне

- Международный сертификат стандарта IPC

- Более 10 000 отремонтированных электронных блоков

- Более 2 000 заказчиков от малого бизнеса до крупнейших корпораций

Подробнее

Как мы работаем

Understanding trip codes is an important part of keeping your equipment running smoothly. Below are some of the more common codes you may come across:

| Trip Code | Condition | Possible Cause |

|---|---|---|

| UU | DC Bus under voltage | Low AC Supply Voltage Low DC Bus voltage when supplied by an external DC power supply |

| OU | DC Bus over voltage | Deceleration rate set too fast for the inertia of the machine Mechanical load driving the motor |

| OI.AC** | Drive output instantaneous over current | Insufficient ramp times Phase to phase or phase to ground short circuit on the drives output Drive requires autotuning to the motor Motor or motor connections changed, re-autotune drive to motor |

| OI.br** | Braking Resistor instantaneous over current | Excessive current in braking resistor Braking resistor value to small |

| O.SPd | Over Speed | Excessive motor speed (typically caused by a mechanical load driving the motor |

| tunE | Autotune stopped before completion | Run command removed before autotune compelte |

| It.br | I2t on Braking Resistor | Excessive braking resistor energy |

| lt.AC | l2t on drive output current | Excessive Mechanical load High impedance phase to phase or phase to ground short circuit at drive output Drive requires re-autotuning to motor |

| O.ht1 | IGBT over heat based on dries thermal model | Over heat software thermal module |

| O.ht2 | Over heat based on drives heatsink | Heatsink temperature exceeds maximum allowable |

| th | Motor thermistor trip | Excessive motor temperature |

| O.Ld1* | User +24v or digital output overload | Excessive load or short circuit on +24v output |

| cL1 | Analogue input 1 current mode, current loss | Input current less than 3mA when 4-20 or 20-4mA modes selected |

| SCL | Serial communication loss time-out | Loss of communication when drive is under remote control |

| EEF | Internal Drive EEPROM trip | Possible loss of parameter values |

| PH | Input phase imbalance or input phase loss | One of the input phases has become disconnected from the drive (applies to 200/400v three phase drives only, not dual rated drives. |

| rS | Failure to measure motors stator resistance | Motor too small for drive Motor cable disconnected during measurement |

| C.Err | SmartStick data error | Bad connection or memory corrupt within SmartStick |

| C.dAt | SmartStick data does not exist | New/empty SmartStick being read |

| C.Acc | SmartStick read/write error fail | Bad connection or faulty SmartStick |

| C.rtg | SmartStick/drive rating change | Already programmed SmartStick read by a drive of a different rating |

| O.cL | Overload on current loop input | Input current exceeds 25mA |

| HFxx trip | Hardware faults | Internal drive hardware fault |

* The Enable/Reset terminal will not reset an O.Ld1 trip. Use the Stop/Reset key

**These trips cannot be reset for 10 seconds after they occur

If you have an AC / DC drive module breakdown or stability issue our engineers are able to analyse the whole machine to identify where the control issues lie. Our extensive experience in retrofit and new projects means we have the knowledge to look deep into the control system where we commonly find the peripheral devices are faulty rather than the drive module.

Our team of engineers are able to offer on site service and breakdown support throughout the UK to get you up and running again quickly.

Заказать продукцию Control Techniques

Главные приоритеты преобразователя частот Commander SK фирмы Control Techniques

Частотные преобразователи – достаточно распространенное и популярное промышленное оборудование. Их можно встретить практически на любом современном производстве. Спектр применения данной техники включает в себя множество отраслей хозяйственной деятельности. Преобразователи частот нужны в промышленности (тяжелой и легкой), в медицинской сфере и в транспортной отрасли. Электроприводы можно встретить в лифтовом, насосном и вентиляционном оборудовании. Их применяют механизаторы, фермеры и частные предприниматели. Поэтому проще назвать те области хозяйственной деятельности, где частотники не используются.

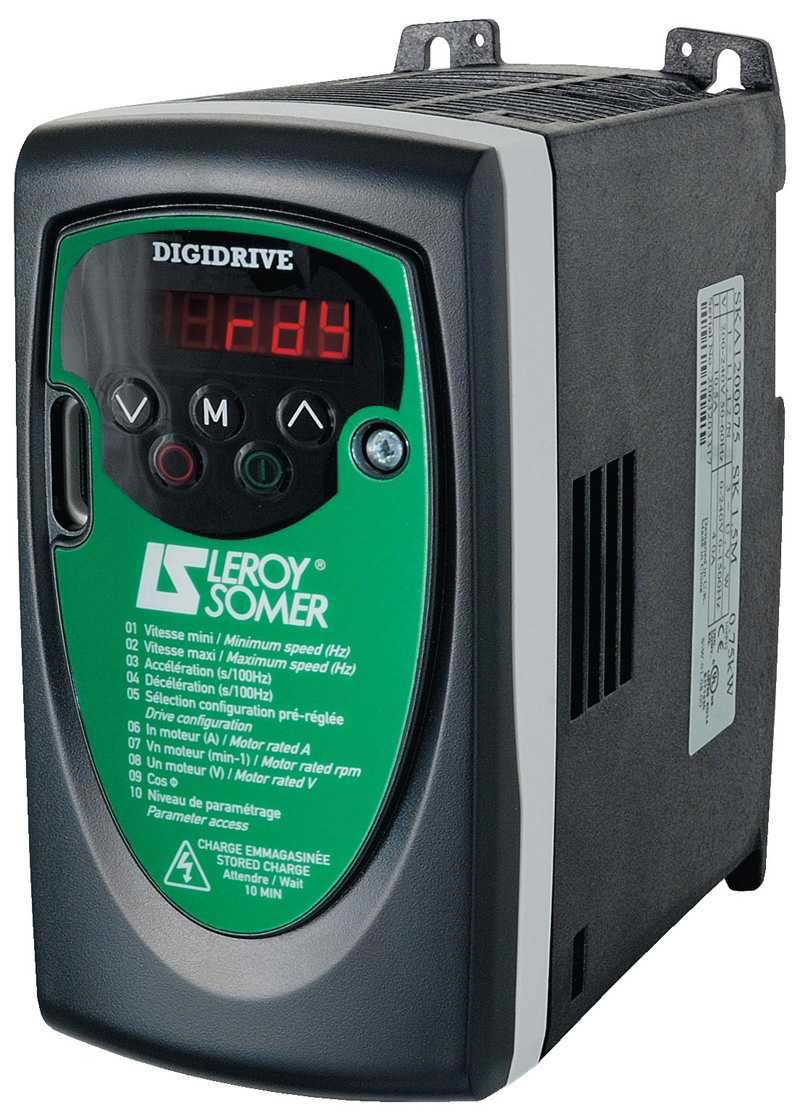

Экономичный и многофункциональный Commander SK

На сегодня выбор преобразователей частот немаленький. Впору растеряться перед обилием современных агрегатов для преобразования параметров частот электротока. Лучше ориентироваться на проверенные фирмы, существующие десятилетиями такие, как Control Techniques. Британский бренд заслужил доверие потребителей, работая на рынке уже свыше 40 лет. Многие предприятия СНГ и всего мира оснастили свои производства преобразователями частоты Commander SK.

Этот электропривод – безотказный в работе, надежный и износоустойчивый. Сейчас частотники серии SK сняты с производства, но их можно купить у проверенного официального поставщика продукции Control Techniques.

Преобразователь частоты Commander SK имеет массу отличительных свойств, которые сделали его конкурентоспособным продуктом на рынке. Очень важно, что у commander sk ошибки практически исключены. Поэтому многие потребители стремятся приобрести именно данный аппарат, а не его аналоги, несмотря на прекращение выпуска продуктов серии SK.

Назовем основные приоритеты покупки частотников Commander SK. Это:

- — низкий уровень потребления энергии промышленным оборудованием, если к нему подключен преобразователь частот;

- — повышается стойкость к износу агрегатов на предприятии;

- — обеспечивается хорошая защита от перепадов напряжения в сети, перегрузки линии;

- — оборудование при наличии частотника имеет большую продуктивность, его коэффициент полезного действия значительно повышается.

Уже доказано, что применение частотного преобразователя не только защищает оборудование от износа, что уже само по себе является хорошей экономией средств. Но с его помощью можно также примерно в два раза меньше затрачивать энергии на технологические процессы, включая операции большой сложности. Все это существенно повышает рентабельность предприятий, учитывая то, что первоначальные затраты на покупку электроприводов не являются особенно высокими. А если еще и добавить к этому, что вам не придется искать в сети commander sk коды ошибок, то ценность таких частотников становится очевидной.

Где купить электропривод серии Commander SK

Преобразователь частоты Commander SK вы всегда можете заказать на сайте официального поставщика. Компания ОЛНИСА – ведущая мультибрендовая фирма, работающая напрямую с мировыми брендами, производителями промышленной электроники. Поставки производятся напрямую из стран ЕС, Америки и Азии. Если вам требуется приобрести снятый с производства Commander SK или другую продукцию Control Techniques, менеджеры компании ОЛНИСА всегда готовы помочь. Делая заказ на сайте поставщика, вы гарантировано получаете:

- — оперативную доставку по России и СНГ сроком от 1-го дня, есть также и доставка прямо к порогу клиента;

- — гарантия на все оборудование;

- — низкие цены без завышения.

Сотрудничая с компанией ОЛНИСА, Вы получаете гарантированно качественный товар, т.к. вся продукция дополнительно проверяется перед отправкой.

Understanding trip codes is an important part of keeping your equipment running smoothly. Below are some of the more common codes you may come across:

| Trip Code | Condition | Possible Cause |

|---|---|---|

| UU | DC Bus under voltage | Low AC Supply Voltage Low DC Bus voltage when supplied by an external DC power supply |

| OU | DC Bus over voltage | Deceleration rate set too fast for the inertia of the machine Mechanical load driving the motor |

| OI.AC** | Drive output instantaneous over current | Insufficient ramp times Phase to phase or phase to ground short circuit on the drives output Drive requires autotuning to the motor Motor or motor connections changed, re-autotune drive to motor |

| OI.br** | Braking Resistor instantaneous over current | Excessive current in braking resistor Braking resistor value to small |

| O.SPd | Over Speed | Excessive motor speed (typically caused by a mechanical load driving the motor |

| tunE | Autotune stopped before completion | Run command removed before autotune compelte |

| It.br | I2t on Braking Resistor | Excessive braking resistor energy |

| lt.AC | l2t on drive output current | Excessive Mechanical load High impedance phase to phase or phase to ground short circuit at drive output Drive requires re-autotuning to motor |

| O.ht1 | IGBT over heat based on dries thermal model | Over heat software thermal module |

| O.ht2 | Over heat based on drives heatsink | Heatsink temperature exceeds maximum allowable |

| th | Motor thermistor trip | Excessive motor temperature |

| O.Ld1* | User +24v or digital output overload | Excessive load or short circuit on +24v output |

| cL1 | Analogue input 1 current mode, current loss | Input current less than 3mA when 4-20 or 20-4mA modes selected |

| SCL | Serial communication loss time-out | Loss of communication when drive is under remote control |

| EEF | Internal Drive EEPROM trip | Possible loss of parameter values |

| PH | Input phase imbalance or input phase loss | One of the input phases has become disconnected from the drive (applies to 200/400v three phase drives only, not dual rated drives. |

| rS | Failure to measure motors stator resistance | Motor too small for drive Motor cable disconnected during measurement |

| C.Err | SmartStick data error | Bad connection or memory corrupt within SmartStick |

| C.dAt | SmartStick data does not exist | New/empty SmartStick being read |

| C.Acc | SmartStick read/write error fail | Bad connection or faulty SmartStick |

| C.rtg | SmartStick/drive rating change | Already programmed SmartStick read by a drive of a different rating |

| O.cL | Overload on current loop input | Input current exceeds 25mA |

| HFxx trip | Hardware faults | Internal drive hardware fault |

* The Enable/Reset terminal will not reset an O.Ld1 trip. Use the Stop/Reset key

**These trips cannot be reset for 10 seconds after they occur

If you have an AC / DC drive module breakdown or stability issue our engineers are able to analyse the whole machine to identify where the control issues lie. Our extensive experience in retrofit and new projects means we have the knowledge to look deep into the control system where we commonly find the peripheral devices are faulty rather than the drive module.

Telephone support

Where appropriate we are often able to offer technical support by phone, we will need the following information from you:

- Your official Purchase order (this must be received prior to any support).

- Details of the Drive.

- Error Codes.

- We may also need copies of drawings and software to aid diagnosis.

Telephone support rates are £100.00 per hour, with a minimum charge of 1 hour.

Our team of engineers are also able to offer on site service and breakdown support throughout the UK to get you up and running again quickly, please enquire for details.

|

(495) 984-51-05 Москва |

Документация | Электроприводы переменного тока

Commander C200 | C300

Commander C200 | C300 — Руководство пользователя по управлению

Commander C200 | C300 — Руководство по установке электропитания | Габариты с 1 по 4

Commander C200 | C300 — Руководство по установке электропитания | Габариты с 5 по 6

Commander C200 | C300 — Руководство по установке электропитания | Габариты с 7 по 10

Commander C200 | C300 — Краткое руководство пользователя | Габариты с 1 по 4

Commander C200 | C300 — Краткое руководство пользователя | Габариты с 5 по 9

Commander C200 — Краткое руководство пользователя | Габариты с 1 по 4

Commander SK — Commander C200 — Брошюра

Commander C200 — Брошюра

Commander C200 — Справочное руководство по параметрам

Commander C300 — Справочное руководство по параметрам

Commander SK

Commander SK — Приступаем к работе (габариты 2 — 6) (pdf, 6286Kb)

Commander SK — Расширенное руководство пользователя (pdf, 5816Kb)

Commander SK — Брошюра (pdf, 8226Kb)

Commander SK — Datasheet size A (pdf, 300Kb)

Commander SK — Datasheet size B (pdf, 353Kb)

Commander SK — Datasheet size C (pdf, 552Kb)

Commander SK — Datasheet size D (pdf, 242Kb)

Commander SK — Технические характеристики (pdf, 8252Kb)

Руководство по замене Commander SE на Commander SK (pdf, 2167Kb)

Commander SK — Руководство пользователя (приступаем к работе, габариты 2 — 6) (pdf, 7523Kb)

Commander SK — Руководство пользователя (приступаем к работе, габариты A — D) (pdf, 1202Kb)

Commander SK — Руководство пользователя (все габариты) (pdf, 11299Kb)

Commander SE (устаревшая модель) — Руководство пользователя (pdf, 1216Kb)

Commander SE (устаревшая модель) — Расширенное руководство пользователя (pdf, 4557Kb)

Commander SE (устаревшая модель) — Брошюра (pdf, 582Kb)

Commander SX

Commander SX — Расширенное руководство пользователя (pdf, 2368Kb)

Commander SX — Брошюра (pdf, 234Kb)

Commander SX — Тормозной контактор (pdf, 137Kb)

Commander SX — Модуль тормозного контактора со входом защитного отключения (pdf, 179Kb)

Commander SX — Тормозной резистор (pdf, 542Kb)

Commander SX — Разводка кабелей (pdf, 604Kb)

Commander SX — Разъединитель (pdf, 675Kb)

Commander SX — Модуль подключения энкодера (pdf, 117Kb)

Commander SX — LCD (pdf, 259Kb)

Commander SX — Защита (pdf, 125Kb)

Commander SX — Руководство пользователя (pdf, 2488Kb)

Commander SX — Карта памяти (pdf, 154Kb)

Commander SX — Опции (pdf, 360Kb)

Unidrive SP

Unidrive SP — Брошюра (pdf, 5453Kb)

Unidrive SP — Руководство пользователя (pdf, 44584Kb)

Unidrive SP — Расширенное руководство пользователя (pdf, 10602Kb)

Unidrive SP — Брошюра по приводам шкафного исполнения от 90 до 675 кВт (pdf, 1806Kb)

Unidrive SPM — Руководство пользователя по модульным преобразователям (pdf, 28999Kb)

Unidrive SP — Руководство по использованию преобразователей для систем рекуперации энергии (pdf, 16382Kb)

Unidrive SP — Контроллер позиционирования APC (Advanced Position Controller) (pdf, 2035Kb)

Unidrive SPM — Брошюра по модульным приводам SPM (pdf, 2138Kb)

Руководство по замене Unidrive на Unidrive SP (pdf, 13641Kb)

Руководство по замене Unidrive SP на Unidrive M600 | M700 (pdf, 5054Kb)

Unidrive SPM — Руководство по модульным преобразователям (pdf, 23528Kb)

Unidrive SP — Брошюра 0-й габарит (pdf, 2174Kb)

Unidrive SP — Руководство по применению с лифтами (pdf, 7924Kb)

Commander GP (устаревшая модель) — Руководство пользователя (pdf, 2721Kb)

Unidrive SP — Расширенное руководство пользователя (pdf, 5891Kb)

Unidrive SP — Функция безопасного останова (pdf, 3830Kb)

Unidrive SP — Руководство пользователя для приводов шкафного исполнения (габариты 6 — 9) (pdf, 20409Kb)

Unidrive SP — Руководство по рекуперации энергии в сеть (pdf, 11208Kb)

Контроллер управления модулями SPM (pdf, 2685Kb)

Unidrive SP шкафного исполнения до 1600 кВт — Брошюра (pdf, 2825Kb)

Affinity

Affinity — Брошюра (pdf, 2033Kb)

Affinity — Руководство пользователя (pdf, 23139Kb)

Affinity — Расширенное руководство пользователя (pdf, 5416Kb)

Affinity — Руководство по настройке макросов (pdf, 616Kb)

Unidrive M

Unidrive M100

Unidrive M100 — Брошюра

Unidrive M100 — Руководство пользователя

Unidrive M100 — Краткое руководство пользователя

Unidrive M100 — M400 — Руководство по установке электропитания | Габариты с 1 по 4

Unidrive M — Руководство по установке электропитания | Габариты с 5 по 6

Unidrive M — Руководство по установке электропитания | Габариты с 7 по 10

Unidrive M200

Unidrive M200 — Брошюра

Unidrive M200 — Руководство пользователя

Unidrive M200 — Краткое руководство пользователя (габариты 1 — 4)

Unidrive M200 — Краткое руководство пользователя (габариты 5 — 6)

Unidrive M100 — M400 — Руководство по установке электропитания | Габариты с 1 по 4

Unidrive M — Руководство по установке электропитания | Габариты с 5 по 6

Unidrive M — Руководство по установке электропитания | Габариты с 7 по 10

Unidrive M300

Unidrive M300 — Брошюра

Unidrive M300 — Руководство пользователя

Unidrive M300 — Краткое руководство пользователя (габариты 1 — 4)

Unidrive M300 — Краткое руководство пользователя (габариты 5 — 6)

Unidrive M100 — M400 — Руководство по установке электропитания | Габариты с 1 по 4

Unidrive M — Руководство по установке электропитания | Габариты с 5 по 6

Unidrive M — Руководство по установке электропитания | Габариты с 7 по 10

Unidrive M400

Unidrive M400 — Брошюра

Unidrive M400 — Руководство пользователя

Unidrive M400 — Краткое руководство пользователя (габариты 1 — 4)

Unidrive M400 — Краткое руководство пользователя (габариты 5 —

Unidrive M100 — M400 — Руководство по установке электропитания | Габариты с 1 по 4

Unidrive M — Руководство по установке электропитания | Габариты с 5 по 6

Unidrive M — Руководство по установке электропитания | Габариты с 7 по 10

Unidrive M600

Unidrive M600 — Брошюра

Unidrive M600 — Руководство пользователя

Unidrive M600 — Краткое руководство пользователя

Unidrive M — Руководство по установке электропитания | Габариты с 5 по 6

Unidrive M — Руководство по установке электропитания | Габариты с 7 по 10

Unidrive M700

Unidrive M700 | M701 — Брошюра

Unidrive M700 | M701 — Руководство пользователя

Unidrive M700 | M701 — Краткое руководство пользователя

Unidrive M — Руководство по установке электропитания | Габариты с 5 по 6

Unidrive M — Руководство по установке электропитания | Габариты с 7 по 10

Unidrive F300

Unidrive F300 — Брошюра

Unidrive F300 — Руководство пользователя

Unidrive F300 — Краткое руководство пользователя

|

Поддержка и помощь |

Продукция сертифицирована |

Доступность |

Сервисное обслуживание |

Оперативная доставка |

Данный сайт носит информационно-справочный характер и ни при каких условиях не является публичной офертой, которая определяется положениями Статьи 437 (2) Гражданского кодекса РФ.

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

EF

www.controltechniques.com

Advanced User Guide

Commander SK

AC variable speed drive for 3

phase induction motors from

0.25kW to 4kW, 0.33hp to 5hp

Part Number: 0472-0001-02

Issue: 2

Related Manuals for Control Techniques Commander SK

Summary of Contents for Control Techniques Commander SK

-

Page 1

Advanced User Guide Commander SK AC variable speed drive for 3 phase induction motors from 0.25kW to 4kW, 0.33hp to 5hp Part Number: 0472-0001-02 Issue: 2… -

Page 2: General Information

If there is any doubt, please contact your local Control Techniques Drive Centre or Distributor. Environmental Statement Control Techniques is committed to minimising the environmental impacts of its manufacturing operations and of its products throughout their life cycle. To this end, we operate an Environmental Management System (EMS) which is certified to the International Standard ISO 14001.

-

Page 3: Table Of Contents

Menu 14: PID controller ……………………139 9.15 Menu 15: I/O Option parameters …………………..145 9.16 Menu 18: Application menu 1 ………………….156 9.17 Menu 20: Application menu 2 ………………….158 9.18 Menu 21: Second motor map ………………….159 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com…

-

Page 4: Introduction

Parameter Keypad and User Advanced parameter Introduction Parameter x.00 CT Modbus RTU CT Soft Menu 0 description format display programming descriptions Introduction Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 5: Parameter X.00

Motor 2 maximum set speed 50.0Hz 60.0Hz 21.06 Motor 2 motor rated frequency 50.0Hz 60.0Hz 21.08 Motor 2 motor rated full load rpm 1500rpm 1800rpm 21.09 Motor 2 motor rated voltage 400V 460V 400V Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com…

-

Page 6: Parameter Description Format

Pr x.00 in every menu is used for storing parameters. The range of this parameter is 4000 and the special codes used are as follows: 1000 Save parameters 1070 Option reset Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 7: Key To Parameter Codes

0 (Auto), 1 (2P), 2 (4P), 3 (6P), 4 (8P) Default 0 (Auto) Second motor Pr 21.11 parameter Update rate Background The top row gives the menu:parameter number and the parameter name. The other rows give the following information. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com…

-

Page 8: Sources And Destinations

3. When a destination is changed, the old destination is written to zero, unless the destination change is the result of loading defaults or transferring parameters from a SmartStick. When defaults are loaded the old destination is set to its default value. 4. Cannot select any of the 32 bit parameters. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 9: Sample/Update Times

Sample/update times The samples/update times shown in the control terminal specification within the Commander SK Product Data Guide are the default sample/update times for the default terminal set-up. The sample/update time depends on the destination/source parameter of the digital or analog inputs/outputs.

-

Page 10: Keypad And Display

Change parameter value Press Parameter number flashing When in Status mode, pressing and holding the MODE key for 2 seconds will change the display from displaying a speed indication to displaying Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 11

Load current as a % of motor rated load current Drive output current per phase in A The operation of the drives keypad and display is explained in the Commander SK Getting Started Guide. When in parameter edit mode, the UP and DOWN keys are used to change parameter values. -

Page 12: Ct Modbu Rtu

Parameter Keypad and User Advanced parameter Introduction Parameter x.00 CT Modbus RTU CT Soft Menu 0 description format display programming descriptions CT Modbus RTU Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 13: User Programming (Plc Ladder Logic Programming)

The combination of the User Programming and SYPTLite mean that Commander SK can replace nano and some micro PLCs in many applications. A Commander SK ladder logic program can contain up to 50 ladder logic rungs, up to 7 function blocks and 10 contacts per rung. The ladder logic program will be stored on the LogicStick.

-

Page 14

See the SYPTLite help file for more information regarding using SYPTLite, creating ladder diagrams and the function blocks available. For the associated User Program parameters, see parameter Pr 11.47, Pr 11.48 and Pr 11.50 in the Commander SK Advanced User Guide. -

Page 15

Parameter Keypad and User Advanced parameter Introduction Parameter x.00 CT Modbus RTU CT Soft Menu 0 description format display programming descriptions CT Soft Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 16: Menu

Post brake release delay (s) Pr 12.47 Fieldbus node address Pr 15.03 Fieldbus baud rate Pr 15.04 Fieldbus diagnostics Pr 15.06 Last trip Pr 10.20 Trip before Pr 55 Pr 10.21 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 17

Digital I/O read word Pr 8.25 Reference on indicator Pr 1.11 Reverse selected indicator Pr 1.12 Jog selected indicator Pr 1.13 Analog input 1 Pr 7.01 Analog input 2 Pr 7.02 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 18

Motor current Pr 23 Speed display units Pr 24 Customer defined scaling Pr 25 Security access Pr 27 Power up keypad reference T6/T5 Pr 28 Parameter cloning Pr 29 Paramerter default Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 19: Advanced Parameter Descriptions

Application menu 2 Second motor parameters *Only appears when an I/O option module is fitted to the Commander SK. Table 9-2 gives a full key of the coding which appears in the following parameter tables. Table 9-2 Key to parameter coding…

-

Page 20: Menu 1: Speed Reference Selection, Limits And Filters

5 ms 1.50 Preset Reference selected indicator 1 to 8 5 ms 1.51 Power up keypad control reference {27} 0 to 2 * The maximum value is Pr 1.06 or Pr 21.01 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 21

Level of reference selected Power up Precision reference Power down Menu 1B keypad reference 1.18 & 1.19 value 1.01 1.51 Preset selected Reference selected indicator indicator 1.49 1.50 Menu 1C Menu 1C Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 22

1.02 1.03 1.01 Menu 1A 1.06 (21.01) 1.07 (21.02) 1.07 (21.02) Skip 1.06 (21.01) x(-1) Frequencies Menu 2 Menu 1C 1.06 (21.01) Jog reference 1.05 1.06 (21.01) Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 23

Menu 1B Menu 2 1.02 1.03 Skip frequency 1 Skip frequency 2 Skip frequency 3 1.29 1.31 1.33 Skip band 1 Skip band 2 Skip band 3 1.30 1.32 1.34 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 24

Update rate Background This parameter is a symmetrical limit on both directions of rotation. Defines drive absolute maximum frequency reference. Slip compensation and current limit can increase the motor frequency further. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 25

Analog input scaling FREQ_MAX FREQ_MAX 1.07 Pr 21.02 -100% 100% -100% 100% -FREQ_MAX 1.10 = 0 (unipolar mode) 1.10 = 1 (bipolar mode) Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 26

On Commander SE, Pr 1.14 (Pr 21.03) used to correspond to Pr 05. On Commander SK, Pr 11.27 corresponds to Pr 05. If Pr 05 or Pr 11.27 is used in a desired system set-up and then Pr 1.14 (Pr 21.03) is then used to change this set-up, although some of these set-ups for Pr 05 and Pr 1.14 (Pr 21.03) are the same, the displayed value showing the set-up of Pr 05 (AI.AV, AV.Pr etc.) will not change to the setting of… -

Page 27

Pr 1.10 Range 0:Pr 1.07 to 1500 Hz or Pr 21.02 to 1500 Hz 1:±1500 Hz 1.18 Precision reference coarse Txt VM DP US RW BU Coding Range ±1500.0Hz Default Update rate Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 28

Skip reference 2 1.33 Skip reference 3 Txt VM DP US RW BU Coding Range 0 to 1500.0Hz Default Update rate Background See Pr 1.30, Pr 1.32 and Pr 1.34 description. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 29

(Pr 1.07 or Pr 21.02) if bipolar (Pr 1.10) is not selected. 1.38 Percentage trim Txt VM DP US RW BU Coding Range ±100.0% Default Update rate See Pr 1.09. 1.39 to 1.40 Unused parameters Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 30

Selects the value of the keypad reference on power-up. Value Display Function keypad reference is zero LASt keypad reference is the last used value PrS1 keypad reference is copied from Preset speed 1 (Pr 1.21) Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 31: Menu 2: Ramps

5 ms 2.36 Deceleration select bit 1 0 or 1 5 ms 2.37 Deceleration select bit 2 0 or 1 5 ms 2.38 Not used 2.39 Ramp rate units 0 or 2 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com…

-

Page 32

Acceleration Rate Selection selector 2.10 Acceleration 2.32 select 0 2.34 2.33 2.32 Output Acceleration 2.33 select 1 Menu 2A 2.30 Acceleration Acceleration 2.34 select 2 selected indicator 1.50 Preset reference selected indicator Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 33

Deceleration rate selector 2.20 Deceleration 2.35 select 0 2.37 2.36 2.35 Output Deceleration 2.36 select 1 Menu 2A 2.31 Deceleration Deceleration 2.37 select 2 selected indicator 1.50 Preset reference selected indicator Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 34

The current demand is fed to the frequency changing current controller and therefore the gain parameters, Pr 4.13 and Pr 4.14 must be set up for optimum control. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 35

The default values have been chosen such that for the default ramps and maximum speed, the curved parts of the S will be 25% of the original ramp if S ramp is enabled. Commander SK Advanced User Guide Issue Number: 2… -

Page 36

When parameter Pr 2.10 is set to 0 the acceleration ramp rate selected depends on the state of bit parameters Pr 2.32 to Pr 2.34. These bits are for control by digital inputs such that ramp rates can be selected by external control. The ramp rate selected depends on the binary code generated by these bits as follows: Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 37

Ramp rate selection by terminal input 1 — 8 Ramp rate defined by parameter number, i.e. 1 = Pr 2.21, 2 = Pr 2.22, etc. Ramp rate selection by parameter Pr 1.50 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 38

100 Hz on the ramp output, therefore with a programmed ramp time of 5 seconds the ramp output will reach 50 Hz from 0 in 2.5 seconds (depending on the setting of Pr 2.39). 2.30 Acceleration selected indicator Txt VM DP US RW BU Coding Range 1 to 8 Update rate Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 39

If Pr 2.11 Acceleration rate 1 is set to 10, the following acceleration time would apply according to the value of Pr 2.39: Pr 2.39 0 to 100Hz 0 to 50Hz 0.5s 100s Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 40: Menu 3: Speed Sensing Thresholds And Frequency Input And Output

3.41 Not used 3.42 Not used 3.43 Maximum reference frequency 0.0 to 50.0 kHz 10.0 3.44 Frequency reference scaling 0.000 to 4.000 1.000 3.45 Frequency reference 0.0 to 100.0% 5 ms Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 41

3.29 Position scaling 32 bit position 3.33 counter 3.34 Reset position 3.32 Terminal B3 Source 8.21 1.01 Frequency output Maximum Menu 8A Frequency output PWM output scaling frequency 3.17 3.18 21.51 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 42

Due to limitations in the hardware, higher output frequencies do not offer the best resolution at the top end of the frequency range. Pr 3.18 Fmax (kHz) Resolution at Fmax 10 bit Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 43

Txt VM DP US RW BU Coding Default Update rate Background 3.33 Position scaling numerator Txt VM DP US RW BU Coding Range 0.000 to 1.000 Default 1.000 Update rate Background Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 44

Scale factor applied to the frequency reference. 3.45 Frequency reference Txt VM DP US RW BU Coding Range 0.0 to 100.0 % Update rate 5 ms Indicates the frequency input value. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 45: Menu 4: Current Control

Not used 4.23 Not used 0.0 to TORQUE_PROD_ 4.24 User current maximum scaling 165.0 CURRENT_MAX % 4.25 Low speed thermal protection mode 0 or 1 ± USER_CURRENT_ 4.26 Percentage torque MAX % Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com…

-

Page 46

4.18 Maximum heavy duty drive Current limit Overload detection current rating 4.07 (21.29) 10.17 Motor rated current 11.32 5.07 (21.07) Motor At 100% overload load accumulator 10.08 4.19 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 47

On the larger Commander SK frame sizes, the ratio between maximum continuous current and maximum overload is less than on the smaller drives. This is handled in the software by specifying the ‘drives rated current’ as maximum current limit level / 1.5, the same as on the smaller drives. The current rating in Pr 11.32 is still the Heavy Duty rating of the drive, but because it is greater than the ‘drive rating’ figure used by the software, the… -

Page 48

Torque = K x active current x frequency at voltage limit / actual frequency Normally the point at which the voltage limit is reached is close to the rated frequency of the motor. 4.03 Unused parameter Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 49

For a negative value, program a digital input to the analog input invert bit. This will give a negative value on the analog input destination parameter. Commander SK Advanced User Guide Issue Number: 2… -

Page 50

The following is a guide to setting the gains for different applications. Current limit operation The current limits will normally operate with an integral term only, particularly below the point where field weakening begins. The proportional term is Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 51

1: Reduce current limit when threshold reached The motor is modelled thermally in a way that is equivalent to the electrical circuit shown below: = RC (I /(K x Motor Rated Current) Temp Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 52

If Pr 4.16 is 1, the current limit is reduced to (K — 0.05) x 100% when the temperature is 100%. The current limit is set back to the user defined level when the temperature falls below 95%. Commander SK Advanced User Guide www.controltechniques.com… -

Page 53

× ——————————————————————————————————- — Pr 4.20 Power factor (Pr 5.10) Motor rated current (Pr 5.07) A positive value in this parameter indicates motoring load and a negative value indicates a regenerating load. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 54

Below base speed, Pr 4.26 is equal to Pr 4.20. Above base speed the percentage torque producing current (Pr 4.20) is adjusted as follows: Pr 4.26 = Pr 4.20 x motor rated frequency (Pr 5.06) /post ramp reference (Pr 2.01) Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 55: Menu 5: Machine Control

Not used 5.42 Not used 5.43 Not used 5.44 Not used 5.45 Not used 5.46 Not used 5.47 Not used 5.48 Not used 5.49 Not used 5.50 Security unlock 0 to 999 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com…

-

Page 56

Rated frequency 21.06 Rated current 5.07 Rated current 21.07 Rated voltage 5.09 Rated voltage 21.09 Rated power factor 5.10 Rated power factor 21.10 No. of motor poles 5.11 No. of motor poles 21.11 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 57

Pr 5.08 to allow correct calculation of the motor poles. 5.05 DC bus voltage Txt VM DP US RW BU Coding Range 0 to +DC_VOLTAGE_MAX V Update rate Background Voltage across the internal DC bus of the drive. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 58

If Pr 5.08 is set to 0 or to synchronous speed, slip compensation is disabled. NOTE If the full load speed of the motor is above 9999rpm, slip compensation should be disabled. This is because a value above 9999 cannot be entered in Pr 5.08. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 59

A square law characteristic is used from 0Hz to rated frequency, and then constant voltage above rated frequency. Low frequency voltage boost raises the start point of the square law characteristic as shown below. Pr 5.09 5.15 + [(freq/Pr 5.06 ) x (Pr 5.09 — Pr 5.15 Pr 5.15 Pr 5.06 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 60

When the test is completed successfully the drive is disabled. The motor can only be restarted if the enable or run command is removed and then re-applied or if the drive is tripped, reset and then given a run command. Commander SK Advanced User Guide www.controltechniques.com… -

Page 61

Else, if |active current| ≥ 0.7 x rated active current V/f ratio = Normal V/f ratio Although the rated frequency varies, the value shown as Pr 5.06 does not vary from that set by the user. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 62

Pr 5.17 remains unchanged. If the necessary current levels can be achieved but the calculated resistance exceeds the maximum allowable value for that particular drive size, an rS trip will occur and Pr 5.17 will contain the maximum allowable value. Commander SK Advanced User Guide www.controltechniques.com… -

Page 63

5.20 to 5.22 Unused parameters Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 64

The level of slip compensation is set by the rated frequency and rated speed parameters. Slip compensation is only enabled when this parameter is set to 1 and Pr 5.08 is set to a value other than zero or synchronous speed. 5.28 to 5.33 Unused parameters Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 65

0 to 999 Update rate Background read Pr 5.50 is not visible from the keypad and holds the value of the security entered to allow parameters to be edited when security is enabled. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 66: Menu 6: Drive Sequencer And Clock

Control word 0 to 32767 2 ms 6.43 Control word enable 0 or 1 2 ms 6.44 Not used 6.45 Force cooling fan to run at full speed 0 or 1 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 67

Enable forward/reverse key (LCD keypad) 6.13 Disable auto-reset on enable 6.14 Hardware Enable sequencer latching 6.40 6.29 enable Cooling fan control disable 6.45 Forward limit switch 6.35 Reverse limit switch 6.36 Menu 6B Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 68

Logic 1 STOP LED keypad function key FUNCTION status 6.11 Drive keypad Logic 1 Sequencer STOP Reference selected Reference indicator 1.49 selection 1.49 = 4 Menu 1A Keypad STOP key enable 6.12 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 69

Normally the controlling system will see that the mains has been lost and even though it has been re-applied, the controller will remove the run terminal so that when it reaches 0Hz, it will go into the ‘rd’ state. Commander SK Advanced User Guide Issue Number: 2… -

Page 70

0.0 to 25.0 s Default Update rate 2 ms Defines the time of injection braking where this is specified in stopping modes 3 and 4 (see Pr 6.01 on page 69). Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 71

On the 400V product setting this bit will enable the drive to run off 240Vac input. The current limit will automatically be reduced therefore only allowing the drive to operate at a lower power rating. Commander SK Advanced User Guide Issue Number: 2… -

Page 72

The sequencer run can only then be reapplied after at least on of the following conditions occurs. 1. Run forward, Run reverse and Run sequencing bits all zero 2. OR the drive is disabled via Pr 6.15 or Pr 6.29 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 73

Range 0.0 to 600.0 Currency/kWh Default Update rate Background When this parameter is set up correctly for the local currency, Pr 6.26 will give an instantaneous read out of running cost. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 74

Update rate Background This parameter gives an instantaneous read out of the cost/hour of running the drive. This requires Pr 6.16 to be set up correctly. 6.27 to 6.28 Unused parameters Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 75

If both are found to be 0 then the sequencer looks at the ‘Run’ bit, and if it is set then the drive is run in the direction commanded by the ‘Fwd/Rev’ bit (0 = forward, 1 = reverse). Commander SK Advanced User Guide Issue Number: 2… -

Page 76

When the drive is required to stop after having been running at the jog speed, the jog (or any other run function) will not be able to go active for approximately 2s, because when the drive is disabled it will coast to a stop and a delay is incurred to allow the rotor flux to decay. Commander SK Advanced User Guide www.controltechniques.com… -

Page 77

.e. coast or injection stop modes) where the output becomes 0 with a delay of 60ms. Toggle 1. The output changes state on each non active to active change at the input Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 78

Bit 12: Trip drive When the control word is enabled (Pr 6.43) bit 12 of the control word becomes active. (Bit 7 of the control word has no effect on this function.) When Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 79

75% of the drive rated current, the fan will continue running at full speed. When this parameter is set to 1, the fan runs at full speed at all times when the drive is powered up. Commander SK Advanced User Guide Issue Number: 2… -

Page 80: Menu 7: Analog Inputs And Outputs

7.32 Not used 7.33 Analog output control (Terminal B1) {36} 0 to 4 Drive reset ± 200 ° C 7.34 IGBT junction temperature 7.35 Drive thermal protection accumulator 0 to 100% Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 81

0 1 2 3 4 Heatsink temperature 7.04 IGBT Junction temperature 7.34 Thermal protection accumulator 7.35 Analogue output control 7.33 Terminal B1 7.19 Source 0.01 Default source Scaling 2.01 7.20 Motor speed 21.51 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 82

3mA. If 4-.20 or 20-.4 modes are selected, Pr 7.28 will switch from a 0 to 1 to indicate that the current reference is less than 3mA. 7.07 Unused parameter Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 83

When analog input 2 is set up for analog input, this parameter is used to scale the input (see Pr 7.08). When the input is defined as a digital input, this parameter has no effect. Commander SK Advanced User Guide Issue Number: 2… -

Page 84

This parameters can be used to scale the analog output if so desired. However in most cases it is not necessary as the output is automatically scaled such that when the source parameter is at its maximum, the analog output will be at its maximum. 7.21 to 7.27 Unused parameters Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 85

————————————————————————————— — × 1.5 Drive rated active current 0 to 200% output current = 0 to 10V × × Pr 5.09 ————————————————— — 1000 Where: I = 150% of drive rated current Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 86

This includes the effects of drive output current and DC bus ripple. The estimated temperature is displayed as a percentage of the trip level in this parameter. If the parameter value reaches 100% an O.ht3 trip is initiated. Commander SK Advanced User Guide www.controltechniques.com… -

Page 87: Menu 8: Digital Inputs And Outputs

{34} 0 to 3 8.36 Not used 8.37 Not used 8.38 Not used 8.39 Not used 8.40 Not used 8.41 Digital output control (Terminal B3) {35} 0 to 8 Drive reset Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com…

-

Page 88

Frequency Input Invert Terminal B7 8.15 Source/ 8.25 Destination 1.01 Default source 1.41 Mode select Monitor Local/Remote Terminal B7 8.05 (Defined by 11.27) 8.35 21.51 Motor thermistor trip Frequency input Menu 3 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 89

Digital I/O Monitoring Monitor Digital I/O read word 8.01 8.20 Digital I/O read word 8.20 Monitor Terminal Binary value for xx 8.02 Monitor 8.03 T5/T6 Monitor 8.04 Monitor 8.05 Monitor 8.07 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 90

Update rate 2 ms Setting these parameters to a 1 causes the input sense to the destination parameter to be inverted or the output sense from the source to be inverted. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 91

Source parameters define the parameter to be represented by the digital output terminal. Only bit parameters can be selected as a source for a digital output. If a non-valid parameter is programmed, then the digital output will remain in the inactive state. 8.26 Unused parameter Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 92

The drive will not trip if the thermistor goes short circuit. NOTE The thermistor going short circuit will not damage the drive. There is no parameter to display the motor temperature. Connect the motor thermistor between 0V and terminal B7. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 93

A user wishing to change the digital output to something other than the ones listed above must first program this parameter to 8. Pr 8.21 should then be programmed to the desired bit parameter. Commander SK Advanced User Guide Issue Number: 2… -

Page 94: Menu 9: Programmable Logic, Motorised Pot And Binary Sum

9.32 Binary sum output 0 to 255 21 ms 9.33 Binary sum destination Pr 1.01 to Pr 21.51 Pr 0.00 Drive reset 9.34 Binary sum offset 0 to 248 21 ms Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 95

Delay Output Source 1 9.14 Invert 9.15 Logic Function 2 0.01 Destination 21.51 Invert 9.20 9.18 Logic output 1.01 Source 2 9.02 9.16 & Invert Delay 9.17 9.19 0.01 21.51 21.51 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 96

Offset Logic ones (LSB) 9.34 9.29 Binary sum Destination 9.31 9.30 9.29 Output logic output 9.33 value 1.01 9.32 Binary sum Logic twos 9.30 21.51 Binary sum Logic fours (MSB) 9.31 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 97

This source parameter and Pr 9.16 defines the inputs for source 2 of the programmable logic functions. Only bit parameters can be programmed into these inputs. If one or both inputs to the logic function are invalid, then the logic output will always be 0. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 98

This destination parameter and Pr 9.20 define the parameters to be controlled by the logic function. Only non-protected bit parameters can be programmed as a destination. If a invalid parameter is programmed, the output is not routed anywhere. 9.11 to 9.13 Unused parameters Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 99

Update rate 21 ms If the delay parameter is positive, the delay ensures that the output does not become active until an active condition has been present at the input for Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 100

When this bit is set to 0 the motorised pot output is limited to positive values only (0 to 100.0%). Setting it to 1 allows negative outputs also (-100.0% to 100.0%). Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 101

Binary sum one’s input 9.30 Binary sum two’s input 9.31 Binary sum four’s input Txt VM DP ND RA NC US RW BU Coding Range 0 or 1 Default Update rate 21 ms Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 102

If the parameter that the binary sum value is routed to has a maximum value greater than 7 then the binary sum output will be scaled evenly across the maximum range of the destination parameter The table below shows how the binary sum function operates with an offset value. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 103

7, (Pr 9.32) i.e. Pr 1.15 with a range of i.e. Pr 5.23 with a range of 0 to 8 0.0 to 25.0 10.0 12.5 15.0 17.5 20.0 22.5 25.0 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 104: Menu 10: Status Logic And Diagnostic Information

0 or 1 10.37 Action on trip detection 0 to 3 10.38 User trip 0 to 255 10.39 Braking energy overload accumulator 0.0 to 100.0% 10.40 Status word 0 to 32767 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 105

US RW BU Coding Range 0 or 1 Update rate Background Indicates that the modulus of the active current is greater or equal to the rated active current as defined in menu 4. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 106

Indicates that the drive has detected mains loss from the level of the DC bus voltage. This parameter can only become active if mains loss ride through or mains loss stop modes are selected (see Pr 6.03 on page 69). 10.16 Unused parameter Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 107

Contains the last 10 drive trips. Pr 10.20 is the most recent trip and Pr 10.29 the oldest. When a new trip occurs all the parameters move down one, the current trip is put in 10.20 and the oldest trip is lost off the bottom of the log. Possible trips for Commander SK are shown in Table 9-13 on page 108. -

Page 108

Option module watchdog timeout. The module has started the watchdog system, but has not subsequently serviced the Sl.tO watchdog within the timeout period. Sl.Er Option module error. The module has detected an error and tripped the drive. The reason for the error is stored in Pr 15.50 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 109

1. Power down save user parameters are saved when UU trip is activated. 2. The UU trip is self-resetting when the DC bus voltage rises above the drive restart voltage level. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 110

Full power braking time (Pr 10.30), T = E / P Where: E is the total energy that can be absorbed by the resistor when its initial temperature is ambient temperature. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 111

If there has been no trip for 5 minutes then the reset count is cleared. Auto reset will not occur on UU, Et, EEF or HFxx trips. When a manual reset occurs the auto reset counter is reset to zero. Commander SK Advanced User Guide Issue Number: 2… -

Page 112

100% is the maximum temperature (trip level). A br.rS warning is given if this parameter is above 75% and the braking IGBT is active. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 113

Not used Pr 10.15 Pr 10.14 Pr 10.13 Pr 10.12 Pr 10.11 Pr 10.10 Pr 10.09 Pr 10.08 Pr 10.07 Pr 10.06 Pr 10.05 Pr 10.04 Pr 10.03 Pr 10.02 Pr 10.01 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 114: Menu 11: General Drive Set-Up

11.47 Drive user program enable 0 to 2 11.48 Drive user program status -128 to 127 11.49 Not used 11.50 User program maximum scan time 0 to 65535 ms User program Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2…

-

Page 115

Coding Range 0 to 247 Default Update rate Background This parameter is used to define the unique address for the drive for the serial interface. The drive is always a slave. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 116

If the drive is active the parameter will return to its pre altered value on exit from edit mode. In all of the settings below, the status relay is set up as the drive healthy relay. Fault Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 117

Local (A2)/Remote (A1) Local (A2)/Remote (A1) speed reference select speed reference select Terminal B7 open: Local voltage speed reference input (A2) selected. Terminal B7 closed: Remote current speed reference input (A1) selected. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 118

+24V output +24V +24V Digital output Digital output (zero speed) (zero speed) Drive Enable/Reset Not stop Run Forward Run Reverse Reference select Reference select Reference selected Preset 2 Preset 3 Preset 4 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 119

From the drive’s display: • Set Pr 71 to 8.23 • Set Pr 61 to 6.33 • Press the Stop/Reset key Terminal B5 will now be set-up as a Forward/Reverse terminal Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 120

Torque mode select select When torque mode is selected and the drive is connected to an unloaded motor, the motor speed may increase rapidly to the maximum speed (Pr 02 +20%) WARNING Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 121

14.10 % to 7.02 14.01 frequency 1.01 I Gain conversion 14.11 Invert PID high 14.13 14.06 limit PID low PID feedback 14.14 limit input 7.01 x(-1) PID enable & Drive healthy Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 122

This parameter indicates the continuous industrial current rating of the drive for heavy-duty operation. If this parameter is programmed into the level two area, the decimal place on the drives four digit display will be adjusted to 1 for drive sizes with current ratings greater than 99.99A. Commander SK Advanced User Guide www.controltechniques.com… -

Page 123

RAM. The drive takes action on the command when the user exits the parameter edit mode. Also, to be backwards compatible with Commander SE and to allow cloning over the serial interface, the drive will action the value programmed on a drive reset. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 124

0 (L1), 1 (L2), 2 (L3), 3 (Loc) Default 0 (L1) Update rate Actioned on exit of edit mode and on drive reset This read write parameter defines the level of security for menu 0. Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 125

RA NC US RW BU Coding Range 0 to 2 Default Update rate Background write This parameter displays the number of the last set of defaults loaded e.g. 1 Eur, 2 USA. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 126

The user program maximum scan time parameter gives the longest scan time within the last ten scans of the drive user program. If the scan time is greater than the maximum value which may be represented by this parameter the value will be clipped to the maximum value. Commander SK Advanced User Guide www.controltechniques.com… -

Page 127: Menu 12: Programmable Threshold And Variable Selector

Brake apply frequency {49} 0.0 to 20.0 Hz 21 ms 12.46 Pre-brake release delay {50} 0.0 to 25.0 s 21 ms 12.47 Post-brake release delay {51} 0.0 to 25.0 s 21 ms Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com…

-

Page 128

6 — 12.12 = Input 1 / (12.15s + 1) Variable selector 7 — 12.12 = Input 1 via Ramp control 8 — 12.12 = Input 1 12.15 9 — 12.12 = Input 1 12.15 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 129

Brake disabled Latch 8.07 Brake release Brake release 12.40 Reset frequency 8.01 12.44 User Brake apply Post-brake Programmable frequency release delay 12.45 12.47 Brake controller Reference on enable 1.11 & 12.41 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 130

This parameter and Pr 12.27 define the parameter which is to be controlled by the threshold parameter. Only bit parameters which are not protected can be set up as a destination. If a non valid parameter is programmed the output is not routed anywhere. Commander SK Advanced User Guide www.controltechniques.com… -

Page 131

Variable selector 1 output Txt VM DP ND RA NC US RW BU Coding Range ±100.0 % Update rate 21 ms Indicates the level of output signal from the variable selector. Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 132

This parameter and Pr 12.05 define the band within which no change will occur on the output. The upper limit for switching is:Level + Hysteresis/2 The lower limit for switching is:Level — Hysteresis/2 Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 133

= input output = 0.02: output = input / 100 Raise to power output = 0.02: output = input / 100 control has any other value: output = input 1 Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com… -

Page 134

The control parameter can be used to input a value when modes 6, 7 and 9 of the variable selector are implemented. See Pr 12.10 on page 131 and Pr 12.30 on page 133 for variable selector modes. 12.36 to 12.39 Unused parameters Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 135: Brake Control Function

Drive healthy output Pr 12.40 Pr 10.01 Zero speed output Drive healthy output 0 or 3 Pr 10.03 Pr 10.01 Zero speed output 0 or 3 Pr 10.03 No change No change Commander SK Advanced User Guide Issue Number: 2 www.controltechniques.com…

-

Page 136

2. Pre-brake release delay 3. Post-brake release delay 4. Wait for brake apply frequency 5. Wait for zero frequency 6. 1s delay as phase 2 of stopping sequence (Pr 6.01 =1,2 or 3) Commander SK Advanced User Guide www.controltechniques.com Issue Number: 2… -

Page 137

(2 or 3 times the rotor time constant of the motor), and the time for slip compensation to become fully active (at least 0.5s). During the Pre-brake delay period the frequency reference is held constant (Pr 2.03 = 1). Commander SK Advanced User Guide Issue Number: 2… -

Page 138