Современные копировальные аппараты Xerox отличаются качество, надежностью и «быстрым» стартом. Также у них существует множество особенностей, которые отличают их от принтеров других производителей. Например, используется тефлоновый вал, а не термопленка.

Однако избегать различных поломок и ошибок пока не удается ни одному устройству. К самым частым неисправностям у принтеров Xerox относятся: залипание или повреждение датчика бумаги, повреждение роликов подачи, часто требуется перепрошивка программного обеспечения.

Если у вас возникнут вопросы насчет того, как исправить код ошибки копировального аппарата Xerox, то вы можете обратиться к специалистам нашего сервисного центра.

Основные коды ошибок копировальных аппаратов Xerox и способы их устранения:

- Коды ошибок Xerox 1012, 1012(RE)

- Коды ошибок Xerox 1020

- Коды ошибок Xerox 1025

- Коды ошибок Xerox 1035

- Коды ошибок Xerox 1038

- Коды ошибок Xerox 2830

- Коды ошибок Xerox 5011, 5012, 5014

- Коды ошибок Xerox 5016, 5017, 5316, 5317

- Коды ошибок Xerox 5018, 5028

- Коды ошибок Xerox 5312, 5313, 5314

- Коды ошибок Xerox 5318, 5320, 5322

- Коды ошибок Xerox 5328

- Коды ошибок Xerox 5330

- Коды ошибок Xerox 5340, 5343

- Коды ошибок Xerox 5345

- Коды ошибок Xerox 5350, 5352

- Коды ошибок Xerox 5355

- Коды ошибок Xerox 5622

- Коды ошибок Xerox XC520, 540, 560, 580

Xerox 1012, 1012(RE)

| Код ошибки | Описание |

|---|---|

| E1 | Jam between paper feed and fuser |

| E3 | Jam in fuser |

| E5 | Clam shell open |

| E6 | Paper feed section cover is open |

| J1 | Toner cartridge near empty |

| J3 | Drum cartridge not seated properly |

| J7 | Waste toner full (replace drum cartridge) |

| L6 | Key counter out |

| L8 | Exposure area overheat |

| U1 | No clock pulse (drive problem) |

| U2 | Scan problem |

| U3 | Lens/mirror problem (RE model only) |

| U4 | Heat problem |

| U8 | Exposure lamp control circuit problem |

| E1 | Jam between paper feed and fuser |

| E3 | Jam in fuser |

| E5 | Clam shell open |

| E6 | Paper feed section cover is open |

| J1 | Toner cartridge near empty |

| J3 | Drum cartridge not seated properly |

| J7 | Waste toner full (replace drum cartridge) |

| L6 | Key counter out |

| L8 | Exposure area overheat |

| U1 | No clock pulse (drive problem) |

| U2 | Scan problem |

| U3 | Lens/mirror problem (RE model only) |

| U4 | Heat problem |

| U8 | Exposure lamp control circuit problem |

Xerox 1020

| Код ошибки | Описание |

|---|---|

| LL | Probable bad heater lamp |

Xerox 1025

| Код ошибки | Описание |

|---|---|

| A1 | DF jam |

| C1 | PF jam cass. 1 |

| C2 | PF jam cass. 2 |

| C3 | PF jam cass. 3 |

| C9 | Bypass jam |

| E1-1 | Paper jam before exit switch |

| E1-2 | Paper jam |

| E1-5 | Paper jam |

| E1-6 | Paper jam |

| E3-3 | Paper jam at exit switch |

| E3-4 | Paper jam at exit switch |

| E5 | Front door open |

| F1 | Collator jam |

| F5 | Collator interlock |

| F8 | No power to collator |

| F9 | Collator bin home switch |

| J7 | 250 copies since toner waste was full |

| L5 | Original cass. not present after clearing interrupt |

| L6 | Key counter |

| L8 | Platen glass too hot |

| U1 | Main motor clock pulse |

| U2 | Scan problem |

| U3-1 | Lens problem |

| U4-1 | Open thermistor |

| U4-2 | Low temperature |

| U4-4 | Temperature |

| U4-5 | Main PWB |

| U6-1 | Main PWB |

| U6-2 | Main PWB |

| U6-3 | Main board battery |

| U6-4 | Initialization |

| U8 | Exposure lamp |

Xerox 1035

| Код ошибки | Описание |

|---|---|

| A9 | Scanner location |

| C1 | Paper feed — upper cassette |

| C2 | Paper feed — lower cassette |

| C9 | Bypass jam |

| E5 | Clam shell is open |

| L6 | Key counter |

| U1 | Off/On |

| U2 | Optics |

| U4 | Low fuser temperature |

Xerox 1038

| Код ошибки | Описание |

|---|---|

| A1 | DF jam |

| C1 | PF jam cass. 1 |

| C2 | PF jam cass. 2 |

| C3 | PF jam cass. 3 |

| C9 | Bypass jam |

| E1-1 | Paper jam before exit switch |

| E1-2 | Paper jam |

| E1-5 | Paper jam |

| E1-6 | Paper jam |

| E3-3 | Paper jam at exit switch |

| E3-4 | Paper jam at exit switch |

| E5 | Front door open |

| F1 | Collator jam |

| F5 | Collator interlock |

| F8 | No power to collator |

| F9 | Collator bin home switch |

| J7 | 250 copies since toner waste was full |

| L5 | Original cass. not present after clearing interrupt |

| L6 | Key counter |

| L8 | Platen glass too hot |

| U1 | Main motor clock pulse |

| U2 | Scan problem |

| U3-1 | Lens problem |

| U4-1 | Open thermistor |

| U4-2 | Low temperature |

| U4-4 | Temperature |

| U4-5 | Main PWB |

| U6-1 | Main PWB |

| U6-2 | Main PWB |

| U6-3 | Main board battery |

| U6-4 | Initialization |

| U8 | Exposure lamp |

Xerox 2830

| Код ошибки | Описание |

|---|---|

| A9 | Scanner location |

| C1 | Paper feed — upper cassette |

| C2 | Paper feed — lower cassette |

| C9 | Bypass jam |

| E5 | Clam shell is open |

| E5 | Clam shell open |

| L6 | Key counter |

| U1 | Off/On |

| U2 | Optics |

| U4 | Low fuser temperature |

Xerox 5011, 5012, 5014

| Код ошибки | Описание |

|---|---|

| C8 | Bypass jam/no paper |

| C9 | Bypass jam |

| E1 | Jam |

| E3 | Fuser jam |

| E5 | Clamshell open |

| E6 | PF section cover open |

| J1 | Toner cartridge amost empty |

| J3 | Copy cart (drum unit) missing/not seated right |

| J7 | Copy cartridge has run 18,000 copies |

| J8 | Copy cartridge. Improperly seated or possible only one of two fuses in the cartridge blew |

| L6 | Key counter |

| L8 | Exposure glass too hot |

| U1 | Drive problem |

| U2 | Scan problem |

| U3 | Lens or mirror drive problem |

| U4 | Fuser problem. Heat lamp, thermoswitch, SSR, thermistor |

| U6 | Battery on main board |

| U8 | Exposure lamp or exposure lamp circuit |

Xerox 5016, 5017, 5316, 5317

| Code | Description |

|---|---|

| A1-1 | Document feeder feed jam |

| A1-2 | Document feeder belt jam |

| A2-1 | Document feeder exit jam |

| A2-2 | Duplex jam |

| A3 | DAD interlock |

| A5 | Duplex and DAD right side interlock |

| A6 | Copier jams after |

| A9 | Document feed belt drive motor |

| C1-3 | Top cassette misfeed |

| C2-3 | Middle cassette misfeed |

| C3-3 | Bottom cassette misfeed |

| C9-3 | Bypass misfeed |

| E1-11 to E1-14 | Paper jam in machine. Did not reach exit switch soon enough |

| E1-6 | Paper path jam |

| E3-31 to E3-34 | Exit switch jam |

| E3-6 | Fuser jam |

| E5 | Front door interlock |

| E6 | Right side interlock or TTM interlock |

| F1 | Sorter jam |

| F5 | Sorter interlock |

| F8 | Sorter board to copier main board communication problem |

| F9 | Sorter bins |

Xerox 5018, 5028

| Code | Description |

|---|---|

| A1 | Document is ADF |

| A1-8 | Main board received reset signal |

| A2 | ADF jams |

| A6, A7 | ADF jams |

| A9 | ADF jams |

| C1 — C4 | Feed jam |

| C5-1 to C5-4 | Jams in various areas |

| C5-2 | Jams in various areas |

| C5-3 | Jams in various areas |

| C5-4 | Duplex jam |

| E0 | Machine has reset |

| E1 | Jam |

| E1-E0 | Registration jam |

| E1-E5 | Clamshell interlock |

| E1-E6 | Right side interlock |

| E1-E7 | Two tray interlock |

| E1-E8 | Sorter interlock |

| E1-E9 | Copy cartridge interlock |

| E2 | Reset signal happened |

| E3 | Jam |

| E4 | Exit jam |

| E4-10 | Exit jam |

| E4-5 | Clamshell interlock |

| E4-6 | Right side interlock |

| E4-7 | Two tray interlock. Duplex interlock |

| E4-8 | Sorter interlock |

| E4-9 | Copy cartridge interlock |

| E5 | Clamshell interlock |

| E6 | Right side interlock |

| E7 | Duplex interlock |

| E9 | Copy cartridge interlock |

| F3-1 | Sorter bin home switch |

| F3-2 | Sorter cam switch |

| F3-3 | Sorter cam switch |

| J1-1 | Add toner |

| J1-2 | Temporary low toner signal |

| J2-0 | Replace copy cartridge |

| L2 | 2000 copies left on copy cartridge |

| L3 | ADF to machine communication problem |

| L4 (flashing) | 1000 copies left on fuser web |

| rr | Bad EPROM on main board |

| U0 | Main board |

| U2 | Scan problem |

| U2-1 | Scan home |

| U3-00 | Cam drive problem |

| U3-01 | Cam movement slow |

| U3-04 | Main board to duplex communication |

| U3-09 | Cam problem |

| U3-12 | Jogger problem |

| U3-19 | Cam problem |

| U3-21 | Cam problem |

| U3-23 | Cam problem |

| U3-29 | Cam problem |

| U3-32 | Cam problem |

| U3-34 | Cam problem |

| U3-39 | Cam problem |

| U3-43 | Cam problem |

| U3-45 | Cam problem |

| U3-49 | Cam problem |

| U3-54 | Cam problem |

| U3-56 | Cam problem |

| U3-59 | Cam problem |

| U4-1 | Fuser problem. Long warm up |

| U4-2 | Low fuser temperature after warm up |

| U4-3 | High fuser temperature |

| U4-4 | Open fuser thermistor |

| U4-6 | Replace fuser web |

| U4-7 | Thermistor signal problem |

| U7-1 | Copy cartridge belt drive problem |

| U9-3 | Exposure lamp problem |

| U9-4 | Toner motor |

| U9-5 | Problem in warm up |

Xerox 5312, 5313, 5314

| Код ошибки | Описание |

|---|---|

| C1 | Upper paper feed problem. Did not reach feed sensor |

| C2 | Lower paper feed problem. Did not reach feed sensor |

| E1 | Exit jam. Paper did not reach exit sensor |

| E3 | Exit jam. Paper still on exit sensor |

| J1 | Add toner |

| J3 | Copy cartridge (drum unit) not installed |

| J7 | Copy cartridge (drum unit) must be replaced |

| J8 | Copy cartridge (drum unit) problem |

| L6 | Problem with an accessory. Installed but not initialized |

| U1 | Drive problem. Main motor, gear etc. |

| U2 | Scan problem |

| U3 | Main board dip switches wrong. Lens drive problem |

| U4 | Fuser problem. Heat lamp, thermal switch, overheat, thermistor. |

| U6 | EPROM error |

| U8 | Auto exposure sensor. No exposure lamp or weak lamp |

Xerox 5318, 5320, 5322

| Code | Description |

|---|---|

| A1-11 | Original ready switch |

| A1-12 | Feed sensor |

| A1-1 to A1-32 | All indicate a paper path problem, etc. in the ADF |

| A1-21 | Original ready switch and document registration sensor or both the document feed sensor and document registration sensor |

| A1-22 | ADF registration sensor |

| A1-23 | Original did not reach ADF registration sensor quickly enough |

| A1-24 | ADF sensor stuck down too long |

| A1-25 | ADF sensor actuated at the wrong time during single sheet feed |

| A1-26 | ADF sensor not actuated quickly enough in sheet feed mode |

| A1-31 | In reverse, ADF sensor is not actuated soon enough |

| A1-32 | In reverse, ADF sensor is actuated too long |

| A2 | ADF exit problems |

| A2-1 | Original ready sensor and ADF exit switch are actuated or ADF feed in sensor and ADF exit switch are both actuated |

| A2-2 | ADF exit switch |

| A2-3 | ADF exit switch is not actuated on time |

| A3 | Irregular size documents |

| A3-1 | Wrong size original sensed in 1:1 mode |

| A3-2 | Wrong size original sensed in the 2:1 mode |

| A5 | ADF interlock |

| A5 | ADF interlock |

| A6 | ADF single sheet document reset. |

| A6-1 | Reset original |

| A6-2 | Reset sheet feeder |

| A7 | Document cover interlock |

| A8 | ADF exit interlock |

| C1 | Tray 1 jam |

| C1-2 | Paper feed problem in tray 1 |

| C1-3 | Paper does not reach registration |

| C2 | Tray 2 jam |

| C3 | Tray 3 jam |

| C3-1 | Paper feed problem from tray 3 |

| C3-2 | Paper feed problem from tray 3 |

| C3-3 | Paper feed problem from tray 1 |

| C6-1 | Duplex paper feed problem |

| C6-2 | Duplex and/or tray 1 paper feed problem |

| C6-3 | Paper feed problem from tray 1 |

| C7-1 | Paper feed problem from HCF |

| C7-2 | Paper feed problem from HCF on tray 1 |

| C7-3 | Paper feed problem from tray 1 |

| C8 | Paper stays in tray or duplex or HCF |

| C8-1 | Paper on tray 1 feed sensor |

| C8-2 | Paper on tray 2 feed sensor |

| C8-3 | Paper on tray 3 feed sensor |

| C8-4 | Paper on HCF feed sensor |

| C8-5 | Paper in duplex section |

| C9 | Bypass feed problem |

| C9-3 | Paper from bypass did not reach registration sensor quickly enough |

| E1-10 to E1-25 | Internal jam |

| E1-6 | Paper on registration sensor |

| E2 | Reset signal happened. Might read E-2 something else. |

| E3-30 to E4-14 | Exit jam |

| E3-30 to E3-35 | Exit switch actuated too long |

| E3-6 | Exit jam |

| E3-6 | Paper on exit switch |

| E4-10 to E4-14 | Inverter sensor not actuated. |

| E4-10 to E4-45 | Paper did not reach inverter switch soon enough |

| E4-15 | Inverter sensor |

| E4-40 to E4-45 | Duplex entry sensor |

| E4-6 | Paper on inverter switch |

| E4-6 | Inverter sensor |

| E5 | Front door interlock |

| E6-1 | Tray 1 interlock |

| E6-2 | 2 tray or duplex interlock |

| E6-3 | HCF interlock |

| E7-2 | Duplex inverter interlock |

| E7-3 | Duplex interlock |

| E8-10 to E8-15 | Paper on duplex feed sensor is not actuated soon enough |

| E8-6 | Paper in duplex |

| E8-6 to E8-15 | Duplex entry sensor |

| F1-1 | Paper did not reach sorter |

| F1-2 | Paper stayed on sorter feed sensor |

| F1-6 | Sorter exit sensor |

| F3 | Paper size not available for sort/stack |

| F5 | Sorter interlock |

| H2-1 | Communication problem between main board and duplex board |

| H2-2 | Side guard sensor problem |

| H3-1 | Communication problem between main board and HCF |

| H3-2 | Upper limit sensor problem on HCF |

| H6-1 | ADF size sensor |

| H6-2 | ADF nudgeer sensor |

| H6-3 | Belt drive motor does not have 24 volts. Black toner is empty, but 100 copies have been run without changing toner |

| J1 | Black toner is empty, but 100 copies have been run without changing toner |

| J3 | Replace copy cartridge |

| J3 | No copy cartridge (drum unit) |

| J7 | Copy cartrige must be replaced |

| J8-1 | Wrong copy cartridge installed |

| J8-2 | Copy cartridge EEPROM must be changed |

| L6 | Auditron or other counter problem |

| L6 | Key counter not installed |

| L8 | Platen glass temperature is too high |

| L9 | Communication problem between interimage erase/edge lamps and main board |

| U1-1 | Main motor drive problem |

| U2-1 | Scan home problem |

| U2-1 to U2-4 | Scan home sensor |

| U2-2 | Scan home problem or optics problem |

| U2-3, U2-4 | Scan home problem |

| U3-1 | Lens sensor problem |

| U4-1 | Fuser thermistor open |

| U4-2 | Fuser did not warm up properly |

| U4-3 | Fuser temperature too high |

| U4-4 | Fuser problem. Staying on too long |

| U4-6 | High fuser temperature |

| U5-1 | Sorter bin home switch not activated |

| U5-2 | Sorter bin home switch stayed actuated |

| U5-3 | Sorter bin home switch |

| U5-4 | Sorter bin home switch |

| U6-1 | ROM problem |

| U6-2 | RAM problem |

| U6-3 | Low battery |

| U6-4 | Incorrect value in NVM. Reinitialize main board with code 20-96 |

| U8-1 | Exposure lamp problem |

| U8-2 | Communication problem main board and exposure board |

| U8-3 | Exposure lamp or exposure lamp board problem |

| U8-4 to U8-6 | Problem with exposure lamp, lamp sensor, lamp board |

Xerox 5328

| Code | Description |

|---|---|

| A1 | Document in ADF |

| A1-8 | Main board received reset signal |

| A2 | ADF jams |

| A6 | ADF registration jam |

| A7 | ADF interlock |

| A9 | Tray 1 jam |

| C1 | Tray 2 jam |

| C2 | Tray 3 jam |

| C3 | Bypass feed jams |

| C4 | Machine has reset |

| E1 | Jam |

| E1-5 | Clamshell interlock |

| E1-6 | Right side interlock |

| E1-7 | Two tray interlock, or duplex interlock |

| E1-8 | Sorter interlock |

| E1-9 | Copy cartridge interlock |

| E1 or E1-0 | Registration jam |

| E2 | Reset signal happened |

| E3 | Jam in transfer area |

| E4 | Exit jam |

| E4-0 | Exit jam |

| E4-5 | Clamshell interlock |

| E4-6 | Right side interlock |

| E4-7 | Two tray interlock |

| E4-8 | Sorter interlock |

| E4-9 | Copy cartridge interlock |

| E5 | Clamshell interlock |

| E6 | Right side interlock |

| E9 | Copy cartridge interlock |

| F3-1 | Sorter bin home switch |

| F3-2 | Sorter cam switch |

| F3-3 | Sorter cam switch |

| F5 | Sorter interlock |

| J1-1 | Add toner |

| J1-2 | Temporary low toner signal |

| J2-1, J2-2 | Replace copy cartridge |

| J5, J6 | ADF to machine communications problem |

| L2 | 2000 copies left on cartridge |

| L3 | ADF to machine communications problem |

| L4 | (flashing) 1000 copier left on fuser web |

| L6 | Auditron or other counter problem |

| LL | Main board. Try simulation 1.1 to initialize |

| rc | Wrong operation panel installed |

| rr | Bad EPROM on main board. Try 1.1 |

| U0 | Main board |

| U2 | Scan problem |

| U2-1 | Scan home |

| U2-2 | Scan home or scan encoder |

| U2-4 | Scan home or scan dual page sensor |

| U2-7 | Scan home |

| U4-1 | Fuser problem. Long warm up |

| U4-2 | Low fuser temperature after warm up |

| U4-3 | High fuser temperature |

| U4-4 | Open fuser thermistor |

| U4-6 | Replace fuser web. |

| U4-7 | Thermistor signal problem |

| U7-1 | Copy cartridge belt drive problem |

| U9-3 | Exposure lamp problem |

| U9-4 | Toner motor |

| U9-5 | Problem in warm-up |

Xerox 5330

| Code | Description |

|---|---|

| A1-1 to A1-32 | All indicate a paper path problem, etc. in the ADF. |

| A2 | ADF exit problems |

| A3 | Irregular size documents |

| A5 | ADF interlock |

| A6 | ADF single sheet document reset. |

| A7 | Platen interlock |

| A8 | ADF exit interlock |

| C1 | Tray 1 jam |

| C2 | Tray 2 jam |

| C3 | Tray 3 jam |

| C6-1, C6-2 | Jams related to duplex |

| C6-3 | Registration sensor, re tray 1 |

| C7-1, C7-2 | HCF feed problems |

| C7-3 | Tray 1 feed problem |

| C8 | Paper stays in tray or duplex or HCF |

| C9 | Bypass feed problem |

| E1-10 to E1-25 | Internal jam |

| E1-6 | Paper on registration sensor |

| E2 | Reset signal happened. Might read E-2 something else. |

| E3-30 to E4-14 | Exit jam |

| E3-6 | Exit jam |

| E4-10 to E4-14 | Inverter sensor not actuated. |

| E4-15 | Inverter sensor |

| E4-40 to E4-45 | Duplex entry sensor |

| E4-6 | Inverter sensor |

| E5 | Front door interlock |

| E6-1 | Tray 1 interlock |

| E6-2 | 2 tray or duplex interlock |

| E6-3 | HCF interlock |

| E7-2, E7-3 | Duplex interlock |

| E8-6 to E8-15 | Duplex entry sensor |

| F1-1 | Sorter entry sensor |

| F1-6 | Sorter exit sensor |

| F3 | Paper size not available for sort/stack |

| F5 | Sorter interlock |

| J1 | Add toner |

| J3 | Replace copy cartridge |

| J7 | Replace copy cartridge |

| J8-1 | Wrong copy cartridge installed |

| J8-2 | Copy cartridge EEPROM |

| L6 | Auditron or other counter problem |

| L8 | Platen glass temperature is too high |

| L9 | Communication problem between interimage erase/edge lamps and main board |

| U1-1 | Main motor drive problem |

| U2-1 to U2-4 | Scan home sensor |

| U3-1 | Lens sensor |

| U4-1 | Open fuser thermistor |

| U4-2 | Fuser did not warm up properly |

| U4-3 | Fuser temperature too high |

| U4-4 | Fuser problem. Staying on too long |

| U4-6 | High fuser temperature |

| U5-1 | Sorter bin home switch not activated |

| U5-2 | Sorter bin home switch stayed actuated |

| U5-3 | Sorter bin home switch |

| U5-4 | Sorter bin home switch |

| U6-1 | ROM problem |

| U6-2 | RAM problem |

| U6-3 | Low battery |

| U6-4 | Incorrect value in NVM. Reinitialize main board with code 20-96 |

| U8-1 to U8-6 | Problem with exposure lamp, lamp sensor, lamp board |

Xerox 5340, 5343

| Code | Description |

|---|---|

| 00-009; 030 to 033 | A door was opened while paper was being fed |

| 00-047 | Paper in duplex |

| 00-1 | Auditron |

| 00-2 | Diagnostic error |

| 00-3 | Faults error |

| 00-4 | Ric error |

| 00-5 | Job manager system error |

| 00-6 | LLM interface |

| 00-7 | Standby error |

| 00-8 | Communications error |

| 00-9 | Xerographic error |

| 01-300 | Front interlock |

| 01-310 | Right upper interlock |

| 01-315 | Left upper interlock |

| 01-320 | Left lower interlock |

| 01-325 | Fuser interlock |

| 02-910 | Key counter missing |

| 02-920 | Wrong combination of accessories |

| 03-321, 322, 326, 327 | LLM to ISIL communications problems |

| 03-328 | IOT communications problem with duplex or tray 4 |

| 03-330 | IOT communications problems with HCF |

| 03-335, 03-336 | LLM communications problems with edit |

| 03-340 | NVM memory |

| 03-341, 03-347 | Communications problems between IOT and sorter |

| 03-350, 03-354 | Communications problem with LLM and user interface |

| 03-363, 03-364 | Communications problem between LLM & optics |

| 03-370, 03-373 | Communications problem between LLM & DADF |

| 03-380, 384 | |

| 03-416, 03-422 | RAM memory problem |

| 03-424, 426 | NVM memory problem |

| 03-430, 432 | Billing problem |

| 03-439 | GRAIB communications problem |

| 03-440 | RIC communications problem |

| 03-441 | RIC NVM problem |

| 03-442 | Modem |

| 03-443, 03-458 | RIC problems |

| 03-460 | Serial communications processor problem |

| 04-300 | Main motor or drive problem |

| 05-100, 05-108 | DADF registration sensor |

| 05-110 | DADF exit sensor |

| 05-115, 120 | DADF jams |

| 05-305 | DADF document drive |

| 05-310, 312 | DADF document sensor |

| 05-316 | DADF registration sensor jam |

| 05-325 | DADF exit sensor |

| 05-335, 341, 345 | DADF interlock switches |

| 06-300, 06-310 | Scan problems |

| 06-315 | Scan drive |

| 06-320A, 320B, 320C, 325 | Scan problem |

| 06-330 | Lens drive |

| 06-340 | Exposure control problem |

| 06-342 | LLM CPU problem |

| 06-344, 06-350 | Exposure cvontrol problem |

| 06-352 | IOT CPU problem |

| 07-300, 315, 330, 345 | Tray faults |

| 07-360, 07-370 | HCF problems |

| 07-375, 380A, 380B | Duplex problems |

| 08-100, 08-110 | Feed problems. Lead edge of copy paper is late getting to feed sensor of tray 1 |

| 08-115, 08-162 | Feed problem. Lead edge of copy paper is late getting to registration sensor |

| 08-165 | Paper jam at registration sensor |

| 08-310, 08-370 | Paper at a sensor when power is turned on |

| 08-330 | DADF nudger sensor |

| 08-380 | Registration side to side problem with home position |

| 08-390 | Nip |

| 09-300 | Copy cartridge finished (drum unit) |

| 09-310 | Add black toner Add color toner |

| 09-320 | Add color toner |

| 09-330 | Wrong copy cartridge (wrong drum unit) |

| 09-340 | Drum cartridge not installed properly |

| 09-350 | Waste toner full |

| 100 | A fault has occurred |

| 10-100 | Exit jam |

| 10-105 | Exit jam |

| 10-110 | Vertical sensor jam |

| 10-120, 122, 125 | Duplex jam |

| 10-150, 155 | Too much or not enough paper in duplex tray |

| 10-300 | Fuser thermistor |

| 10-302 | Low fuser temperature |

| 10-304 | Bad fuser temp |

| 10-308 | High fuser temperature or open thermistor |

| 10-310 | High fuser temperature |

| 10-312 | Fuser not up to temperature after energy save |

| 10-314 | Fuser problem |

| 10-320 | Fuser web finished |

| 10-330, 335, 340 | Exit switch, vertical sensor switch actuated when power is turned on |

| 11-100, 11-116 | Sorter jam |

| 11-150, 11-176 | Sorter auto stapler jam |

| 11-310, 314, 316 | Sorter interlock |

| 11-325A, B, C, D, E, F, G | Sorter index |

| 11-352, 354, 356 | Sorter auto stapler interlocks |

| 11-365A, B, C, D, E | Sorter auto stapler bin |

| 11-370, 371, 372A, 373A, 373B, 374 | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 11-385A, 385B, 390A,B,C,D,E, 396A | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 301 | Fuser web must be replaced |

| 302 | Copy cartridge (drum unit) must be replaced |

| 501 | Tray 1 must be rebuilt |

| 502 | Tray 2 must be rebuilt |

| 503 | Tray 3 must be rebuilt |

| 504 | Tray 4 must be rebuilt |

| 505 | HCF must be rebuilt |

| 506 | Bypass must be rebuilt |

| 507 | Duplex unit must be rebuilt |

| 508 | Replace black developer |

| 509 | Replace red developer |

| 510 | Replace green developer |

| 512 | Replace brown developer |

| 513 | Copy cartridge (drum unit) will need replacing soon |

| 514 | Fuser web will need replacing soon |

| 515 | DADF belt should be replaced |

| 516 | DADF feed rollers should be replaced |

| 517 | Replace exposure lamp |

| 518 | Replace suction filter |

| 519 | Replace ozone filter |

| 520 | Replace optics filter |

| 521 | Replace particle filter |

| 522 | Replace upper fuser roller |

| 523 | Replace fuser pawls |

| 524 | Replace pressure roller |

| 525 | Replace pressure roller pawls |

| 900-905 | Key operator calls |

Xerox 5345

| Код ошибки | Описание |

|---|---|

| 01-01 | Frequency monitoring and zero cross problem |

| 01-02 | Interlock |

| 01-03 | AC power problem |

| 01-04 | Finisher interlock |

| 01-05 | 24v problem |

| 03-01 | Optics to main board communication problem |

| 03-02 | Software reset problem |

| 03-03 | Could be punched holes in the lead edge of the original |

| 03-04 | Software problem |

| 03-06 | Low battery |

| 03-07 | NVM not initialized or is missing or defective |

| 03-17 | Communication problem between main board and finisher board |

| 03-18 | Initializes one NVM counter to agree to others |

| 03-19 | All three NVM counter to agree with others |

| 03-20 | Main board/interface board problems |

| 03-21 | Problem with RIC NVM |

| 03-22 | RIC modem problem |

| 03-23 | RIC real time clock failure. |

| 03-25 | RIC NVM problem or not initialized |

| 03-27 | NVM problem |

| 03-28 | Watchdog software problem |

| 03-29 | Microprocessor crystal not at correct frequency |

| 03-30 | No software response from finisher after 20 seconds have elapsed |

| 06-01 | Lens did not reach 1.1 position |

| 06-02 | 1/2 rate scanner problem |

| 06-03 | Scan home problem |

| 06-04 | Scan home problem |

| 06-05 | Scan home problem |

| 06-06 | Scan encoder |

| 06-07 | Scan encoder |

| 06-08 | Scan drive boost |

| 06-09 | Scan encoder |

| 06-11 | Scan encoder pulse phases |

| 06-12 | Insufficient scan damping |

| 07-01 | Duplex tray not home during duplexing |

| 07-02 | Tray 2 not home when selected |

| 07-13 | Tray 2 height sensor problem |

| 07-15 | Tray 2 empty |

| 07-16 | Tray 1 door open |

| 07-18 | Tray 1 stack sensor |

| 07-22 | Tray 1 empty |

| 07-26 | Tray 1 bypass switch actuated too long |

| 07-27 | Tray 1 bypass switch deactuated too early |

| 07-30 | Paper in duplex |

| 07-31 | Paper in duplex |

| 07-32 | Duplex tray empty, when paper should be there |

| 08-10 | Paper did not reach tray 2 input tray sensor |

| 08-11 | Paper did not reach duplex input sensor |

| 08-12 | Paper did not reach tray 1 |

| 08-14 | Paper did not leave tray 2 input sensor quickly enough |

| 08-18 | Trail edge did not reach tray 2 input sensor quickly enough |

| 08-19 | Trail edge did not reach tray 1 input sensor quickly enough |

| 08-20 | Paper in duplex |

| 08-21 | Paper in tray 2 input |

| 08-22 | Paper in tray 2 or duplex at wrong time |

| 08-23 | Paper at tray 1 input at wrong time |

| 08-24 | Paper in tray 1 at wrong time |

| 08-28 | Upper and lower nips problem |

| 09-08 | Low toner condition |

| 09-12 | Drum signals are out of range |

| 09-13 | Unstable drum patch readings |

| 09-15 | Patch is too dark |

| 09-16 | Patch is too light |

| 09-17 | Open toner container access cover |

| 09-18 | Low toner level |

| 09-21 | Low toner sensor disconnected |

| 09-22 | Low toner condition, even after machine has been theoretically, adding toner |

| 10-02 | Low fuser temperature |

| 10-03 | High fuser temperature |

| 10-06 | Paper did not reach out put switch |

| 10-07 | Paper stayed on output switch |

| 10-10 | Paper did not reach decurler sensor |

| 10-11 | Paper did not reach decurler sensor |

| 10-12 | Paper on decurler sensor |

| 10-13 | Paper did not reach duplex entry sensor in time |

| 10-14 | Paper did not reach duplex entry sensor in time |

| 10-15 | Paper on entry sensor at wrong time |

| 10-17 | Fuser temperature is too high and fuser relay has deactuated |

| 12-01 | Paper at finisher input sensor |

| 12-02 | Paper did not reach finisher |

| 12-03 | Paper reached finisher too soon |

| 12-05 | Paper at stapler |

| 12-06 | Paper at stapler |

| 12-07 | Paper did not reach stapler |

| 12-08 | Paper did not reach stapler |

| 12-10 | Complied motor not working properly |

| 12-15 | Eject motor problem and/or eject encoder |

| 12-20 | Stacker motor problem |

| 12-21 | Stacker interlock |

| 12-22 | Stacker bottom sensor |

| 12-23 | Stacker bottom sensor |

| 12-24 | Stacker bottom sensor senses full |

| 12-25 | Stack height sensor |

| 12-26 | Stack height sensor |

| 12-27 | Stack height sensor |

| 12-30 | Offset home sensor |

| 12-31 | Offset home sensor |

| 12-32 | OCT switch |

| 12-35 | Eject nip carriage |

| 12-36 | Eject cam interlock |

| 12-37 | Eject nip carriage open timing |

| 12-38 | Eject cam interlock |

| 12-40 | Tamper motor |

| 12-41 | Tamper home problem |

| 12-42 | Tamper home sensor |

| 12-43 | Staple load sensor |

| 12-44 | Tamper home sensor |

| 12-45 | Tamper home sensor |

| 12-50 | Low on staples |

| 12-51 | Stapler home sensor |

| 12-52 | Stapler home sensor |

| 12-53 | Eject cam interlock |

| 33-37 | Too few documents |

| 55-01 | RDH interlock switch open during use |

| 55-04 | Paper on bypass sensor |

| 55-05 | Paper at vacuum timing sensor |

| 55-06 | Paper on output sensor |

| 55-10 | No paper reached S31 |

| 55-20 | Paper did not leave S31 at correct time |

| 55-24 | Set counter arm problem |

| 55-25 | Documents in input tray not detected |

| 55-27 | Lead edge did not reach S35 at correct time |

| 55-2955-30 | Trail edge did not reach S35 at correct time |

| 55-31 | S32, ADF registration sensor did not see paper at correct time |

| 55-32 | S32 did not see trail edge at correct time |

| 55-33 | S36 One too many documents |

| 55-36 | One too many documents |

| 55-39 | Hole count problem on document feeder belt |

| 55-40 | Document belt travel problem |

| 55-41 | Document belt mistracking or skewing |

| 55-45 | Paper at inverter sensor |

| 55-47 | Inverter sensor did not see paper lead edge at correct time |

| 55-49 | More than 50 sheets in input tray |

| 55-50 | Right side interlock |

| 55-51 | Left side interlock |

| 55-55 | Document on glass |

| 93-93 | NVM has to be initialized after new software installed |

Xerox 5350, 5352

| Code | Description |

|---|---|

| 00-009, 030, 031, 032, 033 | A door was opened while paper was being fed |

| 00-047 | Paper in duplex |

| 00-1 | Auditron |

| 00-2 | Diagnostic error |

| 00-3 | Faults error |

| 00-4 | Ric error |

| 00-5 | Job manager system error |

| 00-6 | LLM interface |

| 00-7 | Standby error |

| 00-8 | Communications error |

| 00-9 | Xerographic error |

| 01-300 | Front interlock |

| 01-310 | Right upper interlock |

| 01-315 | Left upper interlock |

| 01-320 | Left lower interlock |

| 01-325 | Fuser interlock |

| 02-910 | Key counter missing |

| 02-920 | Wrong combination of accessories |

| 03-321, 322, 326, 327 | LLM to ISIL communications problems |

| 03-328 | IOT communications problem with duplex or tray 4 |

| 03-330 | IOT communications problems with HCF |

| 03-335, 336 | LLM communications problems with edit |

| 03-340 | NVM memory |

| 03-341-347 | Communications problems between IOT and sorter |

| 03-350-354 | Communications problem with LLM and user interface |

| 03-363, 364 | Communications problem between LLM & optics |

| 03-370-03-373 | Communications problem between LLM & DADF |

| 03-380, 384 | |

| 03-416-422 | RAM memory problem |

| 03-424, 426 | NVM memory problem |

| 03-430, 432 | Billing problem |

| 03-439 | GRAIB communications problem |

| 03-440 | RIC communications problem |

| 03-441 | RIC NVM problem |

| 03-442 | Modem |

| 03-443-458 | RIC problems |

| 03-460 | Serial communications processor problem |

| 04-300 | Main motor or drive problem |

| 05-100-108 | DADF registration sensor |

| 05-110 | DADF exit sensor |

| 05-115, 120 | DADF jams |

| 05-305 | DADF document drive |

| 05-310, 312 | DADF document sensor |

| 05-316 | DADF registration sensor jam |

| 05-325 | DADF exit sensor |

| 05-335, 341, 345 | DADF interlock switches |

| 06-300-310 | Scan problems |

| 06-315 | Scan drive |

| 06-320A, 320B, 320C, 325 | Scan problem |

| 06-330 | Lens drive |

| 06-340 | Exposure control problem |

| 06-342 | LLM CPU problem |

| 06-344-350 | Exposure cvontrol problem |

| 06-352 | IOT CPU problem |

| 07-300, 315, 330, 345 | Tray faults |

| 07-360-370 | HCF problems |

| 07-375, 380A, 380B | Duplex problems |

| 08-100-110 | Feed problems. Lead edge of copy paper is late getting to feed sensor of tray 1 |

| 08-115-162 | Feed problem. Lead edge of copy paper is late getting to registration sensor |

| 08-165 | Paper jam at registration sensor |

| 08-310-370 | Paper at a sensor when power is turned on |

| 08-330 | DADF nudger sensor |

| 08-380 | Registration side to side problem with home position |

| 08-390 | Nip |

| 09-300 | Copy cartridge finished (drum unit) |

| 09-310 | Add black toner Add color toner |

| 09-320 | Add color toner |

| 09-330 | Wrong copy cartridge (wrong drum unit) |

| 09-340 | Drum cartridge not installed properly |

| 09-350 | Waste toner full |

| 100 | A fault has occurred |

| 10-100 | Exit jam |

| 10-105 | Exit jam |

| 10-110 | Vertical sensor jam |

| 10-120, 122, 125 | Duplex jam |

| 10-150, 155 | Too much or not enough paper in duplex tray |

| 10-300 | Fuser thermistor |

| 10-302 | Low fuser temperature |

| 10-304 | Bad fuser temp |

| 10-308 | High fuser temperature or open thermistor |

| 10-310 | High fuser temperature |

| 10-312 | Fuser not up to temperature after energy save |

| 10-314 | Fuser problem |

| 10-320 | Fuser web finished |

| 10-330, 335, 340 | Exit switch, vertical sensor switch actuated when power is turned on |

| 11-100-116 | Sorter jam |

| 11-150-176 | Sorter auto stapler jam |

| 11-310, 314, 316 | Sorter interlock |

| 11-325A,B,C,D,E,F,G | Sorter index |

| 11-352, 354, 356 | Sorter auto stapler interlocks |

| 11-365A,B,C,D,E | Sorter auto stapler bin |

| 11-370,371,372A,373A,373B,374 | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 11-385A,385B,390A,B,C,D,E,396A | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 301 | Fuser web must be replaced |

| 302 | Copy cartridge (drum unit) must be replaced |

| 501 | Tray 1 must be rebuilt |

| 502 | Tray 2 must be rebuilt |

| 503 | Tray 3 must be rebuilt |

| 504 | Tray 4 must be rebuilt |

| 505 | HCF must be rebuilt |

| 506 | Bypass must be rebuilt |

| 507 | Duplex unit must be rebuilt |

| 508 | Replace black developer |

| 509 | Replace red developer |

| 510 | Replace green developer |

| 512 | Replace brown developer |

| 513 | Copy cartridge (drum unit) will need replacing soon |

| 514 | Fuser web will need replacing soon |

| 515 | DADF belt should be replaced |

| 516 | DADF feed rollers should be replaced |

| 517 | Replace exposure lamp |

| 518 | Replace suction filter |

| 519 | Replace ozone filter |

| 520 | Replace optics filter |

| 521 | Replace particle filter |

| 522 | Replace upper fuser roller |

| 523 | Replace fuser pawls |

| 524 | Replace pressure roller |

| 525 | Replace pressure roller pawls |

| 900-905 | Key operator calls |

Xerox 5355

| Код ошибки | Описание |

|---|---|

| 01-01 | Frequency monitoring and zero cross problem |

| 01-02 | Interlock |

| 01-03 | AC power problem |

| 01-04 | Finisher interlock |

| 01-05 | 24v problem |

| 03-01 | Optics to main board communication problem |

| 03-02 | Software reset problem |

| 03-03 | Could be punched holes in the lead edge of the original |

| 03-04 | Software problem |

| 03-06 | Low battery |

| 03-07 | NVM not initialized or is missing or defective |

| 03-17 | Communication problem between main board and finisher board |

| 03-18 | Initializes one NVM counter to agree to others |

| 03-19 | All three NVM counter to agree with others |

| 03-20 | Main board/interface board problems |

| 03-21 | Problem with RIC NVM |

| 03-22 | RIC modem problem |

| 03-23 | RIC real time clock failure. |

| 03-25 | RIC NVM problem or not initialized |

| 03-27 | NVM problem |

| 03-28 | Watchdog software problem |

| 03-29 | Microprocessor crystal not at correct frequency |

| 03-30 | No software response from finisher after 20 seconds have elapsed |

| 06-01 | Lens did not reach 1.1 position |

| 06-02 | 1/2 rate scanner problem |

| 06-03 | Scan home problem |

| 06-04 | Scan home problem |

| 06-05 | Scan home problem |

| 06-06 | Scan encoder |

| 06-07 | Scan encoder |

| 06-08 | Scan drive boost |

| 06-09 | Scan encoder |

| 06-11 | Scan encoder pulse phases |

| 06-12 | Insufficient scan damping |

| 07-01 | Duplex tray not home during duplexing |

| 07-02 | Tray 2 not home when selected |

| 07-13 | Tray 2 height sensor problem |

| 07-15 | Tray 2 empty |

| 07-16 | Tray 1 door open |

| 07-18 | Tray 1 stack sensor |

| 07-22 | Tray 1 empty |

| 07-26 | Tray 1 bypass switch actuated too long |

| 07-27 | Tray 1 bypass switch deactuated too early |

| 07-30 | Paper in duplex |

| 07-31 | Paper in duplex |

| 07-32 | Duplex tray empty, when paper should be there |

| 08-10 | Paper did not reach tray 2 input tray sensor |

| 08-11 | Paper did not reach duplex input sensor |

| 08-12 | Paper did not reach tray 1 |

| 08-14 | Paper did not leave tray 2 input sensor quickly enough |

| 08-18 | Trail edge did not reach tray 2 input sensor quickly enough |

| 08-19 | Trail edge did not reach tray 1 input sensor quickly enough |

| 08-20 | Paper in duplex |

| 08-21 | Paper in tray 2 input |

| 08-22 | Paper in tray 2 or duplex at wrong time |

| 08-23 | Paper at tray 1 input at wrong time |

| 08-24 | Paper in tray 1 at wrong time |

| 08-28 | Upper and lower nips problem |

| 09-08 | Low toner condition |

| 09-12 | Drum signals are out of range |

| 09-13 | Unstable drum patch readings |

| 09-15 | Patch is too dark |

| 09-16 | Patch is too light |

| 09-17 | Open toner container access cover |

| 09-18 | Low toner level |

| 09-21 | Low toner sensor disconnected |

| 09-22 | Low toner condition, even after machine has been theoretically, adding toner |

| 10-02 | Low fuser temperature |

| 10-03 | High fuser temperature |

| 10-06 | Paper did not reach out put switch |

| 10-07 | Paper stayed on output switch |

| 10-10 | Paper did not reach decurler sensor |

| 10-11 | Paper did not reach decurler sensor |

| 10-12 | Paper on decurler sensor |

| 10-13 | Paper did not reach duplex entry sensor in time |

| 10-14 | Paper did not reach duplex entry sensor in time |

| 10-15 | Paper on entry sensor at wrong time |

| 10-17 | Fuser temperature is too high and fuser relay has deactuated |

| 12-01 | Paper at finisher input sensor |

| 12-02 | Paper did not reach finisher |

| 12-03 | Paper reached finisher too soon |

| 12-05 | Paper at stapler |

| 12-06 | Paper at stapler |

| 12-07 | Paper did not reach stapler |

| 12-08 | Paper did not reach stapler |

| 12-10 | Complied motor not working properly |

| 12-15 | Eject motor problem and/or eject encoder |

| 12-20 | Stacker motor problem |

| 12-21 | Stacker interlock |

| 12-22 | Stacker bottom sensor |

| 12-23 | Stacker bottom sensor |

| 12-24 | Stacker bottom sensor senses full |

| 12-25 | Stack height sensor |

| 12-26 | Stack height sensor |

| 12-27 | Stack height sensor |

| 12-30 | Offset home sensor |

| 12-31 | Offset home sensor |

| 12-32 | OCT switch |

| 12-35 | Eject nip carriage |

| 12-36 | Eject cam interlock |

| 12-37 | Eject nip carriage open timing |

| 12-38 | Eject cam interlock |

| 12-40 | Tamper motor |

| 12-41 | Tamper home problem |

| 12-42 | Tamper home sensor |

| 12-43 | Staple load sensor |

| 12-44 | Tamper home sensor |

| 12-45 | Tamper home sensor |

| 12-50 | Low on staples |

| 12-51 | Stapler home sensor |

| 12-52 | Stapler home sensor |

| 12-53 | Eject cam interlock |

| 33-37 | Too few documents |

| 55-01 | rdh interlock switch open during use |

| 55-04 | Paper on bypass sensor |

| 55-05 | Paper at vacuum timing sensor |

| 55-06 | Paper on output sensor |

| 55-10 | No paper reached S31 |

| 55-20 | Paper did not leave S31 at correct time |

| 55-24 | Set counter arm problem |

| 55-25 | Documents in input tray not detected |

| 55-27 | Lead edge did not reach S35 at correct time |

| 55-2955-30 | Trail edge did not reach S35 at correct time |

| 55-31 | S32, ADF registration sensor did not see paper at correct time |

| 55-32 | S32 did not see trail edge at correct time |

| 55-33 | S36 One too many documents |

| 55-36 | One too many documents |

| 55-39 | Hole count problem on document feeder belt |

| 55-40 | Document belt travel problem |

| 55-41 | Document belt mistracking or skewing |

| 55-45 | Paper at inverter sensor |

| 55-47 | Inverter sensor did not see paper lead edge at correct time |

| 55-49 | More than 50 sheets in input tray |

| 55-50 | Right side interlock |

| 55-51 | Left side interlock |

| 55-55 | Document on glass |

| 93-93 | NVM has to be initialized after new software installed |

Xerox XC520, 540, 560, 580

| Код ошибки | Описание |

|---|---|

| H2 | Fuser thermistor |

| H3 | Fuser temperature too high. Must be reset in diagnostics |

| H4 | Fuser temperature too low. Must be reset in diagnostics |

| L3 | Scan problem |

| L4 | Min motor drive problem |

| L8 | Exposure lamp not lightning or not enough light reaching auto exposure sensor |

| P | Paper did not feed |

Xerox 5622

| Code | Description |

|---|---|

| A1-1 to A1-32 | All indicate a paper path problem, etc. in the ADF |

| A2 | ADF exit problems |

| A3 | Irregular size documents |

| A5 | ADF interlock |

| A6 | ADF single sheet document reset |

| A7 | Platen interlock |

| A8 | ADF exit interlock |

| C1 | Tray 1 jam |

| C2 | Tray 2 jam |

| C3 | Tray 3 jam |

| C6-1, C6-2 | Jams related to duplex |

| C6-3 | Registration sensor, re tray 1 |

| C7-1, C7-2 | HCF feed problems |

| C7-3 | Tray 1 feed problem |

| C8 | Paper stays in tray or duplex or HCF |

| C9 | Bypass feed problem |

| E1-10 to E1-25 | Internal jam |

| E1-6 | Paper on registration sensor |

| E2 | Reset signal happened. Might read E-2 something else |

| E3-30 to E4-14 | Exit jam |

| E3-6 | Exit jam |

| E4-10 to E4-14 | Inverter sensor not actuated |

| E4-15 | Inverter sensor |

| E4-40 to E4-45 | Duplex entry sensor |

| E4-6 | Inverter sensor |

| E5 | Front door interlock |

| E6-1 | Tray 1 interlock |

| E6-2 | 2 tray or duplex interlock |

| E6-3 | HCF interlock |

| E7-2, E7-3 | Duplex interlock |

| E8-6 to E8-15 | Duplex entry sensor |

| F1-1 | Sorter entry sensor |

| F1-6 | Sorter exit sensor |

| F3 | Paper size not available for sort/stack |

| F5 | Sorter interlock |

| J1 | Add toner |

| J3 | Replace copy cartridge |

| J7 | Replace copy cartridge |

| J8-1 | Wrong copy cartridge installed |

| J8-2 | Copy cartridge EEPROM |

| L6 | Auditron or other counter problem |

| L8 | Platen glass temperature is too high |

| L9 | Communication problem between interimage erase/edge lamps and main board |

| U1-1 | Main motor drive problem |

| U2-1 to U2-4 | Scan home sensor |

| U3-1 | Lens sensor |

| U4-1 | Open fuser thermistor |

| U4-2 | Fuser did not warm up properly |

| U4-3 | Fuser temperature too high |

| U4-4 | Fuser problem. Staying on too long |

| U4-6 | High fuser temperature |

| U5-1 | Sorter bin home switch not activated |

| U5-2 | Sorter bin home switch stayed actuated |

| U5-3, U5-4 | Sorter bin home switch |

| U6-1 | ROM problem |

| U6-2 | RAM problem |

| U6-3 | Low battery |

| U6-4 | Incorrect value in NVM. Reinitialize main board with code 20-96 |

| U8-1 to U8-6 | Problem with exposure lamp, lamp sensor, lamp board |

Режимы

Цветной принтер Phaser 7100

19

Руководство пользователя

Панель управления

На панели управления находится экран, светоиндикаторы и кнопки для управления функциями

принтера. Функции панели управления:

•

Отображение текущего рабочего состояния принтера.

•

Обеспечение доступа к функциям принтера.

•

Обеспечение доступа к отчетам.

•

Обеспечение доступа к меню настройки.

•

Вывод предупреждений о необходимости загрузить бумагу, заменить расходные

материалы или устранить застревание.

•

Отображение ошибок и предупреждений.

1.

Информация — вывод дополнительных сведений об ошибке или статусе, отображаемом

на панели управления.

2.

Дисплей панели управления — вывод сведений об ошибке или статусе.

3.

Меню — вызов или закрытие экрана меню системы.

4.

Меню печати — доступ к документам, сохраненным на принтере или сервере, например, с

помощью функции защищенной печати. Данная функция доступна, если установлен

дополнительный диск ОЗУ или комплект для повышения производительности.

5.

Энергосбережение — переход в режим энергосбережения и выход из него. Данная

кнопка светится в режиме энергосбережения.

6.

Отмена — остановка текущей работы.

7.

OK — выбор или исполнение опции или функции, отображаемой на экране.

8.

Кнопки со стрелками — переход к следующему меню, пункту или варианту.

9.

Назад — переход в меню на один уровень вверх.

10.

Индикатор

HDD — мигает при чтении данных с дополнительного жесткого диска и записи

на него.

11.

Индикатор

Ошибка — горит при наличии ошибки, устраняемой пользователем, такой как

застревание бумаги. Мигает при наличии системной ошибки, для которой зачастую

предусмотрен код ошибки.

12.

Индикатор

Готов — горит, когда принтер находится в сетевом режиме; не горит, когда

принтер находится в автономном режиме или в состоянии ошибки. Мигает, когда принтер

получает данные.

13.

Онлайн — переключение между сетевым и автономным режимами.

Поиск и устр. неиспр.

92

Цветной принтер Phaser 7100

Руководство пользователя

Сбой печати документа

Возможные причины

Решения

В выбранный лоток вложена бумага

другого формата.

1. Проверьте наличие предупреждающего сообщения на

панели управления.

2. Проверьте, какой лоток выбран в драйвере принтера.

Бумага выбранного типа или цвета

недоступна.

Убедитесь в том, что в настройках драйвера правильно задан

тип бумаги и данная бумага загружена в соответствующий

лоток.

Панель управления занята или принтер

находится в автономном режиме.

Убедитесь в том, что принтер не находится в автономном

режиме, а на панели управления не открыто какое-либо меню.

Если отображается «Автономный режим», нажмите кнопку

Вкл.

Если отображается меню, нажмите кнопку

Меню, чтобы

закрыть его.

Возможно, причиной является способ

установки принтера в сети.

• Убедитесь, что принтер подключен к сети.

• Возможно, программа буферизации печати или компьютер,

использующий принтер, помещают в буфер все работы

печати, а затем передают очередь на принтер. Буферизация

может снижать скорость печати.

• Для проверки принтера распечатайте информационные

страницы, например демонстрационную страницу. Если

страницы печатаются, причиной может быть неполадка в

сети или установке принтера. Обратитесь за помощью к

системному администратору.

В приложении и драйвере печати заданы

разные лотки.

Подробности см.

Документ печатается не из указанного лотка

Документ печатается не из указанного лотка

Возможные причины

Решения

В приложении и драйвере печати заданы

разные лотки.

1. Проверьте, какой лоток выбран в драйвере принтера.

2. Перейдите к настройкам макета страницы или параметрам

принтера в приложении, из которого выполняется печать.

3. Задайте источник бумаги, соответствующий лотку,

выбранному в драйвере печати, либо выберите настройку

«Автовыбор».

Проблемы при автоматической двусторонней печати

Возможные причины

Решения

Неподдерживаемая или

неподходящая бумага.

Убедитесь, что формат и плотность используемой бумаги подходит

для двусторонней печати. Для конвертов и наклеек двусторонняя

печать недоступна. Подробности см.

Поддерживаемые форматы и

плотность бумаги для автоматической двусторонней печати

на стр.

Xerox Phaser 7100. Ошибка 094-310

Xerox Phaser 7100 N. После включения на дисплее отображается ошибка: Код ошибки 094-310: сбой датчика CTD. Датчик CTD заменён на новый, замена платы управления MCU PWB результата не приносит. Оговорюсь, что бы не засорять тему, тонер и девелопер оригинальные, дополнительно узлы блока изображения подставлялись с рабочего аппарата.

При инициализации в исправном аппарате на ленте переноса печатаются следующие изображения — последовательно: 4 горизонтальных линии(для 4-х цветов, далее 4 квадрата по одному на цвет для левого датчика CTD, далее 4 квадрата по одному на цвет для правого датчика CTD, далее разноцветные отрезки синусоид(по одному периоду) одновременно для обоих датчиков CTD. После этого аппарат выходит в готовность.

При инициализации в неисправном аппарате на ленте переноса печатаются только 4 горизонтальных линии и дальше после кратковременной работы аппарат выходит в ошибку 094-310.

Где формируются изображения для инициализации? Может ли давать такой дефект микросхема памяти на MCU PWB, поскольку её подставить никак нельзя, она привязана намертво к одному аппарату?

-

lexx53 - новичок

- Сообщения: 20

- Зарегистрирован: 16:51 — 24.09.12

- Баллы репутации: 0

Re: Xerox Phaser 7100. Ошибка 094-310

Mishel01 » 17:19 — 01.02.16

Датчики из сервиса проверяли? Если да — «чего и скока» конкретно напроверяли?

Что такое «изображения для инициализации»?

О которой микросхеме конкретно вы ведете речь?

- Mishel01

- эксперт

- Сообщения: 8413

- Зарегистрирован: 01:10 — 10.01.11

- Баллы репутации: 1

Re: Xerox Phaser 7100. Ошибка 094-310

lexx53 » 22:23 — 01.02.16

В сервисный режим зайти можно, но видимо из-за ошибки есть возможность только переключать пункты меню, выполнить какую-нибудь команду не удаётся, принтер не реагирует.

«Что такое «изображения для инициализации»?» — изображения, инициированные системой принтера и отображённые на ленте переноса, движущиеся над левым и правым датчиками CTD для определения плотности тонера при печати.

«О которой микросхеме конкретно вы ведете речь?»

Об этой

-

lexx53 - новичок

- Сообщения: 20

- Зарегистрирован: 16:51 — 24.09.12

- Баллы репутации: 0

Re: Xerox Phaser 7100. Ошибка 094-310

Mishel01 » 23:12 — 01.02.16

Значит, либо не в тот сервис зашли, либо не то выполнить пытаетесь. Ошибки тут ни при чем — это же сервис.

Изображения — нет, не в NVRAM. Но в MCU.

- Mishel01

- эксперт

- Сообщения: 8413

- Зарегистрирован: 01:10 — 10.01.11

- Баллы репутации: 1

Re: Xerox Phaser 7100. Ошибка 094-310

lexx53 » 12:02 — 02.02.16

«Датчики из сервиса проверяли?»

Service Diagnostics

Fault Diag

DC140 Analog Monitor

092 200 Left CTD Sensor Voltage The density detection signal voltage value of the Left CTD Sensor. значение 01023

092 201 Right CTD Sensor Voltage The density detection signal voltage value of the Right CTD Sensor. после ввода Chain-Link 092-201 кратковременно появляется уведомление «unexpected error»

В Component List видна только одна строка 092-200, вторая не вводится.

«Изображения — нет, не в NVRAM. Но в MCU.»

MCU PWB сейчас стоит 100% исправная, датчик CTD тоже 100% исправен (оба узла новые и проверены на рабочем аппарате)

-

lexx53 - новичок

- Сообщения: 20

- Зарегистрирован: 16:51 — 24.09.12

- Баллы репутации: 0

Re: Xerox Phaser 7100. Ошибка 094-310

lexx53 » 20:51 — 03.02.16

На данный момент значения указанные ниже, соответствуют значениям на исправном аппарате, патчи в виде квадратов стали печататься, только для левого датчика CTD, после этого опять ошибка 094-310.

Service Diagnostics

Fault Diag

DC140 Analog Monitor

092 200 Left CTD Sensor Voltage The density detection signal voltage value of the Left CTD Sensor. значение плавающее от 00001 до 00005

092 201 Right CTD Sensor Voltage The density detection signal voltage value of the Right CTD Sensor. значение плавающее от 00001 до 00005

-

lexx53 - новичок

- Сообщения: 20

- Зарегистрирован: 16:51 — 24.09.12

- Баллы репутации: 0

Re: Xerox Phaser 7100. Ошибка 094-310

solo-81 » 15:15 — 04.02.16

микросхема памяти на MCU PWB, поскольку её подставить никак нельзя, она привязана намертво к одному аппарату?

счего вы взяли ? что к одному аппарату ! если меняете NVM для этого есть процедура Biling data — пропишите там серийники и все будет работать

-

solo-81 - мастер

- Сообщения: 487

- Зарегистрирован: 11:25 — 03.06.08

- Баллы репутации: 0

Re: Xerox Phaser 7100. Ошибка 094-310

tantie » 16:42 — 04.02.16

Добрый день. Не хочу плодить новые темы. У меня с недавних пор такой же принтер 7100. Все бы хорошо, но вот закончались картриджи и теперь пытаюсь отучить принтер от чипов.

Подскажите, это вообще возможно? Т.к. в сервис мануале я толком на эту тему ничего не нашел, везде описывается, что нужно обнулить значения, что я и сделал, но это не помогло. Либо подскажите в каком меню искать хотя бы?

Заранее спасибо.

- tantie

- новичок

- Сообщения: 2

- Зарегистрирован: 03:22 — 04.02.16

- Баллы репутации: 0

Re: Xerox Phaser 7100. Ошибка 094-310

lexx53 » 17:22 — 04.02.16

solo-81 писал(а):lexx53 ну так проблему устранили ? или нет? отпишитесь! если нет тогда раскачаем.

Нет проблема не устранена. Наладил только показания в сервисе по датчикам CTD, как на рабочем принтере, но проблема осталась, прогоняет патчи квадратами над левым датчиком и сразу в ошибку. Незаменённой осталась только NVRAM.

процедура Biling data — пропишите там серийники и все будет работать

— если можно, поподробнее (если здесь неловко, можно в личном сообщении), запасная NVRAM с другого аппарата имеется.

-

lexx53 - новичок

- Сообщения: 20

- Зарегистрирован: 16:51 — 24.09.12

- Баллы репутации: 0

Re: Xerox Phaser 7100. Ошибка 094-310

Mishel01 » 17:33 — 04.02.16

tantie писал(а): закончались картриджи и теперь пытаюсь отучить принтер от чипов. Подскажите, это вообще возможно?

Нет, конечно.

- Mishel01

- эксперт

- Сообщения: 8413

- Зарегистрирован: 01:10 — 10.01.11

- Баллы репутации: 1

Re: Xerox Phaser 7100. Ошибка 094-310

tantie » 17:50 — 04.02.16

Mishel01 писал(а):

tantie писал(а): закончались картриджи и теперь пытаюсь отучить принтер от чипов. Подскажите, это вообще возможно?

Нет, конечно.

Вас понял. Будем посмотреть, спасибо.

- tantie

- новичок

- Сообщения: 2

- Зарегистрирован: 03:22 — 04.02.16

- Баллы репутации: 0

Вернуться в XEROX

Кто сейчас на конференции

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 1

Ремонт МФУ Xerox WC 6015

Сервисный центр Комплэйс выполняет Ремонт Xerox WC 6015

Замятие бумаги WC 6015

МФУ Xerox WC 6015 поступило в ремонт с постоянным сообщением о замятии бумаги, бумаги не было нигде.

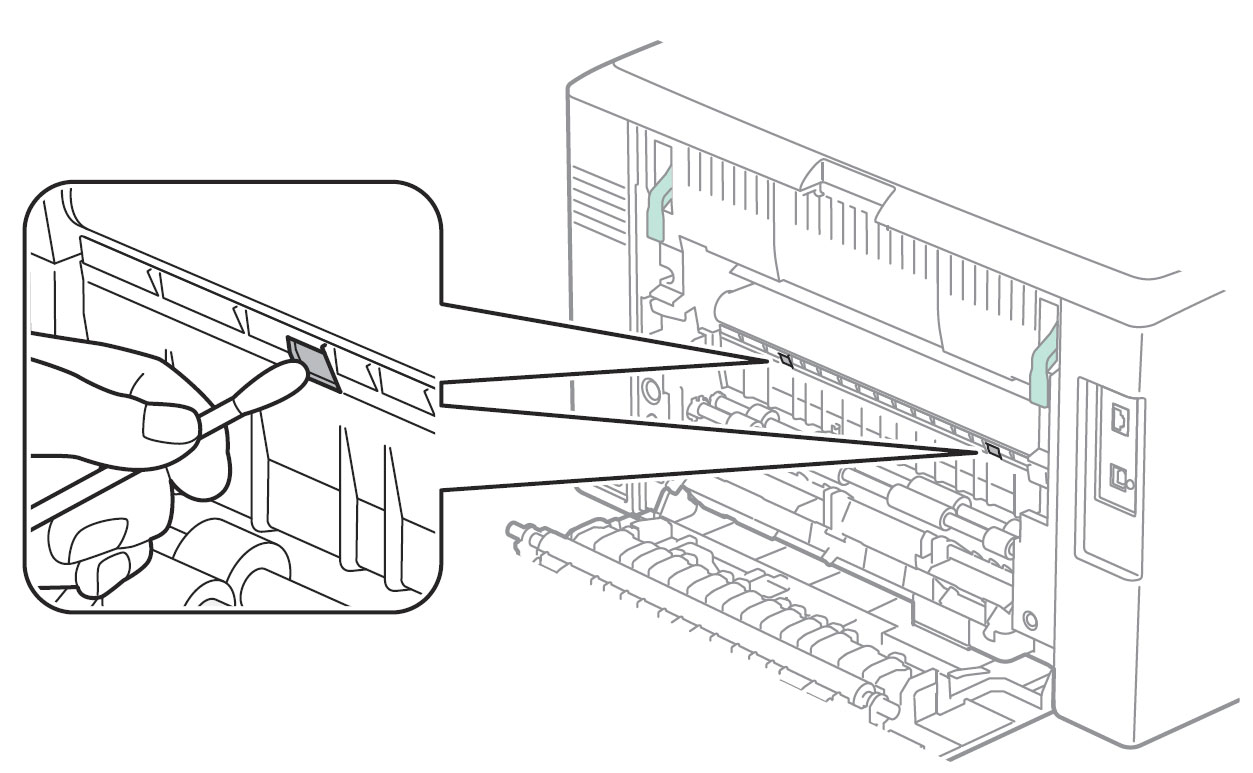

После разборки аппарата подбираемся к датчику бумаги. Сам датчик прохождения бумаги находится сзади, показан стрелкой.

Сломанный датчик заменяем. На этом ремонт МФУ Xerox закончен.

Второй датчик находится в узле закрепления.

Треск при работе WC 6015

Треск в узле ксерографии

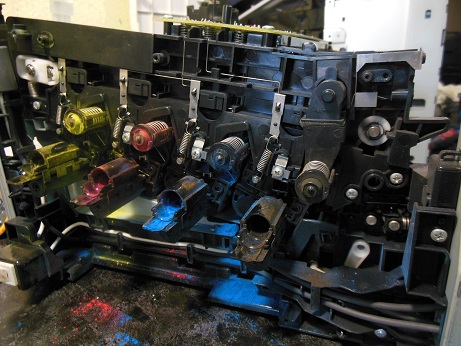

В другом МФУ Xerox WC 6015 при включении и работе раздавался сильный треск. Пришлось разбирать МФУ еще дальше.

Сильный треск был вызван тем, что в синем цвете забился тракт отвода отработанного тонера. После тщательной очистки спрессованного тонера, который превратился в камень, треск исчез. Отработанный тонер стал уходить в картридж.

Треск Xerox WC 6015 в области печки

Треск в области печки означает проскальзывание шестерней. В Xerox WC 6015 такое вероятно, если сломалось крепление печки. При такой неисправности шестерня печки не прижимаются к шестерне редуктора принтера. Поэтому и происходит проскальзывание и сильный треск.

Печка в этом МФУ с задней стороны крепится двумя винтами. А снизу печка цепляется за основание с помощью железных полукруглых упоров.

Если упор отсутствует печка не держится. В нашем случае полукруглый упор был отломан.

Ремонт выполнили следующим образом.

Стоимость ремонта крепления печки 3500 руб. Полукруг не обязателен.

Ошибка 024-360

Разберите по-новой весь принтер и проверьте разъемы на целостность и правильное соединение.Особенно тщательно проверьте контактные концы шлейфов. Если они повреждены, то отремонтируйте.

Ремонт контактной группы картриджей

Если у вас произошло повреждение контактной группы картриджа , то вряд ли найдете новую группу в продаже. Вообще для Xerox WC 6015 с запчастями проблема. Мы научились восстанавливать сломанные контакты. Но есть сложности — контактные группы никто не продает.

Для ремонта контакта нужно разобрать МФУ, вынуть контактную группу, починить сломанную контактную пластину.

Цена восстановления 2500 р.

Ошибка 092-651

Ошибка 092-651 с разными подкодами возникает, когда аппарат не может выполнить калибровку цветов. Эта калибровка осуществляется при включении принтера. Принтер выполняет калибровку путем нанесения на ленту переноса прямоугольных образцов всех 4 цветов по-очереди. Затем считывает плотность этих образцов датчиками CTD. Если плотность печати любого из цветов недостаточна или не изменяется, то выдается ошибка 092-651 с соответствующим подкодом и МФУ блокируется .

Расшифровку подкодов найти не удалось. Особенностью ошибки 092-651 является то, что после этой ошибки принтер не закачивает тонер из картриджей в блок ксерографии и, похоже, простого выхода из этой ситуации нет.

Первая причина ошибки 092-651 — это загрязненные датчики CTD, расположенные сзади принтера под лентой переноса. CTD — Color Toner Density Sensor. Т.е. это датчики плотности тонера для цветовой калибровке в каждом цветном лазерном принтере. Расположены они сзади под лентой переноса. Для решения этой проблемы протираем датчики спиртом и запускаем МФУ снова.

Если проблема не решается, переходим к следующей процедуре.

Вторая причина — в блоке ксерографии недостаточно девелопера, который переносит тонер. Этот вариант происходит, если заправлять картридж не подходящим тонером. Например, универсальным тонером Samsung. В этом случае девелопер уходит и принтер печатает бледно. Чтобы добавить девелопер в блок ксерографии, нужно разобрать весь МФУ. Мало кто выполнить эту работу меньше, чем за 5000 руб.

Третья причина — в блоке ксерогафии мало тонера какого-то цвета. Причиной может быть неисправный картридж. В нашем случае была ошибка 092-651 код 2440000. Причиной являлись дешевые китайские картриджи, в которых выходное отверстие было заклеено липкой бумагой. После удаления бумаги клей остался. После установки картриджей клей плотно приклеился к уплотнительной резинке принтера. Это вызыИногда из-завает перекрытие выходного отверстия для тонера.

Решение такое. Во время включения вручную принудительно закачивать тонер каждого цвета, пока тонер не появится в блоке ксерографии. Когда он появится, принтер оживет и станет самостоятельно подкачивать тонер. Цена работы 2500 руб.

Подкоды ошибки 092-651

Иногда из-за плохого тонера возникает ошибка 092-651 28f0000. При таком коде при калибровке совсем отсутствуют цвета желтый, красный, синий. Есть только черный.

Решение. Замена тонера в цветных картриджах. С помощью сервисного меню можно отдельно запустить двигатели каждого картриджа. Но не более 3 секунд на каждый.

После этого все цвета появятся, но может возникнуть ошибка 092-651 2880000. Это совсем плохо. Скорее всего, код означает, что яркости черного не хватает для калибровки. Значит в блоке ксерографии плохой тонер или недостаточно девелопера. Но за заправку девелопером мы не беремся. Слишком много геморроя.

WC 6015 не печатает с компьютера

Очень типичная ситуация. При подключении Xerox WC 6015 к компьютеру с Windows 7 драйверы устанавливаются автоматически через обновления Windows. Далее пробуете что-нибудь напечатать и ничего не происходит — задания на печать уходят в никуда, даже ошибки не появляется.

Виной всему неправильный драйвер для Windows 7, а, возможно, и для Windows 8 и 10.

Решение: скачайте и установите драйвер с официального сайта Xerox (весит около 200Мб). После установки оригинального драйвера принтер Xerox WC 6015, который ранее не печатал от компьютера, стал печатать под Windows 7 и Windows 10.

Цены на ремонт WC 6015

Ремонт подачи бумаги (застревание) 2500-3000 руб.

Треск — ремонт узла ксерографии — от 3000 руб.

Ремонт контактной группы 2500 руб.

Ремонт крепления печки 3500 руб.

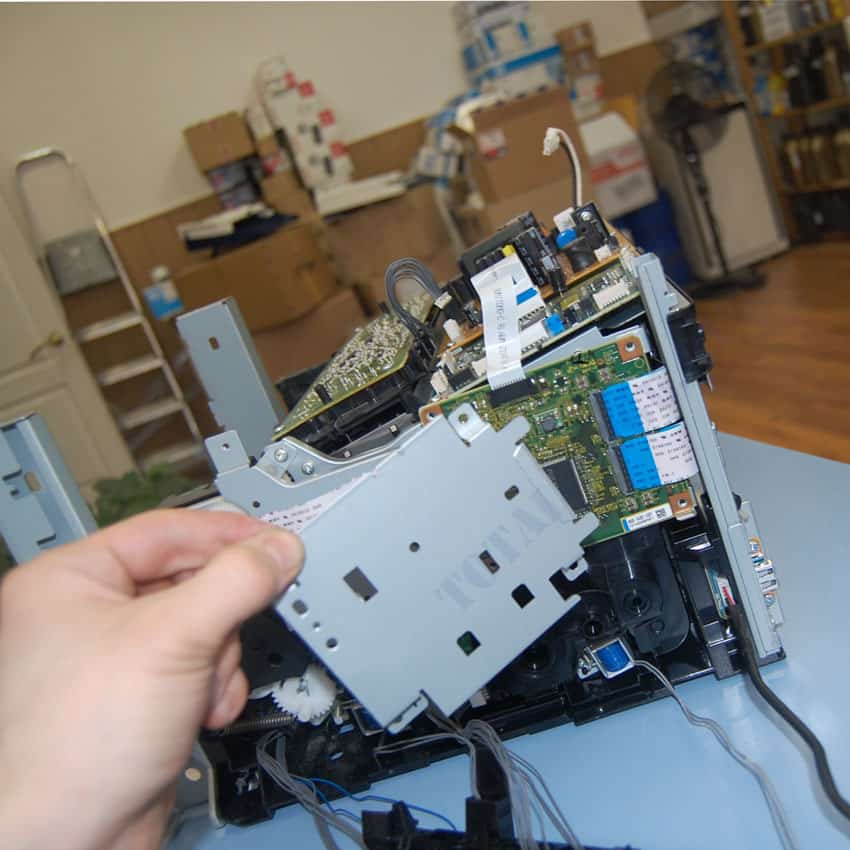

Ремонт WorkCentre 6015 начинается с разборки.

Разборка WC 6015

Сначала нужно снять сканер, для этого снимаем декоративную переднюю синюю крышку, которая крепится на защелках.

Затем снимаем боковую левую крышку.

Отсоединяем шлейфы и кабели, откручиваем спереди держатели лифта сканера, снимаем сканер вверх. Затем откручиваем сверху винты и снимаем верхнюю крышку.

Снимаем заднюю крышку принтера.

Снимаем правую боковую крышку с картриджами.

Следует отметить, что разборка Xerox WC 6015 — чрезвычайно трудоемкое дело. Спроектировано МФУ крайне неудачно для ремонта, требует большой концентрации, аккуратности и времени. За полную удачную разборку и сборку аппарата Xerox WC 6015 можно смело давать звание героя России.

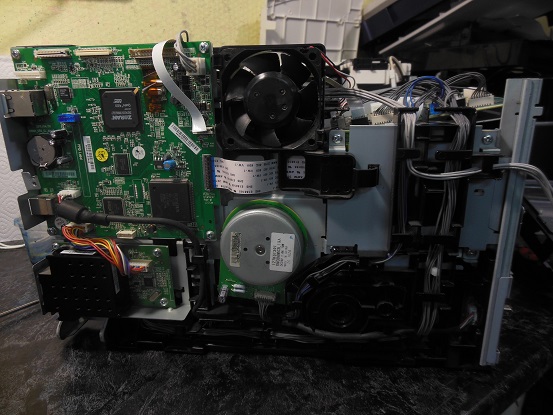

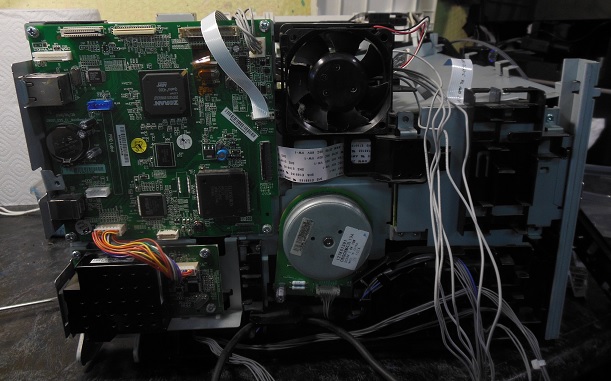

Наверху принтера расположены 3 платы.

Чтобы добраться до узла ксерографии, нужно снять их все.

После этого нужно снять все боковые платы!, чтобы открутить 2 винта, крепящие верхнюю крышку сбоку.

На последнем этапе снимаем плату MCU, за которой и находятся 2 винта.

Если после обратной сборки неправильно соединили какой-нибудь разъем, то при инициализации появится критическая ошибка 024-360. Диагностика тупая — разъем любой, но вероятнее всего шлейф.

Источник

Xerox 6015 ошибка 092 310 очистите датчик ctd

КОНФЕРЕНЦИЯ СТАРТКОПИ

Принтеры, копировальные аппараты, МФУ, факсы и другая офисная техника:

вопросы ремонта, обслуживания, заправки, выбора

Доброго дня!

Продолжение темы Xerox Phaser 6020: Ошибка 092-651 после заправки цветных картриджей.

Пока аппарат отложил в сторону. На днях приехал 6027 с аналогичной ошибкой. Наблюдал за датчиками во время инициализации, и у меня появился вопрос: датчик, который стоит слева, если смотреть на аппарат сзади (https://photos.app.goo.gl/aZEAvPTHgMQac7yd6) имеет видимое излучение красного цвета, которое изменяет свою интенсивность в процессе инициализации. Вот фото платы: https://photos.app.goo.gl/ciK6D9A3fY9K2QXN8

Второй же датчик, который стоит справа, значительно скромнее: https://photos.app.goo.gl/QKkXXK7W6ufmCUWR7, состоит всего из светодиода и фототранзистора: https://photos.app.goo.gl/AzEjiJcys7crTAV66

При этом, его излучения не видно. Так на обоих устройствах. Вопрос к знатокам и владельцам таких девайсов: правый датчик должен так работать? Или, может, с ним есть проблема?

(0)Правый так и должен работать. Я эти аппараты каждую неделю делаю, брак китайских картриджей поражает своим объемом.

(1) То есть причина этой ошибки именно в говнотонере?

(2)В последнее время столкнулся с тем, что сбоит накачка тонера, движок картридж вращает, а тонер с него не поступает. Х знает, как в столь простом механизме картриджа китайцы накосячили, но это носит массовый характер.

(3) Как понять по подкоду 2080000, какой из тонер-картриджей виноват?

И что делаете, чтоб тонер нормально подавался в блок проявки?

Источник

Чистка датчиков плотности цветных тонеров – Инструкция по эксплуатации Xerox Phaser 6000

Страница 56

Цветной принтер Phaser 6000/6010

Руководство пользователя

Чистка датчиков плотности

Датчики плотности цветных тонеров (Color Toner Density, CTD) измеряют оптическую

плотность тонера, отложившегося на маркировочном блоке при калибровке в процессе

печати. С каждой стороны маркировочного блока установлено по одному датчику. Это

обеспечивает одинаковую плотность тонера по всей длине ремня. Для достижения

оптимального качества печати принтер проверяет работу датчиков CTD в начале каждого

цикла калибровки. Датчики CTD следует чистить, когда происходит сбой датчика CTD, или

на панели управления появляется соответствующее сообщение, или Программа настройки

принтера выдает данное указание.

Если тонер попал на кожу или одежду, не удаляйте его тёплой водой или

чистящими растворителями. При использовании теплой воды тонер прилипнет —

тогда его будет трудно удалить. Если тонер попал на кожу или одежду, удалите его

щеткой, сдуйте его или смойте холодной водой с мылом.

Порядок чистки датчиков CTD:

1.

Выключите принтер и выньте вилку шнура питания из розетки.

Откройте заднюю крышку, нажав на фиксатор.

Очистите датчики CTD, протерев отверстия чистым сухим ватным валиком.

Не касайтесь помеченной наклейкой зоны на

нагревательном валу и вблизи него, во фьюзере. Можно получить ожог.

Источник

Xerox 6015 ошибка 092 310 очистите датчик ctd

Этап № 3 Отделение блока ксерографии от основы аппарата.

Извлечение блока ксерографии

Извлеченный блок ксерографии xerox 6010/6015

Вот такое количество шурупов и болтов пришлось открутить, чтобы извлечь блок ксерографии

Удивительно, как много деталей нужно снять для того, чтобы извлечь блок ксерографии! Кстати, оригинальное название данного блока Xero deve LPH belt assy (xerographics assembly)

Внимание!! Блок не имеет парт- номера т.е. как запчасть отдельно не поставляется. Это значит, что если аппарат на гарантии и блок ксерографии вышел из строя, то корпорация Xerox просто подарит вам новый аппарат.

Оцените качество заметки

97 комментариев

Офигеть. вот это да. Вот это работа. Спасибо большое за такой обзор. Осталось узнать, как же можно сам девелопер поменять в блоке. )) Ужас принтер.

WC 3045 с таким же гемором разбирается.

А зачем блок ксерографии снимали?

Корпус снимается так же муторно (разбор одинаков на 95%), но вот редуктор намного проще, да и сам блок ксерографии содержит на порядок меньше деталей. Хотя при первом разборе на выходе получил ошибку светодиодной линейки, к счастью светодиодная линейка и шлейф от Xerox 6000 подошли.

Вы автор этой статьи про разбор Xerox WorkCentre 6015 ? Подскажите пожалуйста название детали. Контакты которые считывают чипы у картриджей как они называются эти контакты, или вся полностью деталь? у меня сломался такой контакт, где можно найти такую деталь?

Это контактная группа чипа, деталь можно достать исключительно с другого аппарата. Ищите писанные аппараты и снимайте оттуда или обращайтесь в сервис

есть такой принтер. сбросьте фото нужной детали neptun-bo@yandex.ru

Сорри, первую часть упустил

ох, помню я этот аппарат, частенько в ремонт приходит.

Один такой разбирал, чтобы вычистить ксерографию, потом так и не завёлся, с ошибкой по плате MCU.

Огромное спасибо за статью! С вашей помощью я сэкономил много сил и времени!

ошибка 124-333 Xerox WC 6015.после разборки выскочила ошибка. ткните носом где смотреть.какой разъем на какой плате. Спасибо.буду рад любой помощи.

Поклон в пояс таким людям как автор.

Большое спасибо за статью. Только у меня после обратной сборки пропал розовый цвет. С одной стороны проявляется немного пятнами. Снимал блок проявки розовый, светодиодную линейку. Три раза уже перебрал, но толку мало. Если есть мысли, помогите.

Не попадает напряжение на магнитный вал или фотовал. Где-то прервалась цепочка

После переборки блока “Drive Assy Deve” Xerox WC 6015 (падал в ошибку 042-372 при печати монохромом), выскочила следующая ошибка: 124-333. Подскажите пожалуйста, на что он ругается. Заранее при много благодарен!))

В редукторе есть большой черный пластиковый блок с шестеренками и датчиком, этот блок отвечает за переключение режимов монохромного и цветного. В этот блок попал тонер и его клинит и датчик не фиксирует режим переключения режимов, что приводит к появлению ошибки. Необходимо очистить шестерни этого блока от грязи и заново смазать

Именно этот блок чистил и смазывал. Так как была ошибка при печати чёрным и слышен был хруст говоривший о клине муфты… А теперь номер ошибки другой. По мануалу вроде как ругается на разъемы P1 и P23. Прозвонил, всё в порядке. Вы не подумайте. Я не сомневаюсь в Вас, хочется понять в чём разница между ошибкой 042-372 и 124-333. Я практикующий мастер и у меня на обслуживании ещё 5 таких аппаратов, рано или поздно в них лезть, а этот аппарат новый и не отработан. Спасибо за понимание и помощь!)))

Невнимательно прочитал Ваш пост, ошибка 124-333. указывает на неисправность ■ LED

Driver Board, PL7.1.5

■ LED/MCU Cable, PL7.1.6

■ MCU Board, PL7.2.2

Проверьте, может один из четырех кабелей неверно зафиксировали?

Теперь в этом филиале окажусь почти через месяц. Но хочется подготовиться. LED Driver Board это ведь панель управления с кнопками управления и дисплеем? Почему-то я так решил со своим кривым знанием английского изучая мануал. Так вот, я снял панель управления для прозвонки, и увидел, что шлейф там всего один с маркировкой на плате “P1”. Всё звонилось, но увидел микротрещины на дорожках. Предположил, что возможны потери из-за повышенного сопротивления и зачистив дорожки чуть выше края, обрезал места с трещинами, в общем стандартная процедура. Но это не помогло. И по поводу четырёх кабелей. Там, как я уже сказал, один шлейф панели управления, второй шлейф линейки сканера, третья проводная-шина насколько я помню полностью относится к сканеру и четвертая это одиночный провод – земля. Перепутать там невозможно. Или это не те четыре кабеля о которых Вы говорите?

То о чем вы говорите, это LCD дисплей,а я говорю о LED. В данном случае имеются в виду светодиодные линейки расположенные в блоке ксерографии. Всего их четыре по одному на каждый цвет, поэтому и четыре шлейфа.

Стыдоба… Теперь понял о чём речь. На другом аппарате чистил синий блок. Спасибо, в конце месяца, как доеду до филиала, отпишусь. Большой опыт работы с Kyocera’ми, пишите на почту, если возникнут сложности, постараюсь помочь.

Здравствуйте! В общем добрался до филиала. Раскидал аппарат, все 4 шлейфа блоков были подключены надёжно. Но… Присмотревшись к контактам через лупу, я увидел металлическую стружку толщиной с волос и длиной в 2 мм. которая замыкала 2 контакта одного из разъёмов. Ума не приложу откуда она там взялась. В общем ваша подсказка мне очень помогла. Спасибо Вам огромное!

Xerox 6000 поменял девелопер теперь не заводится. Включается жужжит но на табло не загорается ни одна кнопка

Начните с правильности подключения разъемов

Здравствуйте! у нас проблема с Xerox WC6015, при сканировании и копировании выдает отпечатки синего фона, с компьютера распечатывает корректно. Можете подсказать в чем проблема?

Если сканируете с автоподатчика, то с правой стороны есть узкое стеклышко, протрите его спиртосодержащей жидкостью.

в этой модели нет автоподатчика.. он полностью все изображение синим выдает после сканирования или копирования

Тогда начните с того, что вытащите и заново вставьте шлейф сканера на плате форматора и сканирующей линейки. Если не поможет, то возможно проблема в сканирующей линейке (или грязь попала или брак). Тут в любом случае необходима помощь специалиста.

Здравствуйте! Блок питания будет выдавать напряжения с отключенными платами ? И какие напряжения должны присутствовать?

Так глубоко аппарат не ковырял

А “закройте заднюю дверцу 077-304 как лечится?

Сзади принтера с правой стороны есть блок с оптическими датчиками, возможно туда попала грязь, часто слетает пружинка с флажка датчика.

Здравствуйте! Хотел высказать свою благодарность за подробную информацию! Все получилось! Спасибо.

Уточнение: “Отсоедините верхнюю часть корпуса. Для этого открутите четыре фиксирующих шурупа и извлеките его, потянув вверх.” Пр факту их 6 (2 со стороны задней крышки).

На данном этапе все понятно с разборкой корпуса Xerox WC 6000-6015, а дальше? Поступил аппарат (Xerox WC 6015)с явным треском (при инициализации и печати) справа внизу (сторона картриджей), явно механика, но вот где искать причину и как туда добраться с наименьшими потерями мне не известно. Такой монстр у меня впервые в отличии от его монохромных братьев. Если есть возможность, подскажите куда копать. Спасибо.

Нашел ваше продолжение второй части и на другом форуме такой комментарий (Если трещит, но при этом работает(выдает копию иль печатает), то похоже заклинило шнек отвода отработки на одном из цветов.) схожий с моей проблемой, буду искать, извините за беспокойство.