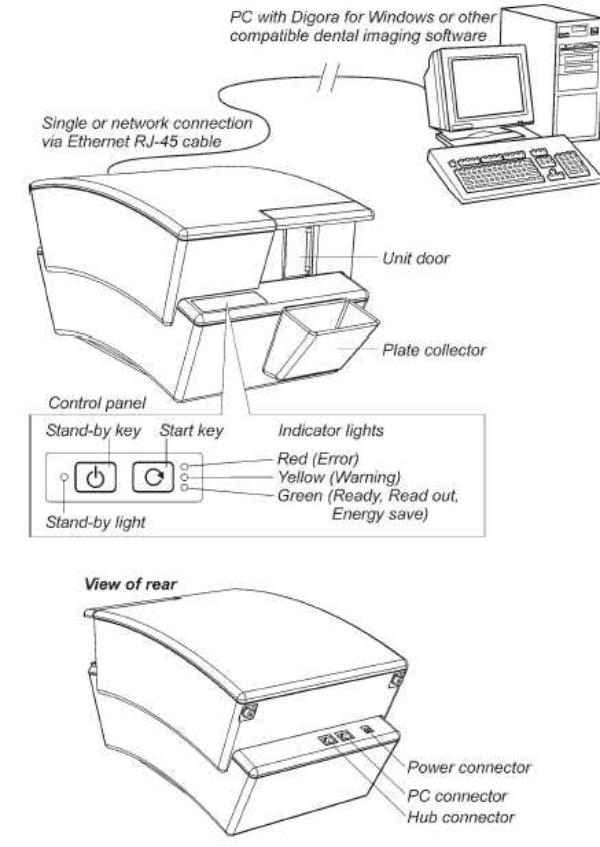

Визиограф Dogora Optime DXR-50 концерна KаVо Kerr Group (торговый бренд — «KaVo«), Германия, не передаёт снимки после сканирования пластины на рабочую станцию. В ПО Digora for Windows 2.5 прогрессбар сканирования проходит до конца, аппарат выталкивает пластину, постоянно горит желтый светодиод и программа зависает.

При перезапуске программы, комп сразу же пытается «получить» снимок из визиографа и опять зависает. И так будет повторяться пока не перезапустишь визиограф.

При этом не выдается никаких сообщений об ошибка и в самом визиографе в логах пусто.

Попробовал установить DfW 2.5 на другой ноутбук — история та же самая.

Прикладываю скрин в момент зависания и скрин с настройками визиографа.

.

Есть тема: «Ап-т для обработки R-снимков ротовой полости Digora Optime Soredex DXR-40 (Неполадки/проблемы, опыт и советы по их устранению)».