Решение проблем

Xerox

®

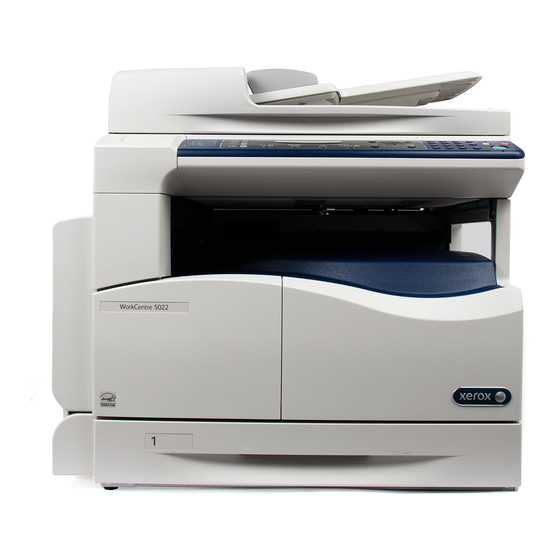

WorkCentre

®

5022/5024 Multifunction Printer

User Guide

13-38

016-598

Размер страницы электронной почты

превышает максимальный размер

сообщения из-за разделения страниц.

Для повтора операции нажмите кнопку

Старт на панели управления, для отмены

— кнопку Стоп.

016-742

016-744

Произошла ошибка.

Выключите аппарат и снова включите

его после того, как погаснет дисплей.

016-749

Произошла ошибка.

Нажмите кнопку Стоп на панели

управления и отмените задание.

016-759

Достигнуто установленное разрешенное

максимальное количество копий. Другой

вариант: в систему вошел пользователь,

исчерпавший лимит копий.

Нажмите кнопку Стоп на панели

управления и отмените задание.

016-764

Ошибка в сети.

Нажмите кнопку Стоп на панели

управления и отмените работу.

016-765

016-766

На сервере SMTP заполнена память для

входящих сообщений электронной почты.

Нажмите кнопку Стоп на панели

управления и отмените задание.

016-767

Не отправляется сообщение электронной

почты из-за неверного адреса

Нажмите кнопку Стоп на панели

управления и отмените задание.

016-768

Ошибка при создании данных

для сообщения электронной почты.

Нажмите кнопку Стоп на панели

управления и отмените задание.

016-776

Задание отменено.

Нажмите кнопку Стоп на панели

управления и отмените задание.

016-781

При отправке сообщения по электронной

почты не распознано имя сервера SMTP.

Нажмите кнопку Стоп на панели

управления и отмените задание.

016-791

В режиме «Сканирование в эл. почту»

«Сканирование на ПК (Сеть)» отправка

данных невозможна.

Нажмите кнопку Стоп на панели

управления и отмените задание.

016-799

В данные печати из приложения включен

недопустимый параметр или не соответствие

между данными и настройками печати.

Нажмите кнопку Стоп на панели

управления и отмените задание.

016-981

Переполнена память электронной

подборки (EPC).

Для повтора операции нажмите кнопку

Старт на панели управления, для отмены

— кнопку Стоп.

016-982

При сканировании первой страницы

в режиме «Сканирование на ПК»

заполнилась память.

Нажмите кнопку Стоп на панели

управления и отмените задание.

016-985

В режиме «Сканирование в эл. почту» размер

вложения превышает максимальный предел.

Для повтора операции нажмите кнопку

Старт на панели управления, для отмены

— кнопку Стоп.

Код

ошибки

Причина

Устранение

Сообщения об ошибке на панели управления

Принтер Phaser® 6280

140

Сообщения о принтере и других элементах

Сообщение

Условие/Причина/Действие

Перегрев, подождите /

Ошибка 042-700,

подождите

Внутренняя температура принтера слишком высокая.

Принтер был остановлен. Подождите 1 час и перезапустите

принтер. Проверьте, что вокруг принтера достаточно места

для охлаждения и что вентиляционные отверстия не

перекрыты.

Нет лотка 024-946 /

Нет лотка.

Вставьте лоток 2

Лоток 2 выдвинут наружу. Задвиньте лоток 2 в

правильное положение.

Нет лотка 024-947 /

Нет лотка. Вставьте

лоток 3

Лоток 3 выдвинут. Задвиньте лоток 3 на место.

Застр. в лотке 1 (MPT)

,

2

или

3

Проверьте лот. 1 (MPT)

,

2

или

3

Откройте двер. А

Застряла бумага в лотке 1 (MPT), 2 или 3.

Вытащите застрявшую бумагу. Откройте и снова закройте

переднюю крышку. См. раздел

Застревание бумаги

на

стр. 120.

Открыта дверца A

Закройте дверцу A

Открыта передняя крышка.

Закройте переднюю крышку.

Функция выкл.

Ошибка 016-158

Пользователь не зарегистрировал цветную печать в

функции идентификации.

Обратитесь к вашему администратору.

Неверное задание

Нажмите кнопку ОК

Ошибка 016-799

Это сообщение выводится, если конфигурация принтера

в драйвере принтера не соответствует используемому

вами принтеру.

Нажмите кнопку Отмена для отмены задания печати.

Проверьте, что конфигурация принтера в драйвере принтера

соответствует используемому вами принтеру.

Неверный польз.

Ошибка 016-757

Пользователь не зарегистрирован для печати на принтере с

помощью функции идентификации.

Обратитесь к администратору.

Превышен лимит

Нажмите кнопку ОК

Пользователь превысил предел на количество

страниц, которое можно распечатать с помощью

функции идентификации.

Обратитесь к администратору.

Неверный польз.

Нажмите кнопку ОК

Пользователь не зарегистрирован для печати на принтере

с помощью функции идентификации.

Обратитесь к администратору.

Do you use printing accounts? If you are make sure that’s configured in the Printer Preferences. You could also try re-installing the driver, or up grade the firmware in the printer. Also make sure the bypass drawer is not open on the printer.

Was this post helpful?

thumb_up

thumb_down

Try using the Global Print Driver PCL6. The 7435 is fully compatible. There is also a driver for WIN7/Win8 (either 32bit, or 64bit).

Was this post helpful?

thumb_up

thumb_down

Right before you print make sure under the paper sizing and handling section the choose paper source by PDF page size should be unchecked. If the case were throwing errors when printing a PDF.

Was this post helpful?

thumb_up

thumb_down

I have the same problem… before I’m using Global Print Driver PCL6 driver but the problem is when I print using Photoshop and using A3 size the printer driver doesn’t recognize it. I search on web for the solution and it needs to update the driver, so I got a new driver which is Xerox Workcentre 7435 GPD PS. Now this same error Aborted (016-799) occurs and even though the tray 5 (bypass) is close it detects as empty and it needs to refill.

Was this post helpful?

thumb_up

thumb_down

Brand Representative for Xerox

anaheim

Hi Kevin,

I was looking through some of the solutions we have on this and a few that you can try:

Select the correct finisher in the driver properties:

1. Open the Printers or Printers and Faxes window.

2. Right-click on the printer and then select [Properties] or [Printer Properties]

3. Select the [Configuration] tab.

4. Click on the [Installable Options] button.

5. Select the correct finisher from the [Finisher/Output Tray] drop down.

6. Click [OK] to save the changes.

Also check to make sure the driver is NOT set to Basic Print Mode:

1. Click on the Start Button on the lower Right, click on Control Panel, Open Print and Fax window.

2. Right click and choose [Properties]

3. Choose the [Configuration Tab]

4. Click on [Bi-Directional Setup]

5. On the top under [Communication] move the radio dot from [Automatic (Recommended)] to [Off]

6. Click on [OK]

7. Select the [Options] Tab

8. Under the words [Xerox Update]…..Click on the word [Configuration]

9. Use the drop down arrow and search for the correct Xerox Device

10. Click on [Close] or [Apply].

If you need further assistance I would recommend contacting Support.

Cathy (Xerox)

Was this post helpful?

thumb_up

thumb_down

Cathy

I’m just wondering if there are any other options I can try? We are having the same issues with our Xerox WorkCentre 7425. The options described above are greyed out and we can’t change. We are having the same excel problem printing.

Job Name Owner Status Type Page Count Output Destination Host Interface Time Completed

Book1 user.name Aborted(016-799) Print 0 — Port 9100 20/10/2014 11:18 AM

Thanks

Was this post helpful?

thumb_up

thumb_down

Brand Representative for Xerox

anaheim

If you shut down Bi-Directional per suggestion 2 before doing option 1 and it won’t be greyed out.

Was this post helpful?

thumb_up

thumb_down

We’re getting a similar error but printing using USB to a Xerox WorkCentre 6015. The error message on the screen is PJL Request, 016-749, Printer Data Violation, Press [OK] Button. This happens when just trying to print a test page from a Windows 7 Pro x64 machine.

Was this post helpful?

thumb_up

thumb_down

Решение проблем

Xerox

®

WorkCentre

®

5022/5024 Multifunction Printer

User Guide

13-35

Коды ошибок

В данном разделе приведено описание кодов ошибок.

Если из-за ошибки некорректно завершается печать или возникает неисправность аппарата,

выводится сообщение и код ошибки (xxx-xxx).

Для заданий факса код ошибки также указывается в отчете «Сведения о работе факса»

и в отчете о передаче факса в разделе недоставленных заданий .

В таблице ниже приведены коды ошибок и способы их устранения.

Note

Когда отображается код ошибки, могут быть утрачены данные печати в аппарате,

а также информация, хранящаяся в памяти аппарата.

Если отображается код ошибки, которого нет в таблице ниже, или ошибку не удается устранить после

выполнения приведенных в таблице указаний, обращайтесь в центр технической поддержки Xerox.

Номер контакта напечатан на наклейке или карточке, прикрепленной к аппарату.

Код

ошибки

Причина

Устранение

003-500

Когда используется функция «Страниц

на стороне», отпечаток не помещается

на бумагу при заданном коэффициенте

масштабирования.

Нажмите кнопку Стоп на панели

управления и измените настройку.

003-754

Произошла ошибка IPS.

Нажмите кнопку Стоп на панели

управления и отмените задание.

003-795

При уменьшении или увеличении

сканируемого оригинала под определенный

формат бумаги значение коэффициента

масштабирования выходит за

установленные пределы.

Нажмите кнопку Стоп на панели

управления и измените настройку.

003-942

В податчик вложен оригинал нестандартного

формата.

Нажмите кнопку Стоп на панели

управления и проверьте оригинал.

003-956

На стекле экспонирования размещается

оригинал нестандартного формата.

Нажмите кнопку Стоп на панели

управления и проверьте оригинал.

003-963

Если для задания копирования для

настройки Подача бумаги выбрано

значение Авто, значит формат сканируемого

оригинала больше формата бумаги для

копирования.

Нажмите кнопку Стоп на панели

управления и измените настройку.

003-972

Превышено максимальное количество

сканируемых страниц для задания

копирования или сканирования.

Для повтора операции нажмите кнопку

Старт на панели управления, для отмены

— кнопку Стоп.

Если МФУ Xerox 5020 вдруг перестал работать, это не повод безотлагательно мчаться в сервисный центр. Отложите поездку, разобравшись сначала с причиной остановки печатного процесса. Ведь большинство неисправностей можно устранить самостоятельно.

Обратите внимание на дисплей аппарата, на нем будет отображаться код ошибки. Найдите комбинацию букв и чисел в таблицах, а затем произведите рекомендуемые действия.

- Таблицы с расшифровкой ошибок Xerox WorkCentre 5020

- A-коды

- C-коды

- E-коды

- J-коды

- N-коды

- Аппаратные ошибки (U-коды)

Таблицы с расшифровкой ошибок Xerox WorkCentre 5020

Все ошибки подразделяются на группы и могут иметь общие рекомендации по восстановлению работы устройства. Главное — избегать аппаратного вмешательства при серьезных поломках. Оставьте сложный ремонт профессионалам!

A-коды

|

A1 |

Бумага в податчике застряла, аккуратно вытяните ее. |

|

A2 |

В податчике находятся листы большего размера, не совместимые со спецификациями МФУ. Они могут застрять. Выньте их и замените на другие. |

|

A5 |

Крышку податчика нужно закрыть. Если используется стекло экспонирования, разделите толстый документ на части и произведите сканирование. |

C-коды

| C0 | Отсканированный документ не помещается на бумаге, загруженной для печати. Уменьшите масштаб или замените бумагу. |

| C1 | В первом лотке подачи застряла бумага. Удалите обрывки. Проверьте направляющие. |

| C2 | Во втором лотке подачи застряла бумага. Удалите обрывки. Проверьте направляющие. |

| C3 | В обходном лотке отсутствует / застряла бумага. Исправьте ситуацию. |

| C5 | В первом лотке отсутствует бумага или размер и ориентация листов не совместимы с заданием печати. |

| C6 | Во втором лотке отсутствует бумага или размер и ориентация листов не совместимы с заданием печати. |

| C7 | Размер и ориентация листов в обходном лотке не совместимы с заданием печати. Загрузите бумагу необходимого формата. |

E-коды

| E0 | Устройство удалило отсканированные документы перед выводом их на бумагу. Перезагрузите Xerox 5020 и повторите операцию. |

| E1 | Произошло замятие бумаги в районе размещения печи (fuser unit). Устраните замятие. |

| E2 | Возле левой крышки произошло замятие. Аккуратно выньте зажеванные листы. |

| E3 | В зоне второго лотка произошло замятие. Аккуратно выньте зажеванные листы. |

| E4 | В зоне левой крышки застряла бумага. Аккуратно выньте зажеванные листы. |

| E5 | Открыты левая / передняя крышка. Перезакройте крышку. |

| E6 | Открыты крышки. Необходимо их закрыть. Если проблема не устраняется, обратитесь в сервисный центр с неполадкой датчиков фиксации. |

| E8 | Формат и ориентация бумаги в лотке не соответствует заданию печати. |

| E9 | Печать выходит за рамки формата бумаги. Измените масштаб в меню аппарата или отмените задание. |

J-коды

| J1 | Закончился тонер. Заправьте бункер хранения с помощью расходника 106R01277. |

| J3 | Картридж установлен неправильно или не может быть распознан. Установите комплектующее. При необходимости замените на новое. |

| J6 | Нужна замена картриджа. |

| J7 | Принт-картридж не работает. |

N-коды

| n1 | Память аппарата переполнена. Отмените задание. Перезагрузите устройство, а затем повторите операцию. |

| n4 | Ошибка передачи файла, отправленного в печать.

Также могут быть проблемы со считыванием документа: в таких случаях замените расширение PDF на JPG / PNG. |

| n5 | Ошибка связи между печатающим механизмом и сканером / ПК. Xerox 5020 автоматически устранит неполадку через некоторое время. |

| n9 | Ошибка связи отдельных элементов принтера. Требуется перезагрузка.

При повторном возникновении неисправности следует вызвать мастера. |

Аппаратные ошибки (U-коды)

Коды ошибок с индексом U (U0, U1, U2 и так далее) — сообщают об аппаратных поломках Xerox 5020. Мы настоятельно рекомендуем избегать самостоятельного ремонта. Обратитесь за помощью в ближайший сервисный центр.

Нужна помощь? Обращайтесь в МосТонер — сервисное обслуживание в режиме 24/7!

#6 Xerox WorkCentre 5019 5021 5022 5024 бледно печатает | Чем и как заправить Xerox 006R01573

#116 МФУ Xerox WC 5019 5021 5022 5024 замена девелопера, барабана | Восстановление 013R00670

Replace waste toner from Xerox 5021 Part 1 YouTube

Xerox Workcentre 5021/ 5019

#51 Копир Xerox WorkCentre 5016 / 5020 восстановление драм картриджа | Фотобарабан Xerox 101R00432

Xerox Printer Installation & Driver Defaults

Разорваный резиновый вал от принтера

Ремонт лотка подачи бумаги XEROX WC 5021

Устранение неисправностей

WorkCentre 5019/5021

Руководство пользователя

11-7

Сдвиг или перекос

копий.

Оригинал размещается

неправильно.

Поместите оригинал правильно.

См. раздел

Размещение оригиналов

на стр. 5-1.

Неправильно вложена

бумага в лоток.

Вложите бумагу правильно.

См. раздел

Загрузка бумаги в лоток 1 и лоток 2

(дополнительный)

на стр. 4-8.

Если бумага подается из

выходного лотка, значит

направляющие не

касаются бумаги.

Вложите бумагу правильно.

См. раздел

Загрузка бумаги в обходной лоток

на

стр. 4-10.

Направляющие

в податчике оригиналов

установлены

неправильно.

Правильно разместите оригинал и установите

направляющие так, чтобы они касались оригинала.

См. раздел

Размещение оригиналов

на стр. 5-1.

Лоток вставлен не до

конца.

Задвиньте лоток в аппарат до упора.

См. раздел

Загрузка бумаги в лоток 1 и лоток 2

(дополнительный)

на стр. 4-8.

Пробелы на копиях.

Бумага влажная.

На влажной бумаги могут получаться пропуски

изображения или нечеткие копии. Вложите бумагу

из неоткрытой пачки.

Бумага в лотке сгибается

или мнется.

Уберите проблемные листы или вложите бумагу из

неоткрытой пачки.

Копируется мятый

оригинал или оригинал

с наклеенными

фрагментами.

Мятый оригинал или оригинал с наклеенными

фрагментами может неплотно прилегать к стеклу

экспонирования. Чтобы добиться правильного

прилегания оригинала к стеклу экспонирования,

прижмите его сверху стопкой белой бумаги.

Полосы на копиях.

Попытка чрезмерного

увеличения копии

оригинала.

При чрезмерном увеличении оригинала на копии

могут появляться полосы. Уменьшите масштаб

копий.

См. раздел

Уменьшить/Увеличить

на стр. 5-12.

Признак

Вероятная причина

Устранение

Устранение неисправностей

WorkCentre 5019/5021

Руководство пользователя

11-8

Признак

Вероятная причина

Устранение

Отпечатки светлы

(блеклые,

нечеткие).

Бумага влажная.

Вложите новую бумагу.

Принт-картридж

выработал ресурс или

поврежден.

Установите новый принт-картридж.

См. раздел

Замена принт-картриджа

на стр. 10-6.

Закончился тонер

в тонер-картридже.

Установите новый тонер-картридж.

См. раздел

Замена тонер-картриджа

на стр. 10-3.

На копиях

появляются черные

пятна.

Принт-картридж

выработал ресурс или

поврежден.

Установите новый принт-картридж.

См. раздел

Замена принт-картриджа

на стр. 10-6.

На отпечатках

появляются черные

или цветные линии.

Принт-картридж

выработал ресурс или

поврежден.

Установите новый принт-картридж.

См. раздел

Замена принт-картриджа

на стр. 10-6.

Загрязнена узкая полоска

стекла.

Очистите узкую полоску стекла.

См. раздел

Чистка прижимной крышки документов

и узкой полоски стекла

на стр. 10-10.

Устранение неисправностей

WorkCentre 5019/5021

Руководство пользователя

11-9

На отпечатках

с равными

интервалами

появляется

загрязнение.

Загрязнение тракта

подачи бумаги.

Распечатайте несколько листов.

Принт-картридж

выработал ресурс или

поврежден.

Установите новый принт-картридж.

См. раздел

Замена принт-картриджа

на стр. 10-6.

На участках

заполнения

черным цветом

появляются белые

пятна.

Неподходящая бумага.

Вложите бумагу подходящего типа.

Принт-картридж

выработал ресурс или

поврежден.

Установите новый принт-картридж.

См. раздел

Замена принт-картриджа

на стр. 10-6.

На руках остаются

следы от

отпечатков.

Тонер не

закрепляется на

бумаге.

Бумага загрязнена

тонером.

Бумага влажная.

Вложите новую бумагу.

Неподходящая бумага.

Вложите бумагу подходящего типа.

Признак

Вероятная причина

Устранение

Направление

подачи бумаги

Устранение неисправностей

WorkCentre 5019/5021

Руководство пользователя

11-10

Отпечаток

полностью черный.

Принт-картридж

выработал ресурс или

поврежден.

Установите новый принт-картридж.

См. раздел

Замена принт-картриджа

на стр. 10-6.

Неисправность

высоковольтного

источника питания.

Обратитесь в центр технической поддержки Xerox.

Отпечаток

получается пустым.

Подача сразу нескольких

листов (двойная подача).

Перед вкладыванием пачки бумаги пролистайте

листы.

Закончился тонер

в тонер-картридже.

Установите новый тонер-картридж.

См. раздел

Замена тонер-картриджа

на стр. 10-3.

Сбой питания или

неисправность

высоковольтного

источника питания.

Обратитесь в центр технической поддержки Xerox.

На отпечатках

белые участки либо

белые или цветные

полосы.

Бумага влажная.

Вложите новую бумагу.

Неподходящая бумага.

Вложите бумагу подходящего типа.

Весь отпечаток

получается

блеклым.

Если используется

обходной лоток, значит

указанный в драйвере

принтера размер или тип

бумаги не соответствует

размеру или типу бумаги

в лотке.

Вложите в обходной лоток бумагу

соответствующего размера и типа.

См. раздел

Загрузка бумаги в обходной лоток

на

стр. 4-10.

Подача сразу нескольких

листов.

Перед вкладыванием пачки бумаги пролистайте

листы.

Признак

Вероятная причина

Устранение

Устранение неисправностей

WorkCentre 5019/5021

Руководство пользователя

11-11

Бумага сминается.

Неподходящая бумага.

Вложите новую бумагу.

Добавление бумаги к уже

вложенной в лоток.

Бумага влажная.

Нечеткий текст.

Неподходящая бумага.

Вложите новую бумагу.

Добавление бумаги к уже

вложенной в лоток.

Бумага влажная.

Белые или цветные

вертикальные

полосы.

Принт-картридж

выработал ресурс или

поврежден.

Установите новый принт-картридж.

См. раздел

Замена принт-картриджа

на стр. 10-6.

Закончился тонер

в тонер-картридже.

Установите новый тонер-картридж.

См. раздел

Замена тонер-картриджа

на стр. 10-3.

Наклона

изображения на

отпечатке.

Неправильно

установлены

направляющие бумаги.

Установите правильно горизонтальную

и вертикальную направляющие бумаги.

См. раздел

Загрузка бумаги в лоток 1 и лоток 2

(дополнительный)

на стр. 4-8.

См. раздел

Загрузка бумаги в обходной лоток

на

стр. 4-10.

Признак

Вероятная причина

Устранение

Направление

подачи бумаги

Проблемы при копировании, Копирование не выполняется, Проблемы при копировании -12

Копирование не выполняется -12, Здел

- Изображение

- Текст

Устранение неисправностей

WorkCentre 5019/5021

Руководство пользователя

11-12

Проблемы при копировании

В данном разделе приведены способы устранения неисправностей, которые могут возникать

при копировании.

Копирование не выполняется

В таблице ниже приведены возможные причины того, что не выполняется копирование.

Признак

Вероятная причина

Устранение

Неправильная

подача оригиналов

податчиком.

Размер оригинала

слишком мал.

Минимальный формат бумаги в податчике

оригиналов: А5

.

Данный тип оригиналов

не поддерживается.

Податчик не подает оригиналы неправильной

формы, визитки, пленки или тонкие документы,

а также оригиналы с наклейками, зажимами

и липкой лентой.

См. раздел

Типы бумаги

на стр. 4-1.

Неправильно

установлены

направляющие

оригиналов.

Установите направляющие по размеру оригинала.

В податчике оригиналов

застряли обрывки.

Откройте крышку податчика оригиналов

и извлеките застрявшие обрывки.

См. раздел

Застревание оригиналов

на стр. 11-36.

Страницы оригинала

разного размера.

Размер страниц оригинала должен быть

одинаковым.

Устранение неисправностей

WorkCentre 5019/5021

Руководство пользователя

11-13

Проблемы с копиями

В таблице ниже приведены возможные причины проблем с копиями.

Признак

Вероятная причина

Устранение

Загрязнение копий.

Загрязнение стекла

экспонирования или его

крышки.

Очистите стекло экспонирования или его крышку.

См. раздел

Чистка стекла экспонирования и его

крышки

на стр. 10-9.

Копируется пленка или

прозрачный материал.

Если загрязнена крышка стекла экспонирования,

при копировании прозрачных оригиналов это

отражается на копиях. Перед копированием

накройте оригинал листом белой бумаги.

Копируется оригинал на

цветной или грубой

бумаге, либо светокопия.

Копируется фоновый цвет. Перед копированием

настройте плотность копий, качество изображения

или подавление фона.

Оригинал напечатан на

глянцевой бумаге.

Глянцевая бумага легко прилипает к стеклу

экспонирования, и на копиях могут

воспроизводиться тени. Перед копированием

подложите под оригинал прозрачный лист или

пленку.

Копии слишком

светлые или

слишком темные.

Неправильно настроена

плотность копий.

Настройте плотность копий.

См. раздел

Светлее/Темнее

на стр. 5-16.

Оригинал светлый.

Настройте плотность копий.

См. раздел

Светлее/Темнее

на стр. 5-16.

Неправильная настройка

качества изображения.

Если копия с черным текстом получается слишком

светлой, установите для параметра «Тип

оригинала» настройку «Текст».

См. раздел

Тип оригинала

на стр. 5-15.

Небольшой сдвиг

копий.

Неправильное

вкладывание бумаги

в лоток.

Выровняйте пачку бумаги и вложите ее так, чтобы

передняя кромка совмещалась с углами лотка.

Устранение неисправностей

WorkCentre 5019/5021

Руководство пользователя

11-14

Пробелы на копиях.

Бумага влажная.

На влажной бумаги могут получаться пропуски

изображения или нечеткие копии. Вложите бумагу

из неоткрытой пачки.

Бумага в лотке сгибается

или мнется.

Уберите проблемные листы или вложите бумагу из

неоткрытой пачки.

Мятый оригинал или

оригинал с наклеенными

фрагментами.

Мятый оригинал или оригинал с наклеенными

фрагментами может неплотно прилегать к стеклу

экспонирования. Чтобы добиться правильного

прилегания оригинала к стеклу экспонирования,

прижмите его сверху стопкой белой бумаги.

Неверный размер

оригинала.

Проверьте правильность установки размера

оригинала.

См. раздел

Размер оригинала

на стр. 5-13.

Неверный размер бумаги.

Проверьте правильность установки размера

бумаги.

См. раздел

Настройка размера бумаги

на стр. 4-14.

Полосы на копиях.

Слишком большое

увеличение оригинала.

При чрезмерном увеличении оригинала на копии

могут появляться полосы. Уменьшите масштаб

копий.

См. раздел

Уменьшить/Увеличить

на стр. 5-12.

Сдвиг или перекос

копий.

Оригинал размещается

неправильно.

Поместите оригинал правильно.

См. раздел

Размещение оригиналов

на стр. 5-1.

Направляющие

в податчике оригиналов

установлены

неправильно.

Правильно разместите оригинал и установите

направляющие так, чтобы они касались оригинала.

Лоток вставлен не до

конца.

Задвиньте лоток в аппарат до упора.

Неправильно

установлены

направляющие бумаги

в обходном лотке.

Правильно разместите оригинал и установите

направляющие так, чтобы они касались оригинала.

Неверный размер

оригинала.

Проверьте правильность установки размера

оригинала.

См. раздел

Размер оригинала

на стр. 5-13.

Неверный размер бумаги.

Проверьте правильность установки размера

бумаги.

См. раздел

Настройка размера бумаги

на стр. 4-14.

Признак

Вероятная причина

Устранение

Устранение неисправностей

WorkCentre 5019/5021

Руководство пользователя

11-15

Размер копий не

соответствует

ожидаемому

размеру.

Загрязнение стекла

экспонирования или его

крышки.

Очистите стекло экспонирования или его крышку.

См. раздел

Чистка стекла экспонирования и его

крышки

на стр. 10-9.

Копируется пленка или

прозрачный материал.

Перед копированием накройте оригинал листом

белой бумаги.

Сдвиг копий.

Поместите оригинал правильно.

См. раздел

Размещение оригиналов

на стр. 5-1.

Направляющие

в податчике оригиналов

установлены

неправильно.

Правильно разместите оригинал и установите

направляющие так, чтобы они касались оригинала.

См. раздел

Размещение оригиналов

на стр. 5-1.

Оригинал со складками.

Распрямите оригинал и поместите его правильно.

См. раздел

Размещение оригиналов

на стр. 5-1.

Неверная настройка

размера оригинала.

Проверьте правильность установки размера

оригинала.

См. раздел

Размер оригинала

на стр. 5-13.

Неверная настройка

размера бумаги.

Проверьте правильность установки размера

бумаги.

См. раздел

Настройка размера бумаги

на стр. 4-14.

Обрезание копий

по краям.

Размер оригинала

больше области печати.

Немного уменьшите масштаб копий.

Неверный размер

оригинала.

Проверьте правильность установки размера

оригинала.

См. раздел

Размер оригинала

на стр. 5-13.

Неверный размер бумаги.

Проверьте правильность установки размера

бумаги.

См. раздел

Настройка размера бумаги

на стр. 4-14.

Признак

Вероятная причина

Устранение

Проблемы при печати, Печать не выполняется, Проблемы при печати -16

Печать не выполняется -16, Здел

- Изображение

- Текст

Устранение неисправностей

WorkCentre 5019/5021

Руководство пользователя

11-16

Проблемы при печати

В данном разделе приведены способы устранения неисправностей, которые могут возникать

при печати.

Печать не выполняется

В таблице ниже приведены возможные причины того, что не выполняется печать.

Признак

Вероятная причина

Устранение

Данные не

исчезают

с пиктограммы

принтера.

Питание аппарата не

включено.

Включите питание аппарата.

См. раздел

Электропитание

на стр. 3-6.

Не подключен кабель

компьютера.

Подключите кабель компьютера.

Не подключен кабель

аппарата.

Подключите кабель аппарата.

См. раздел

Интерфейс USB

на стр. 2-2.

Ошибка аппарата.

Проверьте сведения об ошибке и примите

соответствующие меры.

Данные

отправлены на

аппарат.

Не вложена бумага.

Вложите бумагу.

Отсутствует бумага

указанного размера.

Вложите бумагу указанного размера.

См. раздел

Загрузка бумаги в лотки

на стр. 4-8.

Ошибка аппарата.

Проверьте сведения об ошибке и примите

соответствующие меры.

Работа приостановлена.

Отмените работу с экрана, если это требуется.

Комментарии

- Manuals

- Brands

- Xerox Manuals

- All in One Printer

- WorkCentre 5022

- Service manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Related Manuals for Xerox WorkCentre 5022

Summary of Contents for Xerox WorkCentre 5022

-

Page 1

® Xerox WorkCentre 5022/5024 Service Manual Revised June 2014 702Pxxxxx… -

Page 3

Xerox service documentation is intended for use by certified, product-trained service per- sonnel only. Xerox does not warrant or represent that it will notify or provide to such customer any future change to this documentation. Customer performed service of equipment, or mod- ules, components, or parts of such equipment may affect whether Xerox is responsible to fix machine defects under the warranty offered by Xerox with respect to such equipment. -

Page 4

Preface Version 1.0 06/2014 WC 5022/5024… -

Page 5

Chapter 0 Introduction… -

Page 7

0 Introduction 0.1 Getting to know this Service Manual……………. 0.2 How to use the Service Manual …………….0.3 Description for Terminology And Symbols …………… Version 1.0 Introduction 06/2014 WC 5022/5024… -

Page 8

Introduction Version 1.0 06/2014 WC 5022/5024… -

Page 9

0.1 Getting to know this Service Manual 0.2 How to use the Service Manual This manual is used as the standard service manual for WorkCentre 5022/5024. This manual describes the standard procedures for the servicing this product. Refer to Chapter 1 Service Call Procedure for efficient and effective servicing during maintenance calls. -

Page 10

Abbreviation of Typical Electricity Consumption, which means the stan- dard power consumption. Read as ‘tec’. Installation of any part other than the ones designated by Xerox shall be strictly prohibited because it cannot be guaranteed in quality and safety. Important Information Stored Component (ISC) This component stores all the important customer information that is input after the installation. -

Page 11

Chapter 1 Service Call Procedures… -

Page 13

1 Service Call Procedures 1.1 Before Starting the Servicing ………………. 1.2 Service Call Procedure 1.2.2 Service Call Procedure ………………1.3 Detailed Contents of the Service Call …………..1.4 TRIM Check List………………….. 1.5 Periodic Replacement Parts/Consumables List …………Version 1.0 Service Call Procedures 06/2014 WC 5022/5024… -

Page 14

Service Call Procedures Version 1.0 06/2014 WC 5022/5024… -

Page 15

1.1 Before Starting the Servicing 11. Harmful Laser The customer or service personnel would not be exposed to any harmful laser during the 1.1.1 Safety usual copying or scanning of documents. However, if a customer finds that the lamp that To prevent any accident that may occur during a maintenance service, any warning or any cau- is used for exposing documents is too bright when performing platen copy or scan, it is tion regarding the servicing must be strictly observed. -

Page 16

1.1.2 Things to Take Note When Handling Customer Information 1.1.3 Other Precautions Handling of customer’s electronic information — samples of copy/print/received fax (paper Pay attention to the following when performing maintenance service to avoid wrong or redun- data), log files (Activity Report), and etc. dant servicing: Before you bring back any samples for the purpose of investigation/analysis, always Reference Materials… -

Page 17

1.2.2 Service Call Procedure 1.3 Detailed Contents of the Service Call 1.2.2.1 Initial Actions 1.3.1 Initial Actions Ask the operator(s) about the machine condition. Ask the operator(s) about the machine condition. Record the billing meter readings. • How often and where do paper jams have been occurring recently Inspect any error copies, then check the machine. -

Page 18

1.4 TRIM Check List 1.5 Periodic Replacement Parts/Consumables List C: Perform checking. Clean, replace, or feed if necessary. When servicing, check the number of copies and number of fed sheets for the consumables and parts that require periodical cleaning/replacement. Clean or replace them if necessary. O: Always perform cleaning and checking. -

Page 19

Table 1 HFSI Parts/Consumables Name/ [Chain- Replacement PL No. Link] Interval Check the counter Document Feed No. 955-806 200,000PV Replace the Feed Roll, DADF Feed Roll/Nudger Roll Nudger Roll, and Retard Pad (PL 56.5) at the same time. DADF Retard Pad NOTE: Clean the Platen (PL 56.13) Glass with a Platen Wax… -

Page 20

Service Call Procedures Version 1.0 06/2014 1.5 Periodic Replacement Parts/Consumables List WC 5022/5024… -

Page 21

Chapter 2 Troubleshooting… -

Page 23

2 Troubleshooting 2.1 Introduction CHAIN 10 2.1.1 How to Troubleshoot ………………… 010-311 Fusing Unit Center Thermistor Defect………….. 2-27 2.1.3 Glossary …………………… 010-312 Fusing Unit Rear Thermistor Defect…………..2-27 010-320 Over Heat Temperature Fail …………….2-28 2.2 Product FIP 010-327 Fusing Unit On Time Fail …………….. 2-28 010-379 Fusing Unit Hot Not Ready Return Time Fail……….. -

Page 24

024-954 MSI No Paper ………………..2-51 034-711 Fax Send Count Limit………………2-78 024-958/959/960 MSI/Tray 1/Tray 2 Paper Size Mismatch ……….. 2-51 034-726 Fax Calling Table Full ………………2-78 024-961 Tray 3 Paper Size Mismatch…………….2-52 034-746 Line Connection Fail ………………2-79 024-962 Tray 4 Paper Size Mismatch……………. -

Page 25

062-389 Carriage Over Run Fail (Scan End Side)…………2-106 CHAIN 92 062-396 CCD Cable Connection Fail…………….2-107 092-660/668 ATC Amplitude Fail/ ATC Average Fail…………. 2-135 092-661 Temperature Sensor Fail …………….. 2-135 CHAIN 71 092-910 ATC Sensor Fail………………..2-136 071-105 Regi Sensor On Jam (Tray 1) …………….2-109 CHAIN 93 CHAIN 72… -

Page 26

2.2.4.7 Motor Left Running Failure FIP …………….2-162 2.2.4.8 NIP/RELEASE SOLENOID Not Energized Failure FIP……..2-162 2.3 NET System Fault Check 2.3.1 Interface (Physical/Logical) ………………. 2-165 2.3.2 ‘Cannot connect to the network’ or ‘Print is not found from the PC’ …… 2-165 2.3.3 No output is available, no data is printed ………….. -

Page 27

2.1.1 How to Troubleshoot 2.1.3 Glossary Level 1 Troubleshooting: The following terminology are used throughout the troubleshooting section. The meaning of these terminology must be fully understood when performing problem analysis. • Level 1 Troubleshooting (Level 1 FIP) is the first step to diagnose a problem. Level 1 FIP asks you whether any Fault Code and other problematic symptoms exist, guiding you to Common terms: Level 2 Troubleshooting or BSD to resolve the problem. -

Page 28

• CH 6.2 Zone J4 Refer to Chain 6.2 Zone J4 in Chapter 7 BSD. • REP 4.1.3 Refer to REP 4.1.3 in Chapter 4. • ADJ 4.1.3 Refer to ADJ 4.1.3 in Chapter 4. • Replace the parts in sequence When it is impossible to analyze causes of a problem further, replace the parts in sequence. -

Page 29

2.2.1.1 Level 1 FIP Procedure Ask the operator about the problem. Did the operator operate the machine correctly? Explain the correct way to operate the machine to the operator. Output all jobs that are stored in the memory. Turn the power OFF and ON. Is the UI display normal? Refer to [BSD (CH2.1)] and [2.2.3 Other Failure FIP] to repair the malfunction in UI dis- play. -

Page 30

Status Indicator RAPs Version 1.0 06/2014 2.2.1.1 Level 1 FIP WC 5022/5024… -

Page 31

003-500 N-Up NG Out Of Range 003-754 IPS Overrun BSD-ON:- BSD-ON:- During 2-Up or 4-Up, the reduce/enlarge ration was not within the range of 25 to 400%. The IPS processing has overtook the Scan processing. Cause/Action Cause/Action Press [Stop] on the UI Panel and change the settings. This might be avoided by setting the R/E ratio to 99% or 101%. -

Page 32

003-795 AMS NG Out Of Range 003-942 Not-Supported Doc Size BSD-ON:- BSD-ON:- When [Reduce/Enlarge] is set to [Auto], the reduce/enlarge ratio was not within the range of 50 During DADF Scan of a Copy, Scan and Fax sending Job, an unsupported document size was to 200%. -

Page 33

003-956 Not-Supported Doc Size 003-963 APS NG Out Of Range BSD-ON:- BSD-ON:- During Platen Scan, an unsupported document size was detected. During Copy Job, when APS is selected, the image size obtained from document size x reduce/enlarge ratio was detected to be larger than the largest Standard Paper Size. Cause/Action Cause/Action Press [Stop] on the UI Panel and change the document. -

Page 34

003-972 1Job Max Page Over 003-973 Auto Rotation NG Out Of Range BSD-ON:- BSD-ON:- During Copy Job or Scan Job, the number of pages that can be scanned has been exceeded. During Copy Job, the following conditions were met. Cause/Action •… -

Page 35

004-345 HVPS Communication Error BSD-ON: CH9.1 Communication failure between the ESS/MCU PWB and the HVPS was detected. Cause/Action Turn the power OFF and ON. Turn OFF the power and check the connection between the HVPS J500 and the ESS/ MCU PWB J402 for open circuit, short circuit, and poor contact. If no problem is found, replace the following parts in sequence: •… -

Page 36

Status Indicator RAPs Version 1.0 06/2014 004-345 HVPS Communication Error 2-14 WC 5022/5024… -

Page 37

005-122 DADF Simplex/Side 1 Pre Regi Sensor On Jam 005-123 DADF Simplex/Side 1 Regi Sensor On Jam BSD-ON: CH5.4 BSD-ON: CH5.5, CH5.4 • After Pre-Feed started for the first sheet (DADF Feed Motor On (CW)) in Simplex and The DADF Regi Sensor does not turn ON within the specified time after the DADF Pre Regi Duplex, the DADF Pre Regi Sensor did not turn ON within the specified time. -

Page 38

005-125/145 DADF Regi Sensor Off Jam/ DADF Regi 005-131/132 DADF Invert Sensor On Jam on Inverting/ Sensor Off Jam on Inverting DADF Invert Sensor On Jam BSD-ON: CH5.5, CH5.4 BSD-ON: CH5.5, CH5.4 [DADF Regi Sensor Off Jam] [DADF Invert Sensor On Jam on Inverting] After the DADF Pre Regi Sensor turned OFF at Scan operation, the DADF Regi Sensor did not After the DADF Regi Sensor turned ON at Invert operation, the DADF Invert Sensor did not turn OFF within the specified time. -

Page 39

005-134/139 DADF Invert Sensor Off Jam on Inverting/ 005-135 DADF Side 2 Pre Regi Sensor On Jam DADF Invert Sensor Off Jam BSD-ON: CH5.5, CH5.4 BSD-ON: CH5.5, CH5.4 After the DADF Feed Motor started the reverse rotation at Invert operation, the DADF Pre Regi Sensor did not turn ON within the specified time. -

Page 40

005-136 DADF Side 2 Regi Sensor On Jam 005-147 DADF Pre Regi Sensor Off Jam on Inverting BSD-ON: CH5.5, CH5.4 BSD-ON: CH5.5, CH5.4 After the DADF Pre Regi Sensor turned ON at Invert operation, the DADF Regi Sensor did not After the DADF Feed Motor started the reverse rotation at Invert operation, the DADF Pre Regi turn ON within the specified time. -

Page 41

005-196 Size Mismatch Jam on No Mix-Size 005-197 Prohibit Combine Size Jam BSD-ON: CH5.4, CH5.2 BSD-ON: CH5.4 The 2nd sheet or later of the document was detected to be of a different size conpared to the A Mixed Size document was detected. 1st sheet (the length of the document’s 2nd sheet or later in SS direction is longer). -

Page 42

005-198/199 Too Short Size Jam/ Too Long Size Jam 005-210 DADF Download Fail BSD-ON: CH5.4, CH5.2 BSD-ON: CH1.3 [Too Short Size Jam] When the IISS starts up (including at Power ON/Sleep recovery), it was detected that the DADF is in Download Mode. It was detected that the document length in Slow Scan direction is shorter than the specifica- tions (Simpex: 85 mm, Duplex: 110 mm). -

Page 43

005-275/280 DADF RAM Test Fail/ DADF EEPROM Fail 005-305 DADF Feeder Cover Interlock Open BSD-ON: CH1.3 BSD-ON: CH5.1 [DADF RAM Test Fail] The DADF Feeder Cover Interlock Switch was opened during DADF operation. The DADF PWB RAM failed during the Read/Write operation. (At Power ON) Cause/Action Check the DADF Feeder Cover for mismatch. -

Page 44

005-500 DADF Download Flash Write Error 005-907/908/913 DADF Pre Regi Sensor/DADF Regi Sensor/DADF Invert Sensor Static Jam BSD-ON: CH1.3 BSD-ON: CH5.5, CH5.4 Failed to write into the Flash ROM during DAFD Download. Paper was detected by the applicable sensor at Power ON, Feeder Cover Interlock Close, or Cause/Action DADF Open Sensor Close. -

Page 45

005-940 DADF No Original Fail 005-948 SS-Size Mismatch Jam on No Mix-size BSD-ON: CH5.1 BSD-ON: CH5.4, CH5.2 It was detected that the document was pulled out during document feed. In No Mix mode, it was detected that a document with a shorter size in Slow Scan (SS) direc- tion was transported from the DADF. -

Page 46

Status Indicator RAPs Version 1.0 06/2014 005-948 SS-Size Mismatch Jam on No Mix-size 2-24 WC 5022/5024… -

Page 47

007-270 Tray 1 Paper Size Switch Broken 007-272 Tray 3 Paper Size Switch Broken BSD-ON: CH7.1 BSD-ON: CH7.3 The Tray 1 Size Sensor open circuit was detected. (The AD value is at its largest.) The Tray 3 Size Sensor open circuit was detected. (The AD value is at its largest.) NOTE: If this is already detected, it will be displayed on the UI Panel when a Job is being per- NOTE: If this is already detected, it will be displayed on the UI Panel when a Job is being per- formed. -

Page 48

007-273 Tray 4 Paper Size Switch Broken BSD-ON: CH7.4 The Tray 4 Size Sensor open circuit was detected. (The AD value is at its largest.) NOTE: If this is already detected, it will be displayed on the UI Panel when a Job is being per- formed. -

Page 49

010-311 Fusing Unit Center Thermistor Defect 010-312 Fusing Unit Rear Thermistor Defect BSD-ON: CH10.2 BSD-ON: CH10.2 An open circuit abnormality (the AD value of the STS is equivalent to the open circuit value) of An open circuit abnormality (the AD value of the STS is equivalent to the open circuit value) of the Heat Roll Center Thermistor was detected. -

Page 50

010-320 Over Heat Temperature Fail 010-327 Fusing Unit On Time Fail BSD-ON: CH10.2, CH10.1 BSD-ON: CH10.2, CH10.1 A high temperature error was detected at the Center Thermistor (245 degrees C or higher) or Any of the following was detected: the Rear Thermistor (270 degrees C or higher). •… -

Page 51

010-379 Fusing Unit Hot Not Ready Return Time Fail 010-392 NOHAD Fan Defect BSD-ON: CH10.2 BSD-ON: CH10.3 The High Temperature Not Ready state is not cleared even after the Recovery Time (NVM) has NOHAD Fan failure was detected. When the NOHAD Fan Fail signal indicating an abnormality passed. -

Page 52

010-602 Over Temp Cooling Mode BSD-ON: CH10.2 Unable to print because the temperature in the machine has risen above the specification value. Cause/Action Wait until the temperature in the machine has dropped. Status Indicator RAPs Version 1.0 06/2014 010-602 Over Temp Cooling Mode 2-30 WC 5022/5024… -

Page 53

016-346 Fax Parameter Incorrect 016-372 File Access Error BSD-ON:- BSD-ON:- Parameter Error received from the Fax Board. Self Diagnostic: Parameter Error received. Unable to access the files that had been stored in the device for some reasons (access refused, etc.). Cause/Action Cause/Action Turn the power OFF and ON. -

Page 54

016-500 Controller Download Flash Write Error 016-501 Controller Boot Flash Write Error BSD-ON:- BSD-ON:- Unable to write the Download File of Controller Main into the Flash ROM. Unable to write the Download File of Controller Boot into the Flash ROM. Cause/Action Cause/Action Turn the power OFF and ON. -

Page 55

016-502 UI Panel Download Flash Write Error 016-504 UI panel Font Download Flash Write Error BSD-ON:- BSD-ON:- Unable to write the Download File of UI Panel into the Flash ROM. Unable to write the Download File of UI Panel Font into the Flash ROM. Cause/Action Cause/Action Turn the power OFF and ON. -

Page 56

016-570 No Response from USB-Host for Scan Job 016-571 No Response from USB-Host for Print Job BSD-ON: CH3.3 BSD-ON: CH3.3 When any of the following has occurred as Scan to PC (USB) is in progress. When any of the following has occurred as USB Print or Download data interpretation is in progress. -

Page 57

016-598 E-mail Message Size Over 016-742/744 Download File Error/ Download File Check Sum Error BSD-ON:- BSD-ON:- During Scan to E-mail, the maximum attachment size was exceeded at the 1st page. [Download File Error] Cause/Action Press [Stop] on the UI Panel. It was detected that there is an error with either the file format of the Download File, the Device Identifier, the Device Serial Number, or the Target Device Character String. -

Page 58

016-749/799 HBPL or XPJL Syntax Error/ Print Instruction 016-759 Copy Counter Full Fail BSD-ON:- BSD-ON:- During Multi Account Mode, any of the following has occurred: [HBPL or XPJL Syntax Error] • The general user that is logged in has reached the allotted maximum print count. •… -

Page 59

016-764 SMTP Server Connection Fail 016-765 SMTP Server Disk Full BSD-ON:- BSD-ON:- Unable to continue the E-mail sending process due to some problems. The e-mail send/receive area of the SMTP Server (PC) is full. Cause/Action Cause/Action Press [Stop] on the UI Panel. Press [Stop] on the UI Panel. -

Page 60

016-766 SMTP Server Limit Over 016-768 SMTP Sender Address Error BSD-ON:- BSD-ON:- The e-mail limit value of the SMTP Server (PC) has been exceeded. When the device is performing a send for the very first time to the connected SMTP Server, an address-related error was notified. -

Page 61

016-776 Marker Code Detection Fail 016-781 SMTP Server Refusal BSD-ON:- BSD-ON:- During Copy Job or Print Job, when expanding only up to the size that was specified at the The SMTP Server is refusing to send e-mails for some reasons. expansion, the End Code cannot be found in the compressed data. -

Page 62

016-981 EPC Memory Full 016-982 SCAN Memory Full BSD-ON:- BSD-ON:- During Copy Job, the EPC memory is filled up. During Scan Job (except for Scan to PC (USB)), memory full was detected at the 1st page. Cause/Action Cause/Action Perform any of the following and then turn the power OFF and ON. •… -

Page 63

016-985 Max Attachment Size Over BSD-ON:- During Scan to E-mail, the maximum attachment size was exceeded at the 2nd page or later. Cause/Action Press [Stop] on the UI Panel. Enter the Diag and input NVM [840-167]. Adjust the limit value of attachment size for Scan to E-mail. Lower the resolution setting. -

Page 64

Status Indicator RAPs Version 1.0 06/2014 016-985 Max Attachment Size Over 2-42 WC 5022/5024… -

Page 65

017-745 SMB Size Over BSD-ON:- In Scan to PC (SMB) the upper limit of storage size was exceeded. Cause/Action Lower the resolution setting. Change the document type. Change the output color. Version 1.0 Status Indicator RAPs 06/2014 017-745 SMB Size Over WC 5022/5024 2-43… -

Page 66

Status Indicator RAPs Version 1.0 06/2014 017-745 SMB Size Over 2-44 WC 5022/5024… -

Page 67

024-365 Image Output FIFO Error 024-910/911/915 Tray 1/Tray 2/MSI Paper Length Mismatch BSD-ON:- BSD-ON: CH8.4 An image transfer underrun has occurred. The Paper Size for the applicable Tray is longer by 10.1 mm or more, or shorter by 13.1 mm or more than the setting. -

Page 68

024-912 Tray 3 Paper Length Mismatch 024-913 Tray 4 Paper Length Mismatch BSD-ON: CH8.4 BSD-ON: CH8.4 The Paper Size for the applicable Tray is longer by 10.1 mm or more, or shorter by 13.1 mm or The Paper Size for the applicable Tray is longer by 10.1 mm or more, or shorter by 13.1 mm or more than the setting. -

Page 69

024-946 Tray 1 Unknown Paper Size 024-947 Tray 2 Unknown Paper Size BSD-ON: CH7.1 BSD-ON: CH7.2 One of the following errors was detected. One of the following errors was detected. • During Copy Job and Diag Job, Tray 1 was selected but the paper guides in Tray 1 are in •… -

Page 70

024-948 Tray 3 Unknown Paper Size 024-949 Tray 4 Unknown Paper Size BSD-ON: CH7.3 BSD-ON: CH7.4 One of the following errors was detected. One of the following errors was detected. • During Copy Job and Diag Job, Tray 3 was selected but the paper guides in Tray 3 are in •… -

Page 71

024-950 Tray 1 No Paper 024-951 Tray 2 No Paper BSD-ON: CH7.5 BSD-ON: CH7.6 Any of the following was detected: Any of the following was detected: • The paper in the Tray 1 has ran out. (When the ATS function of Tray 1 is disabled) •… -

Page 72

024-952 Tray 3 No Paper 024-953 Tray 4 No Paper BSD-ON: CH7.7 BSD-ON: CH7.8 One of the following errors was detected. However, this is not detected until the paper is about One of the following errors was detected. However, this is not detected until the paper is about to be fed. -

Page 73

024-954 MSI No Paper 024-958/959/960 MSI/Tray 1/Tray 2 Paper Size Mismatch BSD-ON: CH7.9 BSD-ON:- Any of the following was detected: During Print Job, the paper size settings of the selected Tray is different from the paper size specified for the Job. •… -

Page 74

024-961 Tray 3 Paper Size Mismatch 024-962 Tray 4 Paper Size Mismatch BSD-ON: CH7.3 BSD-ON: CH7.4 During Print Job, the paper size settings of the selected Tray is different from the paper size During Print Job, the paper size settings of the selected Tray is different from the paper size specified for the Job. -

Page 75

024-965 APS NG Unselected 024-966 APS NG Permission Denied BSD-ON:- BSD-ON:- During Copy Job, Print Job, and Report Job with APS settings, the Paper Size and paper ori- Although APS was selected during Copy Job or Print Job, all the Trays are either prohibited for entation (SEF/LEF) settings specified by the Job are different from the settings at Tray 1, Tray APS or malfunctioning. -

Page 76

Status Indicator RAPs Version 1.0 06/2014 024-966 APS NG Permission Denied 2-54 WC 5022/5024… -

Page 77

026-718 D-Fax Instruction Fail 026-737 Network Error BSD-ON:- BSD-ON:- During D-Fax Job, the job cannot be performed using the specified combination of print param- Unable to connect to the Server due to reasons such as there is a network failure, the Server is eters (stored image size, etc.). -

Page 78

Status Indicator RAPs Version 1.0 06/2014 026-737 Network Error 2-56 WC 5022/5024… -

Page 79

027-518 Forwarding Login Error 027-520 SMB Forwarding Bad Volume BSD-ON:- BSD-ON:- Unable to log in normally to the transfer destination. One of the following errors was detected. Cause/Action • A character string that cannot be set has been specified in volume (shared name, path, etc.). -

Page 80

027-522 Forwarding Access Error 027-528 SMB Disk full BSD-ON:- BSD-ON:- Write was refused even though the connection to the transfer destination is normal. Unable to write into the shared folder because the HDD of the PC is full. Cause/Action Cause/Action Press [Stop] on the UI Panel. -

Page 81

027-543 SMB Forwarding Bad Address 027-779 SMTP Server Login Error BSD-ON:- BSD-ON:- The Net BIOS name or the address specified at the FQDN is incorrect. A login error was returned at SMTP-AUTH. Cause/Action Cause/Action Press [Stop] on the UI Panel. Press [Stop] on the UI Panel. -

Page 82

Status Indicator RAPs Version 1.0 06/2014 027-779 SMTP Server Login Error 2-60 WC 5022/5024… -

Page 83

033-313 Fax Board Communication Fail 033-316 Fax Box NVM Data Defect BSD-ON: CH34.1 BSD-ON:- Communication failure with Fax Board was detected. The NVM data of the Fax Board is corrupted. Cause/Action Cause/Action Turn the power OFF and ON. Turn the power OFF and ON. Check the connection of the Fax Board Cable. -

Page 84

033-325 Modem No Response 033-326 Fax Controller File Broken BSD-ON:- BSD-ON:- 0x80 4: Warning T30_MODEM_HANG_UP_ERR. When printing received Fax, the Controller File is damaged. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). Turn the power OFF and ON. Status Indicator RAPs Version 1.0 06/2014 033-325 Modem No Response… -

Page 85

033-503 Receive T1 Time Out 033-504 T2 Time Out BSD-ON:- BSD-ON:- 0x49 4: Warning T30_EOM_T1_TIMEOUT_ERR. 0x43 4: Warning T30_T2_TIMEOUT_ERR. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). Clears automatically (concluded within the Fax Board). Version 1.0 Status Indicator RAPs 06/2014 033-503 Receive T1 Time Out WC 5022/5024… -

Page 86

033-505 T5 Time Out 033-506 DCN Receive BSD-ON:- BSD-ON:- 0x65 4: Warning T30_T5_TIMEOUT_ERR. 0x6A 4: Warning T30_RXD_NULEOR_AFTER_DCN. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). Clears automatically (concluded within the Fax Board). Status Indicator RAPs Version 1.0 06/2014 033-505 T5 Time Out 2-64 WC 5022/5024… -

Page 87

033-507 Unable to receive by remote 033-509 DIS DCS Illegal Command Receive BSD-ON:- BSD-ON:- 0x46 4: Warning T30_RXB_RESP_RCV_ERR. 0x40 4: Warning T30_DCS_RETRY_ERR. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). Clears automatically (concluded within the Fax Board). Version 1.0 Status Indicator RAPs 06/2014 033-507 Unable to receive by remote… -

Page 88

033-510 Fallback Error 033-517 Timeout ECM Between Frame BSD-ON:- BSD-ON:- 0x41 4: Warning T30_TCF_FAIL_ERR. 0x69 4: Warning T30_TXD_RESP_RCV_ERR. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). Clears automatically (concluded within the Fax Board). Status Indicator RAPs Version 1.0 06/2014 033-510 Fallback Error 2-66 WC 5022/5024… -

Page 89

033-526 ECM Send EOR-Q Send 033-529 RTN Receive BSD-ON:- BSD-ON:- 0x51 4: Warning ECM Data Error COMM_RESULTCODE_ECM_DATA_ERROR. 0x66 4: Warning T30_RTN_FAIL_ERR. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). Clears automatically (concluded within the Fax Board). Version 1.0 Status Indicator RAPs 06/2014 033-526 ECM Send EOR-Q Send WC 5022/5024… -

Page 90

033-531 DM Prevention Function Receive Refuse 033-532 Illegal Command Received BSD-ON:- BSD-ON:- 0x4A 4: Warning DM Receive Refuse COMM_RESULTCODE_RX_DM_ERROR. 0x67 4: Warning T30_RXD_INVALID_CMD_RCV_ERR Cause/Action 0x47 4: Warning T30_TXB_INVALID_CMD_RCV_ERR Clears automatically (concluded within the Fax Board). Cause/Action Clears automatically (concluded within the Fax Board). Status Indicator RAPs Version 1.0 06/2014… -

Page 91

033-541 No Destination Specified 033-547 Cancel BSD-ON:- BSD-ON:- ‘Off-hook’ was selected from the service menu when there is no external line connected and 0x01 4: Warning User Cancellation COMM_RESULTCODE_ABORT. then manual sending was executed. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). Press [Stop] on the UI Panel. -

Page 92

033-548 No Manual Send Line Job Cancel 033-549 Fax Service Disabled BSD-ON:- BSD-ON:- [Off-hook] was selected from the service menu to perform manual receive when no external There is a Polling Job from the Fax Board. phone is installed. Cause/Action Cause/Action Press any button on the UI Panel. -

Page 93

033-550 Phone Book Disabled 033-567 Fax AddressInfo Sum Check Fail BSD-ON:- BSD-ON:- Any of the following was received: Mismatched Telephone Book Data received from the Fax Board. • Unable to register Telephone Book: Memory transfer setting in progress Cause/Action • Unable to register Telephone Book: DM refusal setting in progress Press any button on the UI Panel. -

Page 94

033-572 Fax Communication Management Report Full 033-577 Control Channel Synchronization Error BSD-ON:- BSD-ON:- Communication Management Report Full received from the Fax Board. 0x82 4: Warning T30_MODEM_CONTCH_ERR. Cause/Action Cause/Action Press any button on the UI Panel. Clears automatically (concluded within the Fax Board). Print out the current report. -

Page 95

033-578 Primary Channel Off Time Out 033-711 Fax File System Error BSD-ON:- BSD-ON:- 0x83 4: Warning T30_MODEM_PRIMCH_ERR. File System Error received from the Fax Board. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). Turn the power OFF and ON. Print out the Error Report and then replace the Fax PWB (PL 18.5). -

Page 96

033-712 Fax Flash Full 033-725 In receive, memory full (under THRESH_MEMRX) BSD-ON:- BSD-ON:- One of the following errors was detected. 0x14 4: Warning Receiving Memory Full COMM_RESULTCODE_MEMORY_FULL. • During sequential broadcast send, memory full has occurred when the image is being Cause/Action stored. -

Page 97

033-753 Fax Scan Page Full BSD-ON:- During Fax Job, the Controller detected Page Full at the DADF/Platen. Cause/Action Press any button on the UI Panel. (The Fault will be cleared when Auto Reset is in operation and when the Job is started.) Version 1.0 Status Indicator RAPs 06/2014… -

Page 98

Status Indicator RAPs Version 1.0 06/2014 033-753 Fax Scan Page Full 2-76 WC 5022/5024… -

Page 99

034-522 No manual send Line 034-550 Fax Board Loader Download Fail BSD-ON:- BSD-ON:- One of the following errors was detected. When the Controller starts up (including at Power ON/Sleep recovery), it was detected that the Fax Board Loader is in Download Mode. There was an error in Fax Board Loader download; •… -

Page 100

034-711 Fax Send Count Limit 034-726 Fax Calling Table Full BSD-ON:- BSD-ON:- 0x23 4: Warning Redial Error COMM_RESULTCODE_ALL_REDIAL_FAIL. Communication Job Full received from the Fax Board. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). Press [Stop] on the UI Panel. Re-send the Fax and wait for it to complete or wait for the received output. -

Page 101

034-746 Line Connection Fail 034-752 Dial Busy BSD-ON:- BSD-ON:- 0x21 4: Warning Unable to Connect to Line T30_NO_LINE_CONNECT_ERR. 0x22 4: Warning Busy T30_DIAL_BUSY (Including the case where although an external line is connected, sensing was performed manually with no address (the telephone is not dialed)). Cause/Action Cause/Action Press [Stop] on the UI Panel. -

Page 102

034-757 Fax Document Does Not Delete 034-761 Fax Invalid Address book Data are Registered BSD-ON:- BSD-ON:- Unable to delete the specified file received from the Fax Board. Incorrect Address Book content registration (Telephone Book Data Error) received from the Fax Board. Cause/Action Cause/Action Clears automatically. -

Page 103

034-765 Fax Report Disabled BSD-ON:- Report Notification setting of OFF is received from the Fax Board. Cause/Action This Fault will clear automatically. Change the Report Notification setting to ON. Version 1.0 Status Indicator RAPs 06/2014 034-765 Fax Report Disabled WC 5022/5024 2-81… -

Page 104

Status Indicator RAPs Version 1.0 06/2014 034-765 Fax Report Disabled 2-82 WC 5022/5024… -

Page 105

035-550 FAX Board Download Flash Write Error 035-703 DCN Received at Phase B BSD-ON: CH34.1 BSD-ON:- Unable to write the Download File of Fax Board into the Flash ROM (SD Card). Or, the Fax 0x45 4: Warning T30_RXB_CMD_RCV_ERR. Board Communication Fail (033-313) has occurred. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). -

Page 106

035-704 Not Send Ability 035-708 Post Message Resend Over BSD-ON:- BSD-ON:- 0x48 4: Warning Other Party is Unable to Send T30_TRANSMIT_DENY_ERR. 0x60 4: Warning T30_EOP_RETRY_ERR. Cause/Action Cause/Action Press [Stop] on the UI Panel. Clears automatically during memory send (concluded within the Clears automatically (concluded within the Fax Board). -

Page 107

035-728 G3 EOL Not Receive 035-741 ECM Phase Timeout BSD-ON:- BSD-ON:- 0x52 4: Warning T30_RXC_NOEOL_DETECT_ERR. 0x84 4: Warning MODEM_TXTIMEOUT_ERR. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). Clears automatically (concluded within the Fax Board). Version 1.0 Status Indicator RAPs 06/2014 035-728 G3 EOL Not Receive WC 5022/5024… -

Page 108

035-748 Fax Card Stopped 035-758 Fax Document does not exist BSD-ON:- BSD-ON:- 0xFE 4: Warning Forced Stop received from the Fax Board FAX ERROR_ABOR. No specified file received from the Fax Board. Cause/Action Cause/Action Clears automatically. Clears automatically. Status Indicator RAPs Version 1.0 06/2014 035-748 Fax Card Stopped… -

Page 109

035-759 Fax Unable to Cancel Operation 035-761 Fax File Open Error BSD-ON:- BSD-ON:- No Polling Job and Unable to Cancel Job received from the Fax Board. Fail Error received from the Fax Board. Cause/Action Cause/Action Clears automatically. Press [Stop] on the UI Panel. Print out the Error Report and then replace the Fax PWB (PL 18.5). -

Page 110

Status Indicator RAPs Version 1.0 06/2014 035-761 Fax File Open Error 2-88 WC 5022/5024… -

Page 111

036-506 V8 Error 036-550 FAX Board Loader Download Flash Write Error BSD-ON:- BSD-ON:- 0x32 4: Warning V8 Negotiation T30_NO_V34_JM_ERR. Unable to write the Download File of Fax Board Loader into the Flash ROM (SD Card). Or, the Fax Board Communication Fail (033-313) has occurred. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). -

Page 112

036-700 Fax Board Unable Communication 036-740 Fax Board Busy BSD-ON:- BSD-ON:- Unable to do fax operations (machine setting in progress, Diag Mode in progress) received The Fax Board is communicating (receiving, etc.). from the Fax Board. Cause/Action Cause/Action Press [Stop] on the UI Panel. Clears automatically. -

Page 113

036-777 Control Channel Off Time Out 036-796 Fax Document Mix Fail BSD-ON:- BSD-ON:- 0x81 4: Warning T30_MODEM_ABORT_ERR. When memory transfer is in progress, this occurs when the Fax Box is performing mixed (mixed document) receive. Cause/Action Cause/Action Clears automatically (concluded within the Fax Board). Clears automatically (concluded within the Fax Board). -

Page 114

Status Indicator RAPs Version 1.0 06/2014 036-796 Fax Document Mix Fail 2-92 WC 5022/5024… -

Page 115

041-210/211 STM NVM Out-Of-Order/ STM NVM R/W Error BSD-ON: CH3.2 [STM NVM Out-Of-Order] The NVM of the STM is malfunctioning. [STM NVM R/W Error] Unable to perform NVM Read / Write for the STM. Cause/Action Turn the power OFF and ON. If the problem persists, replace the STM PWB. -

Page 116

Status Indicator RAPs Version 1.0 06/2014 041-210/211 STM NVM Out-Of-Order/ STM NVM R/W 2-94 WC 5022/5024… -

Page 117

042-325/614 Main Motor Rotation Error/ Main Motor 042-400 Smell Life Over Rotation Warning BSD-ON: BSD-ON: CH4.1 The Odor Filter is due for replacement. [Main Motor Rotation Error] Cause/Action The Main Drive Motor revolution failure was detected. When the Lock Up (Main Drive Motor •… -

Page 118

042-608 Voc Life Over BSD-ON: The Voc Filter is due for replacement. Cause/Action • Replace the Voc Filter and clear the VOC Filter HFSI Counter (950-806: COUNT_VOC_HFSI_COUNTER). Status Indicator RAPs Version 1.0 06/2014 042-608 Voc Life Over 2-96 WC 5022/5024… -

Page 119

045-310 Image Ready Error 045-313 IOT Logic Fail BSD-ON: CH3.3 BSD-ON:- Unable to send the Image-valid signal cannot within the specified time. The IOT Software error was detected. NOTE: When the attempt to expand the image has failed, [016-776 Marker Code Detection Cause/Action Fail] occurs after the recover operation. -

Page 120

Status Indicator RAPs Version 1.0 06/2014 045-313 IOT Logic Fail 2-98 WC 5022/5024… -

Page 121

047-218 MCU-2TM Communication Error BSD-ON: CH3.2 Communication failure between ESS/MCU PWB and 2TM PWB was detected. Cause/Action Check the connections of the following connectors: • ESS/MCU PWB J413 • STM PWB J541C/ J413C • 2TM PWB J541 Check the following harnesses for open circuits and poor contacts: •… -

Page 122

Status Indicator RAPs Version 1.0 06/2014 047-218 MCU-2TM Communication Error 2-100 WC 5022/5024… -

Page 123

061-321 ROS Motor Fail 061-325 No SOS Fail BSD-ON: CH6.5 BSD-ON: CH6.5 The number of rotation of the ROS Motor did not come within the standard range within the After the detection of ROS Motor Ready (steady rotation), the SOS interval was detected to be specified time (5 s) after the ROS Motor On. -

Page 124

Status Indicator RAPs Version 1.0 06/2014 061-325 No SOS Fail 2-102 WC 5022/5024… -

Page 125

062-277 DADF Communication Fail 062-300 Platen I/L Open BSD-ON: CH3.1 BSD-ON: CH6.1 Transmission cannot be established between the ESS/MCU PWB and the DADF PWB. • The DADF was opened when there is a document inserted in the DADF. • A document is inserted into the DADF when the DADF is open. Cause/Action Turn the power OFF and ON. -

Page 126

062-311 IIT Software Logic Fail 062-360 Carriage Position Fail BSD-ON:- BSD-ON: CH6.3 A software error was detected at the ESS/MCU PWB. Any of the following was detected: Cause/Action • An error with the count value of the Carriage Position Control. •… -

Page 127

062-371/380 Lamp Illumination Fail/ AGC Fail Table 1 Current value Component Name PL No. BSD-ON: CH6.4 This value is not displayed [Lamp Illumination Fail] This value is not displayed This value is not displayed Insufficient light from Lamp detected in CCD. (During white gradation correction/AGC before This value is not displayed Scan starts) LED Lamp Wire Harness… -

Page 128

062-386 AOC Fail 062-389 Carriage Over Run Fail (Scan End Side) BSD-ON: CH6.4 BSD-ON: CH6.3 A CCD output error was detected when performing AOC. The Carriage has overrun at the Scan End. Cause/Action Cause/Action Turn ON the power and enter the Diag mode. Change the value for NVM [715-030] to ‘1’ Check the following: and then perform [NVM Write]. -

Page 129

062-396 CCD Cable Connection Fail BSD-ON: CH3.1 A CCD Flat Cable connection error was detected. Cause/Action Turn the power OFF and ON. Turn OFF the power and check the Flat Cable between the CCD PWB J700 and the ESS/MCU PWB J420 for open circuits, short circuits, and poor contacts (especially, check whether the Flat Cable was inserted in a skewed manner). -

Page 130

Status Indicator RAPs Version 1.0 06/2014 062-396 CCD Cable Connection Fail 2-108 WC 5022/5024… -

Page 131

071-105 Regi Sensor On Jam (Tray 1) BSD-ON: CH8.4, CH4.1, CH8.1 During paper feed from Tray 1, the Regi Sensor did not turn ON within the specified time after the Tray 1 Feed Clutch On. Cause/Action Check the following: • The Regi Sensor (Input Check [071-105]) for operation failure. -

Page 132

Status Indicator RAPs Version 1.0 06/2014 071-105 Regi Sensor On Jam (Tray 1) 2-110 WC 5022/5024… -

Page 133

072-102 Feed Out Sensor 2 On Jam 072-105 Regi Sensor On Jam (Tray 2) BSD-ON: CH8.2, CH7.6 BSD-ON: CH8.4, CH8.2 During paper feed from Tray 2, the Feed Out Sensor 2 did not turn ON within the specified time During paper feed from Tray 2, the Regi Sensor did not turn ON within the specified time after after the Tray 2 Feed Motor On. -

Page 134

072-210 Tray 2 Lift Up Fail 072-212 Tray 2 Size Sensor Broken BSD-ON: CH7.6 BSD-ON: CH7.2 Any of the following was detected: Abnormal output AD value from Tray 2 Paper Size Switch was detected. • A Tray 2 Lifter error. Cause/Action •… -

Page 135

072-215 MCU-STM Communication Fail 072-461 STM NVM Out-Of-Order BSD-ON: CH3.2 BSD-ON: CH3.2 Communication failure between the ESS/MCU PWB and the STM PWB was detected. The NVM of the STM is malfunctioning. Cause/Action NOTE: If this is already detected, it will be displayed on the UI Panel when a Job is being per- formed. -

Page 136

072-470 STM NVM R/W Error BSD-ON: CH3.2 The NVM of the STM cannot be read or written. NOTE: If this is already detected, it will be displayed on the UI Panel when a Job is being per- formed. Initial Actions Refer to the BSD and check the related connectors of the target electrical parts for partial con- nections. -

Page 137

073-102 Feed Out Sensor 3 On Jam (Tray 3) 073-104 Feed Out Sensor 2 On Jam (Tray 3) BSD-ON: CH8.3 BSD-ON: CH8.2 The Feed Out Sensor 3 did not turn ON within the specified time after the Paper had been fed The Feed Out Sensor 2 did not turn ON within the specified time after the Feed Out Sensor 3 is from Tray 3. -

Page 138

073-105 Regi Sensor On Jam (Tray 3) 073-210 Tray 3 Lift Up Fail BSD-ON: CH8.4 BSD-ON: CH7.7 The Regi Sensor did not turn ON within the specified time after the Feed Out Sensor 2 is On One of the following errors was detected. during paper feed from Tray 3. -

Page 139

074-101 Feed Out Sensor 4 On Jam (Tray 4) 074-102 Feed Out Sensor 3 On Jam (Tray 4) BSD-ON: CH8.3 BSD-ON: CH8.3 The Feed Out Sensor 4 did not turn ON within the specified time after the Paper had been fed The Feed Out Sensor 3 did not turn ON within the specified time after the Feed Out Sensor 4 is from Tray 4. -

Page 140

074-104 Feed Out Sensor 2 On Jam (Tray 4) 074-105 Regi. Sensor On Jam (Tray 4) BSD-ON: CH8.2 BSD-ON: CH8.4 The Feed Out Sensor 2 did not turn ON within the specified time after the Feed Out Sensor 3 is The Regi Sensor did not turn ON within the specified time after the Feed Out Sensor 2 is On On during paper feed from Tray 4. -

Page 141

074-210 Tray 4 Lift Up Fail BSD-ON: CH7.8 One of the following errors was detected. • The Tray 4 Lifter error was detected. • The Tray 4 Paper Size detector component malfunction was detected. NOTE: If this is already detected, it will be displayed on the UI Panel when a Job is being per- formed. -

Page 142

Status Indicator RAPs Version 1.0 06/2014 074-210 Tray 4 Lift Up Fail 2-120 WC 5022/5024… -

Page 143

075-135 Regi Sensor On Jam (MSI) BSD-ON: CH8.4, CH4.1, CH8.1 During paper feed from the MSI, the Regi Sensor did not turn ON within the specified time after the MSI Feed Clutch On. Cause/Action Check the following: • The Regi Sensor (Input Check [071-105]) for operation failure. (PL 15.1) •… -

Page 144

Status Indicator RAPs Version 1.0 06/2014 075-135 Regi Sensor On Jam (MSI) 2-122 WC 5022/5024… -

Page 145

077-101 Regi Sensor Off Jam 077-103 Fusing Unit Exit Sensor Off Jam (Long) BSD-ON: CH8.4, CH4.1 BSD-ON: CH10.3, CH4.1, CH10.4 The Regi Sensor did not turn OFF within the specified time after the Regi Clutch On. After the Regi Sensor Off, the Fusing Unit Exit Sensor did not turn OFF within the specified time. -

Page 146

077-104 Fusing Unit Exit Sensor Off Jam (Short) 077-106 Fusing Unit Exit Sensor On Jam BSD-ON: CH10.3, CH4.1, CH10.4 BSD-ON: CH10.3, CH4.1 The time taken for the Fusing Unit Exit Sensor to turn from ON to OFF is shorter than the spec- The Fusing Unit Exit Sensor did not turn ON within the specified time after the Regi Clutch On. -

Page 147

077-129 Regi Sensor On Jam (Duplex Wait) 077-211 2TM Type Error BSD-ON: CH8.4, CH4.1, CH10.4 BSD-ON: CH3.2 During the paper stop at the invert wait position at Duplex print, the Regi Sensor did not turn An unsupported 2TM was detected to be connected. ON within the specified time after the Duplex Clutch On. -

Page 148

077-212 Tray Module Reset Fail 077-300 Front Cover Open BSD-ON: CH3.2 BSD-ON: CH1.4 The Tray Module was detected to be reset. The Front Cover Switch was detected to be open. Cause/Action Cause/Action Turn the power OFF and ON. Check the Front Cover Switch for operation failure. Check voltages of the following pins: •… -

Page 149

077-301 Left Hand Cover Open 077-305 2TM Cover Open BSD-ON: CH1.4 BSD-ON: CH1.4 The Left Hand Cover Switch was detected to be open. The 2TM Left Cover Switch was detected to be open. Cause/Action Cause/Action Check the Left Hand Cover Switch for operation failure. Check the 2TM Left Cover Switch for operation failure. -

Page 150

077-309 STM Cover Open 077-900/901/904 Regi Sensor/Fusing Unit Exit Sensor/ Feed Out Sensor 2 Static Jam BSD-ON: CH1.4 BSD-ON: CH8.4, CH10.3, CH8.2 The STM Left Cover Switch was detected to be open. BSD-ON: Cause/Action Check the STM Left Cover Switch for operation failure. Paper was detected by the applicable sensor at Power ON, M/C Stop, or Interlock Close. -

Page 151

077-905 Feed Out Sensor 3 Static Jam 077-906 Feed Out Sensor 4 Static Jam BSD-ON: CH8.3 BSD-ON: CH8.3 Feed Out Sensor 3 On was detected during Standby. Feed Out Sensor 4 On was detected during Standby. Initial Actions Initial Actions Refer to the BSD and check the related connectors of the target electrical parts for partial con- Refer to the BSD and check the related connectors of the target electrical parts for partial con- nections. -

Page 152

Status Indicator RAPs Version 1.0 06/2014 077-906 Feed Out Sensor 4 Static Jam 2-130 WC 5022/5024… -

Page 153

091-401/402 Drum Cartridge Quality Life Over/ Drum 091-406/424 Drum Cartridge Normal Life Over/ Drum Cartridge Life Over Cartridge Abnormal Life Over BSD-ON: CH4.1 BSD-ON: CH4.1 [Drum Cartridge Quality Life Over] [Drum Cartridge Normal Life Over] The image quality guarantee period for the Drum Cartridge has ended. (When Drum Hard The operation guarantee period for the Drum Cartridge has ended. -

Page 154

091-430 Drum Cartridge Life End 091-440 Drum Cartridge Pre Near End BSD-ON: CH4.1 BSD-ON: CH4.1 The Drum Cartridge must be replaced. Preparation for replacing the Drum Cartridge is required. Cause/Action Cause/Action Replace the Drum Cartridge. (PL 8.1) The Drum Cartridge needs to be replaced soon. Prepare a new Drum Cartridge. Replace the Drum Cartridge as required. -

Page 155

091-441 Drum Cartridge Near End BSD-ON: CH4.1 The Drum Cartridge needs to be replaced soon. Cause/Action The Drum Cartridge needs to be replaced soon. Replace the Drum Cartridge as required. (PL 8.1) NOTE: After replacing the Drum Cartridge, clear the HFSI [950-807] (Drum Cycle Counter) to ‘0’. -

Page 156

Status Indicator RAPs Version 1.0 06/2014 091-441 Drum Cartridge Near End 2-134 WC 5022/5024… -

Page 157

092-660/668 ATC Amplitude Fail/ ATC Average Fail 092-661 Temperature Sensor Fail BSD-ON: CH9.2 BSD-ON: CH9.3 [ATC Amplitude Fail] The output value of the Temperature Sensor is not within the specification range. The output amplitude of the ATC Sensor in the ATC (Automatic Toner Control) measurement is Cause/Action small. -

Page 158

092-910 ATC Sensor Fail BSD-ON: CH9.2 The frequency at which the ATC Average Fail or the ATC Amplitude Fail has been occurring is at the threshold value or higher. NOTE: To clear this Fail, clear the value of NVM [752-036] (ATC Fail) or NVM [752-038] (ATC Fail Continuous Count) to ‘0’. -

Page 159