|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Copyright © 2004-2023 Прокофе.ру |

User manual

3.5.2

LAMP DISPLAY

<< Standby >>

UK

Welcome

Rinse

Heating

Ready

Cash

Espresso

Coffee

Cappuccino

Pot

Hot water

Flashes

Water tank

Page 36

SIGNIFICANCE

The machine is in standby

mode; it is now consuming very

little energy.

Welcome on switching on.

An automatic rinse takes place

when switching on, or the rinsing

programme is active.

The machine is being heated up;

the necessary operating tem-

perature has not yet been

reached

The machine is ready for use.

The green lamp indicates the

optimal operating temperature.

The machine is now ready for

operation and the payment sys-

tem is activated. The green lamp

indicates the optimal operating

temperature.

Drawing of espresso after press-

ing the relevant product button.

Drawing of coffee after pressing

the relevant product button.

Drawing of cappuccino after

pressing the relevant product

button.

Drawing of a pot of coffee after

pressing the product button.

Drawing of hot water.

Flashes:

The water tank is empty or not

correctly inserted.

Illuminated:

Air in the water system

(See chapter

7 Problems and

possible

causes, Page 50).

LAMP DISPLAY

Flashes

No beans

Grinder lid

Grinder block.

Container full

Flashes

Container

Flashes

Hatch open

Cleaning

Flashes

Descaling

Service !!!

SIGNIFICANCE

The beans container is empty.

Further drawing only possible af-

ter filling it.

The lid to the beans container is

not closed correctly.

The grinder is blocked. For

clearance see Operating Instruc-

tions, section.

5.4, Cleaning the

grinder

Page 41.

The grounds container is full.

Further drawing only possible af-

ter emptying it.

The grounds container is not

correctly inserted.

The side door is open. Drawing

only possible after closing it.

The machine must be cleaned,

or the cleaning programme is

active.

The machine must be descaled,

or the descaling programme is

active.

The display alternates with the

current display. Report the ma-

chine to customer service.

(See paragraph

8.1 Service re-

quest

Page 50)

BASL — 02 — V01

Работаем ежедневно c 09:00 до 20:00

без выходных и праздничных дней

8 (495) 135-00-03

Звоните ежедневно с 9:00 до 21:00

м. Кутузовская. ул. Студенческая, д. 35

Кофемашина Schaerer Siena 2 может выдавать ошибку по причине каких-либо неполадок в работе устройства или из-за дефектов элементов. Уточнить, какая именно неисправность постигла вас вы можете в нашем сервисном центре, где работают специалисты высокого уровня с многолетним опытом за плечами. Для связи с нами достаточно заполнить простую форму или позвонить по номерам горячей линии, указанных на сайте. Наши операторы дадут исчерпывающую информацию по интересующим вас вопросам и проконсультирую по ценам на услуги.

Частые неисправности

- Не работает

Проблема может быть в:

— Пустом резервуаре для воды;

— Отсутствии кофе. - Шумит при работе

Причиной проблемы ,может быть:

— Засорение кофемашины;

— Проблемы с насосом. - Нет пара

Проблема может быть связанна с:

— Неисправностью бойлера;

— Неисправностью пароблока;

— Засорение кальцием. - Не мелет кофе

Неисправность связанна с:

— Затупленностью жерновов;

— Неисправностью кофемолки;

— Неисправностью электродвижка кофемолки. - Не наливает воду

Данная проблема, может быть вызвана:

— Требуется чистка вашей кофемашины;

— Проблемы с насосом;

— Замена уплотнительных колец;

— Замена датчиков. - Не наливает кофе

Неисправность могла быть вызвана данными неполадками:

— Засорение кофемашины кофейными маслами (декофинация);

— Обслуживание гидросистемы;

— Чистка диспенсеров. - Не подает пену

Для решения данной проблемы нужно будет:

— Произвести замену капучинатора;

— Провести чистку вашей кофемашины;

— Заменить фильтры;

— Произвести замену жерновов. - Протекает

Проблема может быть в:

— поврежденном уплотнении резервуара воды;

— уплотнительных прокладках;

— уплотнении дозатора;

— неплотной посадки соединительных трубок.

Чаще необходимо

- Диагностика — 0 ₽

- Декальценация — 590 ₽

- Замена ТЭНа — 750 ₽

- Ремонт капучинатора — 850 ₽

- Замена жерновов — 750 ₽

- Ремонт кофемолки — 790 ₽

- Ремонт гидросистемы — 990 ₽

- Ремонт насоса — 700 ₽

Шаги вашего ремонта

-

1

Заявка

Оставляете заявку у нас на сайте или посредством телефонного звонка

-

2

Доставка

Осуществляем забор курьером или доставляете кофемашину к нам в СЦ

-

3

Диагностика

Инженер проводит полную диагностику кофейной машины

-

4

Ремонт

После согласования, производим ремонт кофемашины

-

5

Сообщение

Сообщаем о готовности ремонта и выдаём гарантию до 1 года

инструкцияSchaerer Siena 2

Betriebsanleitung ……………………………………… Seite 2

Operating instructions …………………………. Page 35

Manuel d’utilisation ………………………………… Page 69

Gebruiksaanwijzing ……………………………. Pagina 103

Manual de instrucciones ………………… Página 137

Návod k provozu ………………………………….. Strana 171

Használati utasítás ………………………………. Oldalt 205

V07 / 06.2010

Посмотреть инструкция для Schaerer Siena 2 бесплатно. Руководство относится к категории Кофеварки, 2 человек(а) дали ему среднюю оценку 7.3. Руководство доступно на следующих языках: английский. У вас есть вопрос о Schaerer Siena 2 или вам нужна помощь? Задайте свой вопрос здесь

Главная

Не можете найти ответ на свой вопрос в руководстве? Вы можете найти ответ на свой вопрос ниже, в разделе часто задаваемых вопросов о Schaerer Siena 2.

Как часто следует очищать кофеварку от накипи?

Какой лучший способ очистки кофеварки от накипи?

Как долго можно хранить кофе в зернах?

Как лучше всего хранить кофе?

Как помол сказывается на вкусе кофе?

Инструкция Schaerer Siena 2 доступно в русский?

Не нашли свой вопрос? Задайте свой вопрос здесь

проблема с кофеваркой Schaerer Siena 2 / Абакан

Я запустил очистку кофейной и молочной системы. Всё промылось и машинка была выключена. На следующий день включая машину горела ошибка NTC-Steam. Я проверил хорошо ли закрыты дверцы, вытащил узел пропаривания и задвинул обратно, ничего не изменилось.

Люди с такой же проблемой (0)

Лучшее решение

Просто так совпало. вышел из строя температурный датчик парового бойлера. — замена бойлера

Это решение полезно? Да Нет

2 участника считают, что это решение полезно

Знаете, как решить эту проблему?

Поделитесь своим знанием!

Ваш способ решения:

Наиболее похожие проблемы из этого раздела

Купил, включил, согласно инструкции промыл фильтр, бачок, залил воды чуть ниже максимума, дождался зелёного индикатора, нажал на кнопку насоса — и …

Здравствуйте! Кофемашина Philips 5000 series, при приготовлении капучино сбоку валит пар, молоко пару капель выдаёт, шипит. Что это может быть? И …

Выдаёт ошибку Е5 — ошибка водяного контура… Переустановка бака для воды не помогает. В чём может быть причина, и сколько примерно будет стоить её …

Ошибка E05. Как убрать ошибку и промыть? Вероятно, забился капучинатор.

Кофемашина не включает помол и выдаёт ошибку с-1

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Copyright © 2004-2023 Прокофе.ру |

инструкцияSchaerer Siena 2

Schaerer Siena 1 & 2

Betriebsanleitung ……………………………………… Seite 2

Operating instructions …………………………. Page 35

Manuel d’utilisation ………………………………… Page 69

Gebruiksaanwijzing ……………………………. Pagina 103

Manual de instrucciones ………………… Página 137

Návod k provozu ………………………………….. Strana 171

Használati utasítás ………………………………. Oldalt 205

V07 / 06.2010

Посмотреть инструкция для Schaerer Siena 2 бесплатно. Руководство относится к категории кофеварки, 2 человек(а) дали ему среднюю оценку 7.3. Руководство доступно на следующих языках: английский. У вас есть вопрос о Schaerer Siena 2 или вам нужна помощь? Задайте свой вопрос здесь

Главная

Не можете найти ответ на свой вопрос в руководстве? Вы можете найти ответ на свой вопрос ниже, в разделе часто задаваемых вопросов о Schaerer Siena 2.

Как часто следует очищать кофеварку от накипи?

Какой лучший способ очистки кофеварки от накипи?

Как долго можно хранить кофе в зернах?

Как лучше всего хранить кофе?

Как помол сказывается на вкусе кофе?

Инструкция Schaerer Siena 2 доступно в русский?

Не нашли свой вопрос? Задайте свой вопрос здесь

- Печать

Страницы: [1] 2 Вниз

Тема: Siena 2. Не работает. (Прочитано 14150 раз)

0 Пользователей и 1 Гость просматривают эту тему.

При включении пишет:»Heating…» и что-то шумит.Больше ничего не происходит.Так несколько секунд,потом шум пропадает и появляется сообщение: «Level» и загорается светодиод с восклицательным знаком и все.На нажатие кнопок приготовления кофе не реагирует. В чем может быть проблема?

« Последнее редактирование: Август 17, 2017, 02:55:50 от Suhnny »

Записан

Похоже, что помпа не может закачать воду в паровой бак.

Записан

Записан

Горжусь тобой моя Россия

а он шипит

Нет. Скорее гудит и слегка вибрирует или что-то в этом роде. Наверно правда помпа.

Надо будет проверить. Может ещё будут какие мысли?

Записан

Записан

Дело было в помпе.

Такая же проблема, только level не загорается…. что делать, сервисов в городе нет….

Записан

Вскрыть верхнюю крышку и нажать на кнопочку термопредохранителя, который на основном бойлере находится. Если смотреть в «лицо» машинки, то справа, на боку бойлера.

Записан

Авторизация: Delonghi, Bork, Ariette, Jura, Nivona

Вскрыть верхнюю крышку и нажать на кнопочку термопредохранителя, который на основном бойлере находится. Если смотреть в «лицо» машинки, то справа, на боку бойлера.

Спасибо! Попробую!

Посмотрел — но ни какой кнопки не нашел…. Как она выглядит? и располагается на самом термостате основного бойлера? Сегодня сфотографирую — завтра попробую сюда фотку приложить…

« Последнее редактирование: Октябрь 06, 2014, 11:48:14 от misha »

Записан

Вскрыть верхнюю крышку и нажать на кнопочку термопредохранителя, который на основном бойлере находится. Если смотреть в «лицо» машинки, то справа, на боку бойлера.

Спасибо! Попробую!

Посмотрел — но ни какой кнопки не нашел…. Как она выглядит? и располагается на самом термостате основного бойлера? Сегодня сфотографирую — завтра попробую сюда фотку приложить…

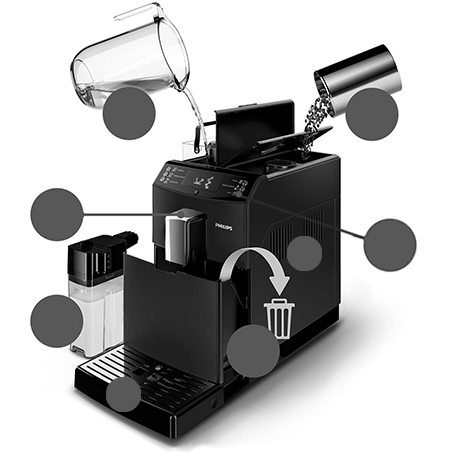

Приложил копию из инструкции — если Вам не трудно можете на ней показать, где находится кнопка перезагрузки термопредохранителя?

Записан

№№6 на кофейном и №№14 на паровом бойлере — это термопредохранители, кнопка между контактами.

Записан

№№6 на кофейном и №№14 на паровом бойлере — это термопредохранители, кнопка между контактами.

Ну никак не мог подумать, что это кнопки, однако нажал и все поехало….

Спасибо за совет!!!!

Записан

Вскрыть верхнюю крышку и нажать на кнопочку термопредохранителя, который на основном бойлере находится. Если смотреть в «лицо» машинки, то справа, на боку бойлера.

Большое спасибо — Вы очень помогли!!!!!!!

Записан

№№6 на кофейном и №№14 на паровом бойлере — это термопредохранители, кнопка между контактами.

Ну никак не мог подумать, что это кнопки, однако нажал и все поехало….

Спасибо за совет!!!!

Пожалуйста. Обращайтесь.

Записан

Level-уровень , ………причина не только в помпе , ….уровень в бойлере не достигается по нескольким причинам: засорение гидросистемы , износ клапанов …….и т.д….

Записан

Такая же проблема как у автора. Не могу снять верхнюю крышку. Помогите разобрать. Может быть там тайный болтик есть ?

Записан

- Печать

Страницы: [1] 2 Вверх

- Manuals

- Brands

- Schaerer Manuals

- Coffee Maker

- Siena 2

Manuals and User Guides for Schaerer Siena 2. We have 4 Schaerer Siena 2 manuals available for free PDF download: Spare Parts Catalog, User Manual, Operating Instructions Manual

Schaerer Siena 2 User Manual (42 pages)

Brand: Schaerer

|

Category: Coffee Maker

|

Size: 2.94 MB

Table of Contents

-

User Manual

2

-

Safety Symbols

3

-

Introduction

4

-

Welcome

4

-

Table of Contents

5

-

-

Safety Notes

7

-

General

7

-

Hygiene

9

-

Liability

9

-

-

Product Description

10

-

Overview — Machine

10

-

Overview — Control Panel

10

-

Detailed Picture of the Foam Head (Siena 2)

10

-

The Display Symbols

10

-

Scope of Delivery

11

-

Overview of Accessories

11

-

Installation Plan for Siena 2

12

-

-

Commissioning

13

-

Before Using for the First Time

13

-

Installing the Milk Nozzle (Siena 2)

14

-

Adjusting Milk Foam (Siena 2)

14

-

-

Operation

15

-

Introduction

15

-

Filling Coffee Beans

16

-

Making the Coffee Maker Ready to Operate

16

-

Switching on the Coffee Maker

16

-

Operating Modes

16

-

Preparing Coffee / Espresso (Whole-Bean Coffee)

17

-

Preparing DECAF Coffee (Coffee Powder)

17

-

Preparing Hot Water (Siena 1)

18

-

Preparing Hot Water (Siena 2)

18

-

Preparing Steam (Siena 1)

18

-

Preparing Cappuccino (Siena 2)

19

-

Preparing Milk Foam (Siena 1)

19

-

Preparing Milk Foam (Siena 2)

20

-

Pre-Heating Cups

20

-

Grinder Settings

20

-

-

Programming

21

-

Navigation through the Programming Level

21

-

Overview: Product Programming

22

-

Overview: Product Programming (Continued)

23

-

Overview: Programming Common Parameters

24

-

Overview: Programming Fixed Parameters

25

-

Default Settings: Products

26

-

Default Settings: Common Parameters

27

-

Default Settings: Fixed Parameters

27

-

-

Cleaning

28

-

Introduction

28

-

Daily and Weekly Cleaning

29

-

Decalcifying

31

-

Installing/Detaching the Foam Head (Siena 2)

32

-

Cleaning the Milk Nozzle (Siena 2)

32

-

-

Troubleshooting

33

-

Malfunctions and Possible Causes

33

-

Service and Maintenance Work

34

-

Service Request

34

-

-

Options

35

-

Coin Tester

35

-

Coin Tester — Operation and Maintenance

35

-

Bean Container

36

-

Base with Supports (Art. No.: 062’489)

36

-

Fixed Water Supply

36

-

Fixed Water Supply — Structural Requirements

36

-

-

Appendix

37

-

Declaration of Conformity

37

-

Cleaning Products

37

-

Kamareta Cleaning Tablet (Art. No.: 062’531)

37

-

Milk Clean» Cleaning Product (Art. No.: 061’913)

38

-

Liquid Decalcifier (Art. No.: 062’869)

39

-

Storing Cleaning Products

39

-

Serial Plate

40

-

Technical Data

40

-

Environmental Aspects

41

-

Contact Address

41

-

Advertisement

Schaerer Siena 2 Operating Instructions Manual (35 pages)

Brand: Schaerer

|

Category: Coffee Maker

|

Size: 17.92 MB

Table of Contents

-

Schaerer Siena

2

-

Introduction

4

-

Safety Symbols

4

-

Welcome

4

-

Table of Contents

5

-

General

6

-

-

Safety Notes

6

-

Hygiene

7

-

Intended Use

8

-

Liability

8

-

Detailed Picture of the Foamer Head (Siena 2)

9

-

Overview — Control Panel

9

-

Overview — Machine

9

-

-

Product Description

9

-

The Display Symbols

9

-

Power Supply

10

-

Water Connection / Draining (Option)

10

-

Installation Plan for Siena 2

11

-

Before Using for the First Time

12

-

-

Commissioning

12

-

Filling Coffee Beans

13

-

Introduction

13

-

Making the Coffee Machine Ready to Operate

13

-

-

Operation

13

-

Switching on the Coffee Machine

13

-

Operating Modes

14

-

Preparing Coffee / Espresso (Whole-Bean Coffee)

14

-

Preparing DECAF Coffee (Coffee Powder)

14

-

Preparing Hot Water (Siena 1)

14

-

Preparing Products

14

-

Preparing Cappuccino (Siena 2)

15

-

Preparing Hot Water (Siena 2)

15

-

Preparing Milk Foam (Siena 1)

15

-

Preparing Steam (Siena 1)

15

-

Grinder Settings

16

-

Milk Foam Quality (Installing the Milk Nozzle)

16

-

Pre-Heating Cups

16

-

Preparing Milk Foam (Siena 2)

16

-

Counter Functions in Standby Mode

17

-

Navigation through the Programming Level

17

-

-

Programming

17

-

Overview: Product Programming (Coffee, Cappuccino)

18

-

Overview: Product Programming (Milk Foam, Hot Water)

19

-

Overview: Programming Common Parameters

20

-

Overview: Programming Fixed Parameters

21

-

-

Cleaning

22

-

Informations about Cleaning

22

-

Daily and Weekly Cleaning

23

-

Coffee System Cleaning

24

-

Milk System Rinsing

24

-

Weekly Cleaning

24

-

-

Descaling

25

-

Cleaning the Milk Nozzle (Siena 2)

26

-

Installing/Detaching the Foam Head (Siena 2)

26

-

Malfunctions and Possible Causes

27

-

-

Troubleshooting

27

-

Service and Maintenance Work

28

-

Service Request

28

-

Bean Container

29

-

Coin Tester

29

-

Coin Tester — Operation and Maintenance

29

-

-

Options

29

-

Base with Supports (Art. No.: 062489)

30

-

Fixed Water Supply

30

-

Applied Standards

31

-

-

Declaration of Conformity

31

-

Manufacturer’s Address

31

-

-

Appendix

32

-

Cleaning Products

32

-

Cleaning Tablet (Art.-No.: 062867)

32

-

Liquid Descaler (Art.-No.: 062869)

32

-

Milkpure» Cleaning Product (Art.-No.: 071531)

32

-

Emergency Information

33

-

Serial Plate

33

-

Storing Cleaning Products

33

-

Technical Data

33

-

Environmental Aspects

34

-

Overview of Accessories

34

-

Schaerer Siena 2 User Manual (35 pages)

Brand: Schaerer

|

Category: Coffee Maker

|

Size: 4.97 MB

Table of Contents

-

Schaerer Siena

2

-

User Manual

2

-

Introduction

4

-

Safety Symbols

4

-

Welcome

4

-

Table of Contents

5

-

General

7

-

-

Safety Notes

7

-

Hygiene

8

-

Intended Use

9

-

Liability

9

-

Detailed Picture of the Foamer Head (Siena 2)

10

-

Overview — Control Panel

10

-

Overview — Machine

10

-

-

Product Description

10

-

The Display Symbols

10

-

Water Connection / Draining (Option)

11

-

Installation Plan for Siena 2

12

-

-

Commissioning

13

-

Filling Coffee Beans

14

-

Introduction

14

-

Making the Coffee Machine Ready to Operate

14

-

-

Operation

14

-

Switching on the Coffee Machine

14

-

Operating Modes

15

-

Preparing Coffee / Espresso (Whole-Bean Coffee)

15

-

Preparing DECAF Coffee (Coffee Powder)

15

-

Preparing Hot Water (Siena 1)

15

-

Preparing Products

15

-

Preparing Cappuccino (Siena 2)

16

-

Preparing Hot Water (Siena 2)

16

-

Preparing Milk Foam (Siena 1)

16

-

Preparing Steam (Siena 1)

16

-

Grinder Settings

17

-

Milk Foam Quality (Installing the Milk Nozzle)

17

-

Pre-Heating Cups

17

-

Preparing Milk Foam (Siena 2)

17

-

Counter Functions in Standby Mode

18

-

Navigation through the Programming Level

18

-

-

Programming

18

-

Overview: Product Programming (Coffee, Cappuccino)

19

-

Overview: Product Programming (Milk Foam, Hot Water)

20

-

Overview: Programming Common Parameters

21

-

-

Cleaning

23

-

Informations about Cleaning

23

-

Daily and Weekly Cleaning

24

-

Coffee System Cleaning

25

-

Weekly Cleaning

25

-

-

Descaling

26

-

Cleaning the Milk Nozzle (Siena 2)

27

-

Installing/Detaching the Foam Head (Siena 2)

27

-

Malfunctions and Possible Causes

28

-

-

Troubleshooting

28

-

Service and Maintenance Work

29

-

Service Request

29

-

Version

29

-

Bean Container

30

-

Coin Tester

30

-

Coin Tester — Operation and Maintenance

30

-

-

Options

30

-

Appendix

31

-

Base with Supports (Art. No.: 062489)

31

-

Declaration of Conformity

31

-

Fixed Water Supply

31

-

Cleaning Products

32

-

IBEDA Cleaning Tablet (Art.-No.: 062867)

32

-

Liquid Descaler (Art.-No.: 062869)

32

-

Milkpure» Cleaning Product (Art.-No.: 071531)

32

-

Emergency Information

33

-

Serial Plate

33

-

Storing Cleaning Products

33

-

Technical Data

33

-

Environmental Aspects

34

-

Overview of Accessories

34

-

Advertisement

Schaerer Siena 2 Spare Parts Catalog (48 pages)

Schaerer Coffee machine Spare parts catalog

Brand: Schaerer

|

Category: Coffee Maker

|

Size: 5.87 MB

Table of Contents

-

Table of Contents

5

-

Revestimiento

7

-

Bastidor (Siena)

9

-

Bastidor (Siena 2)

11

-

Sist. Hidráulico

13

-

Calentador de Agua / Calentador de

15

-

Válvula Cerámica

21

-

Sist. Electrónico

23

-

Calentador

25

-

Accesorios

27

-

Descarga Depósito Recogegotas

33

-

Plano de Instalación

35

-

Subestructura

37

-

Selector de Monedas Izq

39

-

-

Salida de Café / Cappuccinatore CPT

41

-

Espumador de Leche

43

-

Válvula de Salida Agua Caliente / Vapor

45

-

Esquema de Tubos

48

-

Advertisement

Related Products

-

Schaerer Siena 1

-

Schaerer Siena 1/2

-

Schaerer Siena

-

Schaerer S200 Easy Milc

-

Schaerer SCA Plus

-

Schaerer SCA

-

Schaerer Siena-2

-

Schaerer 03.1210.8000

-

Schaerer 03.1210.8001

-

Schaerer 040381-00021EUS

Schaerer Categories

Coffee Maker

Commercial Food Equipment

Medical Equipment

Food Warmer

Kitchen Appliances

More Schaerer Manuals

Even such a small and seemingly unimportant device as a coffee machine can cause problems if it doesn’t work correctly. When you or your family members don’t get the usual cup of coffee, it can be very frustrating and affect you or their performance during the day. Buying a new machine is not always the easiest solution. With the Schaerer troubleshooting advice from the tables below, you may be able to return your coffee machine back to life in a quarter of an hour.

Schaerer Siena coffee machine troubleshooting

| Cause | Remedy |

|---|---|

| Does the coffee maker not switch on? | • The power plug is not properly connected. • The main power switch (on the left-hand side) is not set to ON. • Check fuses. |

| Does the «exclamation point in a triangle» indicator flash? |

• The brew unit has not been properly inserted. • The door is not properly closed. |

| Does the «exclamation point in a triangle» indicator light up and does a message appear on the display? |

• This fault can only be rectified by a qualified service technician. |

| Is the pump causing loud noises and/or does the «crossed out drop» indicator light up? | • The water tank has not been properly inserted (air in the system). Siena 2: • Bleed the device using the «hot water button» (press for ± 6 sec.) (The indicator goes out when the next beverage is dispensed). Siena 1: • Turn the rotary dial (on the right-hand side) to the [ Hot water ] position in order to bleed the device. |

| Is there no milk foam (Siena 2)? | The milk nozzle is clogged (in the milk container). Insert a brush into the milk nozzle |

| Is the milk only hot (Siena 2)? | • The foam nozzle on the milk foam producer is clogged. Insert the air valve pin into the milk nozzle. |

| Does the milk foam have large bubbles (Siena 2)? | • The milk is too warm (always keep milk in the refrigerator). (Optimal milk temperature: 3 °C to 5 °C). • The O-rings on the milk foam producer are defective. Check the O-rings and replace them, if necessary. • The milk suction tube is defective. Check the milk tube and replace it, if necessary. • The milk nozzle (diameter) is too small. |

| Is the milk foam too cold (Siena 2)? | The milk nozzle is defective or a nozzle of the wrong diameter has been fitted. |

| Does the coffee not have any foam? | • The cups are too cold (pre-heat the cups for ideal foam). • The operating temperature (indicator is lit) has not yet been reached. • The coffee is no longer fresh. • The coffee grinder setting is too coarse (high number). • The coffee grinder setting is too fine (low number). • The wrong coffee mixture is being used |

| No hot water? | • Insert a fine needle into the outlet opening. |

| Can the brew unit not be pulled out or inserted? | • The brew unit is not in its basic position. Close the service door and switch on the device. • Use the multi-tool adjusting knob to turn the brew unit a little to the left or right while inserting it (carrier position is incorrect). |

| Does the coffee maker not react to buttons being pressed? | • The operating temperature has not yet been reached. (The indicator lights up). • A rinse or cleaning program is in progress (the cleaning button flashes). • Another indicator flashes/lights up. Rectify the fault/remove the cause. |

Schaerer Coffee Celebration BCL troubleshooting

| Message | Cause | Remedy |

|---|---|---|

| «Under-temperature steam» | • Excessive steam outputs • Phase fuse defective • Safety fuse has opened |

1) Wait for approx. 3 minutes. If during this time «Time-out Heating Steam» appears on the display, check if phase fuse is defective. 2) If the message persists: Contact a qualified service technician. |

| «Under-temperature coffee» | • Excessive coffee outputs • Phase fuse defective • Safety fuse has opened |

|

| «Under-temperature tea» | • Excessive tea / hot water outputs • Phase fuse defective • Safety fuse has opened |

|

| «Flowmeter timeout» | • No water connection • Defective pump (pump pressure < 7.5 bar) (check the manometer) • Brew unit blocked • Water system blocked • Grinder mixture too fine • Electrical problem (PCB, …) |

1) Open the shut-off valve and press the beverage button again. 2) Check the brew unit. 3) Check the grinder mixture. 4) If the message persists: Contact a qualified service technician. |

| «Front door open» | • The front door is open or the lock bolt did not engage • Limit switch is damaged |

1) Close front door. 2) If the message persists: Contact a qualified service technician |

| «Grinder L./B. motor driver error» | Control board defective | Contact a qualified service technician. |

| «Grinder R./F. motor driver error» | ||

| «Brew piston motor driver error» | ||

| «Grinder left no beans» | One of the coffee bean containers is empty. | Fill in 1 kg of fresh coffee beans |

| «Grinder right no beans» | ||

| «Grinder front no beans» | ||

| «Grinder rear no beans» | ||

| «Grinder left blocked» «Grinder right blocked» «Grinder front blocked» «Grinder rear blocked» |

An object (e.g. a stone) is stuck in the grinder. | 1) Unplug the machine from the power supply and vacuum the coffee beans out of the grinder. 2) If the message persists: Contact a qualified service technician. |

| «Timeout level supply» | The water level in the steam generator is not correct. | 1) Check whether the stop valve of the water supply is open. 2) Unplug the machine from the power supply and plug it back in again. 3) If the message persists: Contact a qualified service technician. |

| «Coffee grounds container is missing» | • The coffee grounds container is not inserted correctly. • Limit switch is damage |

1) Place the coffee grounds container correctly in. 2) If the message persists: Contact a qualified service technician. |

| «Temperature sensor steam» | The temperature sensor in the steam boiler is defective. | Contact a qualified service technician. |

| «Temperature sensor coffee» | ||

| «Temperature sensor tea» | The temperature sensor in the hot water boiler is defective. | |

| «Timeout heating steam» | The programmed target temperature was not reached within the specified time. | 1) Switch the machine off and on again. 2) Check the phase fuse. 3) If the message persists: Contact a qualified service technician. |

| «Timeout heating coffee» | ||

| «Timeout heating tea» | ||

| Touchscreen dark

Dark display, no message |

• Plug at power socket is disconnected or main switch is OFF. • Touchscreen defective. |

1) Reconnect plug at power socket or switch main switch to ON. 2) If the message persists: Contact a qualified service technician. |

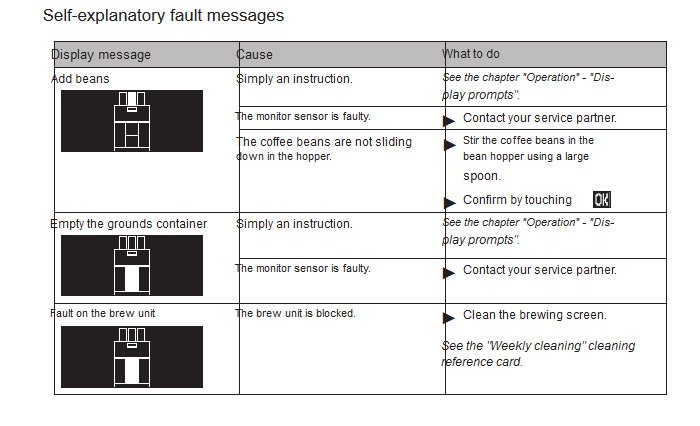

Schaerer JDE Barista troubleshooting

| Display message | Cause | What to do |

|---|---|---|

| Milk level low (small reserve amount still available) |

The container for fresh milk is virtually empty |

Top up the container for the fresh milk as and when. |

| Milk empty | The container for the fresh milk is empty. |

1) Remove the container for the fresh milk. 2) Thoroughly clean the container. 3) Fill the container with fresh milk precooled at ±5°C and insert it back into the machine. |

| Empty the drip tray | The drip tray is full. | 1) Empty the drip tray. 2) Clean the drip tray and reinsert it |

| Drip tray missing | The drip tray is not correctly inserted or is missing. | Insert the drip tray and check for correct seating. |

| Left grinder overloaded/blocked Right grinder overloaded/blocked |

An excessively high current value (>8 A) has been measured over a defined period. The machine attempts to start grinding 5 times, after which the following message appears: «Left/right grinder overloaded». If another beverage is requested in this state and the problems remain, the message changes to «Left grinder overloaded/blocked» or «Right grinder overloaded/blocked». Dispensing of beverages is disabled. |

1) Open the door. 2) Switch off the machine. 3) Check the grinder for blockages and remove any foreign bodies. 4) Restart the machine. 5) If the fault appears again, contact your service partner. |

| Hot water boiler over temperature | 1) The water supply has been interrupted. 2) The brewing unit is blocked. 3) The machine has overheated. 4) The SSR is defective. 5) The Klixon has triggered. |

1) Check the level of the drinking water tank or the condition of the mains water supply. 2) Check and clean the brewing unit. 3) Disconnect the machine from the power supply and let it cool off. 4) Contact your service partner. |

| Steam boiler over temperature | 1) Check the level of the drinking water tank or the condition of the mains water supply. 2) Check and clean the beverage outlet and steam system. 3) Disconnect the machine from the power supply and let it cool off. 4) Contact your service partner. 5) Contact your service partner. |

|

| Hot water temperature too low Steam temperature too low |

Error while heating. | 1) Disconnect the machine from the power supply 2) Connect the machine again and switch it on. |

| Hot water boiler heating timeout Steam boiler heating timeout |

Although the heating is switched on, the set temperature was not reached within 5 minutes. | Contact your service partner. |

| Hot water boiler NTC short Steam boiler NTC short |

The main board does not detect a resistance. A maximum temperature (approx. 150°C) is measured. Dispensing of beverages is disabled. |

|

| Hot water boiler NTC open Steam boiler NTC open |

The temperature sensor is not connected. A minimum temperature is measured. | |

| Brewing unit excess current | Excess current was detected on the brewing unit motor | |

| Brewing unit idle current | Even when the brewing unit is not running, it must consume a minimal amount of current. If it does not, there is a fault. This may be due to the brewing unit, the power board or the wiring. | 1) Check the brewing unit for blockages. 2) If the fault persists, contact your service partner |

| Brewing unit timeout | The brewing unit does not have a switch for the «home position». The position of the brewing cylinder is detect- ed by measuring the current value. The following peak values are detected: upper and lower position. The following timeout is defined: If no current peak is detected within 10 seconds after a brewer movement, the «brewing unit timeout» is displayed. |

Contact your service partner. |

| Water flow error | While a coffee product is being dispensed, the flow meter performs fewer than the defined number of minimum rotations. It is likely there is a blockage or partial blockage somewhere in the water system. |

1) Check the level of the drinking water tank or the condition of the mains water supply. 2) Check the internal or external drinking water tank (saturation of the filter reduces the water flow). 3) Check whether the upper plunger is blocked or partially congested. 4) Check the grinding setting. If the grinding setting is too fine, this can inhibit or completely block the water flow. 5) If the fault persists, contact your service partner. |

| Steam boiler supply error | The level sensor detected a low level in the steam boiler. An attempt was made to fill the boiler. However, no water was detected by the level sensor within 60 sec. Filling is aborted. The dispensing of beverages that require steam is disabled. |

Contact your service partner. |

| Modbus processing error Modbus comm error |

Communication error between the power unit and TouchPanel. | |

| Accounting system is initialising | Status message only. | |

| Accounting system is online | ||

| Accounting system is offline | ||

| Unable to start database Wrong database version Unable to start user interface General error message in control process Unable to start control process Control process has been unexpectedly shut down Unable to initialize control process Unable to set up communication with control process Communication interrupted by control process |

Serious error/internal error Error at software start-up. |

1) Disconnect the machine from the power supply. 2) Connect the machine again and switch it on. 3) Reinstall the software. 4) Contact Schaerer technical support. |

Schaerer Coffee Art troubleshooting

| Display Message | Cause | Remedy |

|---|---|---|

| select product 12:00 07.09.2010 |

Appears when the machine is ready to operate. Beverages can be dispensed. |

|

| selection locked grounds cont missing |

• The grounds container has been pulled out. (Cleaning program). • The end switch is defective. Beverage output is blocked! |

After cleaning the brew chamber, reinsert the grounds container. If the message persists, call for service |

| selection locked empty gr. container |

The grounds container is full. Beverage output is blocked |

1) Empty the grounds container and reinsert it. |

| select product cleaning program |

Appears when a programmed number of beverages has been dispensed without the machine being cleaned. | The machine must be cleaned. |

| selection locked grinder L no beans |

Appears when the bean hopper on the lefthand side is empty or when a coffee bean has become stuck. Beverage output is blocked |

1) Refill the bean hopper with coffee beans (max. 1000g.) and push the «stop» button. 2) If jammed, use the stem of the cleaning brush to «stir» the coffee beans around and unclog the grinder. Then press the «stop» button. |

| selection locked grinder R no beans |

||

| selection locked grinder L overload |

Appears when the grinder on the lefthand side is overloaded or if the grinder is jammed. Beverage output is blocked |

Check the grinder for foreign objects. Press the «stop» button. |

| selection locked grinder R overload |

Appears when the grinder on the righthand side is overloaded or if the grinder is jammed. Beverage output is blocked! |

|

| selection locked grinder L blocked |

An object (such as a stone) has become jammed in the grinder. Beverage output is blocked. |

1) Press the «stop» button. If the message persists, switch off the espresso machine and vacuum out coffee beans with a vacuum cleaner. 2) Check if a foreign object has jammed the grinder. |

| selection locked grinder R blocked |

||

| selection locked grinder current |

PCB or electronics are defective. | Call for service. |

| selection locked brew motor current |

PCB or electronics are defective. | |

| selection locked over curr. brewmotor |

• The brew unit has too much electricity (over 4A). • Brew unit is jammed |

|

| select product water flow error |

• No water connection. • Defective pump (pump pressure < 7.5 bar). • Brew unit blocked. • Water system blocked. • Grinder mixture too fine. • PCB — flowmeter incorrectly connected. • Electrical problem |

1) Open the shut-off valve and press the beverage button again. 2) Check the brew unit. 3) Check the grinder mixture. If the message persists, call for service |

| select product over temp. brewwater |

• Electrical problem between the sensor and the PCB. • Temperature sensor defective. |

Call for service. |

| select product over temp. tea |

||

| select product over temp. steam |

||

| selection locked heating coffee water |

The temperature is 10 °C below the programmed temperature. Beverage output is blocked. |

Wait until the target temperature has been reached. If the message persists, call for service. |

| selection locked heating hot water |

||

| selection locked heating steam |

||

| select product timeout coffee heater |

The programmed temperature of the coffee water boiler was not reached within 4 minutes after the machine was switched on. Beverage output is blocked |

Switch the machine off and then back on. If the message persists, call for service. |

| select product timeout HW heater |

The programmed temperature of the hot water boiler was not reached within 4 minutes after the machine was switched on. Hot water beverage output is blocked. |

|

| select product timeout steam heater |

||

| selection locked coffee sensor def. |

• Electrical problem between the sensor and the PCB. • Temperature sensor defective. Beverage output is blocked! |

Call for service. |

| selection locked HW sensor def. |

||

| selection locked steam sensor def. |

||

| selection locked brew unit time out |

The brew unit motor is not running. Beverage output is blocked. |

|

| selection locked timeout steam suppl. |

The level in the steam boiler was not reached. Beverage output is blocked. |

|

| selection locked exchange filter |

The programmed water volume (liters / months) has passed through the filter. Beverage output is blocked. |

The water filter must be replaced. Call for service. |

| selection locked service request |

The programmed number of beverages (cups / month) has been reached. Service is required. Beverage output is blocked |

Call for service. |

| selection locked Initialising |

The software and the processor are restarted. The brewer moves into the «Home» position. Beverage output is blocked |

Switch the machine off and then back on. If the message persists, call for service. |

Schaerer Coffee Art Plus troubleshooting

Faults in the Best Foam™ milk system:

| Fault | Cause | What to do |

|---|---|---|

| Milk foam appearance does not correspond to the reference. | Milk temperature does not correspond to the temperature during installation (> +3°C) |

Measure temperature. If necessary, adjust according to the deviation. |

| Problem with milk foam | Milk temperature does not correspond to the temperature during installation. |

Measure temperature. If necessary, adjust according to the deviation. |

| Foam too stiff | Incorrect milk temperature. | Measure temperature. If necessary, adjust according to the deviation. |

| Too much air. | Reduce air. | |

| Cold or cool drinks | Connection between Kombiprint and connector interrupted. |

Check connector. |

| Best Foam™ not working | Kink in silicone hoses upstream and/or downstream from the mixer. |

Check the silicone hoses. Rectify the fault as necessary. |

| Milk dispensed at an angle | Beverage outlet contaminated. | Reduce rinse interval (default = 60 min) |

| Beverage outlet partially blocked |

Machine is exposed to a draft. Beverage outlet contaminated. |

Reduce rinse interval (default = 60 min) |

| Milk sprays when a beverage is being dispensed | Milk empty. Milk container monitoring activated? Beverage outlet contaminated. |

Switch the Best Foam™ System off and on again. The milk system is refilled. (Rinsing insufficient). |

| Beverage outlet moves backwards | Machine older than 38/2015 | Modification with 066368 (drawing 072390). |

Faults with display message:

| Display message | Cause | What to do |

|---|---|---|

| Left/right grinder overloaded | • Left/right grinder is overloaded. • Left/right grinder is clogged. |

Check the grinder for foreign objects. If the message persists: Contact your service partner. |

| Grinder current fault | • PC board faulty. • Electronics defective |

Contact your service partner. |

| Brewing unit current fault | ||

| Brewing motor overcurrent | • Brewing unit is consuming too much power (over 4 A). • Brewing unit is blocked |

|

| Water flow error | No water supply connection. • Pump defect. (pump pressure < 7.5 bar) • The brewing unit is blocked. • Water system clogged. • Grind level too fine. • PC board and flow meter incorrectly connected. • Electrical problem (e.g. PC board) |

1) Open the stopcock and press the beverage field again. 2) Check the brewing unit. 3) Check the grinder mixture. 4) If the message persists: Contact your service part- ner. |

| Crit. coffee temp. | • Electrical problem between sensor and PC board. • Temperature sensor defective |

Contact your service partner. |

| Crit. hot water temp. | ||

| Crit. steam temp. | ||

| Coffee heater timeout | The set temperature of the coffee boiler was not reached within 4 minutes of the unit switching on. | Switch the machine off and back on. If the message persists: Contact your service partner. |

| Hot water heating timeout | The set temperature of the hot water boiler was not reached within 4 minutes of the unit switching on. | |

| Steam heater timeout | The set temperature of the steam boiler was not reached within 4 minutes of the unit switching on. | |

| Coffee sensor defective | • Electrical problem between sensor and PC board. • Temperature sensor defective. |

Contact your service partner. |

| Hot water sensor defective | ||

| Steam sensor defective | ||

| Brewing unit timeout | The brewing unit motor does not run. | |

| Steam dispenser timeout | The level in the steam boiler was not reached. | |

| Milk system disabled | The steam temperature has fallen to 115 °C | 1) Wait until the temperature has been reached again. 2) Switch the machine off and back on. 3) Contact your service partner |

| Initialising | • The software and the processor are restarted. • The brewing unit moves into the initial position. |

1) Switch the machine off and back on. 2) Contact your service partner. |

| Display dark | • Machine is not connected to the mains supply. • Machine is not switched on. |

1) Check whether the machine is connected to the mains supply. 2) Check whether the machine is switched on. 3) If the fault persists: Contact your service partner. |

| No milk | • The milk container is empty. • The milk system is clogged. • The milk system was incorrectly disabled. |

1) Check whether the milk container is filled. 2) Perform the daily cleaning routine. 3) If the fault persists: Contact your service partner |

| No milk foam |

Schaerer Coffee Vito troubleshooting

Fault messages with fault code:

| Code | Designation | Cause | Instruction |

|---|---|---|---|

| 6 | The brew unit is blocked. |

The brewing screen is contaminated| clogged | Clean the brewing screen. |

| 26 | Right mill blocked | 1) The grinding fineness setting is too fine. The fine dust contaminates the mill too quickly. 2) The grinder is blocked. |

1) Set the grinding fineness one level coarser. 2) Contact your service partner. |

| 36 | Left mill blocked | 1) The grinding fineness setting is too fine. The fine dust contaminates the mill too quickly. 2) The grinder is blocked. |

1) Set the grinding fineness one level coarser. 2) Contact your service partner. |

| 88 | Boiler temperature too high. |

The water supply is interrupted. Dispensing of beverages is blocked. |

Option 1: With water tank * Check that the water tank is filled and installed correctly. Option 2: With fixed water supply * Check that water is being supplied |

| The brew unit is blocked. Dispensing of beverages is blocked. |

Clean the brew unit. | ||

| The machine is overheated. Dispensing of beverages is blocked. |

* Switch off the coffee machine and let it cool. * Switch it back on. |

||

| 89 | Boiler heating time fault |

Fault while heating. | Switch the machine off and back on. |

| 161 | Brew water fault | The water supply is interrupted. Dispensing of beverages is blocked. |

Option 1: With water tank * Check that the water tank is filled and installed correctly. Option 2: With fixed water supply * Check that water is being sup- plied. |

| The brew unit is blocked. Dispensing of beverages is blocked. |

Clean the brew unit. | ||

| The grinding fineness setting is too fine. The fine dust contaminates the mill too quickly. |

Set the grinding fineness one level coarser. |

||

| The highest quality level can lead to a brew water fault. |

Lower the quality. | ||

| 163 | Warm rinse water fault. |

The water supply is interrupted. Dispensing of beverages is blocked. |

Option 1: With water tank * Check that the water tank is filled and installed correctly. Option 2: With fixed water supply * Check that water is being sup- plied. |

| The brew unit is blocked. Dispensing of beverages is blocked. |

Clean the brew unit. | ||

| 186 | Steam boiler level | Ground container not (correctly) in- stalled. Dispensing of beverages is blocked. |

* Check that the grounds container has been installed correctly. * Switch the coffee machine off and back on. |

| 188 | Steam boiler temperature too high | Steam outlet or beverage outlet is clogged. Dispensing of beverages is blocked. |

Check and, if necessary, clean the steam outlet or beverage outlet. |

| The machine is overheated. Dispensing of beverages is blocked. |

* Switch off the coffee machine and let it cool. * Switch it back on. |

||

| 189 | Steam boiler heating time fault. |

Fault while heating. | Switch the coffee machine off and back on. |

Faults without message:

| Fault description | Instruction |

|---|---|

| Hot water is not being dis- pensed but there is water in the grounds container. |

1) Clean the hot water outlet. 2) Contact your service partner. |

| Choc is not being dispensed but there is water in the grounds container. |

1) Stop using the Choc outlet. 2) Contact your service partner. |

| Choc dosing unit is blocked; Choc is only dispensed with water. |

1) Clean the dosing unit. 2) Empty the powder. 3) Turn the screw by hand until all powder has been removed. 4) Rinse with water, if necessary. 5) Let it dry fully. |

| Dispensing of coffee differs on the left/right. |

Clean the combination outlet. |

| Milk foam/milk is not being dis- pensed although there is milk in the container. |

1) Check whether the milk hose is kinked or pinched. 2) Route the milk hose properly. 3) Clean the combination outlet. 4) If the suction nozzle is clogged, clean it. 5) If the milk cooler is iced up, defrost it. |

| Milk foam is not correct, temper- ature is too cold. |

1) Change the milk nozzle (green nozzle for cooled milk, white nozzle for uncooled milk). 2) Clean the combination outlet. |

| Milk cooler is not cooling the milk. |

Check that the milk cooler was switched on using the separate switch. |

| Pump is running continuously, water in the grounds container. |

1) Unplug the machine and plug it back in. 2) If the fault persists, call customer service. |

| Milk foamer and water tank are difficult to mount/remove. |

Lightly grease the O-rings with Schaerer «Grease for sealing rings». |

| Choc/Topping container cannot be installed. |

Manually turn the dosing unit screw drive slightly clockwise at the dosing unit. |

Schaerer Coffee Joy troubleshooting

| Display message | Cause | What to do |

|---|---|---|

| Place brewer | The brewing unit is not inserted. | Insert the brewing unit. |

| Brewer position switch. | The brewing unit is not correctly inserted. | Check that the brewing unit is correctly seated. |

| The brewing unit is stiff. | Remove the brewing unit. 1) There are two nozzles with black sealing rings on the inside of the machine. 2) Grease the sealing rings with grease from the accessories. 3) Put the brewing unit back in place. |

|

| Clear flow stopped | There is too much air in the pipes. | Dispense a cup of hot water. This bleeds the pipes. |

| The water filter or the associated sieve is clogged. |

1) Clean the sieve of the water filter. If this does not eliminate the problem: 2) Change the water filter. |

|

| The non-return valve at the outlet of the drinking water tank is contaminated. |

Clean the outlet and the non-return valve with one of the small brushes in the accessories. | |

| The brewing unit is clogged. | Remove and clean the brewing unit. | |

| The grind level is too fine. The fine cof- fee powder contaminates the pipes. |

1) Set the grind level to a coarser setting. 2) Remove and clean the brewing unit. |

|

| Cleaning halted Clear flow stopped. |

The brewing screen is clogged. | Clean the brewing screen. |

| EEPROM error | System error | Switch the machine off and back on. |

| motor driver error | System error | Switch the machine off and back on. |

| grinder blocked | The grinder is blocked. | 1) Switch off the machine and disconnect the power plug. 2) Stir the coffee beans in the bean hopper using a spoon. If the error persists: 3) Switch off the machine and disconnect the power plug. 4) Extract the beans, check the grinder and remove any blockages. |

| Temperature sensor steam | Overheating | Switch off the machine and let it cool for some time. |

| Temperature sensor water | Overheating | Switch off the machine and let it cool for some time. |

Faults without display message:

| Fault description | Cause | What to do |

|---|---|---|

| No milk foam or milk output although there is milk in the container. | 1) The milk hose is kinked at some location, preventing milk from flowing. 2) The foamer head is clogged. |

1) Check the milk hose and reroute if necessary. 2) Take the foamer head out of the beverage outlet and clean it. |

| No milk foam, only warm milk. | Blockage in milk system. | Clean the milk system. |

| The milk or milk foam is too cold. | Wrong milk nozzle. | The scope of delivery contains two different milk nozzles. Change the milk nozzle. |

| The milk is too hot, its quantity is too low or the milk foam has bubbles. |

The milk in the milk container is too warm. |

1) Only use pre-cooled milk (3 – 5°C). 2) Cool the milk constantly during use. |

| Wrong milk nozzle. | 1) The scope of delivery contains two different milk nozzles. 2) Change the milk nozzle. |

|

| The water tank is difficult to slide in place. | The O-ring on the water outlet connec- tor must be greased. |

Grease the O-ring with grease from the accessories. |

| The brewing unit is difficult to pull out and slide back in. |

The brewing unit is stiff. | 1) Remove the brewing unit. There are two nozzles with black sealing rings on the inside of the machine. 2) Grease the sealing rings with grease from the accessories. 3) Put the brewing unit back in place. |

| The pump makes loud noises. | There is too much air in the pipes. | Dispense a cup of hot water. This bleeds the pipes. |

| The coffee has no crema. | The coffee is no longer fresh. | Replace the beans. |

| The grind level is too coarse. | Set the grind level to a finer setting. | |

| The brewing unit cannot be reinserted. | The brewing unit is in the wrong position. | While inserting the brewing unit, readjust it using the multitool until it can be reinserted. |

| The brewing unit cannot be pulled out. | The brewing unit is in the wrong position. | Readjust the brewing unit using the multitool until it can be pulled out. |

| Internal/external cooling unit does not cool. | The cooling unit is not switched on or is switched on incorrectly. |

Set the rocker switch on the rear of the cooling unit to «COLD». |

Schaerer Coffee Factory troubleshooting

| Error display |

Error description |

Action instruction |

|---|---|---|

| 6 | Brewing unit lockup current / Brewing unit stiff |

Switch off the coffee machine Cleaning the brewing unit |

| 26 36 |

Right grinder blocked Left grinder blocked |

1) Switch off the coffee machine 2) Disconnect mains plug 3) Remove bean hopper 4) Turn grinder disk counter-clockwise using only Multitool (square button). 5) Replace hopper 6) Switch on coffee machine If this occurs frequently: Set grinding degree one stage coarser |

| 88 | Boiler overtemperature |

Beverage dispensing temporarily blocked. 1) Check that mains tap is on or that the water tank is filled and inserted correctly If still not OK: 2) Switch off the coffee machine 3) Cleaning the brewing unit 4) Switch on and try again (Release follows when cooled down to normal temperature). 5) Switch off coffee machine, allow to cool and switch on again. |

| 89 | Boiler heat-up time error |

Switch machine off and on again |

| 161 | Brew water error | Between each of the following steps switch the machine off and on again. If fault not remedied carry out the next step. 1) Check that mains tap is on or that the water tank is filled and inserted correctly 2) Cleaning the brewing unit 3) Set grinding degree coarser 4) Reduce quality |

| 163 | Warm rinsing water error | Between each of the following steps switch the machine off and on again. If fault not remedied carry out the next step. 1) Check that mains tap is on or that the water tank is filled and inserted correctly. 2) Cleaning the brewing unit. |

| 186 | Steam boiler level |

Beverage dispensing temporarily blocked. 1) Check that coffee grounds container correctly inserted. 2) Switch machine off and on again. |

| 188 | Steam boiler overtemperature |

Beverage dispensing temporarily blocked. 1) After releasing, check milk foam and steam outlet. 2) Switch off machine, allow to cool and switch on again. |

| 189 | Steam boiler heat-up time error |

Switch machine off and on again |

Errors without error display:

| Error pattern | Action instruction |

|---|---|

| No hot water output but water in coffee grounds container |

1) Clean hot water spout 2) Call Schaerer Service |

| No Choc dispensing but water in grounds container |

1) Do not use Choc 2) Call Schaerer Service |

| Choc portion controller blocked, Choc dispensed only with water |

1) Clean portion controller 2) Empty powder 3) Turn dosing auger manually until all powder removed 4) If necessary rinse with water 5) (Allow to) dry completely |

| Coffee dispensing on the left / right differs |

Clean the combi spout |

| No milk foam / milk output, but milk in milk container |

1) Check whether the milk hose is kinked or squashed 2) Re-route tube correctly 3) Clean the combi spout 4) Milk nozzle blocked 5) Milk cooler iced |

| Milk foam incorrect, temperature too cold |

1) Change milk nozzle — green nozzle for cooled milk — white nozzle for uncooled milk 2) Clean the combi spout. |

| The cooler does not cool | Check if the cooler has been properly turned on using the separate switch. |

| Pump runs permanently, water in coffee grounds container |

Switch machine off and on again If not remedied call Schaerer Service. |

| Coffee machines with water tank assembly / disassembly stiff |

Lightly smear the O-rings with Schaerer gasket grease. |

| Choc / Topping hopper cannot be inserted |

Manually turn the drive for the dosing auger at the portioner slightly in a clockwise direction |

Schaerer Coffee Press Error codes

| Display Message | Cause / Error Description | Remedy |

|---|---|---|

| Your selection pls 08:15 13.11.2013 |

Appears when the machine is ready to operate. | |

| beverage sel. locked grounds cont.missing |

The grounds container has been removed (Cleaning program) | Reinsert the grounds container. If the message persists, call for service. |

| empty grounds cont. | • The grounds container is full. | Empty the grounds container and reinsert it. |

| machine cleaning OK: care pad |

Appears when the machine needs a cleaning cycle. |

The machine must be cleaned. |

| refill beans left |

Appears when the bean hopper on the left-hand side is empty or when a coffee bean has become stuck. | Refi ll the bean hopper with coffee beans (max. 1.7 lbs.). Press the beverage button again. If the message persists, call for service. |

| refill beans right |

Appears when the bean hopper on the right- hand side is empty or when a coffee bean has become stuck. | Refi ll the bean hopper with coffee beans (max. 1.7 lbs.). Press the beverage button again. If the message persists, call for service |

| empty drip tray | Appears when the drip tray is full. | Remove and empty drip tray. If the message persists, call for service |

| insert ground coffee select beverage |

Appears when the maual insert lid is open. | Insert ground coffee then close the manual insert. Select the desired beverage from the beverage button panel. Touch «C» to cancel. If the message persists, call for service. |

| beverage blocked | Close the manual insert lid. If the message persists, call for service. |

|

| your selection pls replace water filter. |

Appears when the machine must be descaled. | Call for service. |

| — | Insert the brewing unit. | Replace or reseat the brewing unit. If the message persists, call for service |

| F 6 | Brewing unit lockup current / brewing unit stiff. | Switch off the coffee machine. Clean the brewing unit. If the message persists, call for service. |

| F 26 | The right grinder is blocked. | Switch off the coffee machine. Empty bean hoppers and check if a foreign objects has jammed the grinder. If the message persists, call for service |

| F 36 | The left grinder is blocked. | |

| F 88 | Boiler: over-temperature. | Call for service. |

| F 161 | Flow error: during the brewing cycle. | |

| F 162 | Flow error: when cleaning or when dispensing hot water | |

| F 164 | ||

| F 188 | Heater error. |

Schaerer Ambiente coffee machine troubleshooting

| Messages on display | Cause |

|---|---|

| selection locked heating up |

When the coffee machine is switched on, no products can be served until the system warms up (approx. 5 min.) |

| selection locked cup missing |

No products can be served because the cup sensor has failed to detect a cup. Place a cup under the outlet. |

| selection locked container n. i. place |

Insert the grouts container. If the message is still displayed, the switch is defective: Contact After Sales Service! |

| <> selection locked |

The product key is stuck or dirty. This problem can be solved by cleaning or pressing the key several times. If not: Contact After Sales Service! |

| selection locked clean machine |

All product selection is blocked. Execute the cleaning program. |

| selection locked watertank empty |

Fill up the fresh water tank with drinking water and press the [«minus» ] key (only applies to coffee machines without a fixed water supply). |

| selection locked waste watertank full |

Empty the wastewater tank and press the [«minus» ] key (only applies to coffee machines without a wastewater outlet). |

| selection locked 12:00 15.10.2001 |

All products have been blocked using the KEY BLOCK card. |

| selection locked heating timeout |

Grouts container is missing or is not pushed in far enough. — Heater problem. Contact After Sales Service. |

| selection locked comms. interrupted |

Communication with an external device has been interrupted. Check that the external devices are properly connected to the mains and to the coffee machine. If so, and the message still appears: Contact After Sales Service |

| selection locked ** LAN-Timeout ** |

Communication with an external device has been interrupted. Check that the external devices are properly connected to the mains and to the coffee machine. If so, and the message still appears: Contact After Sales Service. |

| selection locked error account system |

Communication with an external device has been interrupted. Check that the external devices are properly connected to the mains and to the coffee machine. If so, and the message still appears: Contact After Sales Service. |

| selection locked door open |

The service door (panel) is not shut properly. Check it and if necessary, shut it. |

| selection locked milk door open |

Product selection remains blocked until the milk panel is properly closed. |

| selection locked outlet missing |

Outlet is incorrectly placed (or is missing). If this message is still displayed after verification: Contact After Sales Service |

| battery flat | The internal control unit battery needs replacing. |

| ** EEPROM error! | Serial EEPROM is defective. |

| motor current | Switch off coffee machine, wait for 10-30 seconds and then switch back on. If the problem persists, switch off the coffee machine. Contact After Sales Service! |

| motor driver error | Switch off the coffee machine. Contact After Sales Service! |

| selection locked clean machine |

No products at all can be selected when this message is displayed. Execute the cleaning program. |

| select product grinder right empty |

The right-hand coffee mill is out of coffee beans. Fill the bean container. |

| select product grinder left empty |

The left-hand coffee mill is out of coffee beans. Fill the bean container. |

| selection locked empty container! |

Empty grouts container and put it back in place. |

| select product grinder left blocked or select product grinder right block |

Press [‘minus’ ] key. If the problem persists, open the bean container hatch and remove the bean container. Remove the remaining coffee beans (e.g. using a vacuum cleaner) and make sure that nothing (e.g. a piece of gravel) is stuck in the mill. If not and the problem persists: Contact After Sales Service |

| temp. sensor coffee | The temperature sensor in the instantaneous coffee heater is defective. |

| heating up coffee | Wait for approx. 5 minutes (too much coffee water may have been served). If the message does not disappear: Contact After Sales Service. |

| rinsing selection locked |

The coffee machine is being automatically rinsed. If it is programmed to do so: no error |

| piston motor timeout | The hoist motor is defective. |

| selection locked clean machine |

No products at all can be selected when this message is displayed. Execute the cleaning program. |

| temp. sensor steam | The temperature sensor in the steam generator is defective. Steam emission is blocked. |

| level probe steam | The level sensor in the steam generator is defective. Steam emission is blocked. For the first 2 minutes after the display lights up, or when the coffee machine has been switched off, no tea or coffee can be served either. Make sure that the water tap is turned on. If the problem persists: switch the machine off, wait for 10-30 seconds and switch it on again. If the problem persists: Contact After Sales Service |

| Timeout heat. steam | If the system does not reach the programmed temperature after 8 minutes, the following message is displayed: «Timeout heat. steam». Contact After Sales Service. |

| heating steam | Wait for approx. 5 minutes (too much steam may have been drawn off). If the message does not disappear, the message «heating steam» is displayed. Contact After Sales Service. |

| selection locked clean machine |

No products at all can be selected when this message is displayed. Execute the cleaning program. |

| timeout heat. tea | If the system does not reach the programmed temperature after 8 minutes, the following message is displayed: «Timeout heat.tea» |

| temp. sensor tea | The temperature sensor in the instantaneous water heater is defective: No hot water can be served for tea: Contact After Sales Service |

| heating tea | Wait for approx. 2 minutes (too much hot water may have been drawn off). If the message does not disappear, the message «heating steam» appears: Contact After Sales Service. |

| selection locked container full ! |

Empty grouts container and put it back. Five further coffee products can be served after this message is displayed, after which the coffee machine blocks. — Empty grouts container. |

| select product clean machine |

Clean the coffee machine. Products can still be served. If the coffee machine is so programmed, up to 50 coffees can be served, or coffees can be served for up to one hour, after which the coffee machine blocks and must be cleaned (obligatory cleaning). |

| select product button locked |

Product key is disabled. (KEY BLOCK or key not programmed) |

| credit operation button locked |

Product key is disabled |

| select product temp. sensor outside |

Optional automatic steam cut-off is enabled, but steam can be drawn off after timeout. |

| select product flowmeter defect |

The coffee water flow meter is defective. Water dosing is time-controlled and products can still be served (this message can only be deleted by the service engineer). |

| system-data error! | An error has occurred in the product key programming or the general system data. If a product key also lights up, it may be unusable. Press the [«stop’ ] key to proceed: Contact After Sales Service. |

| select product replace water filter |

The installed water filter needs cleaning, filling or replacing. |

| select product milk empty |

This message is displayed if the optional milk sensor is mounted and enabled. Products can be served if enabled. Products cannot be served if disabled. |

| select product service wanted |

Reminder that service by a licensed after sales agent is required. Products can still be served. Nevertheless, your after sales service should be informed rapidly. This message can be suppressed using the CHEF card. |

| select product please rinse cappuc. |

After a cappuccino is served, the coffee machine requests manual rinsing of the cappuccino unit if programmed to do so. |

| * read error remove card |

The card in the card reader is incorrectly inserted (note direction of arrow) or defective. |

| * wrong card remove card |

The coffee machine is requesting another card type. A MONEY card has been inserted for the first time or credit is zero. The MONEY card has not been logged on. Load credit onto the MONEY card using the LOAD card and/or log it on. No payment system is installed. |

| * mistake remove card | An error occurred during data transfer to the SAVE card. The card was withdrawn from the card reader too early. Data transfer was incomplete or data are corrupted. — save data again. |

| product — * 5 Error! Press any key.. |

An error occurred during data transfer from the SAVE card coffee machine. The card was withdrawn from the card reader too early. Data transfer was incomplete or data are corrupted. Press [ ‘minus’] key, wait for five seconds, then save data again. |

| * data error remove card |

The data structure on the card has been damaged because the card was withdrawn from the card reader during data transfer, or the card is new and needs logging on, enabling or loading. |

| *wrong PIN-code remove card |

The wrong PIN code (Personal Identification Number) was entered. Repeat procedure. |

| no accounting | No payment system is installed. |

| Cup sensor | If a product is served even though no cup is under the outlet, wipe the lens of the cup sensor with a soft damp cloth. If the problem persists: Contact After Sales Service. |

| Cup sensor | If products cannot be served although a cup has been placed under the outlet, first clean the lens as described above. If the problem persists: Contact After Sales Service. |

проблема с кофеваркой Schaerer Siena 2 / Абакан

Я запустил очистку кофейной и молочной системы. Всё промылось и машинка была выключена. На следующий день включая машину горела ошибка NTC-Steam. Я проверил хорошо ли закрыты дверцы, вытащил узел пропаривания и задвинул обратно, ничего не изменилось.

Люди с такой же проблемой (0)

Лучшее решение

Просто так совпало. вышел из строя температурный датчик парового бойлера. — замена бойлера

Это решение полезно? Да Нет

2 участника считают, что это решение полезно

Знаете, как решить эту проблему?

Поделитесь своим знанием!

Ваш способ решения:

Наиболее похожие проблемы из этого раздела

Купил, включил, согласно инструкции промыл фильтр, бачок, залил воды чуть ниже максимума, дождался зелёного индикатора, нажал на кнопку насоса — и …

Не готовит пенку крема (нет совсем кофейной пены). Меняла и кофе, и помол, и количество кофе, но всё равно пенки нет совсем.

Здравствуйте! Кофемашина Philips 5000 series, при приготовлении капучино сбоку валит пар, молоко пару капель выдаёт, шипит. Что это может быть? И …

Выдаёт ошибку Е5 — ошибка водяного контура… Переустановка бака для воды не помогает. В чём может быть причина, и сколько примерно будет стоить её …

Ошибка E05. Как убрать ошибку и промыть? Вероятно, забился капучинатор.

Работаем ежедневно c 09:00 до 20:00

без выходных и праздничных дней

8 (495) 135-00-03

Звоните ежедневно с 9:00 до 21:00

м. Кутузовская. ул. Студенческая, д. 35

Кофемашина Schaerer Siena 2 может выдавать ошибку по причине каких-либо неполадок в работе устройства или из-за дефектов элементов. Уточнить, какая именно неисправность постигла вас вы можете в нашем сервисном центре, где работают специалисты высокого уровня с многолетним опытом за плечами. Для связи с нами достаточно заполнить простую форму или позвонить по номерам горячей линии, указанных на сайте. Наши операторы дадут исчерпывающую информацию по интересующим вас вопросам и проконсультирую по ценам на услуги.

Частые неисправности

-

Не работает

Проблема может быть в:

— Пустом резервуаре для воды;

— Отсутствии кофе. -

Шумит при работе

Причиной проблемы ,может быть:

— Засорение кофемашины;

— Проблемы с насосом. -

Нет пара

Проблема может быть связанна с:

— Неисправностью бойлера;

— Неисправностью пароблока;

— Засорение кальцием. -

Не мелет кофе

Неисправность связанна с:

— Затупленностью жерновов;

— Неисправностью кофемолки;

— Неисправностью электродвижка кофемолки. -

Не наливает воду

Данная проблема, может быть вызвана:

— Требуется чистка вашей кофемашины;

— Проблемы с насосом;

— Замена уплотнительных колец;

— Замена датчиков. -

Не наливает кофе

Неисправность могла быть вызвана данными неполадками:

— Засорение кофемашины кофейными маслами (декофинация);

— Обслуживание гидросистемы;

— Чистка диспенсеров. -

Не подает пену

Для решения данной проблемы нужно будет:

— Произвести замену капучинатора;

— Провести чистку вашей кофемашины;

— Заменить фильтры;

— Произвести замену жерновов. -

Протекает

Проблема может быть в:

— поврежденном уплотнении резервуара воды;

— уплотнительных прокладках;

— уплотнении дозатора;

— неплотной посадки соединительных трубок.

Чаще необходимо

- Диагностика — 0 ₽

- Декальценация — 590 ₽

- Замена ТЭНа — 750 ₽

- Ремонт капучинатора — 850 ₽

- Замена жерновов — 750 ₽

- Ремонт кофемолки — 790 ₽

- Ремонт гидросистемы — 990 ₽

- Ремонт насоса — 700 ₽

Шаги вашего ремонта

-

1

Заявка

Оставляете заявку у нас на сайте или посредством телефонного звонка

-

2

Доставка

Осуществляем забор курьером или доставляете кофемашину к нам в СЦ

-

3

Диагностика

Инженер проводит полную диагностику кофейной машины

-

4

Ремонт