MENU

5 5 5 5 5

DIAGNOSIS

DIAGNOSIS

DIAGNOSIS

DIAGNOSIS

DIAGNOSIS

Description of the alarms signalled by the diagnostic LED.

The alarm code is shown in parentheses. A detailed description is given in the section

1 BLINK = Logic anomaly (EEPROM DATA KO, EEPROM PAR. KO, EEPROM CONF.

1 BLINK

1 BLINK

1 BLINK

1 BLINK

2 BLINKS

2 BLINKS

2 BLINKS = Running request on startup or error in handle/speeds sequence (INCORRECT

2 BLINKS

2 BLINKS

3 BLINKS

3 BLINKS

3 BLINKS = Error on VMN test (NO FUL CONDUCTION).

3 BLINKS

3 BLINKS

4 BLINKS

4 BLINKS = Accelerator high in standby — this error inhibits machine operation (VACC > 1 V).

4 BLINKS

4 BLINKS

4 BLINKS

5 BLINKS

5 BLINKS

5 BLINKS = Error in reading current — this error inhibits machine operation (1 HIGH AT

5 BLINKS

5 BLINKS

6 BLINKS

6 BLINKS

6 BLINKS

6 BLINKS = Malfunctioning of the contactor driver circuit (DRIVER SHORTED, COIL

6 BLINKS

7 BLINKS

7 BLINKS

7 BLINKS = Excessive temperature, greater than 80_ (TH. PROTECTION).

7 BLINKS

7 BLINKS

CONTINUOUS BLINKING (32 BLINKS) =Low battery charge, battery with < 10% of

CONTINUOUS BLINKING (32 BLINKS)

CONTINUOUS BLINKING (32 BLINKS)

CONTINUOUS BLINKING (32 BLINKS)

CONTINUOUS BLINKING (32 BLINKS)

5.1

5.1

5.1

5.1

5.1

DECODING THE ALARMS DISPLAYED ON CONSOLE

DECODING THE ALARMS DISPLAYED ON CONSOLE

DECODING THE ALARMS DISPLAYED ON CONSOLE

DECODING THE ALARMS DISPLAYED ON CONSOLE

DECODING THE ALARMS DISPLAYED ON CONSOLE

1) 1) 1) 1) 1) STAND BY VMN LOW

STAND BY VMN LOW

STAND BY VMN LOW

STAND BY VMN LOW

STAND BY VMN LOW

The test is carried out in standby. If the VMN voltage is lower than 1/3 of the battery

voltage, an alarm is signalled. Possible causes:

a) Check the motor wiring to make sure it is correct.

b) Chopper broken, replace.

2) 2) 2) 2) 2) NO FULL COND.

NO FULL COND.

NO FULL COND.

NO FULL COND.

NO FULL COND.

The test is carried out in full conduction.

If, in this condition, the VMN is found to be greater than 1/3 VBATT, the diagnostic

circuit

persists, replace the logic.

3) 3) 3) 3) 3) TH.PROTECTION

TH.PROTECTION

TH.PROTECTION

TH.PROTECTION

TH.PROTECTION

An indication that the chopper temperature has exceeded 80°C.

The maximum current is gradually reduced, reaching 0 at a temperature of 85°C. If the

alarm occurs while cold:

a) Check the thermal sensor connection.

b) Thermal sensor failure.

c) Connection on the power interrupted (check the connector that connects the logic to

the

d) Logic failure.

4) 4) 4) 4) 4) BATTERY

BATTERY

BATTERY

BATTERY

BATTERY

The battery charge is low.

The alarm is signalled only if the BATTERY CHECK option has been selected. All

functions except hydrdrive are inhibited.

KO, EEPROM OFF-LINE, CHOPPER NO CONF, WATCH-DOG).

START).

STAND, I=0 EVER).

SHORTED).

is faulty, causing a safety risk, and thus machine operation is inhibited. If the defect

power unit).

residual charge (BATTERY).

Pagina 19

Fault Code / FaultName

1 «NO SEAT SWITCH»

8 «WATCHDOG»

13 «EEPROMKO»

17 «LOGIC FAILURE #3

18 «LOGIC FAILURE #2

19 «LOGIC FAILURE #1

30 «VMNLOW»

31 «VMNHIGH»

36 «INPUT ERROR #1»

37 «CONTACTOR CLOSED»

38 «CONTACTOR OPEN»

53 «STBY 1 HIGH»

60 «CAPACITOR CHARGE»

61 HIGH TEMPERATURE»

65 «MOTOR TC START»

66 «BATTERY LOW»

71 «MOTOR SHUTDOWN»

72 «MOTOR LOCKED»

74 «DRIVER SHORTED»

75 «CONTACTOR DRIVER»

76 «COIL SHORTED»

77 «MAINTENANCE HOURS»

78 «VACC NOT OK»

79 «INCORRECT START (SRO)»

80 «FORWARD + REVERSE»

81 «TH MOTOR SENSOR KO»

82 «ENCODER ERROR»

86 «PEDAL WIRE KO»

150 «WATCHDOG»

155 «EEPROMKO»

160 «LOGIC FAILURE #2»

161 «LOGIC FAILURE #1»

171 «MOTOR SHUTDOWN»

172 «VMN LOW»

173 «VMNHIGH»

174 «TH MOTOR SENSOR KO»

182 «MOTOR LOCKED»

195 «STBY 1 HIGH»

196 «THERMIC SENSOR KO»

201 «THERMIC SENSOR KO»

202 «CAP CHARGE»

203 «CAP CHARGE»

204 «VACC NOT OK»

205 «INCORRECT START»

206 «PEDAL WIRE KO»

207 «MOTOR TC START»

208 «BATTERY LOW

209 «DRIVER SHORTED»

210 «CONTACTOR DRIVER»

211 «COIL SHORTED»

212 «COIL INTERUPTED»

217 «WRONG SET BATTERY»

218 «SAFETY»

222 «NOCANMSG»

223 «WATING FOR TRAC»

224 «SEATKO»

225 «AUX OUTPUT KO»

243 «NO CAN MSG 5»

244 «SAFETYKO»

245 «WRONG SET BATTERY»

246 »SAFETY»

247 «NO CAN MSG 4»

248 «CHECKUP NEEDED»

249 «THERMIC SENSOR KO»

251 «WATING FOR NODE»

253 «AUX OUTPUT KO»

255 «HANDBRAKE»

Blank «DASH DISPLAY»

Fault Code Charts

|

Fault Code |

Fault |

Fault |

Control |

Troublabootiug |

|

|

|

No input from seat |

|

• Controller detects the seat switch is |

|

|

|

Watchdog circuit |

|

• It is a self-diagnosing test |

|

|

|

Warning: EEprom |

|

• Fault in the area of memory in which the |

|

|

|

Failure in overload |

|

• Fault in the hardware section of the |

|

|

|

Failure in U,V,W |

|

• Fault in the hardware section of the |

|

|

|

An over voltage or |

|

• This fault signals that the under voltage 1 |

|

|

|

Wrong voltage on |

|

• This test is carried out during initial |

|

|

|

|

Wrong voltage on |

|

• This test is carried out during initial |

|

|

|

|

Warning : Seat |

|

• The seat switch is open with over speed |

|

|

|

|

Line contactor |

|

• Before driving the line contactor coil, |

|

|

|

|

Line contactor |

|

• The controller has driven the line contactor, but the contactor did not close. |

|

|

53 |

«STBY |

Wrong voltage in |

|

• The microprocessors verify if the feed |

|

|

|

Power Capacitor |

• Wben key is switched on, the controller |

|

|

|

|

• Temperature of control is greater than |

||

|

|

«MOTOR |

|

• Drive motors analog temperature sensor |

Check temperature Shown on handse in tester mode. Replace controller |

|

|

«BATTERY |

|

• When battery leve! reaches 10% or less |

|

|

|

«MOTOR |

|

• This fault occurs when the motor temper |

Replace controller |

|

|

«MOTOR |

|

• After 15 seconds the motor stalled with |

|

74 |

|

Line contactarcoil |

|

• When the key is turned ON, the micro |

|

|

75 |

|

Line contactar coil |

|

• When the initial diagnosis is fmished, |

|

|

76 |

|

Init: Line contac- |

• When the key is tumed on, the micro |

|

|

|

|

|

Displayed when |

|

• This is just an indication that the vehicle |

|

|

|

Warning: Accel |

|

• This fault indicates that the accelerator |

|

|

|

|

Warning: Wrong |

|

• IfSRO FUNCTION is active, every time |

|

|

|

|

Warning: For |

|

• Processor is continuously checking for a |

|

|

|

«TH SENSOR |

Warning:Motor |

|

• The range of the motor temperature ana |

|

|

|

Motor speed sen- |

|

• This fault indicates that the frequency |

|

|

|

|

Fault in Accelera- |

|

• Check accelerator wiring and connec- |

Repair wiring as |

|

|

|

Watchdog circuit |

|

• It is a self-diagnosing test |

|

|

|

|

Warning: |

|

• Fault in the area of memory in which the |

|

|

|

|

|

|

|

|

|

|

Failure in overload |

|

• Fault in the hardware section of the con |

|

|

|

|

Failure in U,V,W |

|

• Fault in the hardware section of the con- |

|

|

|

|

An over voltage or |

|

• This fault signals that the under voltage 1 |

|

|

|

|

Warning: Pump |

|

• This fault occurs when the purnp motor |

|

|

|

Wrong voltage on |

|

• This test is carried out during initial |

|

|

173 |

«VMN |

Wrong voltage on |

|

• This test is carried out during initial |

|

|

|

SENSOR |

Warning:Motor |

|

• The range of the motor temperature ana |

|

|

|

|

|

|

• After 15 seconds of the motor being |

|

|

|

|

Wrong voltage in |

|

• The microprocessors verify if the feed |

|

|

|

|

Warning: Pump |

|

• The range of the temperature sensor is |

|

|

|

Motor speed sen- |

|

• This fault indicates that the frequency |

|

|

|

|

Power Capacitor |

|

• When key is switched on, the inverter |

|

|

|

|

Warning: Pump |

|

• Temperature of control is greater than |

|

|

|

|

Warning: Lift |

|

• This fau1t indicates that the Lift Sensor |

|

|

|

|

Warning: Wrong |

|

• This fau1t indicates an incorrect starting |

|

|

|

|

Fault in Accelera- |

|

• Check accelerator wiring and connec |

|

|

|

|

Warning: Pump |

|

• Pump motor analog temperature sensor |

Check tempera |

|

|

|

Warning: Battery |

|

• When battery level reaches 10% or less, |

|

|

|

|

Line contactor coil |

|

• When the key is turned on, the micro |

|

|

|

|

Line contactor coil |

|

• When the initial diagnosis is finished, |

|

|

211 |

|

Init: Line contac- |

|

• When the key is turned on, the micro |

|

|

|

|

|

• Check for open wiring to the brake coil. |

|

|

|

|

Battery voltage |

|

• Tbis fault indicates tbat actual battery |

|

|

|

|

Input B5 is not |

|

• Check that the jumper is in place |

|

|

|

|

Pump has lost Can |

|

• This Fault is present in combi Systems |

|

|

|

|

Pump is waiting |

|

• This alarm is present in combi Systems |

|

|

|

|

Seat input read by |

|

• Check seat switch wiring at TB4 and |

|

|

|

|

EB coil driver |

|

• The rnicroprocessor checks the driver of |

|

|

|

|

Traction has lost |

|

• Traction (node #2) signals that it has lost |

|

|

|

|

Alarm: Pump |

|

• Check wiring pin B5 is connected to pin |

|

|

|

Battery voltage |

|

• This fault indicates that actual battery |

|

|

|

|

Alarm: Pump |

|

• Check jumper pin B5 to pin B11 on the |

|

|

|

|

Warning: Trae |

|

• The range of the temperature sensor is |

|

|

|

|

Traction is wait |

|

• This alarm is present in combi systems |

|

|

|

|

EB coi! driver |

|

• The microprocessor checks the driver of |

|

|

|

|

|

|

• lndicate that handbrake is activated |

Repair wiring |

|

|

|

|

|

• Check 5 volt power supply for dash dis- |

Replace 5 V |

- 24 Дек 2014

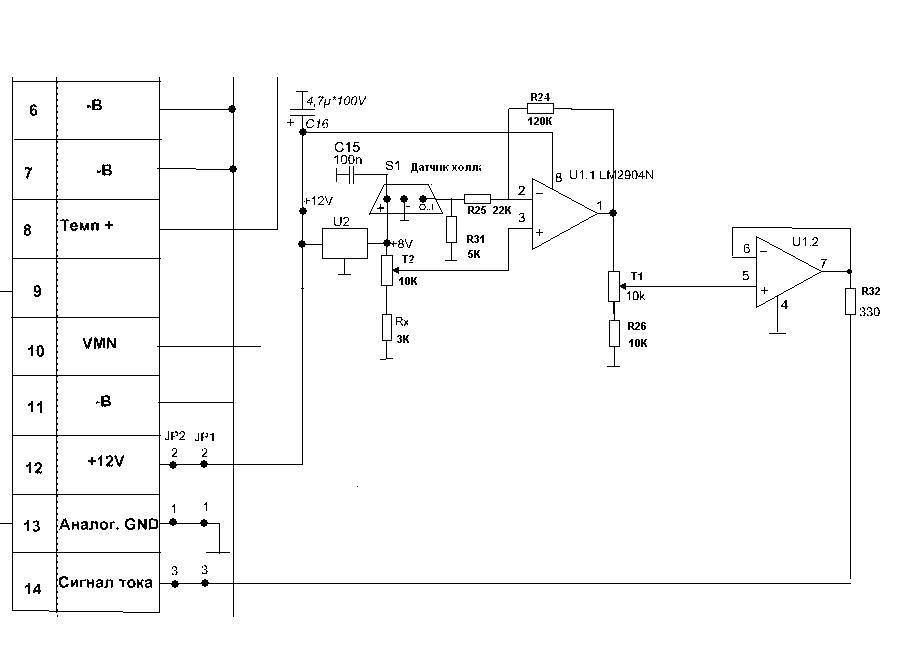

После вполне стандартной замены кучи силовых транзисторов, резисторов, диода, прозвонки и внешней проверки подал питание с БП на рабочем столе, тест показал ошибку VMN. Напряжение на CN1-14 показало 1,95В. Смотрите фрагмент схемы

Проверка узла контроля и замена датчика Холла ничего не выявили. Оба датчика одинаково реагировали на сильный магнит ( U1-1 порядка до 9-10В,U1-7 порядка до 4-5В).

Пришлось крутить резисторы, чего ранее, никогда не требовалось делать.

Ошибка пропала после одного оборота Т2.

Я крутил, отслеживая напряжение на CN1-14 — два оборота по часовой (70мв), так и оставил Т1 по 4 оборота в обе стороны практически не меняет показания.

Полез в поисковик, нашёл на зарубежном сайте рекомендацию установить 20мв, один спец рекомендовал 0в. В моём случае «0» не удалось вообще установить, Минимально при 3-х оборотах -40мВ, потому и оставил 70мВ.( в 3-х вариантах схем контроля T2, Rx, R26 имеют разные номиналы).

Блок был отправлен на проверку клиенту (в другой город)

Выяснилось, при включении кары ошибок нет, но при, попытке движения вперёд-назад, снова возникает ошибка статора VMN.

В общем, блок едет обратно и хотелось его встретить с почётом потому и вопросы к более опытным спецам:

1 как правильно отрегулировать момент срабатывания, в каком порядке, какими резисторами

2 какое должно всё же быть напряжение

3 Почему оно вообще ушло (есть подозрение на источник +12В, на разных блоках оно бывает до14В, и более , проверю) 8-ми вольтовый стабилизатор работает

4 Может, аналогичную ошибку вызывают другие факторы

Кто что скажет.

Автор ForkliftMan, 24 августа 2020, 18:16:54

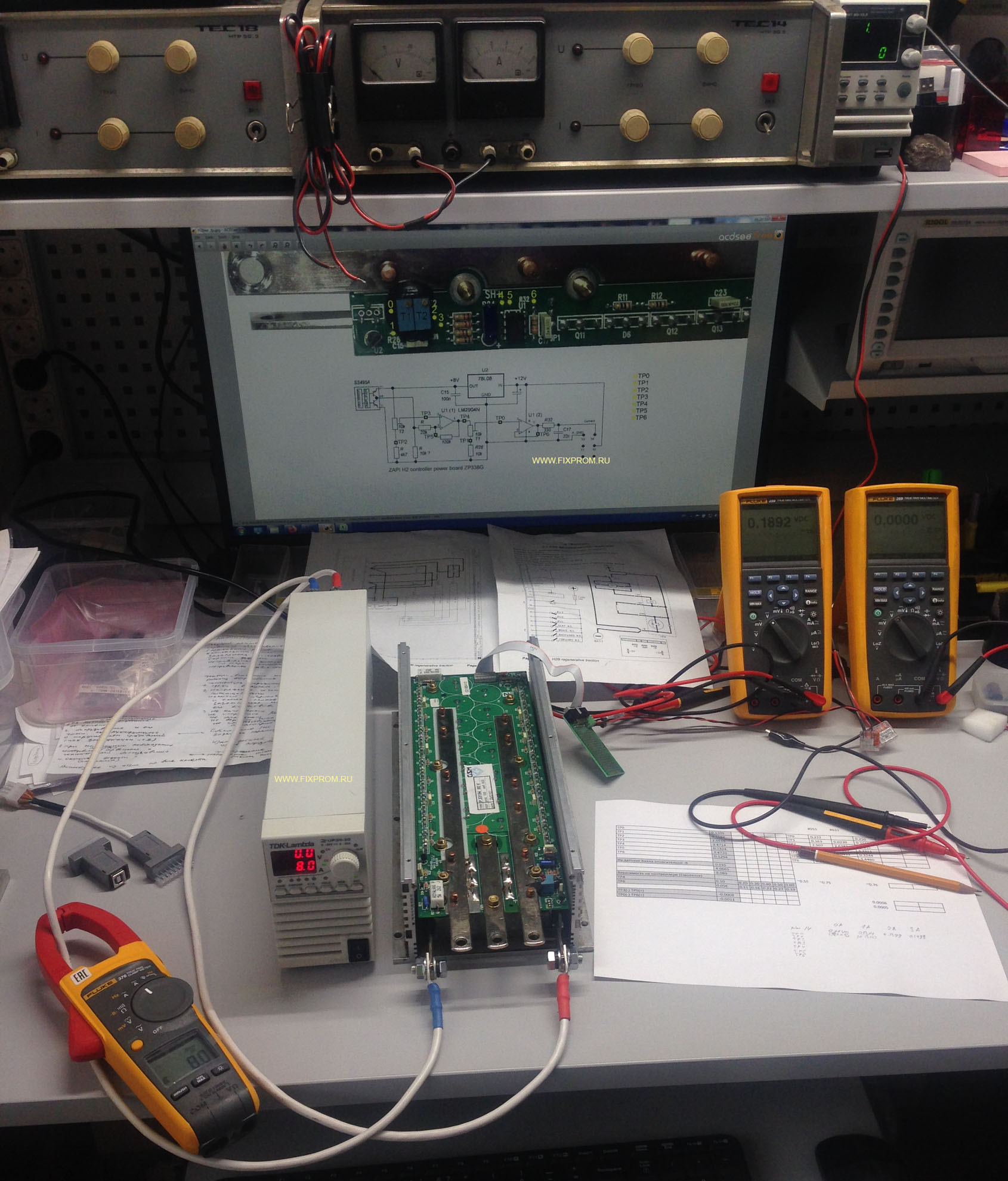

При ремонте очередного контроллера Zapi H2 возникла необходимость в замене и последующей калибровке датчика тока, реализованного на датчике Холла SS495A. В сервисной документации на контроллер Zapi этот момент не освещен. Попытка подстройки на стенде с нагрузкой на двигатель постоянного тока не давала 100% повторяемости результата. Ток контролировался на источнике питания стенда и по показаниям консоли Zapi Ultra, подключенной непосредственно к блоку H2. Лучшие результаты повторяемости получились при включении контроллера как блока управления гидравлической помпой. Тем не менее результаты были не однозначны. Один контроллер откалибровался, второй периодически уходил в ошибку. Пришла мысль собрать импровизированный стенд для калибровки датчика тока на столе, используя имеющееся оборудование.

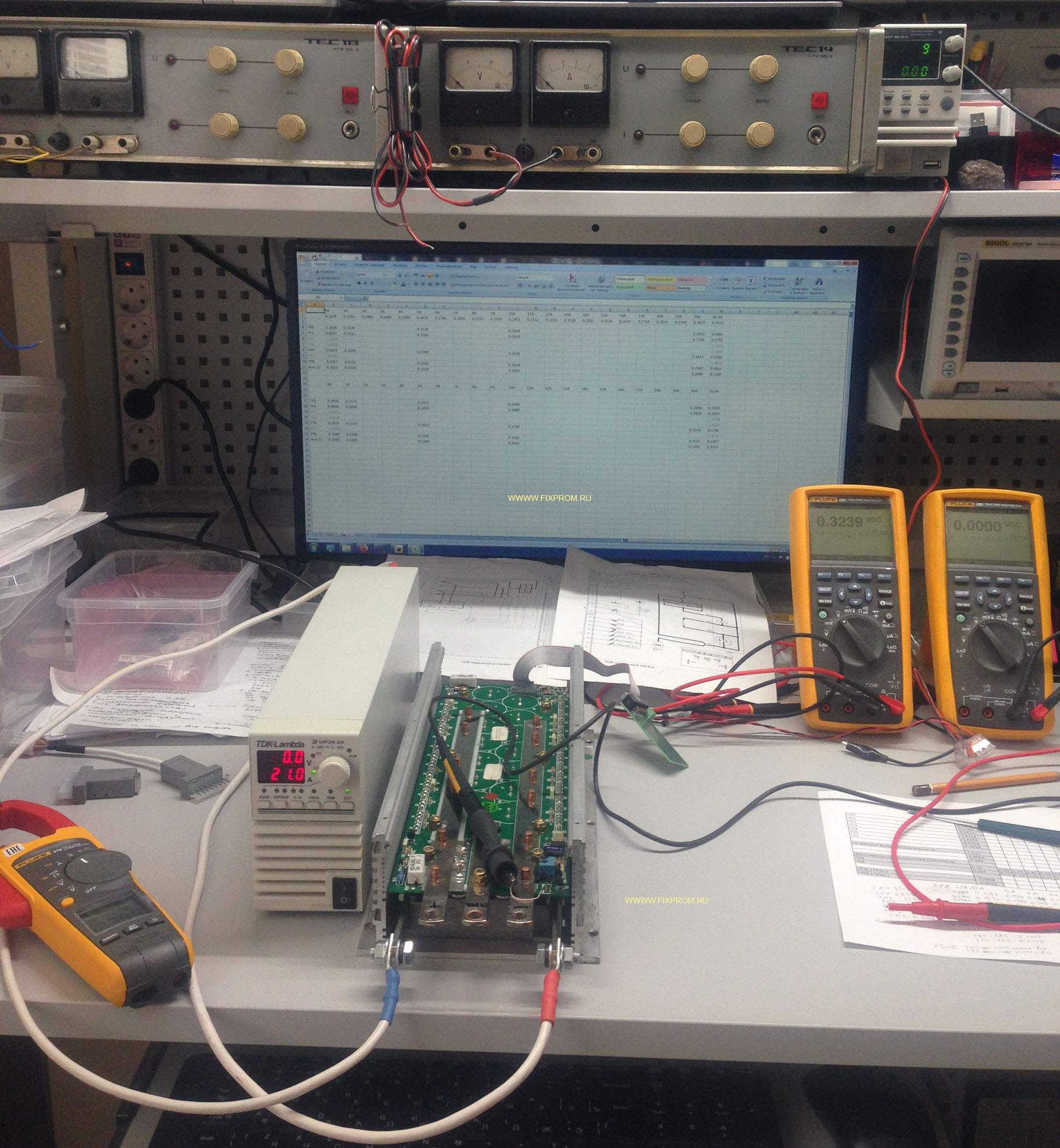

С эталонного контроллера Zapi H2 была снята карта напряжений по контрольным точкам согласно схемы, всё это проделано при разных значениях тока, проходящего через токовый шунт. Токовый шунт запитан непосредственно от регулируемого источника постоянного тока TDK-Lambda ZUP20-20, тем самым был исследован диапазон измерения токов от 0 до 21А. Показания тока дополнительно контролировались токовыми клещами Fluke 376. На самом деле контроль токовыми клещами оказался избыточным, достаточно показания тока источника. Карта напряжений снималась при помощи двух мультиметров Fluke 289 и записывалась в таблицу excel с точностью до 4 знака в дробной части. Один мультиметр постоянно контролировал выход на плату управления, вторым делались замеры по контрольным точкам. После составления таблицы, на место эталонного контроллера была установлена силовая часть от ремонтного контроллера Zapi H2.

Путём подстройки резисторов T2 и T1 удалось добиться точной повторяемости результата, аналогичного замеренному на эталонном контролере по контрольным точкам и по выходу на 12 pin шлейфа, во всём диапазоне токов, которые мог обеспечить источник. Изменение позиции датчика Холла на ремонтируемой плате при этом не потребовалось. Далее следует проверка на стенде с электродвигателем постоянного тока и на рабочей машине.

После замены палёных компараторов на плате управления ZAPI ZP321H и проверке на стенде удалось убедиться в схожем показании тока на консоли Zapi Ultra 3.13 в подменю TESTER > MOTOR CURRENT и токовых клещей Fluke 376. Остаётся проверить отремонтированный блок на технике под максимальной нагрузкой. На данный момент результат наглядный, данный метод калибровки датчика тока на контроллере H2 оказался рабочим.

Доброго времени суток! Имею схожую проблему. Принесли контроллер с погрузчика JAC — ZAPI H2B конфигурация REGENERATIVE TRACTION. светодиод мигает пять раз и если подключить консоль, то пишет STBY I HIGH. Если через лампочку посадить VMN на массу, то консоль пишет VMN LOW, Если на + то соответственно VMN HIGH. На столе подал питание, VMN в воздухе висит, тоже пишет STBY I HIGH. В мониторинге через приложение ток 0А. Проблемы в обвязке операционника LM2904 были устранены, ошибка в состоянии покоя на столе пропала. Установили на машину, движения нет, ошибка на дисплее 053 расшифровывается по книге как «Резерв тока высокий». Подстроечные резисторы явно кто то крутил. Сейчас напряжения в состоянии покоя

1 0.956

2 3.59

3 3.59

4 0

5 0.739

6 0.745

7 0.745

8 14.22

Есть данные по исправному контроллеру?

0.745v для выхода многовато будет.

В идеале в состояние покоя там 0 должен быть.

Первая половина операционника смещает пол питания с выхода

датчика тока к нулевой точке, на второй половине регулируется максимальная амплитуда.

Как-то примерно так оно работает.

Вот карта напряжений на блоках Zapi H2 H2B для разных токов от 0 до 20,5 Ампер.

В сравнении участвовали контроллеры старого и нового типа.

Но в данной части схемотехника у них одинакова.

Единственная информация, которую нам удалось найти по методике настройки датчика тока на Zapi.

PDF на шведском языке, но думаю это сейчас не проблема.

Добрый день! Спасибо за информацию! Если делать как по шведской мурзилке, то базовое значение у меня 0,0712 прибавил 20 мВ , выставил 0,092. Убей меня Бог с рогатки, не понимаю как заставить его «ехать» на столе. Собрал по схеме ,на выходы TI и TA повесил лампочки, подаю питание на вход переключателя «вперед» лампочка моргнет и ошибка DIR CONT. OPEN. В общем забил на эту идею, выставил по документу, будем пробовать ставить на машину.

DIR CONT. OPEN

Надо «немного» контакторов навесить.

У нас до 4 штук на Zapi H2 приходилось навешивать на стенде, согласно схемам из мануала.

Без этого движок крутить не удавалось, контроллеры падали в ошибки.

Добрый день! Всё поехало, спасибо!

Дада, точно так. При чем раскручено там было далеко за. Ещё раз СПАСИБО!

- Технический форум: Ремонт промышленной электроники и спецтехники

-

►

Ремонт электроники -

►

Zapi -

►

Ремонт контроллера Zapi H2 — настройка датчика тока

The ALARMS logbook in the MAIN MENU’ records the alarms of the controller. It

has a FIFO (First Input First Output) structure that means the oldest alarm is lost

when the database is full and a new alarm occurs. The logbook is composed of

five locations getting possible to stack five different type of alarms with the

following information:

1) The alarm code

2) The times that each alarm occurs consecutively

3) The Hour Meter value when the first event of every alarm occurred

4) And the inverter temperature when the first event of every alarm occurred.

This function permits a deeper diagnosis of problems as the recent history can be

revised.

4

NOTE: if the same alarm is continuously happening, the controller does not use

new memory of the logbook, but only updates the last memory cell increasing the

related counter (point 2) of previous list). Nevertheless, the hourmeter indicated

in this memory refers to the first time the alarm occurred. In this way, comparing

this hourmeter with the controller hourmeter, it is possible to determine:

— When this alarm occurred the first time.

— How many hours are elapsed from the first occurrence to now.

— How many times it has occurred in said period.

12.1 Faults diagnostic system

The fault diagnostic system of ACE0/ COMBI AC0 controller is divided into 2

main groups of faults:

ALARMS: these are the faults which open the power section, which means

WARNINGS: these are faults which do not stop the truck or stop it by a

Page — 58/79

the power bridge is opened and, when possible, the LC is opened

and EB is applied.

These are faults related to:

— failures in the motor/controller that the power system is not

anymore able to drive the truck

— safety related failures

controlled regen braking. In other words, the controller is working

well, but it has detected conditions to reduce the performances or

to stop the truck without opening the power devices.

These warnings are related to:

— wrong operator sequences

— conditions which require performance reduction (like high

temperatures, ….)

AF6ZP0AL — COMBIAC0 & ACE0 — User Manual